What's new

Editor's pick

Research Article

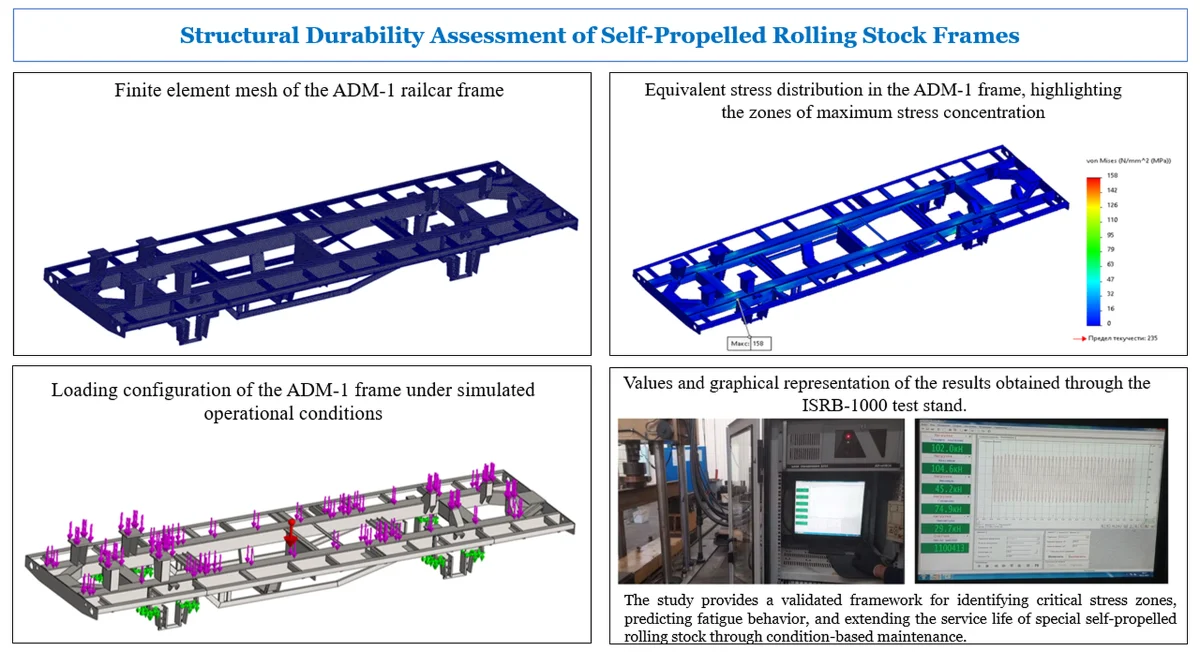

Experimental and finite element analysis of the structural durability of special self-propelled rolling stock frames

By Izzatillo Raxmiddinov, Sherzod Fayzibaev, Yusufov Abdulaziz, You Taiwen, Khusan Kosimov, Nusratillo Abdullayev

The study presents an experimental-numerical assessment of the structural durability and residual life of the ADM-1 self-propelled railcar frame operating under cyclic and static loading conditions. A combined methodology integrating full-scale cyclic bench testing and finite element modeling (FEM) was developed to determine the frame’s stress–strain state and fatigue resistance. The experimental tests, performed at the accredited laboratory of “Quyuv Mexanika Zavodi” JSC using the ISRB-1000 hydraulic loading stand, simulated real operational loads up to 2×106 cycles, equivalent to approximately ten years of service. A detailed FEM model was created in SOLIDWORKS Simulation to replicate these loading conditions, analyze stress distribution, and validate experimental data. The numerical and experimental results showed strong correlation (r > 0.9) with a deviation below 8 %, confirming the accuracy of the proposed approach. The maximum equivalent (von Mises) stresses remained below 0.6σ0.2 for St3sp steel, indicating that the structure operated entirely within the elastic range and met the strength requirements of GOST 31846-2012. Fatigue life estimation using Miner’s cumulative damage rule yielded a damage factor of D= 0.72, corresponding to 8-12 years of effective service life, with a residual fatigue resource of approximately 35-40 %. The developed hybrid methodology provides a reliable framework for condition-based maintenance and life-extension of special self-propelled rolling stock.

December 22, 2025

Applied Physics

Research Article

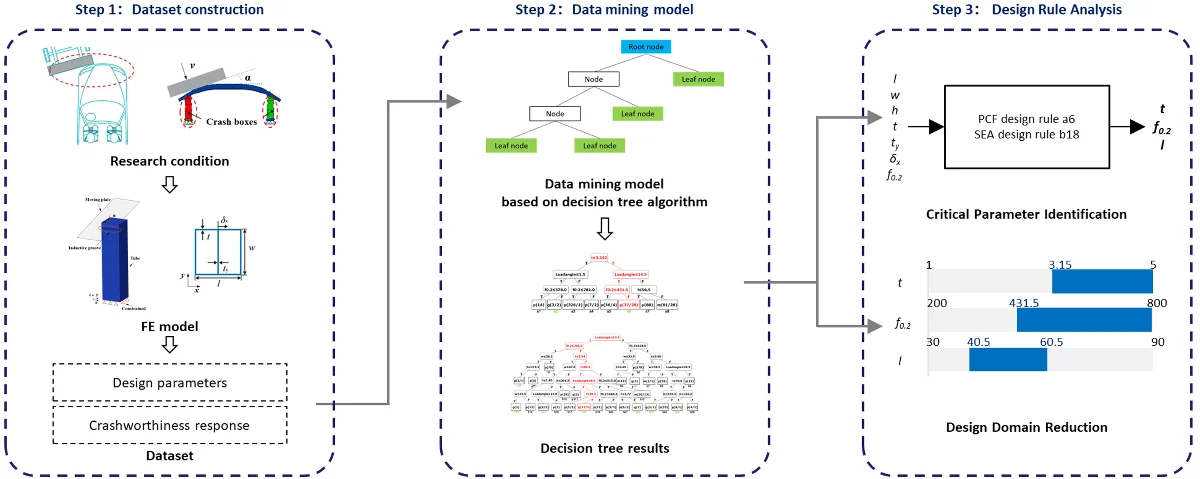

Crashworthiness design of automotive double-cell thin-walled tubes under oblique loading based on data mining

The deformation behavior of automotive double-cell thin-walled tubes under oblique loading is inherently complex. To address this crashworthiness design challenge, this study employs a decision-tree-based data-mining method to guide the structural design of thin-walled tubes. In contrast to conventional black-box optimization approaches, the proposed approach not only accomplishes structural optimization but, more importantly, derives design rules for the tubes, enabling critical parameter identification and design domain reduction. By analyzing the crashworthiness responses of double-cell tubes under oblique loading, the method establishes an interpretable linkage between design variables and crashworthiness performance, thereby providing engineers with design guidance. The results show that the optimization design efficiency based on data mining improved by nearly 10 times relative to traditional methods, highlighting its potential to significantly reduce design time and development cost.

