Abstract

This paper presents the results of an experimental study on self-compacting concrete (SCC) incorporating recycled crushed concrete aggregate and an organic-mineral additive based on nanosilica and a polycarboxylate superplasticizer. The multi-stage “soft” crushing of concrete waste significantly improves the properties of the recycled aggregate, in particular its void content, water absorption and crushing strength, by reducing the amount of adhered cement paste. The fine fractions generated during this process are used as a dispersed filler in SCC. An organic-mineral additive was developed using a sol-gel route to ensure a homogeneous concrete mixture with enhanced stability of rheological properties. The experimental results demonstrate that SCC with a compressive strength exceeding 55 MPa at 28 days under normal curing conditions can be produced using the products of concrete waste crushing, confirming the potential of this approach for sustainable concrete construction.

1. Introduction

On construction sites, several million tons of concrete waste are generated annually [1]. The main sources of this waste include technological losses at precast concrete plants and construction sites, remnants of concrete and reinforced concrete structures demolished during the rehabilitation of old buildings, and wastes produced in industry or as a result of natural disasters [13]. After crushing the concrete waste and separating the reinforcement, these materials can be used to obtain recycled crushed stone. However, if the waste is not sorted by strength grade, it is difficult to obtain a high-quality aggregate [2, 3]. Even when the waste is sorted, the quality indicators of the recycled aggregate are generally inferior to those of natural crushed stone because a significant amount of adhered cement paste remains on its surface, which is weaker than the coarse and fine aggregate particles [4, 14].

A key way to improve the strength and other performance characteristics of recycled crushed stone is to use a crushing regime that promotes the removal of weak cement paste while minimizing damage to the aggregate grains [6]. For this purpose, cone and jaw crushers are typically employed. Conventional jaw crushers can be operated in a multi-stage “soft” mode to enhance the properties of the recycled aggregate [15]. In this mode, the discharge opening is kept relatively wide and the crushing chamber is completely filled, so that the material interacts intensively with itself in a “clogging” regime [16]. Unlike conventional “hard” crushing, where the material primarily interacts with the moving jaw, the “soft” mode favors the selective destruction of low-strength cement paste particles [17], improving the quality of the recycled aggregate.

In the context of mineral additives in concrete, self-compacting concrete (SCC) occupies a prominent place [7, 8]. When large amounts of cement paste are used as a matrix to ensure the required rheological properties, concrete consumption increases and the economic performance of concrete production deteriorates [7-9]. To reduce cement consumption, SCC typically incorporates a significant volume of finely dispersed mineral fillers together with high-range water-reducing admixtures. Appropriate fillers and efficient plasticizers make it possible to obtain concrete with the desired strength, reduced water demand and sufficient fluidity of the cement paste [8-10, 18].

At present, the most common mineral fillers used in SCC are fly ash, microsilica and finely ground limestone or other powders [7]. These materials are relatively expensive and are characterized by a very high specific surface area [19]. From an economic and environmental point of view, it is more reasonable to use stone screenings generated during the production of recycled crushed stone as a finely dispersed filler [20]. Due to their chemical composition, these screenings are close to the main components of concrete and do not deteriorate its durability, which makes them suitable for use in SCC. Therefore, the aim of the present research is to develop self-compacting concrete using stone screenings and other products obtained from the multi-stage crushing of waste concrete as mineral fillers.

2. Results

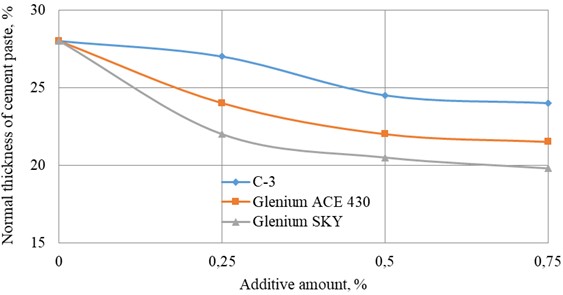

To evaluate the suitability of different superplasticizers for SCC, the effect of several organic admixtures on the standard consistency of cement paste was first investigated (Fig. 1). The comparison included a conventional naphthalene sulfonate-based superplasticizer (C-3 type) and a polycarboxylate-based superplasticizer.

