Abstract

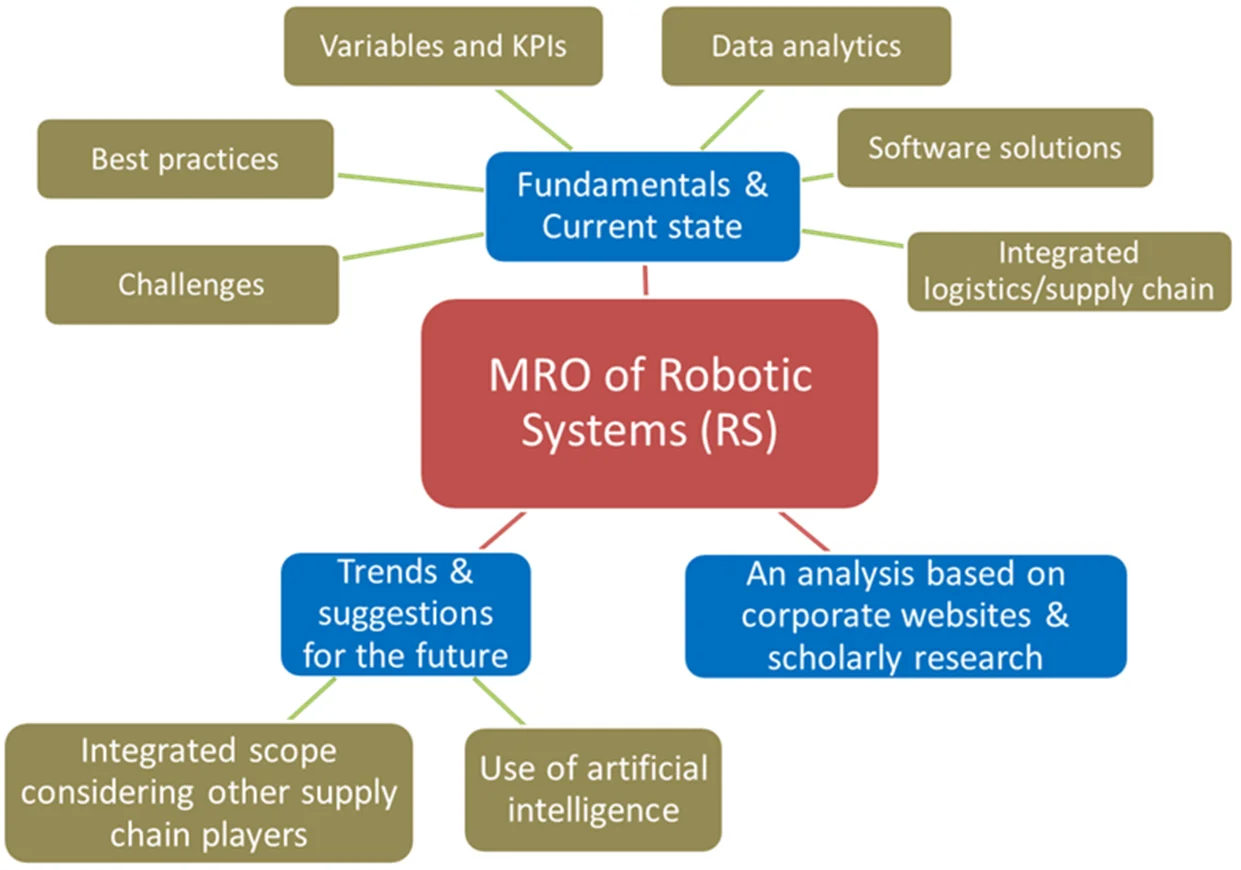

This paper not only explores the fundamental aspects of but also brings new ideas for maintenance, repair, and overhaul (MRO) operations of robotic systems (RS). This synthesis is based on the limited scholarly research in this area and on information gathered from comprehensive web searches and analysis of corporate websites so that the results reflect the current views of RS developers and operators. The paper describes several crucial areas concerning RS MRO: maintenance of robotic systems, challenges and best practices for RS MRO, predictive maintenance variables and key performance indicators, data analytics, software solutions for RS MRO, and logistics/supply chain approach that should be considered. These insights provide not only a comprehensive understanding of the current state of RS MRO but also describe trends and suggestions for the future of RS MRO, emphasizing the novelty of the proposed research conducted. Key trends that organizations will need to address include the use of artificial intelligence (AI) models and the increasing importance of RS MRO logistics and supply chain management.

Highlights

- Challenges and best practices for the Maintenance, Repair and Overhaul (MRO) of robotic systems

- Variables, KPIs, and Data analytics

- Market software solutions

- An analysis based on corporate websites and scholarly research

- Trends and suggestions for the future of robotic systems MRO: Integrated logistics/supply chain players and Artificial Intelligence

1. Introduction

This paper describes fundamental aspects of maintenance, repair, and overhaul (MRO) of robotic systems (RS), going through definitions, industries, performance indicators, data analytics, software solutions, and logistics and supply chain needs. When discussing MRO and RS, one can distinguish two approaches:

1) Maintenance, repair, and overhaul of robotic systems (RS MRO) enhances operational efficiency, reduces downtime, and improves the overall reliability of robotic systems. It is driven by the increasing need for operational excellence and efficiency in industries that rely heavily on robotic systems.

2) Using robotic systems for MRO operations focuses on leveraging robotic systems to automate and enhance various MRO activities in aircraft maintenance, manufacturing, and other industrial settings. This includes tasks like inspections, repairs, cleaning, and component handling.

This study focuses on the first approach and addresses the following questions: What are the challenges of implementing RS MRO operations? What types of maintenance strategies are used? What are the key variables that are used to monitor the efficiency and cost-effectiveness of RS MRO operations? How are data analytics used to improve RS MRO operations? What types of software are available to support these operations? For these reasons, it brings new and interesting developments, contributing to those working in the related areas considered herein.

For this study, the authors reviewed the limited scholarly research on RS MRO and corporate websites that describe the current views and practices of RS developers, operators, and MRO solution providers. AI search tools, including Gemini and ChatGPT, were used to find and analyze these websites. The contents were then revised, organized and structured to present a snapshot of the state-of-the-art in RS MRO, which can motivate and inform future research and development activities.

