Abstract

The paper presents a universal and extremely simple method for studying railway traffic safety, which enables the measurement of safety-related aspects to be conducted with reference to both infrastructure and rolling stock at the same time. The method proposed in the article is an attempt to face up to the challenge of the aforementioned constraint, enabling measurements of characteristics of the railway line infrastructure and of the rolling stock by means of common accelerometers installed in mobile phones. Result obtained illustrates accelerations recorded in three axes. Studying average characteristics for the same train set, one can reveal anomalies related to the track or the rolling stock condition.

1. Introduction

Railway traffic safety may be analyzed from the perspective of personal, infrastructural, rolling stock specific and railway traffic control related aspects. Each of the said analyses is basically conducted by application of separate measurement procedures and using different measuring equipment. The authors of this article have proposed a universal and extremely simple method for studying railway traffic safety, which enables the measurement of safety-related aspects to be conducted with reference to both infrastructure and rolling stock at the same time (also from the personal angle, to a certain extent).

Measurements of railway infrastructure related parameters are currently conducted by means of dedicated equipment (measuring trolleys, manual gauges). The available specialized rolling stock intended for studying technical condition of the infrastructure is not capable of servicing the entire network length with a frequency which may be regarded as satisfactory considering the actual needs [1, 2]. The Polish railway network is managed by PKP Polskie Linie Kolejowe (PKP PLK). As of 31 December 2011, this company was managing ca. 22 thousand kilometers of railways, out of which ca. 88 % of lines are currently in service (18 thousand kilometers). Official records mention that there are ca. 50 thousand turnouts in the PLK network, which translates into ca. 2.63 turnouts per a running kilometer of track in service.

Safety of railway traffic is affected by a number of parameters, including switch clearance, rail cracks, status of rolling profile of wheels in a wheel set, rail mounting to substructure elements, technical condition of the railway track substructure and of the railway embankment, rail head defects and deformations, rolling stock condition, on-board personnel status etc. [3-5]. There are multiple methods used to study the technical condition of each of the aforementioned facilities and elements of the railway network. The competence in this respect has been divided between different bodies of railway institutions and companies. Works comprising inspection of technical condition of the railway infrastructure are often conducted with long intervals (usually counted in months, e.g. every half a year). Using dedicated high-precision machines (trolleys, special trains) to examine the technical condition of railway infrastructure elements causes (on account of their low availability across the entire network) that intervals between specialized technical tests become extended. Therefore, it is reasonable to seek other methods which, bearing their reduced measuring accuracy in mind, may be used to characterize the condition of both railway infrastructure and rolling stock with increased frequency and in larger numbers of measuring cross-sections of the railway network (simultaneously).

2. Research

Studies of the infrastructure in question should be essentially divided into tests of track and substructure condition (flaw detection in rails and track geometry measurement). In Poland, supplementary tests using auxiliary equipment (mobile measuring trolleys, ultrasonic flaw detectors, road-rail vehicles etc.) are conducted for purposes of track examination by 24 defectoscopy teams equipped with two pieces of apparatus [1]. A single team examines up to 8 km of track a day, on average, and these are very accurate examinations. The only vehicle in disposal of the Diagnostics Centre, running with the speed of 40-50 km/h, is capable of testing 250 km of track a day, on average. According to the information provided by the Diagnostics Centre, it allows for examination of up to 52 thousand km of track per annum [1]. This translates into ca. 2 tests of each running kilometer of track throughout a year. For most types of railway lines, the foregoing is an unacceptable parameter. Track geometry of the network administered by PKP is currently examined by two EM 120 measuring trolleys conducting measurements of up to 35 thousand km of track per annum. This translates into a factor only slightly exceeding 0.5 of a visit per each track kilometer throughout a year [1]. It should also be added that the examinations conducted using trolleys are not as accurate as those performed by means of manual measuring instruments [1]. A single trolley can cover an area of 150 thousand square kilometers, and one diagnostic set – 13 thousand square kilometers.

Unlike the studies of infrastructure, studies of rolling stock are slightly less inconvenient, since they are limited to examinations conducted in discrete elements of track infrastructure, usually in specific time intervals and circumstances. In a limited scale, the examinations in question are also repeated before a train set is put into service. However, the foregoing paradoxically constitutes a significant constraint for the practice, since – as the authors claim – the rolling stock may also be diagnosed in the course of operation on route. This matter has been discussed in this article.