February 11, 2026

Vibration Engineering

Research Article

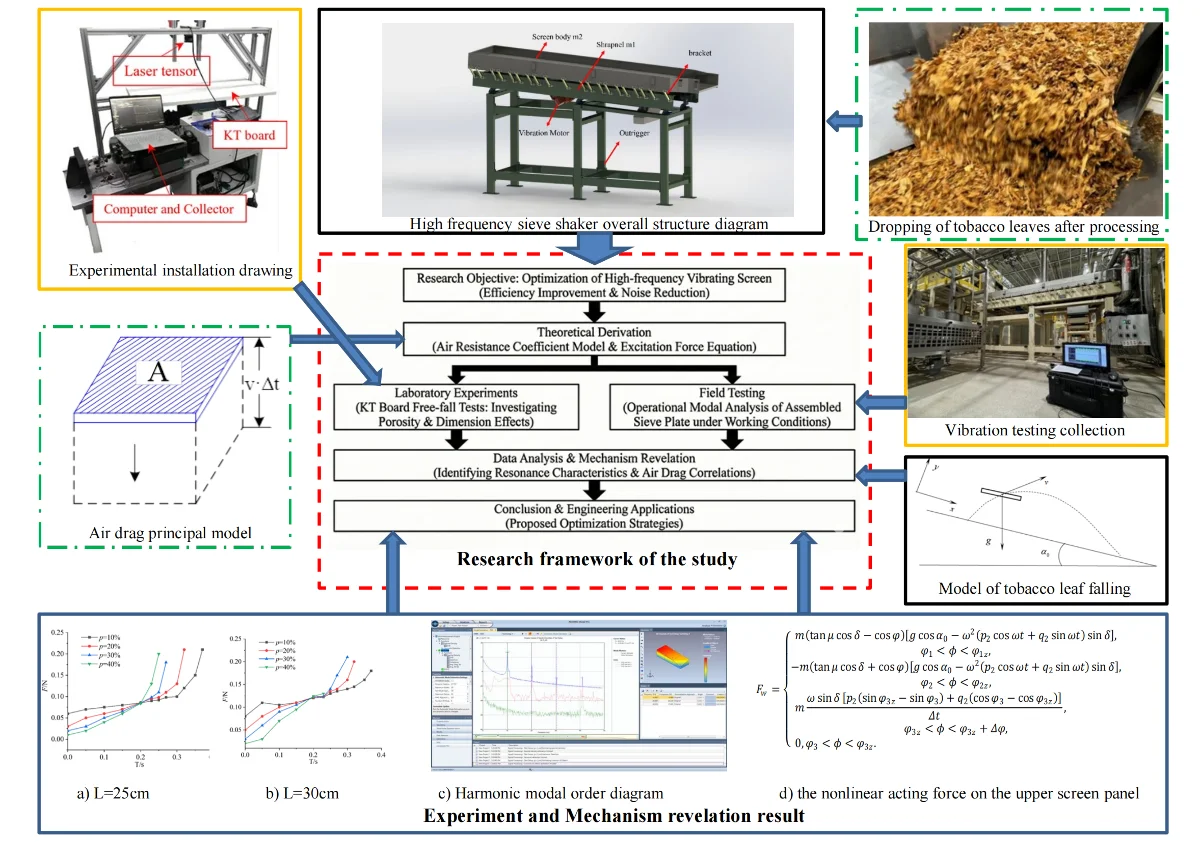

The airflow behavior of light particulate materials during free fall and their impact dynamics on screening surfaces

To optimize the efficiency and noise performance of high-frequency vibrating screens, this study investigates the airflow behavior of lightweight materials during free fall and their impact dynamics on the screening surface. Based on the energy conservation theorem and the characteristics of tobacco screening, a computational model for the air resistance coefficient was derived. KT board specimens were employed as experimental substitutes for tobacco leaves to examine the effects of porosity and geometric dimensions on descent velocity and air resistance. The results indicated that materials with higher porosity exhibited greater descent velocities and lower air resistance, whereas larger geometric dimensions lead to increased aerodynamic drag and higher resistance coefficients. Furthermore, field operational modal analysis revealed that the sieve plate exhibited subharmonic resonances within the 9.9-10 Hz and 20-30 Hz frequency bands under nonlinear excitation. These findings could provide theoretical and data support for structural optimization aimed at noise reduction and screening efficiency enhancement.