This paper is organized as follows: Section 2 explains some of the characteristics of RS MRO in practice. Section 3 discusses general procedures, challenges and difficulties, variables and KPIs in implementing RS MRO. Section 4 describes data analytics and software solutions for RS MRO. Section 5 brings a brief analysis on MRO logistics and supply chain integration. Lastly, Section 6 presents a summary and conclusions.

2. Maintenance of robotic systems

Robotic systems are being maintained, repaired, and overhauled in many real-world applications [1-22]:

– Robotic arms performing welding or assembly tasks in an automotive factory require regular maintenance, including lubrication, cleaning, inspection, and software updates.

– Surgical Robots (robots used in surgery), like the da Vinci Surgical System, require stringent maintenance to ensure their precision and reliability. This includes regular calibration, software updates, and preventive servicing.

– Rehabilitation and Physical Therapy Robots (robots used to assist patients in therapy) need regular maintenance to ensure they function correctly and safely.

– Cleaning and Disinfection Robots (autonomous robots are used to clean and disinfect healthcare facilities, improving efficiency and infection control) need regular maintenance, including checking and cleaning sensors, updating navigation systems, and ensuring proper operation of disinfection components.

– Autonomous Mobile Robots (AMRs) are used for tasks like order fulfillment and inventory management, require regular maintenance to ensure their mobility, navigation systems, and sensor accuracy. Predictive maintenance strategies, using AI and machine learning, monitor AMR performance and schedule maintenance proactively, reducing errors and enhancing supply chain efficiency.

These types of robots (and many others) are being used in many industries and activities, including industrial manufacturing, automotive manufacturing, electronics assembly and testing, pharmaceuticals, healthcare, textiles and clothing manufacturing, food and beverage manufacturing, agriculture, construction, mining, energy, military, public safety, logistics and warehousing, and retail [23-28].

Table 1Robot maintenance procedures [2], [14], [20], [29]

Maintenance procedure | Time period |

Preventive maintenance: visual inspection, checking of abnormal signals, self-diagnostic of control system | Daily |

Check and clean sensors, wheels, and drive systems. | Weekly |

Periodic maintenance service: battery replacement | Annually |

Overhaul: greasing and lubrication, replacing filters and fans | Every 3 To 5 Years |

Refurbishment: cleaning, replacing components that are defective or damaged, e.g. bearings, brakes, gears, motors | After 10 To 15 Years |

Robotics systems are complicated machines that combine mechanical actuators, electrical systems, computing, and many types of sensors [30], and robots can fail in many ways. Table 2 summarizes common robot malfunctions and typical causes [30]. Wang and Christensen [15] described battery failures, auto charging problems, mechanical failures, device driver failures, network connectivity issues, and software problems on a mobile tour guide robot. Inside a robot motor, the brake, bearings, encoders, and other components can fail [32].

Correspondingly, a wide variety of maintenance activities are required to prevent or repair robot failures. Organizations are using both preventive maintenance strategies (cf. Table 1) and predictive maintenance strategies (see Section 3.1) for their robotic systems [1], [3]. A robot’s computer requires data backups and software updates [14]. Robot maintenance requires skills in software, electrical, mechanical, and control engineering in order to diagnose the causes of failures and perform the necessary repairs.

Table 2Common robot malfunctions [31]

Fault type | Fault description | Possible causes |

Mechanical faults | Joint sticking or vibration | Lack of lubrication, part wear |

Abnormal noise | Bearing damage, loose connections | |

Electrical faults | Motor unable to start | Insulation damage, bearing wear |

Inaccurate motion | Encoder damage, circuit failure | |

Drive system faults | Power transmission failure | Component wear, gear dislocation, parameter error |

Control system faults | Program execution error | Programming logic error, parameter setting error |

Communication interruption | Network failure, protocol configuration error | |

Structural faults | Arm failure | Joint bearing wear, telescopic axis damage, loose parts |

Sensor faults | Sensing abnormality | Position, torque sensor failure |

Power supply faults | Power supply abnormality | Unstable or faulty power supply |

Operation faults | Abnormal operation | Incorrect parameter setting, etc. |

Environmental impacts | Reliability degradation | Temperature, dust, etc. |

The costs of robot maintenance include training staff to perform the maintenance activities, purchasing and managing spare parts, and repairing robots when they fail [34], [35]. Because some industrial robots are large and powerful, accidents such as collisions, crushing, and trapping can occur [36], and maintenance staff need to follow safety guidelines and guidelines [37].

3. Implementation, variables and performance measures for MRO of robotic systems

To maximize robot reliability, availability, and productivity, effective RS MRO is essential to reduce robot failures and delays due to MRO operations. Implementing RS MRO operations involves technical, personnel, data management, financial, and logistics challenges, as detailed below [10], [38-47]:

1) Technical Complexity and Integration Issues:

– Integrating robots with existing systems and workflows can be technically challenging due to sophisticated configurations and potential compatibility issues.

– The intricate design and numerous components of robotic systems can make it difficult to pinpoint the root cause of failures and accurately predict maintenance needs.

– Legacy systems or highly customized processes within MRO operations can complicate the integration of new robotics technology.

– Choosing modular systems that can be easily integrated with existing infrastructure and adhering to interoperability standards can help address these challenges.

2) The personnel challenges involve the need to work with new technologies:

– Integrating new technologies often requires a shift in workforce dynamics and can lead to resistance from employees concerned about job displacement.

– There can be a shortage of skilled personnel required to operate, maintain, and repair complex robotic systems.

– Training employees on new systems and technologies can be time-consuming and costly.

– Involving employees in the planning and implementation process, providing comprehensive training programs, and implementing change management strategies can help overcome resistance and facilitate smoother adoption.

3) Data Management and Quality:

– Effective MRO data management is crucial for smooth operations in asset-heavy industries.

– MRO data can be plagued with challenges such as duplication, unstructured data, incomplete information, and conflicting data.

– Predictive maintenance relies on the analysis of large volumes of data, requiring robust data management infrastructure for storage, bandwidth, and computational resources.

– Data quality and integrity are critical for accurate predictions and can be undermined by inaccuracies, inconsistencies, or errors in the collected data.

– Regulatory and ethical concerns, such as safety standards, data privacy, and ethical considerations, are also important factors to address during implementation, particularly in sensitive sectors like healthcare and hospitality.

