Abstract

The paper presents the results of the hydropneumatic suspension strut researches on indicator test stand. The front hydropneumatic suspension strut for Citroen BX and C5 was researched. The aim of this investigation was to determine the damping characteristics (points of force for maximum linear velocity). The stroke and rotary velocities were selected on indicator test stand. For that extortion parameters force versus displacement and force versus velocity diagrams were determined. The damping characteristics were determined too.

1. Introduction

The technical condition of the shock can be examined on indicator shock absorber test stand. Such an examination can plot the work graph of the shock absorber (force versus displacement) as well as the velocity graph (force versus linear velocity) and determine damping characteristics [1, 2, 4, 5]. Determination of the damping characteristics can be achieved in two ways (the basis of designated force-displacement diagram at a constant stroke and variable angular velocity or the angular velocity is constant and the value of the stroke is changed). The damping characteristic is determined assuming a value for the maximum damping piston velocity (separately compression and decompression). The implementation of the designation of the characteristics of those two methods may lead to some discrepancies in the designated characteristics [6].

Determining of damping characteristic of hydropneumatic strut is carried out in conjunction with a gas spring (the gas spring is part of hydraulic cylinder). Suspension vibration is causing changes in the volume of gas separated from the liquid susceptible membrane. The fluid flows through the gland – central hole and hole around overshadowed disc springs – play the role of shock absorber in hydropneumatic strut. The disc springs play the role of bump valves in shock absorber. Dimensions of central hole and holes around and disc spring characteristic determine the characteristics of hydropneumatic strut.

Fig. 1View of hydropneumatic strut and damper [9]

![View of hydropneumatic strut and damper [9]](https://static-01.extrica.com/articles/10029/10029-img1.jpg)

![View of hydropneumatic strut and damper [9]](https://static-01.extrica.com/articles/10029/10029-img2.jpg)

2. Test stand and measurement system

The indicator test stand used in researches has been depicted in Fig. 2 [3, 7, 8].

Fig. 2View of laboratory indicator test stand (Citroen BX and C5 strut)

Determining of damping characteristic of hydropneumatic strut is carried out in conjunction with a gas spring, so it is necessary pressurizing of fluid in hyropneumatic strut. For this purpose single section hand pump shown on Fig. 3 was used.

Fig. 3View of single section hand pump

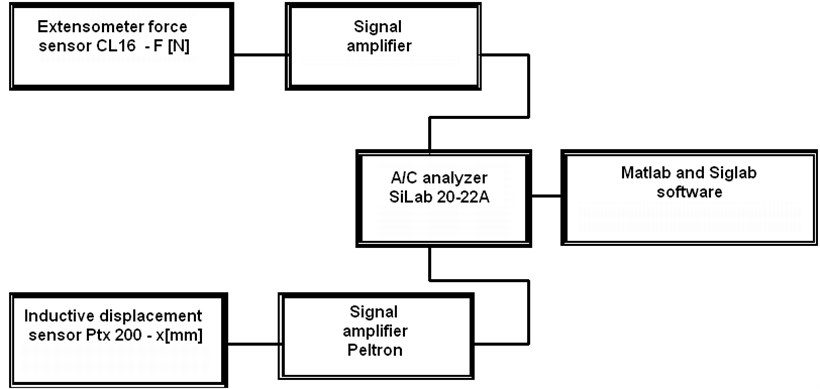

The measurement system used in the test is shown in Fig. 4. The force sensor CL 16 and displacement transducer PTx-200 were used to perform the measurement of force and displacement. The analyzer SigLab 20-22 was used for recording signals.

Fig. 4Scheme of measurement system

3. Results of research

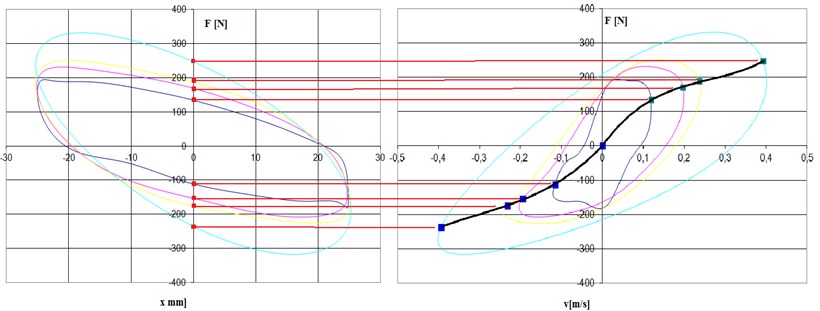

For the purpose of determining the damping characteristics of the hydropneumatic column it is important that the pressure of fluid for vehicle static load is known. Hydropneumatic suspension is a kind of adaptive suspension which keeps constant clearance independent of the static load. Determining of damping characteristic on indicator test stand for Citroen BX and C5 strut was made for 50 mm stroke and changeable angular velocity. The pressure of fluid in strut was corresponding to empty car. In this examination was plotted the work graph (force versus displacement) as well as the velocity graph (force versus linear velocity) and damping characteristics were determined (value of force for the maximum piston velocity, separately for compression and decompression) – Fig. 5.