February 11, 2026

Mechanical Engineering

Research Article

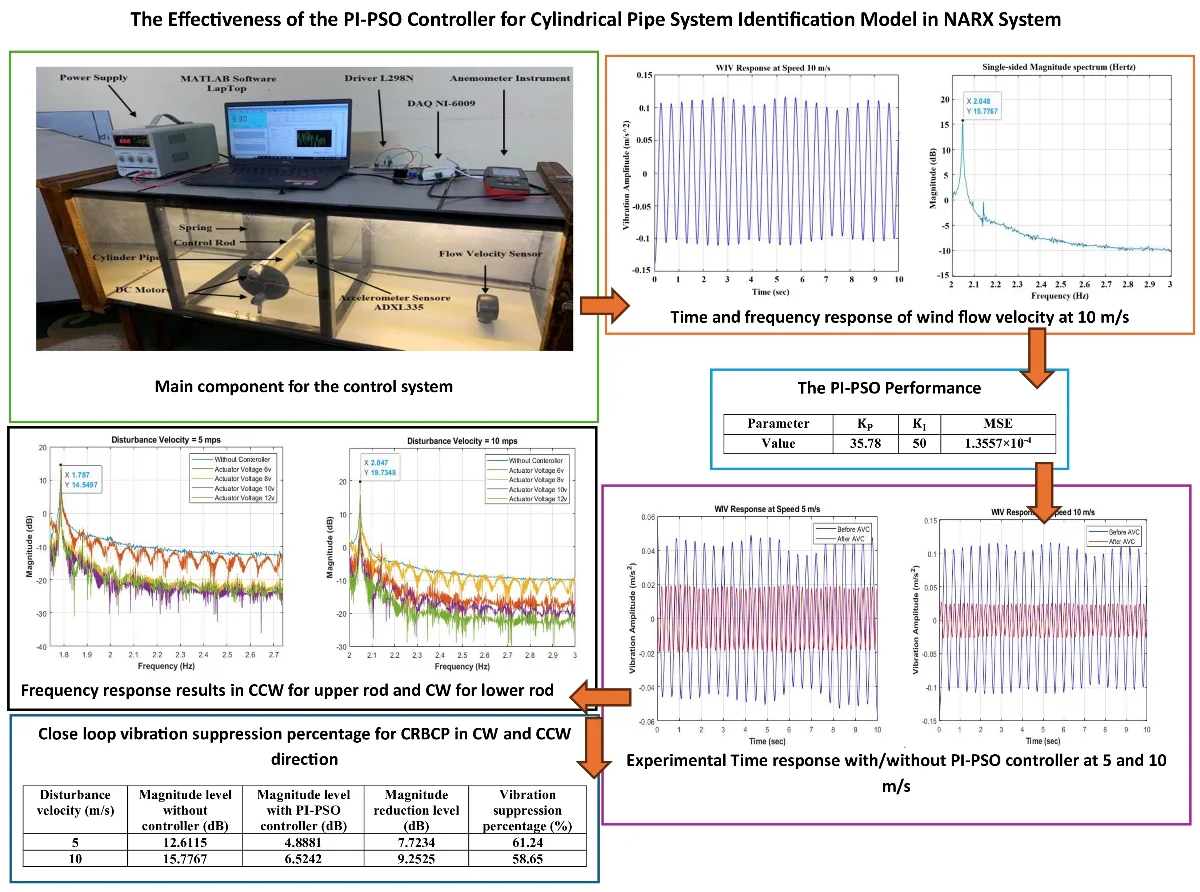

The effectiveness of the PI-PSO controller for cylindrical pipe system identification model in NARX system

One of the main issues in the pipes’ structure that could be affected by wind that led to the failure of the cylinder pipe structure is vortex-induced vibration (VIV). Therefore, there is a need to control the wind that is going through the pipe to avoid vibration. This phenomenon leads to the failure of the structure due to the resonance phenomenon when the natural frequency of the structure is equal to the vortex frequency. The main contributions of this work are mathematical modeling of the system using NARX and suppressing the vibration caused by wind currents through simulation and experiment ways. PI-PSO control employed to reduce the unwanted vibration as a simulation work. Then, an experimental study implemented on the structure as an open and closed loop control techniques to decrease the vibration with disturbance vibrations of 5 and 10 m/s. Open loop active vibration control (OLAVC) is proposed in this work using dual control rods made from hollow stainless steel and driven by dual DC motors in two positions at 6, 8, 10, and 12 DCV. The control rods are located beside the main cylinder pipe (CRBCP) and from the upper and lower of the hollow cylinder pipe. The effectiveness of the passive control strategy was confirmed before supplying electricity to the two DC motors on both sides. The PI controller tuned by the PSO method was developed to control unwanted model vibration. Based on the control results, the best values of KP and KI were 35.78 and 50 respectively at the lowest MSE of 1.3557×10-4, and the frequency magnitude was reduced by 81.17 %. The findings also showed that the cylinder pipe vibration could not be sufficiently suppressed by the passive control method. While OLAVC succeeded in reducing the vibration when the motor voltage was at 12 V. Finally, the closed-loop control technique decreased the vibration up to 61.24 % and 58.65% for disturbance wind speeds of 5 and 10 m/s, respectively.

February 8, 2026

Informatics

Research Article

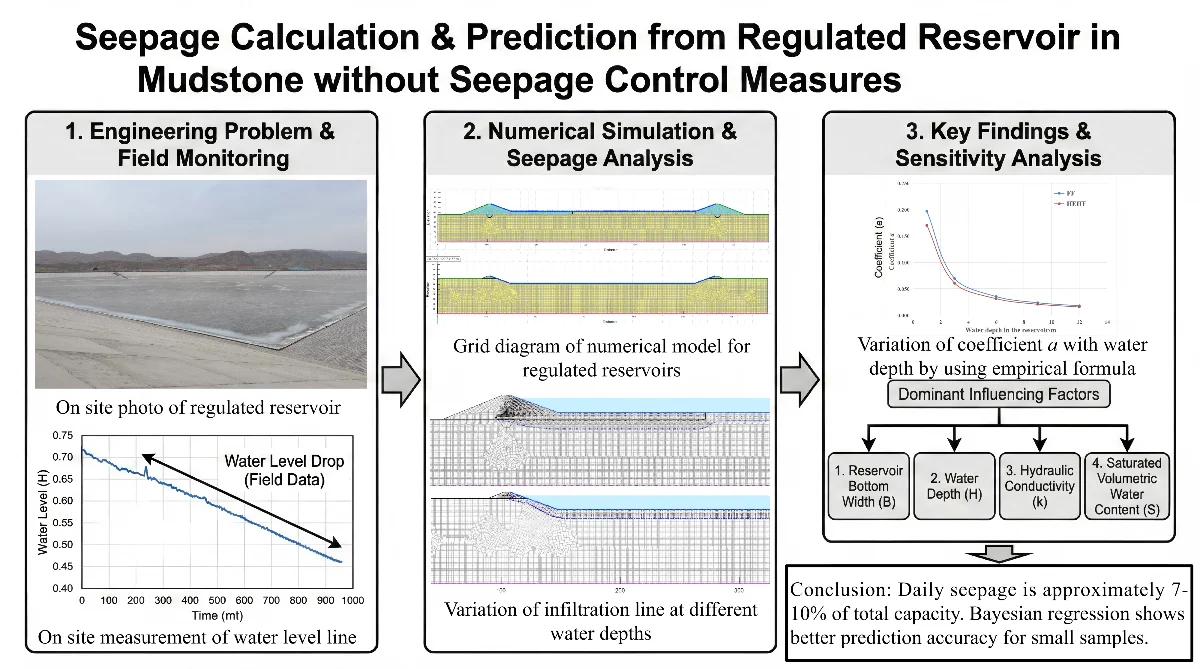

Calculation and prediction of seepage from regulated reservoir in mudstone without seepage control measures

