Abstract

A station-level analysis was conducted to improve customer service at loading and unloading fronts for cargo flows. According to the results of the analysis in 2025, it was found that at the Tashkent Regional Railway Junction, the allocation of wagons at the client's request takes an average of 3-6 days, and this situation is associated with a shortage of wagons and uneven supply due to the different organization of cargo flows. To eliminate this problem, a new technology has been developed based on an optimization model aimed at the rational distribution of empty cars; lease and contract mechanisms with private car owners are also taken into account. The software developed on the basis of the model operatively recalculates orders and forms decisions on the allocation of wagons to customers in real time (practical tests showed a reduction in the delivery time of empty wagons by ~25 % and a reduction in downtime by > 20 %).

Highlights

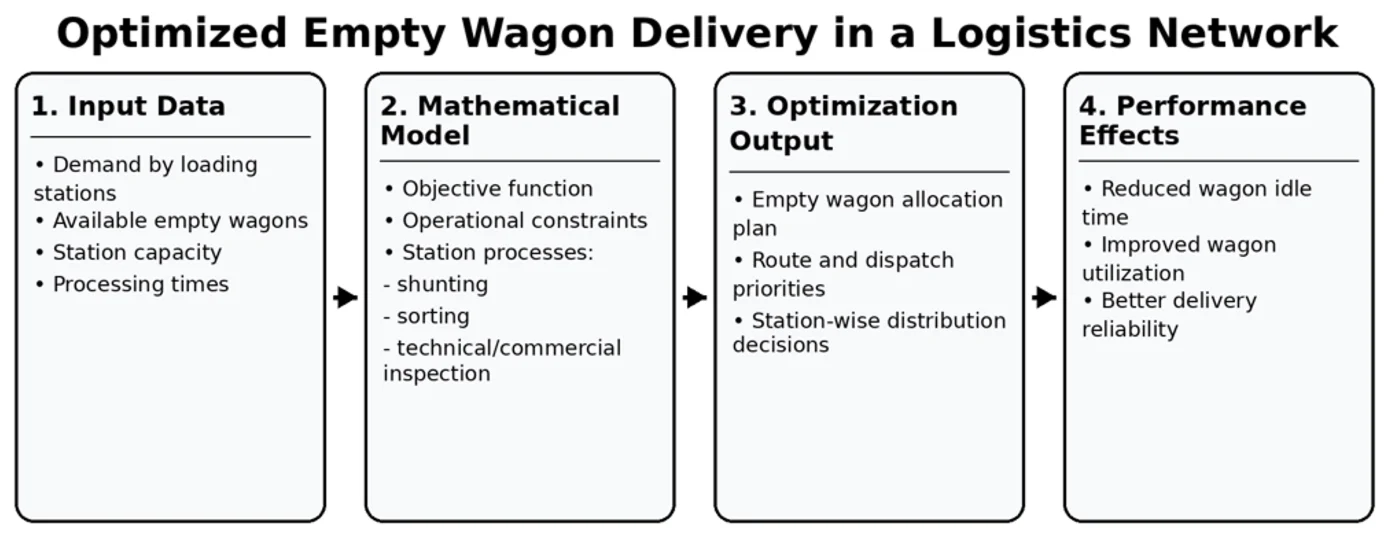

- A mathematical model for empty wagon delivery in a logistics network is developed.

- Key operational factors, including station capacity, wagon availability, and processing times, are incorporated.

- The approach accounts for station-level operations: shunting, sorting, and technical/commercial inspection.

- An optimization-based mechanism for empty wagon allocation and dispatch planning is proposed.

- The method reduces wagon idle time and improves delivery reliability and wagon utilization.