The method proposed in the article is an attempt to face up to the challenge of the aforementioned constraint, enabling measurements of characteristics of the railway line infrastructure and of the rolling stock by means of common accelerometers installed in mobile phones. According to this method, examinations of both the infrastructure and the rolling stock are conducted through simplified measurements, this being essentially an innovation. The method proposed for studying technical condition of railway infrastructure and rolling stock is based on measurements of linear accelerations observed in vehicles and means of rail transport by means of standard recording devices, such as accelerometers (ACC, MEMS). The simplicity of the method in question consists in application of systems commonly installed in GSM (Global System for Mobile Communication) telephony devices [6, 7]. The method proposed is basically to be deployed at the same time across the entire railway network in a system of distributed studies. On-board personnel of every rail vehicle or train set put into service in the network (drivers and conductor teams in passenger trains) will be equipped with device(s) enabling accelerations to be measured (mobile phones with the authors’ software installed). By that means, the railway network can be studied from a holistic perspective. It is obvious that the inferior accuracy of the measurements taken (using medium-class mass-produced MEMS recording devices) in this kind of examination and the fact that specialized studies of characteristics (using dedicated measuring rolling stock) are substituted with mere measurements of accelerations in three axes are compensated with a large number of measuring points at which data can be recorded simultaneously across the entire network as well as with much shorter intervals separating consecutive recordings of the railway infrastructure characteristics. Such a holistic nature of the method in question, even on lower measurement accuracy, yet with a far larger statistical data sample, is essentially aimed to enable recording deviations of parameters of the railway infrastructure and of the rolling stock from average values recorded in longer periods. Regardless of how considerable the deviations found in such an examination are, they must be diagnosed from the perspective of establishing the railway traffic safety of trains on individual lines where the deviations might have occurred and bearing in mind that specific safety procedures (checking the line) may be potentially initiated.

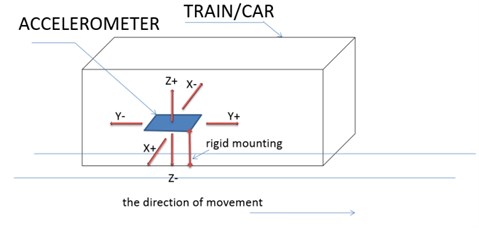

Fig. 1 provides a diagram illustrating the layout of installation of a recording device on board of a vehicle or a means of rail transport. The number of recording devices to be installed on a train set mainly depends on the type of the set being marshalled. In the least favorable arrangement, the recording device should be mounted on every unit or in every car of the train set (for different train set compositions). The recording device is assumed to measure at least three linear accelerations (in longitudinal axis of movement, in transverse axis and in vertical axis). When highly advanced mobile phones with state-of-the-art MEMS solutions are used, it is also possible to measure angular accelerations. Thus the vibration signal can be considered as source of proper information [8-13].

Fig. 1Diagram showing sample installation of a recording device with the mobile measuring application installed

The authors are convinced that such a measurement of chosen characteristics of the railway network infrastructure and of the rolling stock, being simplified yet holistic in its range and scope (enabling reference to be made simultaneously to the entire network and rolling stock), makes it possible to assess railway traffic safety to a certain extent. The rationale behind the concept is substantial, since any anomalies in characteristics of the railway infrastructure or the rolling stock (statistically examined) found in the course of measurements may constitute premises for undertaking well-grounded corrective measures in this scope. The foregoing will basically be limited to dispatching dedicated measuring equipment to railway network infrastructure elements exposed to the hazards revealed in order to verify the data obtained by application of the simplified method. It is also reasonable as the method proposed does not require high investment expenditure to be incurred.

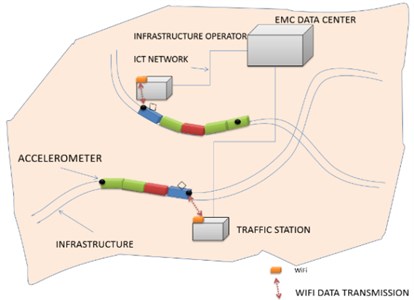

Fig. 2Concept of the measurement method

Fig. 2 illustrates the concept behind the measurement method addressed. While running on the track, the train collects data from recording devices installed on board. Passing next to traffic control stations, it remotely feeds local servers with the data which, in turn, are transferred to the main data center via the infrastructure operator’s ICT system. This is where the data are archived and processed. Special software based on statistical procedures seeks anomalies in the measurement data with reference to the given line as well as to the rolling stock. In a breakdown into specific measurement groups, data are each time compared with historical (averaged) entries.

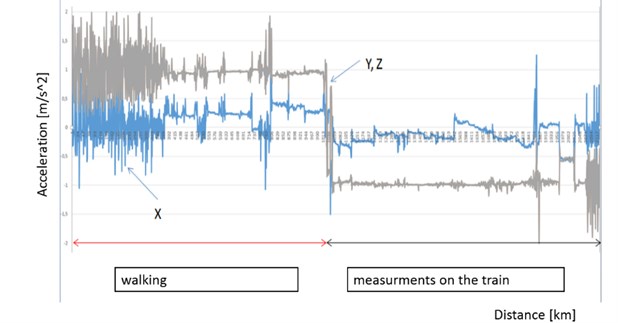

Fig. 3 provides a section of such a measurement data entry acquired by studying accelerations of a passenger train running between Mikołów and Katowice (Poland). This graph illustrates accelerations recorded in three axes. Studying average characteristics for the same train set, one can reveal anomalies related to the track or the rolling stock condition. Following the measurement method proposed, as the authors postulate, based on numerical data of linear accelerations in individual axes, one may correlate the results in disposal with the condition of the railway line in which the given train set runs. In each free axis, characteristic amplitude spectra occur, indicating characteristic elements of the railway network, such as bends and switches, crossings, culverts, overbridges etc.