Correctly assessing seepage amount of the regulated reservoir is vital to water resources efficlent utilization and engineering safety. A regulated reservoir in mudstone area without seepage control measures was used as the engineering prototype. Based on the mutual verification of field monitoring and numerical simulation, the estimation formula of the seepage amount of the regulated reservoir was determined. In addition, the sensitivity analysis of the factors affecting the seepage amount of the regulated reservoir was carried out, and the seepage prediction models were established based on the different optimization algorithms. The research results indicate that the regulated reservoir without lying geomembranes exists in a certain amount of seepage every day, accounting for about 7 to 10 % of the total reservoir capacity. The sensitivity ranking of influencing factors in descending order is as follows: reservoir bottom width, water depth, hydraulic conductivity, and saturated volumetric water content. The prediction accuracy of Bayesian regression is significantly better than that of traditional regression models under small training samples. This research approach provides a highly accurate and strongly robust solution to the small sample engineering prediction problem.

February 7, 2026

Materials Science

Latest from engineering

Research Article

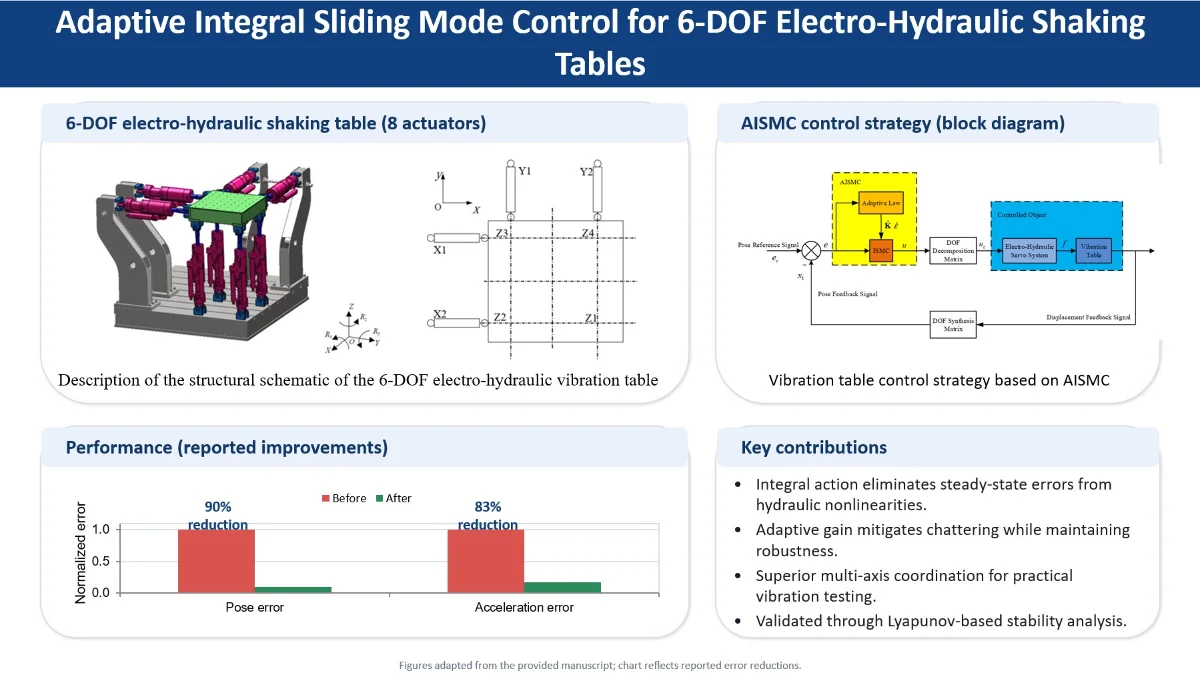

Adaptive integral sliding mode control for attitude tracking of 6-DOF electro-hydraulic shaking tables

Accurate attitude tracking of six degree of freedom electrohydraulic shaking tables (EHSTs) is restricted by parameter uncertainty, nonlinearity, strong coupling, and external disturbances. Existing sliding mode control schemes are limited by fixed switching gains and the absence of integral compensation, which restrict steady-state accuracy and dynamic adaptability under nonlinear hydraulic effects and multi-axis coupling. An Adaptive Integral Sliding Mode Control (AISMC) scheme is developed to address these factors through two coordinated elements: an integral sliding surface that removes steady state deviation caused by static disturbances such as servo valve dead zones and hydraulic leakage, and an adaptive switching gain that regulates the reaching dynamics online without reliance on conservative bounds; a decay term in the gain update restrains parameter drift and keeps the adaptation bounded. Lyapunov analysis establishes closed loop stability and finite time convergence of the tracking error under bounded uncertainties and excitations. Simulation studies on a six degree of freedom EHST with a broadband random reference (0.1-10 Hz, 10 mm) compare AISMC with Sliding Mode Control (SMC) along X, Y, and Z. Pose tracking shows consistent gains, with the maximum value reduced by about 11.5-11.9 % and the root mean square (RMS) reduced by about 34.9-35.1 %. Pose error decreases from 0.392-0.396 mm to 0.035-0.036 mm in maximum value and from 0.175-0.177 mm to 0.015-0.016 mm in RMS. Acceleration tracking under AISMC approaches the reference in X and Z and improves in Y, while acceleration error decreases by about 83.5 % in X and Y and about 88 % in Z. The results indicate higher control precision, smoother transients with reduced chattering, and robust multi axis coordination suitable for practical vibration testing applications.