1. Introduction

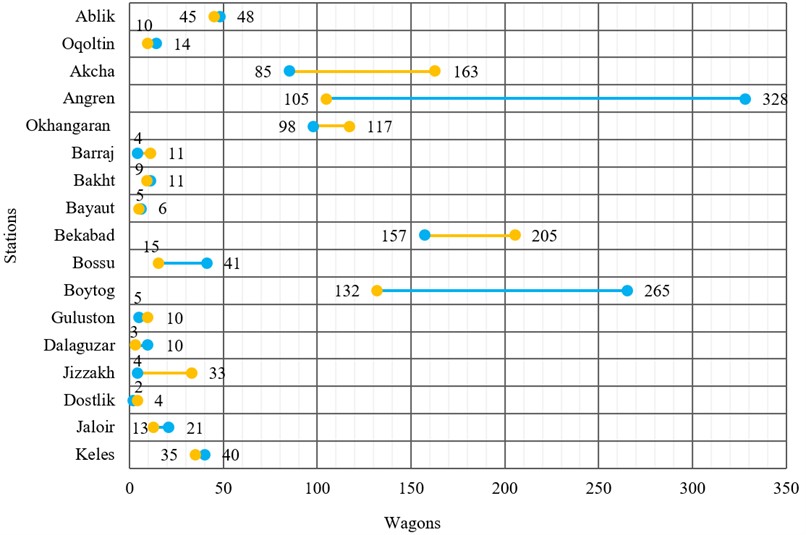

It has been analyzed that a redistribution methodology needs to be developed to optimize the delivery of wagons and containers for loading in railway transport. According to the average daily analytical results for 2024, at the Tashkent regional railway junction, a maximum of 19,680 tons of cargo is loaded at the station, and cargo is unloaded from 105 wagons. Meanwhile, at another station, cargo is unloaded from 205 wagons while 157 wagons are being loaded. It has been determined that wagon distribution should take into account the different types of wagons and ensure that the wagons allocated for unloading are also considered for loading. An optimal distribution method has been proposed for delivering wagons while considering the imbalance in loading and unloading perishable goods.

Today, organizing freight transportation processes in railway transport in accordance with modern requirements is of great importance in ensuring high-quality services for various categories of customers, including logistics centers, siding owners, partner organizations, and cargo owners at public freight terminals. In recent years, the transfer of the wagon fleet previously under the jurisdiction of “Uzbekistan Railways” JSC to the balance of “Temiryо‘lcargo” JSC has led to organizational and operational difficulties in the targeted distribution of empty wagons to cargo owners. The purpose of this study is to develop a methodology for the redistribution and optimization of the operational distribution of empty wagons at the Uzbek railway junction to ensure their timely provision at the customer's request. As one of the optimal options for the delivery of empty wagons at the request of clients, the use of leased and private wagons on a contractual basis is required. It is necessary to ensure stability in providing customers with empty wagons for loading [1].

Recent studies affirm that the causes of the delays in a railway are a complex interplay of technological, operational, and stochastic factors. Any small interruption in station processing will spread across the network and have a substantial negative impact on the reliability of delivery [2-4]. This effect is further enhanced by constraints in yard and track capacity, which cause conflicts and queue formation with high utilization, even when the schedules of the trains are not impossible.

The real-time optimization and rescheduling techniques that have been designed to manage delay propagation are primarily focused on train conflicts instead of wagon-level technological processing in the various types of shipments [5]. Logistics-wise, it can be seen that delivery performance is not merely based on the length of the route but also the number of intermediary handling operations. Intermodal and containerized transportation studies indicate that minimization of re-handling steps leads to great enhancement in delivery time and dependability, even with a greater distance [6]. Poor scheduling of railways thus has a direct impact of increasing the cost of transport and losses through delayed delivery [7-9].

At the same time, most existing studies consider delays within the framework of train collisions and schedule problems, however, there are insufficient solutions that jointly take into account the disproportion of wagon type and cargo flow, linking empty wagons with station-level technological processes (acceptance-transfer, sorting, inspection, delivery to the front). In particular, the operational management of the two-stage turnover of one wagon (loading after unloading) during loading and unloading processes has not been fully established in practice [12].

The scientific and practical novelty of the research is as follows:

– Formation of contracts with private, lease, and international car owners when distributing empty wagons, taking into account the types of wagons, the imbalance of freight flows, and the technological processes of the station.

– Rules for making decisions that accelerate wagon turnover have been developed, linking the wagons allocated for unloading with the needs of subsequent loading.

– A mechanism for the use of private, leased, and international wagons for stable customer satisfaction has been introduced into the methodology.

The 2nd section of the article provides a literature review, the 3rd section describes the model and algorithm, the 4th and 5th sections provide discussion and results, and the 6th and 7th sections define the conclusion and future work.