4) Cost and Investment:

– The complexity of robotic systems also increases the initial and recurring costs of RS MRO operations. Exploring leasing and financing options, government grants and subsidies, and collaborative partnerships can help organizations manage the financial burden of adopting robotic systems (and their respective MRO support).

5) MRO Logistics and Supply Chain Management.

– Purchasing and managing the spare parts, increase availability and reduce maintenance costs [13]. Parts classification is a useful strategy for supplies, and consumables needed for RS MRO operations is another challenging domain. Generally, effective MRO logistics can prioritizing the mechanical parts, sensors, and electronics that robots use [34]. Typically, organizations use three categories: (1) high-criticality parts are essential for the robot’s operation, such as motors, control boards, and sensors; (2) medium-criticality parts (such as wheels or secondary actuators) affect the robot’s performance but don’t cause immediate shutdowns; and (3) low-criticality parts are inexpensive wear-and-tear components, such as belts and housings, that are easy to replace. Different inventory management policies are used to manage these different types of parts (sometimes called A, B, and C parts) [48], [49].

Organizations can address these challenges through careful planning, vendor support, training programs, predictive maintenance, and ensuring regulatory compliance to effectively integrate robotic systems into their current or new MRO operations.

3.1. Normal procedures and predictive maintenance variables to anticipate robot failures

Predictive maintenance relies on gathering and analyzing data from various sensors and sources to anticipate a failure and perform maintenance activities before the failure occurs. Although the specific type of robot and its failure modes must inform any predictive maintenance approach, the following types of variables can be used for predictive maintenance of robotic systems: Here are some key variables to consider for predictive maintenance of robots [30], [32], [33], [36], [50], [58]:

Condition monitoring variables: vibration, temperature, power consumption, pressure, and sound. These variables can be tracked by sensors that monitor the electrical and mechanical aspects of a robotic system. Unusual vibration patterns might indicate wear and tear in motors, bearings, or joints. Excessive temperatures might indicate detect electrical faults, lubricant breakdown, or impending component failures. Changes in the power consumption might indicate excessive strain or component degradation. For robots with hydraulic or pneumatic subsystems, changing pressure levels might indicate leaks or blockages. Data from acoustic sensors can detect changes or anomalies that might indicate failing components.

Performance data variables: cycle time, precision and repeatability, and error rates. The cycle time is the time required for a robot to perform a routine, repetitive task. Significant changes in this time might indicate component degradation. Likewise, changes in the robot’s ability to perform the task correctly every time or more frequent alarms might indicate a failing component or subsystem.

Maintenance data variables: Maintenance logs are important sources of data about past failures, repairs, and other maintenance activities. Changes in the frequency of these events can indicate that a robotic system is developing more general or systemic problems.

Qiao and Weiss [59] demonstrated a framework for robot performance degradation prognostics and health management (PHM), which includes health monitoring, diagnostics, prognostics, and maintenance. Their approach includes (1) a top level PHM that detects accuracy degradation with a vision-based position and orientation measurement system and (2) a component level PHM that provides data for root cause analysis.

Predictive maintenance has some challenges, however, including inaccuracies (false alarms) and the time and cost of implementing the sensors and software required [40]. In order to implement it effectively, some basic monitoring and diagnostics variables are of particular importance:

1) Condition Monitoring Variables:

– Vibration: Sensors can monitor vibration patterns, which may indicate wear and tear in motors, bearings, or joints.

– Temperature: Monitoring temperature can help detect electrical faults, lubricant breakdown, or impending component failure.

– Power Consumption: Changes in power draw can reveal excessive strain or degradation within specific parts of the robot.

– Pressure: Sensors can track pressure levels, useful for monitoring hydraulic or pneumatic systems for leaks or blockages.

– Acoustic Data: Acoustic sensors can measure equipment sound and detect anomalies that might indicate problems.

2) Performance Data Variables:

– Cycle Time: Deviations in the time it takes the robot to complete tasks can indicate issues.

– Precision and Repeatability: Tracking accuracy and consistency in robot movements helps detect subtle deviations that might indicate developing problems.

– Error Rates: An increase in the frequency of errors or alarms can be a significant indicator of potential failure.

3) Operational Data Variables:

– Operating Hours: Cumulative operating hours or cycles can be used in time-based models to predict remaining useful life.

– Environmental Conditions: Data on ambient temperature, humidity, and other environmental factors can help assess external influences on robot performance.

4) Maintenance and Contextual Data:

– Maintenance Logs and Historical Data: Records of past maintenance activities, repairs, and failures are essential for training predictive models and identifying patterns.

– Robot Model/Type: The specific robot model and its known failure modes can inform the selection of monitoring parameters.

5) AI-Based Variables and Metrics:

– Remaining Useful Life (RUL): AI and machine learning algorithms can analyze data to predict how much longer a component or system is likely to function before failure.

– Anomaly Detection: AI algorithms can identify unusual patterns in sensor data that might indicate developing problems.

– Key Performance Indicators (KPIs): These metrics, such as mean time between failures (MTBF) and asset uptime, provide a baseline for normal operation and help measure the effectiveness of the predictive maintenance program. Some of these indicators are briefly explained in the next sub-section.

By collecting, integrating, and analyzing these variables using sensors, IoT devices, and machine learning, you can build a comprehensive predictive maintenance system that can anticipate robot failures and enable timely interventions. This proactive approach can lead to reduced downtime, improved efficiency, and lower maintenance costs.

3.2. RS MRO performance variables/KPIs

Monitoring the efficiency and cost-effectiveness of RS MRO operations involves tracking multiple metrics or Key Performance Indicators [1], [56], [60-63]:

Reliability: Metrics such as the mean time between failures (MTBF), which tracks the average operating time between failures, and the mean time to repair (MTTR), which measures the average time to fix equipment, are key to understanding robotic system reliability and availability.

Maintenance efficiency and effectiveness: These indicators include overall equipment effectiveness (OEE), which combines availability, performance, and quality; planned maintenance percentage (PMP), which shows the proportion of planned versus total maintenance; emergency maintenance percentage, which tracks emergency repairs; preventive maintenance compliance; and maintenance backlog.

Operational performance: These metrics describe the performance of maintenance actions. They include the response time, the task time, and the number of repairs completed. Key operational metrics include Uptime, measuring operational availability; Accuracy and Precision, assessing task performance and consistency; Speed, evaluating task completion rate; Throughput, indicating processing rate; and Latency and Response Time, crucial for real-time control.