February 7, 2026

Vibration Engineering

Research Article

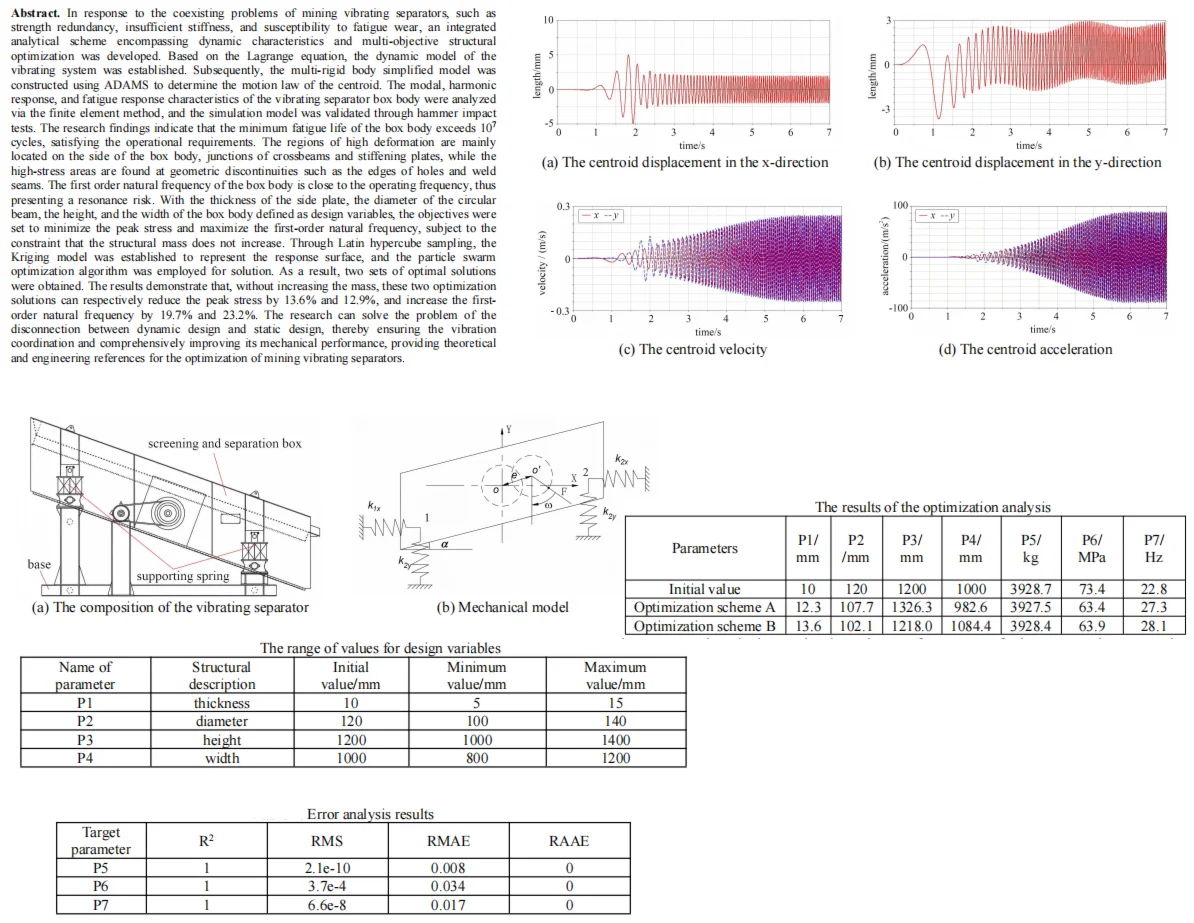

Study on dynamic characteristics and structural optimization of mining vibrating separator

In response to the coexisting problems of mining vibrating separators, such as strength redundancy, insufficient stiffness, and susceptibility to fatigue wear, an integrated analytical scheme encompassing dynamic characteristics and multi-objective structural optimization was developed. Based on the Lagrange equation, the dynamic model of the vibrating system was established. Subsequently, the multi-rigid body simplified model was constructed using ADAMS to determine the motion law of the centroid. The modal, harmonic response, and fatigue response characteristics of the vibrating separator box body were analyzed via the finite element method, and the simulation model was validated through hammer impact tests. The research findings indicate that the minimum fatigue life of the box body exceeds 107 cycles, satisfying the operational requirements. The regions of high deformation are mainly located on the side of the box body, junctions of crossbeams and stiffening plates, while the high-stress areas are found at geometric discontinuities such as the edges of holes and weld seams. The first order natural frequency of the box body is close to the operating frequency, thus presenting a resonance risk. With the thickness of the side plate, the diameter of the circular beam, the height, and the width of the box body defined as design variables, the objectives were set to minimize the peak stress and maximize the first-order natural frequency, subject to the constraint that the structural mass does not increase. Through Latin hypercube sampling, the Kriging model was established to represent the response surface, and the particle swarm optimization algorithm was employed for solution. As a result, two sets of optimal solutions were obtained. The results demonstrate that, without increasing the mass, these two optimization solutions can respectively reduce the peak stress by 13.6 % and 12.9 %, and increase the first-order natural frequency by 19.7 % and 23.2 %. The research can solve the problem of the disconnection between dynamic design and static design, thereby ensuring the vibration coordination and comprehensively improving its mechanical performance, providing theoretical and engineering references for the optimization of mining vibrating separators.