2. Literature review

This article reviews the works of foreign researchers on the distribution of loaded and empty wagons:

[13] Benoit Crevier, Jean-Francois Cordeau, and Gilles Savard studied how maximizing profits in the railway industry is strongly linked to the integration of logistics activities and better revenue management. They also analyzed how the operational policies chosen by the carrier significantly impact network profitability and, consequently, overall revenue.

Researchers Xiaodong Zhang, Ping Li, Xiaoning Ma, and Yanjun Liyu [14] studied information flows related to wagon routing in railway transport through analysis. Their research on wagon routing involves predicting and identifying the areas where wagons are likely to be present in advance.

Dr. [15] has discussed train operation models, railway traffic control and dispatching issues, technical schemes of railway stations, terminal operations, and timetable design. Additionally, the scientific works of local researchers such as Muxamedova Z., Suyunbayev Sh. M., Rasulov M. X., and other scholars have been studied [16-18].

In the reviewed scientific studies, it can be observed that the aspect of providing high-quality customer service in wagon distribution has not been fully accomplished.

The distribution of empty wagons must be carried out while ensuring the continuity of the transport logistics process. Statistical analysis was carried out taking into account the average indicator of the lack of empty cars on railway sections. It was analyzed that these indicators were not provided with empty wagons at the Tashkent regional railway junctions in April 2025 (Fig. 1).

After the shipper is notified about the need to load cargo onto railway transport according to the plan, the following must be coordinated and reviewed: checking the condition of available wagons, inspecting wagons at other stations, determining wagon ownership, identifying the plan for loaded and empty wagons at stations within the section, and distributing them along designated routes.

The Freight Transport and Commercial Operations Department issues detailed monthly freight orders, referred to as GU in subsequent cases (GU-12 form). These orders are sent to regional railway junctions before the start of the planned month and are then communicated by the regional railway hubs to the heads of loading stations and multimodal logistics complexes.

According to Article 26 of the Railway Charter of the Republic of Uzbekistan (hereinafter referred to as the Charter), The fulfillment of the main monthly transportation plan is recorded in an accounting card. The railway approves the form and filling rules of the accounting card. The accounting card must be signed by the head of the railway station and the consignor at the end of each reporting day [10, 11, 16].

Fig. 1Daily average analysis of wagon loading and unloading in the section, 2025.04.08

Station and logistics center managers must adhere to the GU-12 form monthly freight transportation plan and ensure its implementation throughout the planned month. Stations must formalize and maintain the ten-day order form (GU-11), the ten-day loading assignment form (GU-100), and the transportation plan execution record (GU-1) in accordance with the GU-12 freight transportation orders (plan). In fulfilling the freight request, an additional transportation operations plan must be developed to provide customer service. For this purpose, the distribution of loaded and empty wagons to loading and unloading points has been analyzed (Fig. 1).

The analysis of the above literature shows that, although there are many approaches to reducing delays, the issue of operational distribution of private, leased, and international empty wagons at the station level, taking into account the types of wagons and loading and unloading imbalances, requires more practical solutions. Therefore, the next section presents the proposed methodology and mathematical model for the redistribution of empty wagons.

3. Methods

To efficiently deliver empty wagons to customers, it is necessary to develop a mathematical model with some modifications [8, 9]. For this:

if , then the effective N should be given, where: (1, 2,..., ; , ,..., );

secondly, if , the number of empty wagons delivered is taken as , where is a leading large number, for example:

; as a result a square matrix of size () consisting of elements is formed.

There are several algorithms for empty wagon delivery [1]. However, in cases where it is necessary, in addition to the constraints specified in the model, it is advisable to develop a special algorithm that takes into account additional conditions. For example, completing a certain number of shipments in a given time is not considered efficient.

In such cases, it would be useful to have an algorithm that can analyze not only the optimal plan, but also the permissible plans that are close to it.

For the effective organization of the supply of empty wagons at loading and unloading points, it is necessary to create an automated control system [10]. To create an automated control system, a number of influencing factors are considered. When delivering wagons to loading and unloading points, it is necessary to take into account points (1, 2,..., ; 1, 2,..., ); – point where an empty wagon is parked, – point where an empty wagon is required, is the time it takes to travel between two points.

In this case, if there is an empty wagon at point , the flow of empty wagons required at point is determined to be brought to the requested point in time . In addition to the time unit, other factors are also taken into account due to the influencing factors. As a result of the influence on the time unit, the idleness of the empty wagon, the travel time, the processing time, all these factors affect the economic efficiency.