Fig. 1Dependence of the normal thickness on the type and quantity of the additive

As shown in Fig. 1, polycarboxylate-based admixtures exhibit a higher water-reducing capacity than naphthalene sulfonate. This difference arises from the distinct mechanisms of action in cement systems: naphthalene sulfonate-based admixtures primarily provide electrostatic repulsion between cement particles, while polycarboxylate admixtures create a steric hindrance effect that enhances the dispersion and “sliding” of particles. In practice, the more effective admixture is preferred regardless of the specific mechanism. Owing to their excellent water-reducing performance, polycarboxylate-based admixtures were selected as superplasticizers for SCC in this study. In addition, the hydration of cement can be significantly intensified by the introduction of nanomodifying additives. Therefore, an organic-mineral additive (OMA) based on nanosilica and a polycarboxylate superplasticizer, synthesized by the sol-gel method [11], was used in the experimental program.

The effect of the crushing mode on the quality of recycled crushed stone was examined in the following phase of the study. Research has demonstrated that using the multi-stage crushing method can enhance the characteristics of recycled crushed stone. Table 1 shows that the characteristics of 5-10 mm fractional crushed stone, such as water absorption, porosity, and average grain thickness, greatly improve following 3-4 stages of crushing in the “soft” mode.

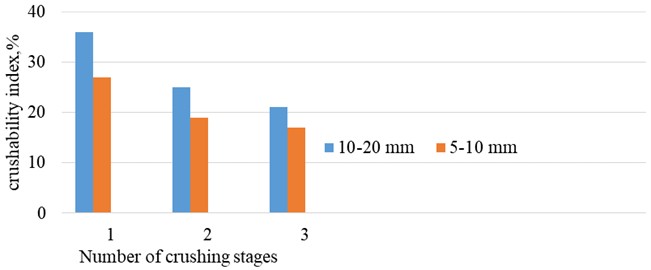

As illustrated by Table 1, the water absorption of the 5-10 mm recycled crushed stone decreases as the number of crushing stages increases. After the first crushing of the waste concrete, the water absorption is 7.54 %; after the second, third and fourth stages it decreases to 7.42 %, 6.56 % and 5.67 %, respectively. This trend is associated with the progressive reduction of the adhered cement paste thickness on the aggregate surface. Consequently, the porosity of the recycled crushed stone also decreases, from 4.78 % after the first stage to 4.55 % after the fourth stage. Fig. 2 shows the corresponding evolution of the crushing strength index of recycled aggregates as the number of crushing stages increases.

Table 1Crushing’s effect on secondary crushed stone properties. Between 5 and 10 mm

Number of crushing stages | Water absorption, % | Average grain thickness, mm | Porosity, % |

1 | 7.54 | 4.78 | 4.78 |

2 | 7.42 | 5.24 | 4.73 |

3 | 6.56 | 5.53 | 4.64 |

4 | 5.67 | 5.89 | 4.55 |

Fig. 2The effect of repeated crushing on the strength of various fractions of recycled crushed stone

As the number of crushing stages increases for both the 5-10 mm and 10-20 mm fractions, the crushing strength index of the recycled aggregate grows accordingly. According to GOST 32495-2013, the crushing strength index for the 10-20 mm fraction increases from 300 after single-stage crushing to 600 after three-stage crushing. These values indicate that crushed stone obtained after three stages of “soft” crushing can be used in concrete up to strength class 300 while satisfying standard requirements. For the 5-10 mm fraction, the crushing strength index increases from 400 after one stage to 800 after three stages of crushing. As the standard requires the concrete strength grade to be approximately half of the aggregate strength grade, 5-10 mm recycled crushed stone produced by multi-stage “soft” crushing can be successfully used as a coarse aggregate in concrete of grade 400 without additional modifiers.

Given the granular composition of the products obtained by multi-stage “soft” crushing, self-compacting concrete is considered one of the most promising applications for these materials. SCC technology allows the utilization of a large volume of fine fractions generated during the crushing of waste concrete, since the use of finely dispersed mineral fillers is a key feature of SCC mix design [9]. An additional advantage of using recycled concrete products in SCC is the limitation on the maximum size and volume fraction of coarse aggregate, which facilitates the incorporation of recycled fines. From a cost perspective, replacing part of the conventional mineral powders with finely ground products derived from concrete waste makes it possible to reduce the overall cost of SCC while improving resource efficiency.

