Abstract

This work is devoted to experimental study of the peculiarities of ultrasound wave propagation in magnetorheological fluid (MRF) with complex disperse phase under evaluation of changing of ultrasonic waves (UW) velocity in MRF on the base of water, oxide powder and carbonyl iron particles vs. intensity of applied magnetic field have been obtained. It was found that in the result of magnetic field separation the oxide layer thickness of MRF is increasing with the field value and can be determined by 2-3 µm and lesser.

1. Introduction

Magnetorheological fluids (MRF) belong to class of fluids which structure evolution is developing when magnetic field applied. Changing of its properties is caused by efficiency of magnetic particles polarization, determined by shear conditions, field intensity and its direction, structural and physicochemical characteristics of dispersed phase, volume concentration of magnetic particles , fluids base, stabilization components, as it was founded for the similar electrorheological fluids [1] and in magnetorheological fluids with simple dispersive phase [2]. Diagnostic and determination of the peculiarities of ultrasound wave propagation in magnetorheological fluids (MRF) with complex disperse phase in applied field is of great interest: (a) to get additive information as about magnetic particle interaction and their interaction at the boundary solid-MRF when structure processes take place and (b) to control properties of such fluids during its preparing and using in apparatus and technology processes.

Analysis of up-today methods of the different fluids properties evaluation shows that acoustical properties (ultrasonic velocity and attenuation coefficient ) are very sensitive to structure parameters changing. There are a lot of works devoted to theoretical and experimental study of acoustical properties of magnetic fluids (MF) [3-6], in which acoustical anisotropy has been found. Formally, this class of colloidal solutions is more close to class of MRFs. But sizes of and magnetic moments of particles in stable colloidal solutions MF subjected to magnetic field much less than in rheological fluids. But some of MFs have low aggregation and sedimentation stability depending on the way of their preparing and conditions of using. As theoretical analysis show there are different mechanisms of ultrasonic wave (UW) interaction with structure which cause dynamic and dissipative processes and changing in ultrasonic velocity and attenuation coefficient under applied field. These mechanisms are of non-Knezer or (non-local) nature and include: thermal and viscous effects, Raleigh scattering, magnetodifussion, magnetocaloric, magnetostatic, magnetostriction processes and et al. It should be noted that the theories describing action of magnetic field on mechanism of UW interaction with structure in colloidal MFs are not well developed and there are no enough reliable experimental data on this problem. So the structure of MRF and MF systems (particle’s sizes and its form), way of stabilization are different. The former theories were created only for diluted dispersive mediums and did not take into account very important processes of the magnetic particles formation in the fluid volume and interaction of particles and its aggregates at the boundary. As for known experimentally obtained data of acoustical properties, we can conclude that a lot of them have been obtained for fluids with simple solid phase in conditions when the form-factor of the fluid’s volume in acoustical cell, spectral characteristic of the acoustical pulse, information about the way of the fluid preparing and its stability, have not been done.

This work is devoted to experimental study of acoustical properties of magnetorheological fluids with complex dispersive phase subjected to homogeneous magnetic field of different magnitude.

2. Experimental technique

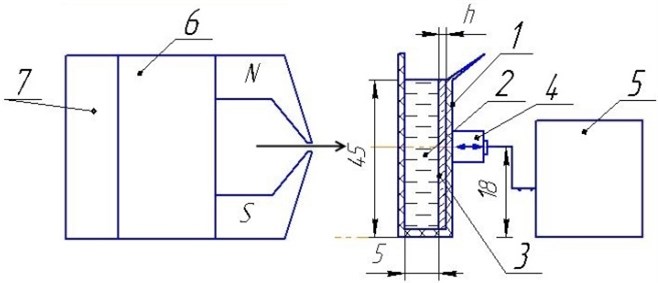

The scheme of experimental equipment to study peculiarities of ultrasound wave propagation in magnetorheological fluid with complex disperse phase is illustrated by Fig. 1. It consist of acoustical sell 1 with the probe 2 installed and electronic system in which are: radiator of electrical pulses 3 and its receiver 4, oscilloscope 5 and device with electrical delay line to measure time and phase shift and to control generator and oscilloscope. The source of inhomogeneous magnetic field is set on platform to move along the probe’ acoustical. Ultrasonic generator radiates pulses with number of 7-8 and is receiving by amplifier block of device UD2-12 and then (non-detected) goes to oscilloscope.