If the following is known:

– conditional estimate of the idle cost per unit time of a wagon that is unloaded at point and ready to be sent to point at time ;

– conditional estimate of the cost of waiting for a unit of time for a cargo ready for transportation at point ;

is the conditional value of the time costs of transporting an empty wagon from point to point . When transporting wagons, it is necessary to construct a wagon movement function taking into account the impact on them if they are carried out within a unit of time. When delivering empty wagons, the following conditions must be met to construct a mathematical model of the objective function:

– if the wagon is at the unloading station, it is loaded onto an empty wagon right there. As a result, the costs of delivering the wagons are zero, since the delivery is made from this station itself.

in this case, the condition of delivering wagons within a certain time interval is met. In this case, the distance traveled by the empty wagon affects the economic efficiency. Here, the distance traveled by the station relative to the time taken is considered to be the flow of local trains.

A mathematical model was developed to organize the most efficient work of distributing empty wagons at stations. The following formula was derived for the distribution at stations, taking into account all types of wagons, their location at stations, wagon-km and locomotive-km costs, and the flow of wagons on the section [19, 20].

– stations, stations on the site.

– network routes on the site. For a simple linear network, intermediate or load stations between technical stations are taken into account: and .

is a set of wagon types.

– distance between station and station (km).

– number of empty wagons of type available at station (supply).

– number of empty wagons of type required at station (demand).

– cost per wagon-kilometer (currency / wagon·km).

– cost per locomotive-kilometer (currency / locomotive·km).

– the maximum number of wagons in a train that a single locomotive can carry in one run.

When creating a mathematical model for the effective implementation of decisions on the organization of the flow of empty wagons, the following should be determined:

number of wagons of type along the route.

by locomotive direction (the locomotive’s run produces locomotive-km by the length of the distance between stations).

– number of excess empty wagons left at the end of the station wagon type distributed according to.

It is necessary to reduce the time spent on distributing empty wagons and realize the economic efficiency of empty wagon operation. In this case, it is necessary to balance the time and economic efficiency of distributing wagons.

When delivering empty wagons, it is necessary to minimize wagon-km and locomotive-km hourly costs in a generalized manner [21]:

Each station and type the total number of wagons leaving the station for the train was initially available. not to exceed:

For each station and wagon type , the incoming wagons must satisfy the demand at least:

Each station and for wagon type:

The proposed mathematical model is aimed at optimizing the distribution of empty wagons according to customer demand, which enables a reduction in both locomotive-kilometer and empty wagon-kilometer operating costs. The developed mathematical model makes it possible to predict wagon flows in advance by planning the distribution of empty wagons. The distribution of wagons is carried out independently and automatically, along with planning. As a result, the timely delivery of empty wagons to the required locations is ensured, the utilization efficiency of the wagon fleet increases, and the continuity of freight transportation operations is maintained. Thus, the proposed mathematical model contributes to improving the technical and economic efficiency of empty wagon distribution in railway transport.

Let’s present the algorithm of the developed mathematical model. The algorithm is constructed as follows.

The algorithm for the distribution of empty wagons in the ASU system is implemented as follows.

In this work, it is understood that real-time distribution is recalculated every 2 hours depending on the updating of the database and generates decisions in a time interval close to client requests. This approach allows for the prompt elimination of unevenness in the supply of wagons. A database is created in accordance with client requests.

– number of client requests depending on the type of cargo.

– number of wagons at the station, excluding wagons that are balanced (except for empty ones needed).

– daily freight flow schedule of the station.

– local train traffic on the section.

– the cost of delivery of the empty wagon and the time that influences it.

Result of the distribution of empty wagons:

A - planning the distribution of empty wagons under the contract.

Perform sequential planning:

1) Process requests received from clients in real-time using the ASU system.

2) Route wagons at the station according to requests, excluding balanced wagons.

3) Develop efficient options for delivering wagons at the station in accordance with the daily plan.

4) Take into account local trains operating on the forming section.

The destination function is activated along the distributed route of empty cars:

5) Wagon mileage, locomotive mileage, wagon downtime, delivery time, total costs.

Implementation of restrictions on the organization of empty cars:

6) Compliance of the station wagon with the application, compliance with the route, compliance with the station operation plan, availability of a contract.

7) Developing a model of rational plan options in contract A when compiling the matrix for the distribution problem.