Cost management: The key MRO cost metrics include maintenance cost per unit of production, emergency supply costs, and obsolescence rate.

Other Important Factors: Additional metrics to monitor include safety metrics, like emergency stop activations; robustness, evaluating environmental adaptability; and energy consumption, for assessing efficiency.

Tracking and analyzing these variables provide a comprehensive understanding of robotic system performance, helps identify issues early, optimize maintenance, and improve overall operational efficiency, reliability, and safety.

4. Data analytics and software solutions to RS MRO

4.1. Data analytics to optimize robotic system MRO

Data about MRO operations can be used to support predictive maintenance and other improvements. Data analytics plays a vital role in optimizing robotic system maintenance, moving beyond traditional, reactive approaches to proactive and strategic maintenance strategies. By collecting and analyzing various data points, businesses can gain deep insights into robot performance and health, leading to numerous benefits.

Reactive maintenance can troubleshoot problems and determine the root causes of faults and errors more quickly when the robot is saving data about its state and activities and the staff can easily access and get insights from that data. Analyzing the records of such events can yield effective maintenance strategies that reduce the risk of those failures. The maintenance staff can also identify the most effective interventions and standardize their procedures.

When maintenance schedules are based on robot usage (such as hours of use or the number of activities performed), real-time data about a robot allows staff to schedule its maintenance activities at the optimal times (instead of too early or too late) [64].

Condition-based maintenance requires continuous monitoring of a robot using sensors that can collect data about various parameters like vibration, temperature, and pressure, allowing the system to detect potential issues before they escalate [64]. Monitoring data about robot performance and repeatability can yield insights about potential problems [56].

Predictive maintenance, powered by machine learning, minimizes downtime by identifying equipment issues before they escalate. This proactive approach ensures continuous production and cuts operating expenses [65]. Predictive maintenance depends on data-driven models, built using traditional statistical approaches and machine learning algorithms, which can predict when the next failure might occur [66]. Then, maintenance staff can intervene and perform maintenance proactively, which prevents breakdowns and reduces downtime.

Analyzing data about maintenance events and activities can also improve spare parts inventory management, which can also reduce downtime and reduce the need for expensive emergency purchases.

Beyond the direct improvements to MRO operations, data analytics allows maintenance staff to measure and compare the performance of different robots, which helps them to prioritize their improvement initiatives [66]. Finally, data analytics enables them to evaluate the impact of policy changes and improvement initiatives, which supports continuous improvement. All of these improvements can reduce the number of failures, downtime, MRO costs, and increase robot availability and productivity.

4.2. Market software solutions specific MRO of robotic systems

In addition to general purpose Computerized Maintenance Management Systems (CMMS) and Enterprise Asset Management (EAM) systems that are not specifically for robotic systems [67]-[70], some vendors offer software solutions that are designed to support RS MRO.

Predictive maintenance software can predict potential robot failures and recommend preemptive measures. Some versions are designed for specific robotics applications. For example, XMPro’s Intelligent Business Operations Solutions (iBOS) supports predictive maintenance for robotic arms in the automotive industry [54].

Robot fleet management software provides a centralized platform for reviewing and analyzing information about the status of multiple robots. The software can provide alerts and track maintenance activities, and having a single repository supports data analytic [71], [72]. Examples include Energy Robotics [73], KUKA iiQoT [74], and Robo Server Manager [75], and, as listed below, there are a growing number of software solutions catering specifically to the Maintenance, Repair, and Overhaul operations of robotic systems. They can be organized into four categories of solutions [46], [54], [67-80]:

1) Computerized Maintenance Management Systems (CMMS) & Enterprise Asset Management (EAM): These broader platforms are often adapted or offer specialized modules for robotic systems.

– Features: Asset tracking, work order management, preventive maintenance scheduling, inventory management, and reporting.

– Benefits for Robots: Streamline maintenance, reduce downtime, track performance, and manage asset lifecycles efficiently.

– Examples: WAKU Robotics offers a modern CMMS specifically for robots, cobots, and other machinery. TMA Systems offers an EAM solution that emphasizes predictive maintenance through tech integration.

2) Predictive Maintenance Software: Focused on using data analytics and machine learning to anticipate failures.

– Features: Real-time monitoring, data integration and analysis, predictive analytics, automated alerts and maintenance scheduling, and digital twin simulation.

– Benefits for Robots: Minimizing downtime, optimizing maintenance schedules, and extending the lifespan of robotic components.

– Examples: XMPro's iBOS offers a predictive maintenance solution for robotic arms. KUKA iiQoT monitors robot condition and schedules maintenance based on data. MaintainX is an AI-powered, mobile-first CMMS that integrates with sensors and offers predictive capabilities.

3) Robot Fleet Management Software: Designed to coordinate, monitor, and manage a group of robots.

– Features: Centralized control, real-time monitoring, task allocation, performance analytics, and predictive maintenance.

– Benefits for Robots: Optimized task allocation, improved maintenance scheduling, data-based decision making, and cost reduction.

– Examples: Energy Robotics Cloud Brain integrates different robot types into an Asset Management System with AI analytics.

4) Specialized Robotics Maintenance Software: Some solutions are designed specifically for robot maintenance and repair, often offered by robot manufacturers or specialized service providers.

– Examples: Roboworx's Robo Server Manager (RSM) helps optimize robot maintenance for field service technicians.

These software solutions are becoming increasingly sophisticated, incorporating AI and advanced analytics to enable more proactive and efficient robot MRO.

5. MRO logistics and supply chain integration

With industries using robotic systems to improve productivity, quality and reliability more and more every year, maintaining their operation the best way possible is a challenge to the MRO area. The key trends for future RS MRO should include the integration of logistics operation, or more widely speaking, the supply chain surrounding the MRO tasks, in order to better maintain and operate robotic systems. Effective Logistics and Supply Chain Management (SCM) are crucial for optimizing MRO of robotic systems but does not seem to get much attention. Key aspects and analyses should consider [13], [34], [35], [81]-[84]:

1) MRO Inventory Management:

– Balancing Availability and Cost: MRO inventory management is about having the right parts and tools available when needed while minimizing excess stock that ties up capital and incurs storage costs.