February 5, 2026

Informatics

Research Article

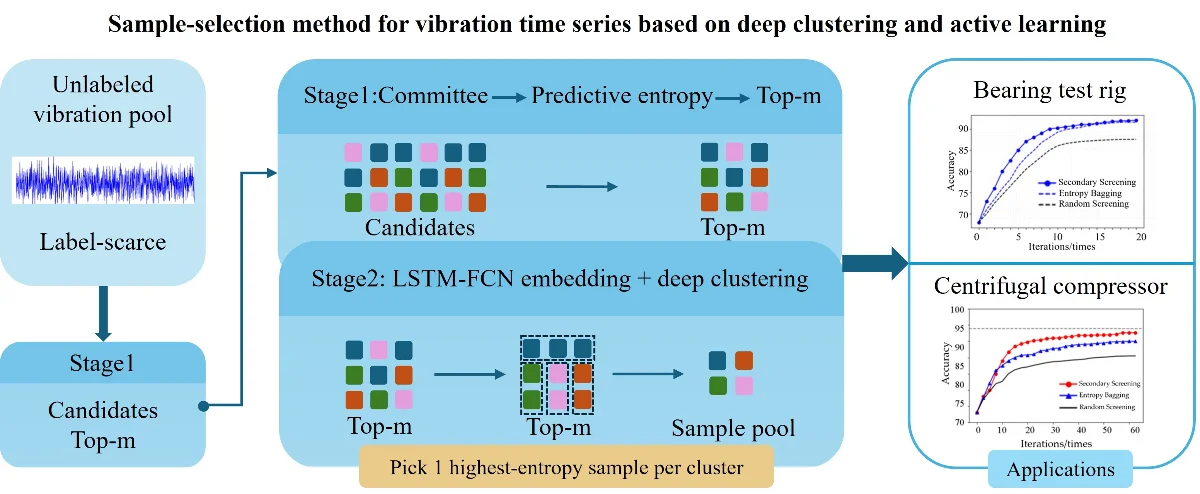

Anomaly detection in rotating machinery via active learning of unlabeled vibration samples

In response to the challenges posed by the substantial volume of monitoring data from rotating machinery, the considerable effort required for manual interpretation, and the scarcity of labeled fault samples, this study proposes a vibration-based anomaly-detection method that applies active learning to unlabeled vibration signals. The key novelty is a redundancy-aware batch active learning scheme, in which predictive-entropy from a committee is combined with a long short-term memory fully convolutional network (LSTM–FCN) deep-clustering module. One most representative sample is selected from each cluster to increase diversity and reduce labeling cost. The method comprises two stages: first, predictive entropy is computed for all unlabeled samples to rank uncertainty and perform an initial screening; second, a deep-clustering procedure mitigates redundancy among high-uncertainty candidates, after which the highest-entropy instance in each cluster is selected for expert labeling. Evaluations on vibration datasets from a rolling-bearing accelerated-life rig and a centrifugal-compressor rig show consistent improvements in accuracy and recognition stability over conventional clustering-based anomaly-detection methods, alleviating the dependence on scarce labeled anomalies in real-world rotating machinery monitoring.

February 5, 2026

Applied Mathematics

Research Article

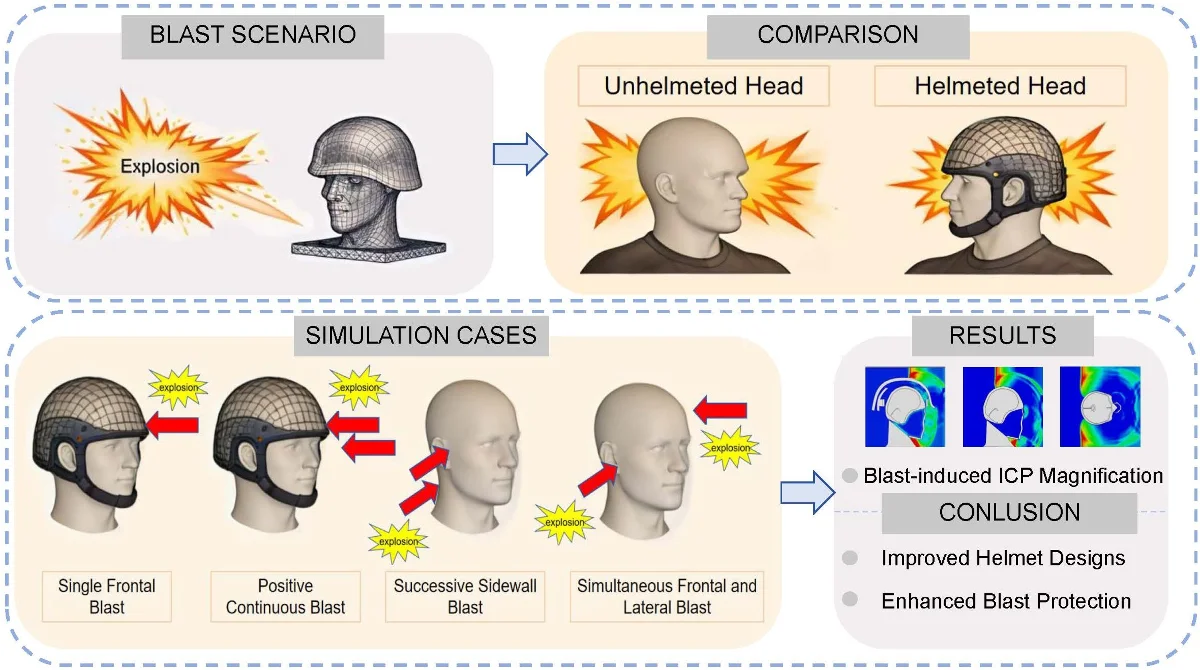

Study on craniocerebral dynamic response and helmet protection performance under accompanying shock wave