8) Sending the independently developed rational version to the train dispatcher.

9) Placing empty wagons into the ASU system during distribution.

The algorithm's operation is described as follows. This algorithm develops rational options for contracts for the supply of empty wagons, taking into account the flow of wagons in real time. Wagon requests submitted by customers are received through the ASU train traffic dispatching system, after which stations with available empty wagons are identified. The implementation of empty wagons is determined based on the station's daily work schedule. The provision of empty wagons to customers is carried out by ensuring the unloading of wagons under lease, belonging to the railway enterprise, and on international routes along the route. An optimization model is formulated to minimize overall transportation and operational costs. This model aims to reduce wagon-kilometer and locomotive-kilometer indicators, as well as minimize wagon idle time and the risk of delays. The distribution of empty wagons is determined by implementing restrictions according to the correspondence with the type of cargo, suitability for the route, and compliance with the contract terms. Once the optimal allocation matrix is obtained, the final distribution plan is sent to the dispatcher for approval. The algorithm addresses the issue of allocating empty wagons according to customer demands. It primarily involves finding customers for empty wagons belonging to the railway enterprise, leased wagons, and other state-owned wagons to prevent them from traveling empty along their routes. The allocation of empty wagons to customers can be determined in real-time within the ASU system.

4. Discussion

A mind mapping approach was employed to structure the key factors influencing the wagon allocation process. This approach enabled the identification of causal interdependencies among freight demand intensity, station handling capacity, wagon processing duration, locomotive availability, and the dynamic behavior of freight flows. Today, when there are inconveniences and shortages of empty wagons for customers on the railways of Uzbekistan, it is necessary to implement it through the methodological basis we propose.

According to Article 25 of the Charter, the consignor must submit a loading order, including a calendar schedule of loading volumes by day, to the head of the regional railway division through the head of the railway station no later than three days before the start of the ten-day period. Such situations may additionally delay the freight transportation plan. The head of the regional railway division, together with the consignor, may establish a procedure for submitting orders for a longer period. According to regulations, the head of the railway station must inform each consignor about the wagons to be delivered daily for the ten-day period at least one day before its start. Consignors are required to submit a GU-11 form order, including a ten-day loading schedule, to the railway management through the station head no later than three days before the start of each ten-day period, excluding the order submission date.

The head of the regional railway junction may establish a procedure for submitting agreed-upon orders with the consignor for a longer period instead of every ten days.

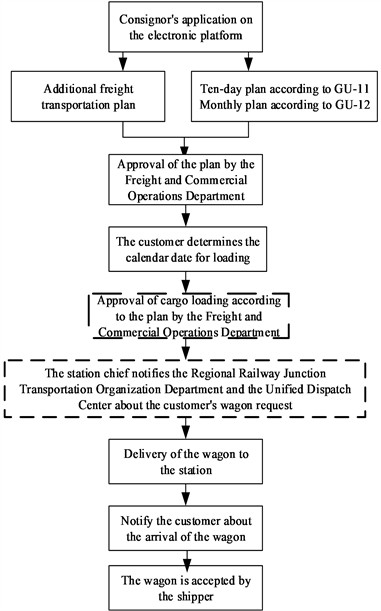

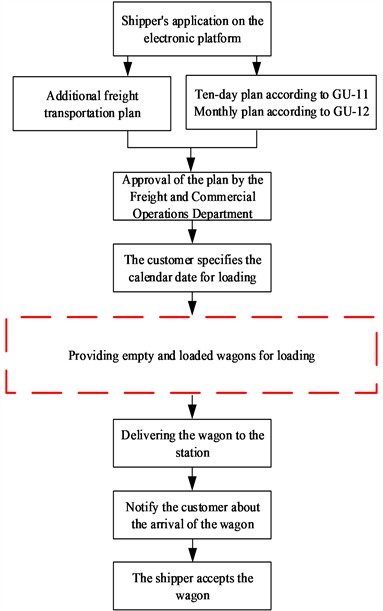

Fig. 2Block diagram of wagon and container allocation for loading and unloading

a) Existing technology

b) Proposed technology

Railway transport is required to provide wagons within 3 days when customers request them for cargo transportation. However, it has been identified that in most cases where wagons are not provided, the waiting period is close to 10 days. In such instances, the shipper is held liable for not loading the cargo on time, that is, for failing to fulfill the plan. The absence of the consignor’s order is recorded in the GU-1 form accounting sheet [5].