– Challenges are related to inconsistent maintenance planning, poor data quality, and loose purchasing controls can lead to inefficiencies and increased costs. On the other hand, best practices can focus on:

a) Leveraging AI-powered tools and data analytics can help identify slow-moving and obsolete inventory, forecast demand, and automate reorder processes.

b) Categorize parts based on criticality (high-criticality, medium-criticality, and low-criticality) to prioritize stocking and ensure essential components are always available.

c) Standardize parts across different robot models where possible to reduce complexity in inventory management and improve repair times.

d) Maintain a digital inventory of spare parts using a Computerized Maintenance Management System (CMMS) or other software for real-time tracking.

2) Spare Parts Management: Ensuring Continuous Availability. In this sense, spare parts management is crucial for minimizing downtime due to equipment failures. Other as aspects to be considered are:

– Integrate spare parts management with predictive maintenance to ensure parts are ordered before failure occurs.

– Implement Just-in-Time (JIT) ordering for non-critical parts to reduce inventory costs, while maintaining a small stock of essential components for high-criticality items.

– Establish strong relationships with suppliers to ensure timely delivery of parts.

– Track part lifecycle and usage, by monitoring when parts were last replaced, their performance, and when they are likely to fail to guide future decisions and optimize stocking levels.

– Monitor for obsolescence, keeping track of which components are still supported by manufacturers and which may need to be phased out.

3) Maintenance Programs and Schedules:

– Proactive Planning by developing maintenance plans that proactively identify and address potential issues, minimizing unexpected breakdowns.

– Proper coordination and scheduling of maintenance and service needs are vital, along with clear communication about timelines and addressing potential supply chain issues.

– Employ data analytics to predict maintenance needs, optimize robot deployment, and streamline operations based on insights.

4) Real-Time Tracking and Visibility:

– Real-time tracking of MRO operations improves efficiency, optimizes response strategies, and increases productivity by eliminating redundant tasks.

– Providing a holistic view of processes helps sharpen inventory forecasting, reduce costs, and prevent system failures.

– Real-time tracking tools enable proactive responses and facilitate more efficient MRO operations.

5) Import/Export Strategies for MRO Supply Chain:

– Develop well-planned import and export procedures to manage the sourcing and importing of parts from global suppliers, minimizing delays due to customs, tariffs, and taxes.

– Form strong partnerships with foreign suppliers based on openness and trust to ensure on-time delivery, quality, and compliance with regulations.

– Utilize technology like AI and digitalization to streamline customs procedures, enable real-time tracking, and enhance communication between suppliers and logistics partners.

6) Cost Optimization: Optimize MRO supply chain operations to improve time efficiency and cost savings through:

– Inventory Management: Better inventory management reduces overall operating costs.

– Consolidating Shipments: Consolidating international shipments can decrease per-unit costs.

– Optimizing Logistics: Strategic product scheduling reduces the need for expensive expedited shipping.

– Negotiating Favorable Terms: Strong supplier relationships can lead to discounts and favorable pricing.

6. Conclusions

Based on a review of relevant research and online information, this paper reviewed the state-of-the-art in RS MRO, which is increasingly important as organizations in many industries adopt and deploy robotic systems in their operations. Although similar in some ways to general MRO activities, the technical complexity of robotic systems increases the challenges of RS MRO and the need for new approaches, including new performance measures, new types of data analytics, new types of software for managing a fleet of robots, and a holistic logistics/supply chain approach for better RS MRO.

Other industries that currently do not rely on RS but will do eventually, such as Hospitality and Tourism, Creative Arts and Entertainment, Education, Domestic and Personal Assistance, Construction, and Environmental Cleanup [76], [81], [85], [95] will have to think carefully about their needs regarding RS MRO, considering that the future of robotics in these emerging sectors will likely involve greater integration, driving innovation and efficiency, and potentially creating new opportunities alongside humans.

The implementation of larger, more capable AI models will give organizations more tools for managing and improving MRO operations. On the other hand, future robotic systems that use AI models and have more autonomy than those deployed today will create new MRO challenges. Autonomous systems often need to communicate with the AI models that cannot be run with onboard computers, which increases the importance of maintaining the advanced technology (such as 5G communication networks) for fast, reliable network connections [95]. Diagnosing the problems caused by these AI models (such as control system faults) will be difficult due to their black-box nature and the limitations of explainable AI (XAI) to date [97].

As robotic systems move from experiments to essential equipment, the spare parts logistics and supply chain management will become more important in more industries and organizations. Hence, future RS MRO studies will be focusing on key aspects and analyses considering, for instance: MRO Inventory Management, Spare Parts Management, Maintenance Programs and Schedules, Real-Time Tracking and Visibility, Import/Export Strategies for MRO Supply Chain, and Cost Optimization. Among these, it is especially important to manage the risk of disruptions such as diminishing manufacturing sources and material shortages through appropriate sourcing strategies [98].

The future of robotics in these emerging sectors will likely involve greater integration, driving innovation and efficiency, and potentially creating new opportunities alongside humans and by implementing robust logistics and supply chain strategies along with AI and advanced analytics, organizations will be able to ensure operational excellence, minimize downtime, reduce costs, and ultimately enhance the overall efficiency and resilience of their RS MRO operations at just the right time.

References

-

“Mastering the art of predictive maintenance: a game-changer for automated robotics.” Robotics Technician Training, Jan. 2024, https://www.onlinerobotics.com/news-blog/mastering-art-predictive-maintenance-game-changer-automated-robotics.

-

“Industrial robot maintenance: An ultimate guide.” Standard Bots, Jul. 2025, https://standardbots.com/blog/industrial-robot-maintenance.

-

“The ultimate guide & checklist for optimal robot maintenance.” eWorkOrders, 2025, https://eworkorders.com/cmms-industry-articles-eworkorders/ultimate-checklist-robot-maintenance/.

-

A. Mok, “How AI and robotics can help prevent breakdowns in factories – and save manufacturers big bucks.” Business Insider, May 2025, https://www.businessinsider.com/artificial-intelligence-robotics-predictive-maintenance-manufacturing-factory-solutions-2025-5.

-

M. Walgude. “The future of care: exploring emerging technologies in robot maintenance.” Linkedin, Feb. 2025, https://www.linkedin.com/pulse/future-care-exploring-emerging-technologies-robot-mayur-walgude-leraf.