In the first SCC composition, limestone flour with a specific surface area of 340 m2/kg is used as a finely dispersed filler, together with crushed granite aggregate of strength grade 1200 and density 2880 kg/m3 to optimize the granular structure of the aggregate skeleton [12]. In the second composition, sand with a fraction of 0.63-5 mm obtained from waste concrete crushing is employed as part of the fine aggregate, while recycled crushed stone of 5-10 mm and 10-20 mm fractions is used as coarse aggregate. Additionally, powders with a specific surface area of 340 m2/kg are produced by grinding fine particles smaller than 0.063 mm in a laboratory ball mill and are applied as a mineral filler.

In both compositions, fine aggregate from the Bahramtepe sand deposit is used as the main sand component. More than 90 % of this sand consists of particles smaller than 0.63 mm, and it is supplemented by slurry derived from crushed stone or residual concrete. To achieve the required flowability of SCC, a nanosilica-based organic–mineral additive (OMA) and a Glenium SKY polycarboxylate superplasticizer are introduced. When an appropriate dosage of OMA is used, the stability of the rheological properties of the modified cement system is approximately doubled compared to unmodified systems [8]. The mix proportions and compressive strengths of the concretes investigated are summarized in Table 2.

Table 2The characteristics of the investigated concretes and their compositions

No mix | Composition of concrete | Component consumption, kq/m3 | Spread of standard cone, mm | Strength, MPa (after) | ||

1 day | 28 days | 365 days | ||||

1 | Cement | 313 | 575 | 22.6 | 58.4 | 76.6 |

Water | 172 | |||||

Sand | 256 | |||||

Grushed stone (10-20) | 256 | |||||

Grushed stone (5-10) | 510 | |||||

Screening | 720 | |||||

Limestone filler | 290 | |||||

OMA | 1.3 | |||||

2 | Cement | 313 | 548 | 15.2 | 55.6 | 75.4 |

Water | 190 | |||||

Sand | 256 | |||||

Grushed stone (10-20) | 256 | |||||

Grushed stone (5-10) | 450 | |||||

Сoncrete sand | 690 | |||||

Fine filler based on crushed concrete | 285 | |||||

OMA | 1.3 | |||||

As shown in Table 2, the concrete mixture incorporating the products of waste concrete grinding requires a higher water content, yet it exhibits a somewhat lower slump-flow. This is mainly due to the increased specific surface area and angularity of the recycled fines, which intensify water demand. As a result, the one-day compressive strength of the SCC mixture with recycled aggregate is approximately half that of the mixture with premium natural aggregate, reflecting the combined influence of higher water content and the presence of weaker recycled particles. Nevertheless, after 28 days the loss of strength in SCC with recycled aggregate is limited to about 4-8 % compared with the reference mixture. After one year of storage under air-dry conditions, the SCC made with recycled crushed stone attains a compressive strength of about 75.4 MPa, confirming its suitability for structural applications.

3. Conclusions

The research carried out allows the following conclusions to be drawn. First, concrete waste can be effectively used as aggregate for self-compacting concrete after multi-stage “soft” crushing, which improves the water absorption, porosity and crushing strength of the recycled aggregate. Second, SCC mixtures prepared with Glenium SKY superplasticizer and an organic-mineral additive based on nanosilica exhibit stable rheological properties and maintain the required flowability. Third, replacing high-quality natural aggregates with products of concrete waste crushing leads to a moderate reduction in compressive strength (on the order of 4-8 %), while the resulting SCC still develops strengths exceeding 55 MPa at 28 days and about 75 MPa at one year of air-dry curing. Finally, the proposed technology for processing concrete waste makes it possible to obtain low-cost mineral fillers and aggregates with a suitable granular composition for the production of high-performance self-compacting concretes, contributing to more sustainable use of raw materials in the construction industry.

References

-

A. A. Kalgin and M. A. Fakhratov, “Effectiveness of the use of crushed concrete in the production of concrete and iron concrete products,” CPI: International Concrete Production, No. 5, pp. 162–163, 2007.

-

A. A. Guvalov, “Research of crushed stone obtained from the crushing of different brands of rubble concrete in Azerbaijan,” Construction and Architecture, Scientific and Practical Journal, No. 2, pp. 69–78, 2022.