Reducing the delivery time of empty wagons does not always correspond to a reduction in overall operational costs. In certain cases, ensuring faster delivery requires routing wagons through longer distances, which increases wagon-km and locomotive-km expenditures. Hence, the proposed technology adopts a joint evaluation of time-related and economic performance criteria, aiming to achieve an optimal trade-off between delivery speed and cost efficiency.

Today, freight transportation involves ensuring customer service by providing wagons for loading and delivering cargo on time. The analysis of tasks required for the digitalization of these processes has been carried out using a block diagram (Fig. 2).

Through the proposed technology, once the station chief receives a notification from the Regional Railway Junction’s Transport Organization Department and the Unified Dispatch Center regarding the customer's need for a wagon, they issue a command via the simulation model interface. This determines which wagon should be allocated to the loading/unloading point. In our proposed approach to wagon distribution, we have identified the possibility of reducing technological processes while organizing the optimal method for allocating empty wagons. This, in turn, provides an opportunity to streamline the technological processes being carried out (Fig. 2).

5. Results

To develop the simulation model, a digital station mapping interface was implemented. The coordinates and names of loading and unloading stations were entered into the system, allowing for the identification of potential wagon routing paths. The model determines suitable wagon types according to cargo classification using the unified tariff statistical nomenclature. Based on customer requirements, options for contracting specific wagons emerge, taking into account the types of wagons available nearby and the location of stations. After the agreement for the provision of wagons is concluded, the most optimal options for delivering the wagons are independently developed. In addition to existing wagons, the service also offers rental and other international wagons.

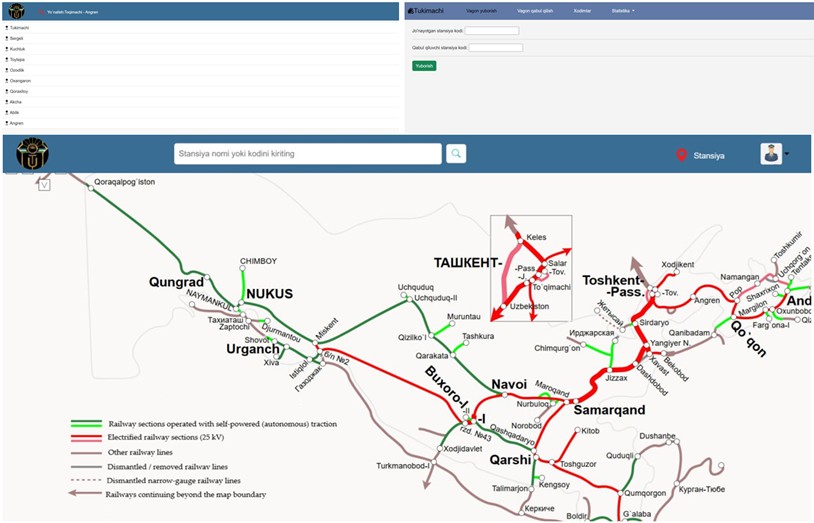

This will enable faster transportation of wagons to loading and unloading points. The non-English inscriptions shown in Fig. 3 are the names of existing stations in Uzbekistan, which are used in the application software interface to designate stations on the map of the real railway network.

A certificate has been obtained for the program titled “Calculation Methodology for the Distribution of Empty Wagons for Customer Service” in accordance with the Law of the Republic of Uzbekistan “On Legal Protection of Software and Databases for Electronic Computing Machines”. The software interface is shown in Fig. 3.

The scientific work presented in this article has been carried out under Contract No. 45 in collaboration with “Uztemiryulkonteyner” JSC.

As a result of implementing the proposed optimization model in practice, operational inefficiencies are significantly reduced. In particular, the average delivery time of empty wagons decreases by approximately one-fourth, indicating a noticeably faster wagon circulation process. It is also planned to increase the efficiency of wagon use by 10 %. In addition, it has a positive impact on the level of locomotive utilization. This, in turn, determines the implementation of resource saving of rolling stock. Furthermore, the idle time of wagons at stations is reduced by more than 20 %, which leads to increased throughput capacity and greater stability in freight handling processes. With the provision of empty wagons, customer confidence in loading has increased, and the quality of service has improved thanks to the developed methodology.