-

“Aircraft inspection robots and drones: some can fit in your hand!” Spartan College of Aeronautics and Technology, Oct. 2021, https://www.spartan.edu/news/aircraft-inspection-robots-and-drones-some-can-fit-in-your-hand/.

-

“MRO Operations.” ABCO Systems, 2023, https://abcosystems.net/mro-operations/.

-

E. Vuorinen, “Aviation maintenance technologies that will change the industry.” QOCO, Oct. 2021, https://www.qoco.aero/blog/aviation-maintenance-technologies-that-will-change-the-industry.

-

“Are robots the MRO workers of the future?” Satair, Feb. 2023, https://www.satair.com/knowledge-hub/are-robots-the-mro-workers-of-the-future/.

-

“Exploring health care robots: Are they ready for clinical use today?” Standard Bots, Jul. 2025, https://standardbots.com/blog/exploring-health-care-robots-are-they-ready-for-clinical-use-today.

-

“Robotic technology: cleaning trends for healthcare facilities 2023.” Ice Cobotics, Jun. 2023, https://icecobotics.com/blog/robotic-technology-cleaning-trends-for-heatlhcare-facilities-2023.

-

L. Bjerregaard, “Gallery: how robots are revolutionizing MRO.” Aviation Week, Dec. 2022, https://aviationweek.com/mro/emerging-technologies/gallery-how-robots-are-revolutionizing-mro.

-

“MRO in logistics: leveraging real-time visibility to optimize maintenance, repairs & overhauls.” Carrier 911, Jan. 2024, https://www.carrier911.com/blog-posts/mro-in-logistics-leveraging-real-time-visibility-to-optimize-maintenance-repairs-overhauls.

-

“6 critical maintenance tasks to extend the life of robotics.” Global Electronic Service, 2025, https://gesrepair.com/6-critical-maintenance-tasks-to-extend-the-life-of-robotics/.

-

S. Wang and H. I. Christensen, “TritonBot: first lessons learned from deployment of a long-term autonomy tour guide robot,” in 27th IEEE International Symposium on Robot and Human Interactive Communication (RO-MAN), pp. 158–165, Aug. 2018, https://doi.org/10.1109/roman.2018.8525845

-

“Real-world applications of technological innovation.” Technological Innovation, 2025, https://www.csiic.ca/examples.

-

A. Prasad, B. Sharma, J. Vanualailai, and S. Kumar, “Stabilizing controllers for landmark navigation of planar robots in an obstacle-ridden workspace,” Journal of Advanced Transportation, Vol. 2020, pp. 1–13, Dec. 2020, https://doi.org/10.1155/2020/8865608

-

“AIRTuB: To make inspections and maintenance easier.” Topsector Energie, Jul. 2024, https://topsectorenergie.nl/en/projects/airtub-to-make-inspections-and-maintenance-easier/.

-

“Aerospace MRO: how robots are transforming maintenance, repair, and operations.” Augmentus, May 2024, https://www.augmentus.tech/blog/aerospace-mro-how-robots-are-transforming-maintenance-repair-and-operations/.

-

“Optimal maintenance cycles for robots – AGV and AMR.” WAKU robotics, Aug. 2024, https://www.waku-robotics.com/en/magazine/optimal-maintenance-cycles-for-robots-agv-amr.

-

“The revolutionary world of robotics: advancements and applications.” Atlantic International University, Jun. 2024, https://www.aiu.edu/blog/the-revolutionary-world-of-robotics-advancements-and-applications/.

-

“Maintenance cycles for AGV and AMR: ensuring smooth operations,” WAKU Robotics, Aug. 2024.

-

M. Fairchild, “Top industries using robots.” HowToRobot, Sep. 2021, https://howtorobot.com/expert-insight/top-industries-using-robots.

-

B. Tran, “Top industries using robotics: market share by sector.” PatentPC, Jul. 2025, https://patentpc.com/blog/top-industries-using-robotics-market-share-by-sector.

-

“15 types of warehouse robotics for optimal efficiency.” Modula, May 2024, https://modula.us/blog/warehouse-robotics/.

-

S. Bieller, V. Behrens, and O. Gisbert, “Robotics industry doubles since 2015.” World Intellectual Property Organization (WIPO), May 2024, https://www.wipo.int/en/web/global-innovation-index/w/blogs/2024/robotics-industry.

-

“Top 10 industries utilizing robots and robotics in business.” Probot, 2025, https://www.probotcorp.com/post/top-10-industries-utilizing-robots-and-robotics.

-

“Which industry uses the most robots?” IndMALL Automation, 2025, https://www.indmallautomation.com/faq/which-industry-uses-the-most-robots/.

-

A. Kampa, “The review of reliability factors related to industrial Robo,” Robotics and Automation Engineering Journal, Vol. 3, No. 5, p. 555624, Nov. 2018, https://doi.org/10.19080/raej.2018.03.555624

-

“Every type of sensor in robots, explained (easy guide).” Standard Bots, Jul. 2025, https://standardbots.com/blog/every-type-of-sensors-in-robotics---explained.

-

Z. Ren, Z. Yu, W. Zhang, and Q. Lei, “Streamlining industrial robot maintenance: an intelligent voice query approach for enhanced efficiency,” IEEE Access, Vol. 12, pp. 121864–121881, Jan. 2024, https://doi.org/10.1109/access.2024.3452269

-

“Addressing common fanuc robot motor failures: causes and solutions.” T.I.E. Industrial and Robots.com, 2025, https://www.robots.com/articles/addressing-common-fanuc-robot-motor-failures-causes-and-solutions.

-

C. Palumbo, “Preventive and predictive maintenance best practices.” Llumin, 2025, https://llumin.com/predictive-maintenance-best-practices-llu/.

-

“How to do spare parts management for robots.” Waku Robotics, Sep. 2024, https://www.waku-robotics.com/en/magazine/how-to-master-spare-parts-management-for-robots-agv-amr-industrial.

-

C. Mannion. “Logistics robots: work smarter, not harder.” AutoStore, Jun. 2024, https://www.autostoresystem.com/insights/logistics-robots-work-smarter-not-harder.

-

“Potential robot hazards and how to avoid them.” Robots Done Right, 2025, https://robotsdoneright.com/articles/potential-robot-hazards-and-how-to-avoid-them.html.

-

J. R. Etherton, “Safe maintenance guidelines for robotic workstations,” U.S. Department of Health and Human Services, NIOSH Technical Report, Mar. 1988.