Fig. 3Sample characteristics recorded on 6 November 2014 at 6:17 a.m.

3. Conclusions

By application of the method proposed, one cannot conduct direct studies of such aspects as track gauge, differences in rail heights, track twist, horizontal irregularities of rails, vertical irregularities of rails as well as values of synthetic track condition factor “”. Nevertheless, for instance, rail heights should be reflected in the lateral linear acceleration () values obtained. In accordance with the applicable official instruction, the track condition assessment is conducted by comparing the measurement results obtained for individual parameters with their nominal values. Such nominal values may be acquired through test runs on a classified track with the recording device proposed installed on board, using traditional testing techniques or by means of a simulation micromodel as the source of reference points. In such a case, the linear acceleration values recorded should be treated as nominal, i.e. providing a reference pattern for further comparisons in the course of the track operation. Similarly, irregularities of vertical rail sections should be recorded under the characteristic of vertical linear accelerations (), and analogically, irregularities of horizontal rails – in longitudinal linear accelerations (). Developing guidelines for the application of such a method is mainly a matter of organization of wide-scale statistical studies conducted across the entire network on different train sets.

References

-

http://www.tpi.com.pl/system_pomiarow_torow_kolejowych.

-

Materna J. Diagnostics Centre. Concerned about safety. Diagnostyka i bezpieczeństwo infrastruktura transportu (Diagnosis and safety of transport infrastructure), Vol. 4, 2009.

-

Wieczorek A. N. The role of operational factors in shaping of wear properties of alloyed Austempered Ductile Iron. Part I. Experimental studies abrasive wear of Austempered Ductile Iron (ADI) in the presence of loose quartz abrasive. Archives of Metallurgy and Materials, Vol. 59, Issue 4, 2014, p. 1665-1674.

-

Doleček R., Novák J., Černý O. Experimental research of harmonic spectrum of currents at traction drive with PMSM. Radioengineering, Vol. 20, Issue 2, 2011, p. 512-515.

-

Doleček R., Černý O.Sýkora P., Pidanič J., Němec Z. The traction drive of the experimental rail vehicle. 4th International Conference on Power Engineering, Energy and Electrical Drives, 2013, p. 650-654.

-

Celiński I., Sierpiński G. Concept for calculating technical characteristics of road infrastructure elements using the GSM and GPS technologies. Magazyn Autostrady, Vol. 5, 2014, p. 112-118.

-

Młyńczak J., Celiński I., Sierpiński G. Method for dynamic stock taking of railway infrastructure. Logistyka, Vol. 6, 2014, p. 7593-7601.

-

Pankiewicz J., Deuszkiewicz P., Dziurdź J., Zawisza M. Modeling of powertrain system dynamic behavior with torsional vibration damper. Advanced Materials Research, Vol. 1036, 2014, p. 586-591.

-

Kłaczyński M., Wszołek T. Detection and classification of selected noise sources in long-term acoustic climate monitoring. Acta Physica Polonica A, Vol. 121, Issue 1A, 2012, p. 179-182.

-

Konieczny Ł.,Burdzik R., Figlus T. The possibility to control and adjust the suspensions of vehicles. Activities of Transport Telematics, Vol. 395, 2013, p. 378-383.

-

Dąbrowski Z., Zawisza M. Investigations of the vibroacoustic signals sensitivity to mechanical defects not recognized by the ODB system in diesel engines. Mechatronic Systems, Mechanics and Materials, Solid State Phenomena, Vol. 180, 2012, p. 194-199.

-

Wierzbicki S. Laboratory control and measurement system of a dual-fuel compression ignition combustion engine operating in a cogeneration system. Solid State Phenomena, Vol. 210, 2014, p. 200-205.

-

Siergiejczyk M., Rosinski A. Analysis of power supply maintenance in transport telematics system. Mechatronic Systems, Mechanics and Materials II, Solid State Phenomena, Vol. 210, 2014, p. 14-19.

-

ID-3, Technical Conditions of Track Substructure Maintenance. PKP PLK, Warsaw, 2009.

-

ID-4, Instruction on Visual Inspections, Technical Testing and Maintenance of Turnouts. PKP PLK, Warsaw, 2014.

-

ID-7, Instruction on Supervision of Railway Lines. PKP PLK, Warsaw, 2005.

-

ID-8, Instruction on Diagnostics of Track Superstructure. PKP PLK, Warszawa 2005.

-

ID-10, Instruction of Flaw Detection Tests for Rails, Joints and Welds in Railway Tracks. PKP PLK, Warsaw, 2005.

-

ID-14, Instruction on the Procedure of Measurements, Tests and Assessment of Track Condition. PKP PLK, Warsaw, 2005.

About this article

This article is the result of Research Program DEMONSTRATOR+ Supporting Scientific Research and Development Works in Demonstration Scale, the title of the Project is Integrated System for Support the Management of Information in Passenger Railway Transportation (No. DEM/1/RT4/2013/0 PASAŻER).