The effectiveness of the proposed model was assessed based on data for the period from April to September 2025 for 54 stations of the Tashkent regional hub. The results confirm that the model accelerates decision-making in practical conditions and increases the stability of service quality.

Fig. 3The interface of the working window for distributing empty wagons and containers to the loading and unloading points

6. Conclusions

Proper distribution of empty wagons and containers to loading and unloading points reduces transportation costs, increases the efficiency of wagon utilization, and ensures the continuity of freight transportation processes. The creation of an intelligent system for the developed technology will improve the quality of service by providing empty wagons to the entire railway network. Currently, when customers request wagons through an application, they must be provided within three days. However, due to delays in wagon allocation beyond this period, the proposed technology and software aim to eliminate delays, ensuring that freight reaches its destination faster and more efficiently.

The proposed approach serves to fulfill the requirement for the timely provision of empty wagons upon request, and the provision of wagons is determined within 3 days. In the future, by expanding the model, it will be possible to take into account the multi-criteria selection of stations capacity, locomotive resources, and priority loads more deeply.

7. Future work

Our future research work is aimed at developing a predictive model for changes in cargo flow by attracting customers to railway transport. Currently, due to the location of the ASU system management server on the Russian Railway, the task is to create a local ASU intelligent system. The creation of this intelligent system will enable multi-criteria decision-making based on preliminary assessments of resource efficiency in railway transport. It is anticipated that the implementation of the ASU automated intelligent system will incorporate operational planning capabilities.

Further work on software development includes the following areas:

1) Development of a forecast model for a preliminary assessment of the change in freight flows and taking into account the factors of attracting customers to railway transport.

2) Creation of a local intelligent module of the ASU control system in order to reduce dependence on the external server.

3) Integration of multi-criteria decision-making and operational planning functions into the system based on a preliminary assessment of resource efficiency.

References

-

J. Kobulov, E. Shermatov, S. Saidivaliev, S. Sattorov, and J. Barotov, “Overdue waiting of wagons on railway branch tracks: problems and solutions,” in E3S Web of Conferences, Vol. 515, p. 03008, Apr. 2024, https://doi.org/10.1051/e3sconf/202451503008

-

H. Venes, R. D., E. A. Rosa, L. C. Resendo, and R. P. Pestana, “Planning the distribution of empty wagon batches from marshalling yards to meet mine loading demand,” International Journal of Logistics Systems and Management, Vol. 49, No. 3, pp. 389–411, Jan. 2024, https://doi.org/10.1504/ijlsm.2024.142615

-

V. Naumov and J. Starczewski, “Approach to simulations of goods deliveries with the use of cargo bicycles,” in Computational Technologies in Engineering (TKI’2018): Proceedings of the 15th Conference on Computational Technologies in Engineering, Vol. 2078, p. 020070, Jan. 2019, https://doi.org/10.1063/1.5092073

-

A. Vasin, O. Grigoryeva, and N. Tsyganov, “A model for optimization of transport infrastructure for some homogeneous goods markets,” Journal of Global Optimization, Vol. 76, No. 3, pp. 499–518, May 2019, https://doi.org/10.1007/s10898-019-00785-y

-

J. L. Moura, A. Ibeas, and L. Dell’Olio, “Optimization-simulation model for planning supply transport to large infrastructure public works located in congested urban areas,” Networks and Spatial Economics, Vol. 10, No. 4, pp. 487–507, Jun. 2008, https://doi.org/10.1007/s11067-008-9065-8

-

L. Makhova, M. Haykin, I. Glazkova, and O. Domnina, “Development of mathematical models for trucks and cargo,” Infrastructures, Vol. 8, No. 2, p. 17, Jan. 2023, https://doi.org/10.3390/infrastructures8020017

-

A. Zabielska, M. Jacyna, M. Lasota, and K. Nehring, “Evaluation of the efficiency of the delivery process in the technical object of transport infrastructure with the application of a simulation model,” Eksploatacja i Niezawodność – Maintenance and Reliability, Vol. 25, No. 1, Jan. 2023, https://doi.org/10.17531/ein.2023.1.1

-

V. M. Yanchuk, A. G. Tkachuk, D. S. Antoniuk, T. A. Vakaliuk, and A. A. Humeniuk, “Mathematical simulation of package delivery optimization using a combination of carriers,” arXiv:2011.01200, Jan. 2020, https://doi.org/10.48550/arxiv.2011.01200