-

G. Patrick, “Challenges and solutions in implementing service robotics.” Verified Market Research, Jun. 2024, https://www.verifiedmarketresearch.com/blog/challenges-and-solutions-in-implementing-service-robotics/.

-

N. Acharya, “Overcoming integration challenges in implementing robotics and automation.” Fulfillment IQ, May 2024, https://fulfillmentiq.com/integrating-robotics-automation-supply-chain/.

-

M. Banetti, “Disadvantages of predictive maintenance: 10 major drawbacks.” Banetti, 2025, https://info.banetti.com/disadvantages-of-predictive-maintenance-10-major-drawbacks/.

-

“AI & robotics: unlocking the potential.” Aviation Business News, May 2024, https://www.aviationbusinessnews.com/mro/ai-robotics-unlocking-the-potential/.

-

S. Kulavil, “MRO at a crossroads: embracing digital technology to overcome industry challenges.” Capgemini, Feb. 2025, https://www.capgemini.com/insights/expert-perspectives/mro-at-a-crossroads-embracing-digital-technology-to-overcome-industry-challenges/.

-

“Challenges and considerations in implementing predictive maintenance.” Sensemore, Feb. 2024, https://sensemore.io/challenges-in-implementing-predictive-maintenance/.

-

“The basics of MRO data management [with solutions].” Verdantis, 2025, https://www.verdantis.com/mro-data-management/.

-

“How to become a robotics technician.” Universal Technical Institute, Jul. 2025, https://www.uti.edu/blog/robotics-and-automation/how-to-become-a-robotics-technician.

-

A. Santamaria, “The impact of AI for industrial MRO management.” Advanced Technology Services, 2025, https://www.advancedtech.com/blog/ai-and-industrial-mro/.

-

J. Blumenau, S. Rajarajan, J. Stone, and K. Low, “Robotic process automation improving life at MROs.” Aviation Maintenance Magazine, Mar. 2025, https://avm-mag.com/robotic-process-automation-improving-life-at-mros.

-

W. J. Hopp and M. L. Spearman, Factory Physics. Waveland Press: Long Grove, Illinois, 2008.

-

A. R. Ravindran, J. D. P. Warsing, and P. M. Griffin, Supply Chain Engineering. Boca Raton: CRC Press, 2023, https://doi.org/10.1201/9781003283393

-

“What is predictive maintenance? How it works.” Standard Bots, Jul. 2025, https://standardbots.com/blog/what-is-predictive-maintenance.

-

A. Ucar, M. Karakose, and N. Kırımça, “Artificial intelligence for predictive maintenance applications: key components, trustworthiness, and future trends,” Applied Sciences, Vol. 14, No. 2, p. 898, Jan. 2024, https://doi.org/10.3390/app14020898

-

“7 essential strategies for implementing predictive maintenance.” Sensemore, Jun. 2023, https://sensemore.io/7-essential-strategies-for-implementing-predictive-maintenance/.

-

R. Chupryna and S. Leleko, “Predictive maintenance with machine learning: a complete guide.” SPD Technology, Apr. 2025, https://spd.tech/machine-learning/predictive-maintenance/.

-

“Predictive maintenance for robotic arms in the automotive industry.” Xmpro, 2025, https://xmpro.com/solutions-library/asset-performance-management,manufacturing,predictive-maintenance,use-cases/predictive-maintenance-for-robotic-arms-in-the-automotive-industry/.

-

“What are some failure prediction models in predictive maintenance?” Upkeep Technologies, 2025, https://upkeep.com/learning/failure-prediction-models-predictive-maintenance/.

-

“What metrics are used for evaluating robot performance?” IndMALL: B2B Marketplace, 2025, https://www.indmall.in/faq/what-metrics-are-used-for-evaluating-robot-performance/.

-

Y. Mota, “AI in predictive maintenance: A guide to proactive asset management for leaders.” N-iX, Nov. 2024, https://www.n-ix.com/ai-in-predictive-maintenance/.

-

S. Redfearn, “How AI agents are reshaping the workforce in manufacturing.” Red-Ferm, Dec. 2024, https://www.red-fern.co.uk/engine-room/digital-minds/how-ai-agents-are-reshaping-the-workforce-in-manufacturing/.

-

G. Qiao and B. A. Weiss, “Monitoring, diagnostics, and prognostics for robot tool center accuracy degradation,” in ASME 2018 13th International Manufacturing Science and Engineering Conference, Vol. 51371, p. V003T02A029, Jun. 2018, https://doi.org/10.1115/msec2018-6603

-

“Maintenance KPIs: how to calculate and track key metrics.” Accruent, Jan. 2025, https://www.accruent.com/resources/knowledge-hub/maintenance-kpis.

-

“Robotics KPIs.” KPI Depot, 2025, https://flevy.com/kpi-library/industry/robotics-393.

-

“8 maintenance key performance indicators (KPIs).” Nexgen, 2025, https://www.nexgenam.com/blog/maintenance-kpis/.

-

M. J. Boyd, “What MRO inventory metrics should you track?” Innovapptive, Feb. 2024, https://www.innovapptive.com/blog/what-mro-inventory-metrics-should-you-track.

-

“Robotics and automation in maintenance: transforming industry practices.” Micromain Corp, May 2024, https://micromain.com/robotics-and-automation-in-maintenance-transforming-industry-practices-2/.

-

J. Chicas, “Automation and data analytics in manufacturing: building a resilient future.” Applaudo, Dec. 2024, https://applaudo.com/es/insights/articles/automation-and-data-analytics-in-manufacturing-building-a-resilient-future/.

-

“Process optimization in production – the path to more efficient industrial processes.” Ai-Omatic Solutions GmbH, Apr. 2025, https://www.ai-omatic.com/en/magazine/process-optimization-in-production-with-ai.

-

L. Olanrewaju, “Choosing the best predictive maintenance software.” MaintainX, Nov. 2024, https://www.getmaintainx.com/blog/best-predictive-maintenance-software.

-

C. Kolosky, “Comprehensive guide to predictive maintenance software: key features and best solutions.” Knack, Dec. 2024, https://www.knack.com/blog/predictive-maintenance-software-guide/.

-

J. Mcvay, “What is a CMMS? (Computerized maintenance management system).” TMA Systems, 2025, https://www.tmasystems.com/resources/what-is-a-cmms.