To systematically investigate the protective effects of helmets against human head injuries under various shock wave conditions, a finite element head-helmet coupling model was developed. This model analyzed how helmets influence biomechanical response parameters, such as intracranial and cranial pressure, when subjected to a single blast wave and its accompanying shock wave. While extensive research exists on single blast scenarios, studies on the more complex and militarily relevant accompanying shock waves, which pose a greater threat due to prolonged loading and multiple reflections, remain scarce. Several impact scenarios were considered, including single frontal impact, positive continuous impacts, successive sidewall impacts, and simultaneous frontal and lateral impacts. The study examined the dynamic changes in brain tissue within a blast environment to assess the efficacy of helmets in protecting the human head. In single frontal impact scenarios, helmets effectively reduced intracranial pressures in the frontal, occipital, and parietal lobes by 32 %, 38 %, and 19 %, respectively, while significantly decreasing the stress peak at the back of the skull. During positive continuous impacts, helmets decreased intracranial pressure in the parietal and occipital lobes by 36 % and 21 %, respectively, although their effectiveness in reducing frontal lobe pressure was limited due to inadequate facial protection. For successive sidewall impacts, helmet protection delayed the blast wave, reducing intracranial pressure in the frontal lobe by 60 kPa but increasing pressure in the parietal lobe by 80 kPa. This alleviated stress on the skull’s rear while increasing stress on the opposite side. In scenarios involving simultaneous frontal and lateral impacts, lateral blasts increased parietal intracranial pressure by 20 kPa, with the right hemisphere experiencing more pressure than the left due to the mitigating effect of reflective side blasts on skull stress. The study found that, compared to single blast waves, accompanying shock waves present a greater risk of cranial injuries due to their prolonged impact. These findings address a critical gap in blast neurotrauma research and provide valuable insights into the biomechanics of head injuries under realistic multi-blast conditions, which can directly inform the design of improved helmets with enhanced protection in complex blast environments. However, because shock waves may originate from multiple directions and elevations, the protective capability of conventional helmets for the facial region remains limited.

January 11, 2026

Mechanical Engineering

Recently published

Research article

January 9, 2026

Multi-scale rheological properties of municipal solid waste fly ash-asphalt mastic materials

By Weili Chen

Recently published

Research article

December 29, 2025

Maintenance, repair, and overhaul of robotic systems

By Guilherme E. Vieira, Jeffrey W. Herrmann

76th International Conference on VIBROENGINEERING

Seismic Safety, Construction Digitalization and Sustainable Engineering

Date

April 28-29, 2026

Submission deadline

3/1/2026 11:55:00 PM

Conference format

Hybrid

Best of engineering

Editor's pick

Research article

December 20, 2025

Design of a composite repetitive controller for grid-connected inverters with a notch filter

By Fen Liang, Xiao Liang, Huanke Cheng, Ho-Joon Lee

Editor's pick

Research article

October 31, 2025

Application of GSABO-VMD-KELM in rolling bearing fault diagnosis

By Qiang Li, Chao Wu, Qing Lv, Jin Wang

Editor's pick

Research article

September 30, 2025

Modernization of the electromagnetic vibration stand for testing aviation industry products

By Ivan Kolodiy, Oleksii Lanets, Pavlo Maistruk, Iryna Derevenko, Ihor Nazar, Ivan Khomych

Editor's pick

Research article

September 13, 2025

Development of a flexible piezoresistive sensor prototype using resin doped with magnetically oriented nanoparticles

By Rafael Hernando Blanco Gómez, Andres Felipe Rubiano Navarrete, Carlos Andrés Palacio Gómez, Leonel Paredes-Madrid, Yaneth Pineda Triana