-

G. Mukunzi and C.-W. Palmqvist, “The impact of railway incidents on train delays: A case of the Swedish Railway Network,” Journal of Rail Transport Planning and Management, Vol. 30, p. 100445, Jun. 2024, https://doi.org/10.1016/j.jrtpm.2024.100445

-

I. Lebid et al., “Construction of a simulation model of goods delivery in international road transportation taking into account the functioning efficiency of logistics supply chain,” Eastern-European Journal of Enterprise Technologies, Vol. 3, No. 3 (123), pp. 57–67, Jun. 2023, https://doi.org/10.15587/1729-4061.2023.280886

-

A. Šperka, J. Čamaj, M. Dedík, and Z. Bulková, “Evaluation methodology of the railway stations using the AHP method in the transport hubs from the freight transport point of view,” Infrastructures, Vol. 8, No. 12, p. 177, Dec. 2023, https://doi.org/10.3390/infrastructures8120177

-

J. Geischberger, N. Weik, and J. Pannek, “Reliability evaluation of rail freight transport processes – An agent-based approach combining microscopic rail simulation and freight network logistics,” Journal of Rail Transport Planning and Management, Vol. 37, p. 100558, Mar. 2026, https://doi.org/10.1016/j.jrtpm.2025.100558

-

B. Crevier, J.-F. Cordeau, and G. Savard, “Integrated operations planning and revenue management for rail freight transportation,” Transportation Research Part B: Methodological, Vol. 46, No. 1, pp. 100–119, Jan. 2012, https://doi.org/10.1016/j.trb.2011.09.002

-

X. Zhang, P. Li, X. Ma, and Y. Liu, “Railway wagon flow routing locus pattern intelligent recognition algorithm based on SST,” Smart and Resilient Transportation, Vol. 2, No. 1, pp. 3–21, Apr. 2020, https://doi.org/10.1108/srt-10-2019-0008

-

K. Shenfeld, S. Zakharov, and Y. Cherkashin, “Studies and measures to provide wheel/rail performance of heavy and long train operation in the Russian Railways,” in 9th International Heavy Haul Conference: Heavy Haul and Innovation Development, pp. 1005–1011, 2009.

-

J. Barotov, J. Kobulov, S. Saidivaliyev, S. Sattorov, G. Fayzullayev, and A. Kibishov, “Effective organization of acceleration of local train movement at railway transport departments,” in E3S Web of Conferences, Vol. 515, p. 02002, Apr. 2024, https://doi.org/10.1051/e3sconf/202451502002

-

Z. Mukhamedova and D. Mukhamedova, “Prospects of using blockchain technology in the organization of the transportation process and supply chain,” International Journal of Intelligent Systems and Applications in Engineering, Vol. 12, No. 2s, pp. 379–387, 2023.

-

M. Masharipov, A. Gulamov, M. Rasulov, S. Suyunbayev, N. Adilova, and M. Rasulmukhammedov, “Development of enhanced method for planning train locomotives ready to operate the next day,” in E3S Web of Conferences, Vol. 458, p. 03009, Dec. 2023, https://doi.org/10.1051/e3sconf/202345803009

-

C. Zhao, L. Yang, and S. Li, “Allocating freight empty cars in railway networks with dynamic demands,” Discrete Dynamics in Nature and Society, Vol. 2014, pp. 1–12, Jan. 2014, https://doi.org/10.1155/2014/349341

-

A. Shatokhin, G. Bilenko, A. Kuznetsova, and I. Kartsan, “Optimization of empty wagon flows in the formation of the technical work plan for the railway network,” Transportation Research Procedia, Vol. 61, pp. 361–365, Jan. 2022, https://doi.org/10.1016/j.trpro.2022.01.058

-

M. Marinov and J. Viegas, “A mesoscopic simulation modelling methodology for analyzing and evaluating freight train operations in a rail network,” Simulation Modelling Practice and Theory, Vol. 19, No. 1, pp. 516–539, Jan. 2011, https://doi.org/10.1016/j.simpat.2010.08.009

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The analyses in the article were developed by Jamshid Kobulov. The software tool and results were developed by Jamshid Barotov.

The authors declare that they have no conflict of interest.