-

J. Pino, “EAM evolution: tech-driven predictive solutions for cost savings.” TMA Systems, Oct. 2024, https://www.tmasystems.com/resources/eam-tech-driven-predictive-maintenance.

-

“What is robot fleet management?” Standard Bots, Jul. 2025, https://standardbots.com/blog/robot-fleet-management.

-

“Best robot fleet management software companies.” CB Insights, 2025, https://www.cbinsights.com/esp/industrials/warehousing-&-logistics-tech/robot-fleet-management-software.

-

“Unified software for managing a global robot fleet.” Energy Robotics, 2025, https://www.energy-robotics.com/robotic-inspection-software.

-

“KUKA iiQoT – leveraging the industrial IoT for a more transparent and efficient robot fleet.” KUKA Deutschland GmbH, 2025, https://www.kuka.com/en-de/products/robot-systems/software/cloud-software/iiqot-robot-condition-monitoring.

-

“Roboworx announces RSM, the industry’s first robot service maintenance optimization software system.” Roboworx, May 2025, https://www.roboworx.io/news/roboworx-announces-rsm%2c-the-industry%e2%80%99s-first-robot-service-maintenance-optimization-software-system.

-

“The future of robotics: 7 predictions for 2025 and beyond.” Standard Bots, Jul. 2025, https://standardbots.com/blog/future-of-robotics-predictions.

-

“Modern maintenance management (CMMS) – success stories.” Waku Robotics, 2025, https://www.waku-robotics.com/en/use-cases/computerized-maintenance-management-software-cmms.

-

“Enterprise asset management (EAM).” Waku Robotic, 2025, https://www.waku-robotics.com/en/use-cases/asset-management.

-

“Automate 2025: Roboworx announces robot service maintenance optimization software system.” Robotics 24/7, May 2025, https://www.robotics247.com/article/automate_2025_roboworx_announces_robot_service_maintenance_optimization_software_system.

-

J. Lu, “Choosing the best MRO Software.” QOCO Systems, May 2025, https://www.qoco.aero/blog/choosing-the-right-solution-for-aviation-maintenance.

-

“MRO supply chain optimization: import/export strategies for aviation maintenance.” One Union Solutions, May 2025, https://oneunionsolutions.com/blog/mro-supply-chain-optimization/.

-

“Spare parts inventory optimization: maximizing efficiency and reducing costs.” Throughput Inc., Apr. 2025, https://throughput.world/blog/spare-parts-and-mro-inventory-optimization/.

-

“Building resilience in MRO supply chain logistics.” Aviation Business News, Jun. 2024, https://www.aviationbusinessnews.com/mro/building-resilience-in-mro-supply-chain-logistics/.

-

“What is maintenance, repair and operations (MRO)?” IBM, May 2023, https://www.ibm.com/think/topics/maintenance-repair-and-operations.

-

A. Ferrara, A. Nidmarti, B. Nagda, and M. Shue. “The autonomous robotics future is around the corner.” Bessemer Venture Partners, Feb. 2024, https://www.bvp.com/atlas/the-autonomous-robotics-future-is-around-the-corner.

-

R. Kanekar and S. Raut, “The evolution of robotics research: from industrial robotics to field and service robotics,” International Journal of Advance Research and Innovative Ideas in Education, Vol. 11, No. 2, 2025.

-

“Futures of human-robot interaction reshape our lives and what it means to coexist.” Critical Playground, Nov. 2024, https://criticalplayground.org/futures-of-human-robot-interaction/.

-

L. Saul and R. Etemad-Sajadi, “Service robots and AI: what impact on the future of hospitality?” EHL Insights, Mar. 2022, https://hospitalityinsights.ehl.edu/service-robots-future-of-hospitality.

-

“How hotel robots enhance the art of hospitality.” Swiss Education Group, 2025, https://www.shms.com/en/news/robots-in-hospitality-industry/.

-

R. Lässig, M. Lorenz, E. Sissimatos, I. Wicker, and T. Buchner, “Robotics outlook 2030: how intelligence and mobility will shape the future.” Boston Consulting Group, Jun. 2021, https://www.bcg.com/publications/2021/how-intelligence-and-mobility-will-shape-the-future-of-the-robotics-industry.

-

“6 unconventional applications of robotics technology.” Hokuyo Automatic, 2025, https://www.hokuyo-usa.com/resources/blog/6-unconventional-applications-robotics-technology.

-

“Robotic trends in 2025: innovations transforming industries.” Robotnik, Jan. 2025, https://robotnik.eu/robotic-trends-in-2025-innovations-transforming-industries/.

-

“10 advantages of robots in hospitality industry: transforming futuristic hotels.” Proven Robotics, Oct. 2023, https://provenrobotics.ai/advantages-of-robots-in-hospitality-industry/.

-

J. Maida, “Hospitality robots market to grow by USD 663.2 Mn (2025-2029), boosted by increasing penetration of AI in robots, AI’s impact on market trends.” Technavio, Feb. 2025, https://www.prnewswire.com/news-releases/hospitality-robots-market-to-grow-by-usd-663-2-mn-2025-2029-boosted-by-increasing-penetration-of-ai-in-robots-ais-impact-on-market-trends---technavio-302369825.html.

-

K. Matthews, “6 robotics applications.” The Robot Report, May 2019, https://www.therobotreport.com/6-robotics-applications-new-markets/.

-

J. Cheng, Y. Yang, X. Zou, and Y. Zuo, “5G in manufacturing: a literature review and future research,” The International Journal of Advanced Manufacturing Technology, Vol. 131, No. 11, pp. 5637–5659, Mar. 2022, https://doi.org/10.1007/s00170-022-08990-y

-

V. Hassija et al., “Interpreting black-box models: a review on explainable artificial intelligence,” Cognitive Computation, Vol. 16, No. 1, pp. 45–74, Aug. 2023, https://doi.org/10.1007/s12559-023-10179-8

-

P. Sandborn and W. Lucyshyn, System Sustainment: Acquisition and Engineering Processes for the Sustainment of Critical and Legacy Systems. World Scientific, 2023.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Guilherme E. Vieira: conceptualization, analysis, writing-original draft preparation, writing-review and final version editing. Jeffrey W. Herrmann: writing-original draft preparation, writing-review.

The authors declare that they have no conflict of interest.