Fig. 5Determining of damping characteristic

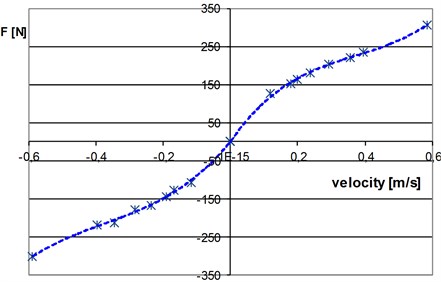

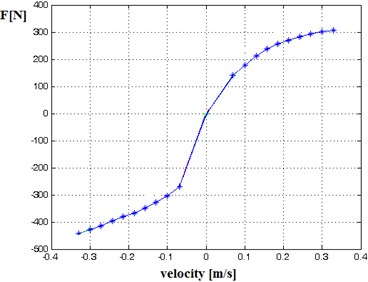

Damping characteristic for Citroen BX is presented in Fig. 5 and for Citroen C5 is presented in Fig. 6.

The damping characteristics for Citroen BX and Citroen C5 struts are similar. Since the suspension is “soft” (used gas spring with constant mass of gas) so the damping forces are not as large as in case of mechanical suspension with coli spring and hydraulic shock absorber. The characteristics are nonlinear and unsymmetric.

Fig. 6Damping characteristic: a) Citroen BX strut, b) Citroen C5 strut

a)

b)

4. Conclusions

There are many differences between damping characteristic for hydraulic shock absorber and hydopneumatic strut. Damping characteristic of hydropneumatic strut is carried out in conjunction with a gas spring, so it is necessary to perform pressurizing of fluid in hyropneumatic strut. The research must be repeated for different values of static pressure (static load of vehicle). The force sensor of test stand must allow measurement of static force and the dynamic changes in the forcing.

Nowadays, when hydropneumatic and active suspensions are more commonly used, it is necessary to develop new universal methods for testing all kinds of suspensions. The comparison of measurement methods for determining damping characteristics of classic, hydropneumatic and active suspensions can be a first step to develop universal methods.

References

-

Burdzik R., Gardulski J., Konieczny Ł. Methodology for determining the damping forces of the hydropneumatic strut on t indicator test stand. Przegląd Mechaniczny, Vol. 2, 2007, p. 38-40, (in Polish).

-

Dixon J. C. The Shock Absorber Handbook. Society of Automotive Engineers Inc., Warrendale, PA, 1999.

-

Gardulski J., Warczek J. Investigation on force in frictional kinematic pairs to assess their influence on shock absorber characteristic. Transport Problems, Vol. 3, Issue 1, 2008, p. 19-24.

-

Konieczny Ł., Gardulski J. Application of simulation researches in diagnostic's of vehicle hydropneumatic suspension. Transport Problems, Vol. 2, Issue 1, 2007, p. 13-21.

-

Konieczny Ł. Determination of the damping characteristics of hydropneumatic strut taking into account the chosen parameters. Zeszyty Naukowe Politechniki Śląskiej, Transport, Vol. 69, 2010, p. 85-89, (in Polish).

-

Konieczny Ł., Burdzik R., Warczek J. Determinations of shock absorber damping characteristics taking stroke value into consideration account. Diagnostyka, Vol. 3, 2010, p. 51-54.

-

Konieczny Ł. The use of nonlinear effects in the vibro-acoustic diagnosis of hydropneumatic suspension. Zesz. Nauk. Pśl. Nr. 1862, Transp., Vol. 74, 2012, (in Polish).

-

Konieczny Ł. Identification of damping characteristic of hydropneumatic strut for example front column Citroen C5. WibroTech 2012, XVI Scientific Conference of Vibroacoustics and Vibroengineering, XI Polish Seminar Vibroacoustics in Technical Systems, Kraków, 2012, (in Polish).

-

Potocki W. Citroen BX. Publishing House Komunikacji i Łączności, (in Polish).