You might also like

Most downloaded

Research Article

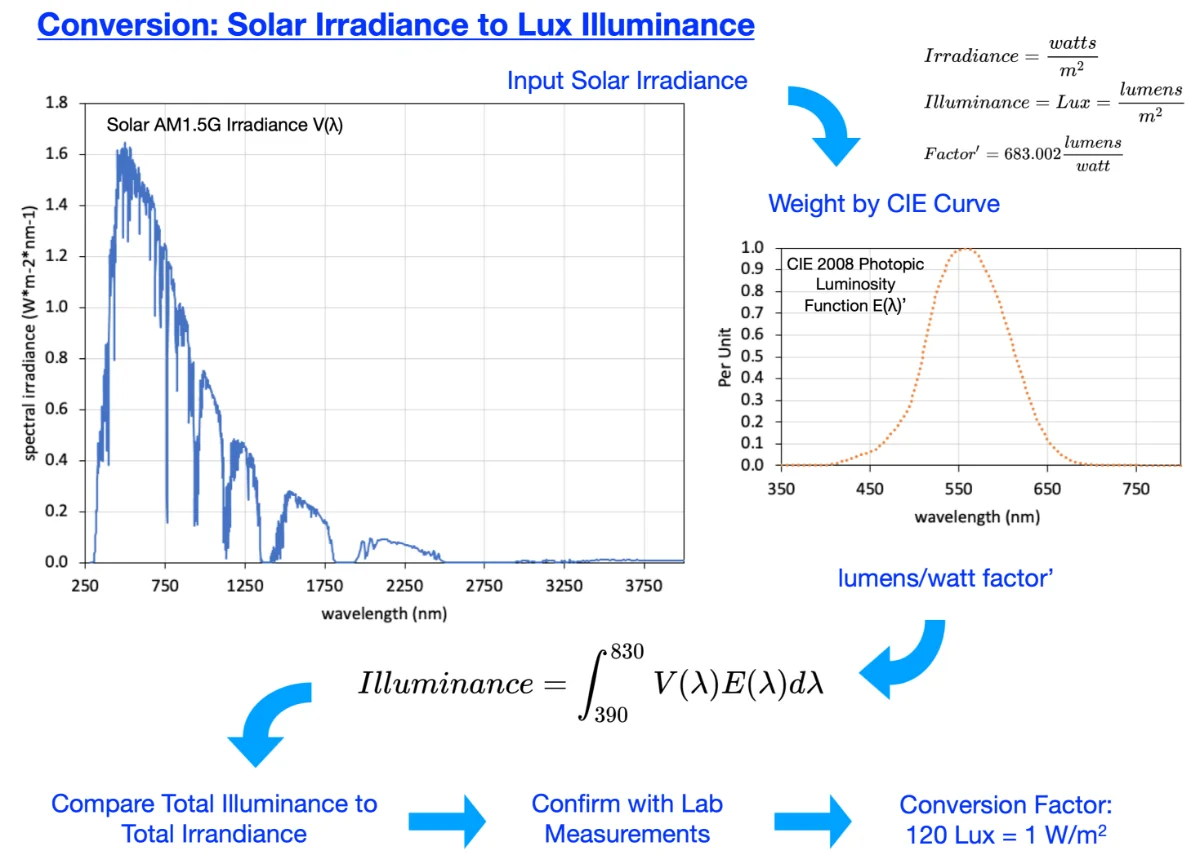

A conversion guide: solar irradiance and lux illuminance

By Peter R. Michael, Danvers E. Johnston, Wilfrido Moreno

The standard for measuring solar irradiance utilizes the units of watts per meter squared (W/m2). Irradiance meters are both costly and limited in the ability to measure low irradiance values. With a lower cost and higher sensitivity in low light conditions, light meters measure luminous flux per unit area (illuminance) utilizing the units of lumens per meter squared or lux (lx). An effective conversion factor between W/m2 and lx would enable the use of light meters to evaluate photovoltaic performance under low solar irradiance conditions. A survey of the literature found no definitive and readily available “rule of thumb” conversion standard between solar irradiance and illuminance. Easy-to-find Internet sources contain conflicting and widely varying values ranging from 688449 to 21000 lx for 1000 W/m2 (1 Sun) of solar irradiance. Peer-reviewed literature contains Luminous Efficacy equivalent values ranging from 21 to 131 lx per W/m2. This manuscript explores the relationship and establishes a theoretical and laboratory measurement guide for the conversion between solar irradiance and illuminance. The conversion factor includes standards data, equipment calibration accuracy, and uncertainty estimates. Solar Irradiance of 1 Sun (1000 W/m2) for an LED-based solar simulator is (116 ± 3) klx and (122 ± 1) klx for outdoor sunlight.

December 4, 2020

Applied Physics

Most downloaded

Research Article

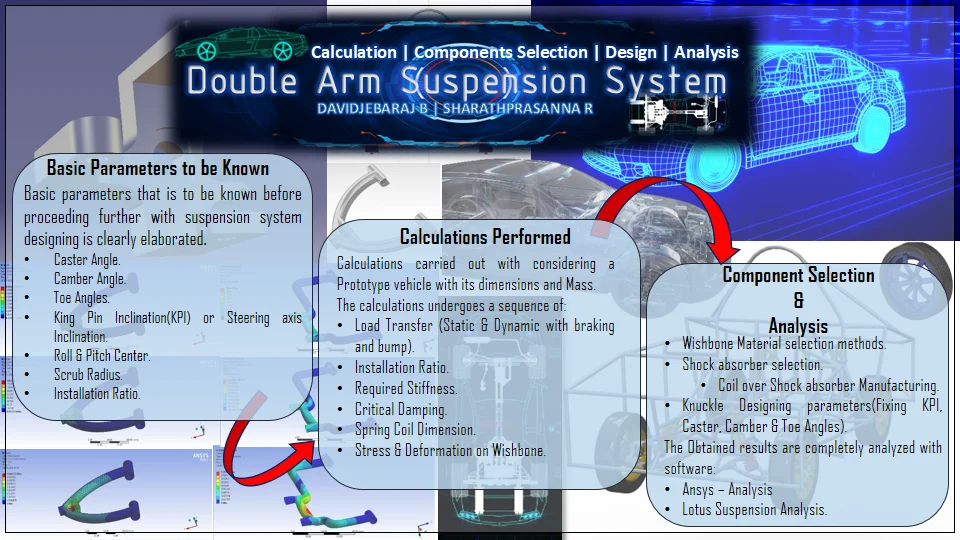

Design and calculation of double arm suspension of a car

By David Jebaraj B, Sharath Prasanna R

Suspension system is one of the challenging portions in designing a vehicle. The complete stability of the vehicle under dynamic conditions depends on the suspension system of the vehicle. Suspension system of a vehicle is interlinked with other systems such as steering, Wheels and Brakes. The main objective of this document is to provide complete guidance in designing and calculation of an independent suspension system with double control arms. The required parameters are calculated on considering a prototype vehicle with gross weight of 350 kg such as required stiffness of shock absorbers, Ride frequency, Motion ratio, Coefficient of damping etc. A CADD model was made with CATIA v5 r20 and SOLIDWORKS on the basis of calculations obtained and stress analysis was carried out for this model in various software such as Ansys. The complete assembled model was tested in LOTUS Shark and the result was obtained.

June 30, 2020

Industrial Engineering

Modal finite element analysis of PCBs and the role of material anisotropy

Printed Circuit Boards (PCBs) are epoxy resin-impregnated and cured sheets of counter woven glass fabric (e.g. FR4) laminated between thin sheets of Copper. The nature of the PCB is inherently anisotropic and inhomogeneous but previous modal FEMs of PCBs have assumed isotropic, anisotropic (transversely isotropic and orthotropic) material properties and shown good correlation with test data for specific scenarios [1-3]. This paper details part of a research program aimed at gaining a better understanding of accurately modeling PCB’s dynamic behavior. New investigations into the impact of material anisotropy and, in particular, the effect of material orthogonal plane definition (Ex and Ey) on eigenfrequencies is analysed. A modal FEM of a JEDEC PCB is created, verified, and validated using well established theories by Steinberg and empirical data by others [4, 5]. The relative contributions of Ex, Ey and Ez on PCB eigenfrequencies is examined using a parametric modal FEM, analysing the role of material isotropy verses anisotropy. The impact of transversely isotropic material properties is also analysed for a typical JEDEC PCB. This analysis details the mesh density required for accurately modeling the PCB eigenfrequencies. The results show that a 100 % increase in Ez has only a 0.2 % difference in the eigenfrequency where as a 100 % increase in Ey has a 1.2 % difference in the eigenfrequency. The effect of orthotropic plane definition (alternating Ex with Ey) on the JEDEC PCB amount to a 7.95 % delta in eigenfrequency.

Coilgun design and evaluation without capacitor

Capacitors with high voltage and capacity values are used in most induction coilguns that are designed and constructed. The fact that capacitors are quite bulky and slow in energy transfer and how a coilgun can be made without using capacitors is the study subject of this article. Two and four coil gun samples were made to find the essential components of an electric gun, and the results are reported in this article. The accuracy of the results is also confirmed by FEMM analysis for these models. The harmony of experimental and theoretical results shows that smaller and low cost portable electrical weapons can be a powerful alternative to firearms in the future.