-

M. V. A. Florea and H. J. H. Brouwers, “Properties of various size fractions of crushed concrete related to process conditions and re-use,” Cement and Concrete Research, Vol. 52, pp. 11–21, Oct. 2013, https://doi.org/10.1016/j.cemconres.2013.05.005

-

M. Surya, K. R. Vvl, and P. Lakshmy, “Recycled aggregate concrete for transportation infrastructure,” Procedia – Social and Behavioral Sciences, Vol. 104, pp. 1158–1167, Dec. 2013, https://doi.org/10.1016/j.sbspro.2013.11.212

-

A. A. Guvalov and S. I. Abbasova, “Effect of nanodisperse fillers on the properties of solutions,” in The 26th International Scientific Symposium: Glass: Triumph of Victory, pp. 250–253, 2022.

-

P. N. Kurochka and R. R. Mirzaliev, “Properties of crushed stone from the products of crushing of secondary concrete as an inert aggregate of concrete mixtures,” (in Russian), Engineering Bulletin of the Dona, No. 4 (part 2), pp. 56–60, 2012.

-

A. A. Guvalov, “Mineral additives for concrete,” in 20th Petersburg Readings on Strength Problems, Apr. 2012.

-

A. A. Guvalov and S. I. Abbasova, “Influence of rheological active additives on the properties of self – compacting concrete,” Journal of Wuhan University of Technology-Materials Science Edition, Vol. 36, No. 3, 2021.

-

M. Ouchi, “Concrete at the Turn of the Third Millennium,” in 1st All-Russia Conference on Concrete and Reinforced Concrete, pp. 209–215, 2001.

-

A. A. Guvalov and E. Q. Shahbazov, “Study of the swelling process of nanobentonite clays,” Scientific Works AzUAC, No. 2, pp. 127–130, 2021.

-

A. A. Guvalov and S. I. Abbasova, “Effect of complex modifiers on properties of cement systems,” Chemical Problems, Vol. 18, No. 1, pp. 26–32, Jan. 2020, https://doi.org/10.32737/2221-8688-2020-1-26-32

-

M. D. Butakova and F. A. Zyryanov, “Study of the properties of concrete mixtures and concretes based on fine-grained mineral wastes of mining production,” (in Russian), Don Engineering Herald, No. 3, p. 68, 2012.

-

V. I. Loganina et al., “Influence of polysaccharide additives on carbonization of lime coatings,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030053, Jan. 2025, https://doi.org/10.1063/5.0267323

-

N. Ferraa, M. Ouakki, K. Alaoui, M. Cherkaoui, and M. Bennani Ziatni, “Sustainable enhancement of steel corrosion inhibition in saline environments using Ca2.7Mg6.3 (HPO4)(PO4)5(OH) and Ca3Mg7(PO4)6(OH)2: Synthesis, characterization, electrochemical and chemometric investigations,” Journal of Molecular Structure, Elsevier BV, 2025.

-

I. Azghay et al., “Corrosion inhibition of mild steel in acidic media using benzimidazolium salts: An experimental and computational approach,” Colloids and Surfaces A: Physicochemical and Engineering Aspects, Vol. 726, p. 137815, Dec. 2025, https://doi.org/10.1016/j.colsurfa.2025.137815

-

E. M. Almetwally, M. El Hadi Attia, M. A. Elazab, M. Bassyouni, and A. E. Kabeel, “Improving thermal efficiency and water production in conical solar stills through integrating pistachio shells and paraffin wax phase change material,” Energy Conversion and Management, Vol. 346, p. 120462, Dec. 2025, https://doi.org/10.1016/j.enconman.2025.120462

-

M. Raman, T. Ryan, and L. Olfman, “Designing knowledge management systems for teaching and learning with wiki technology,” Journal of Information Systems Education, Vol. 16, No. 3, pp. 311–320, 2005.

-

T. Alexiou Ivanova, K. Paramonova, O. Talipov, N. Tanyrbergenov, T. Zhakupov, and A. Akayev, “Assessment of common reed (Phragmites australis (Cav.) Trin. ex Steud.) biomass suitability for solid biofuels production,” Sustainability, Vol. 16, No. 17, p. 7378, Aug. 2024, https://doi.org/10.3390/su16177378

-

A. Muxtorov, A. Toshev, and T. Kodirov, “Innovative leather composites in construction: environmental performance of modified silk hydrolysate fillers,” in E3S Web of Conferences, Vol. 648, p. 03006, Sep. 2025, https://doi.org/10.1051/e3sconf/202564803006

-

R. F. Fatullayev, “Optimal short duration of flow construction production,” Scientific Works, No. 2, p. 146, 2024.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.