Fig. 1Scheme of equipment to study acoustical properties of MRF in applied magnetic field on the boundary between layers of oxide and magnetic particles: 1 – acoustical sell, 2 – МRF, 3 – oxide layer; 4 – probe working in echo regime, 5 – electronic measuring complex, 6 – magnetic field source, 7 – base

In this experiment magnetic field of different intensity is applied on MRF and using electronic block to measure amplitude and time (phase) shift of reflected signal. These results and theoretical model [7] are used to determine the thickness of oxide layer.

The objects of study – two samples of MRFs (MRF-1, MRF-2) with different of oxide particles and content of magnetic particles – by 38 %.

3. Results and discussion

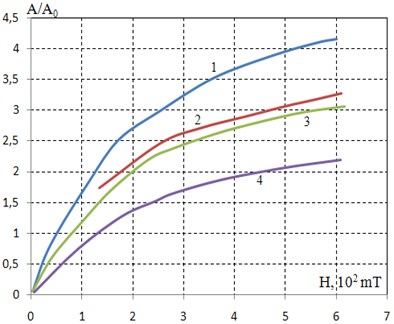

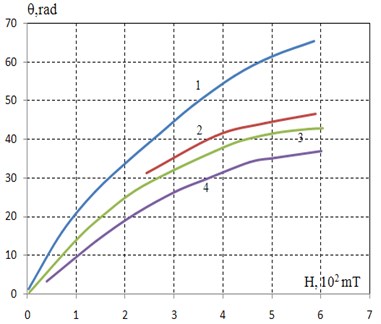

The results of the study are illustrated in Fig. 2 and Fig. 3. Dependences of amplitude and phase shift of ultrasonic waves reflected from the boundary solid (or sound line)-MRF vs. field intensity and its middle gradient directed along the probe acoustical axes are in Fig. 2. The former magnetic field parameters are to characterize the gradient of pounder motive pressure or mass force nearly boundary sound line-MRF (Fig. 1).

As seen from Fig. 2 dependences of the reflected signal parameters and vs. magnetic field value are increasing functions. And for 10 MHz we can observe the more variations of and . So we can see that magnitude of the signal amplitude in MRFs increasing by 3-4 time but phase shift – up to 35-65 grad.

Fig. 2a) Dependences of amplitude and b) angular shift of the signal reflected from the boundary oxcide-magnetic particles layers in MRF vs. magnetic field; 1, 2 – MRF-1; 3, 4 – MRF-2; f= 10 MHz (1, 3), 7, 9 MHz (2, 4)

a)

b)

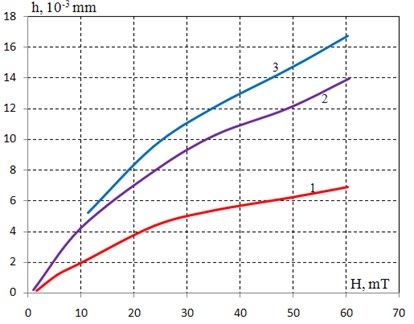

Fig. 3Dependence of the evaluated oxide layer thickness in MRF vs. magnitude of magnetic field: 1 – MRF-1, 2, 3 – MRF-2; 3 – step changing of magnetic field

Fig. 3 illustrates dependences of the evaluated oxide layer thickness vs. magnitude of magnetic field acted on MRF. As it follows from experimental data action of inhomogeneous magnetic field creates conditions for increasing of the thickness of the oxide-magnetic particles layers in MRF. This phenomena is explained by the effect of magnetic separation [8].

As it was shown changing of the thickness of oxide layer increase up to 16 μm for fluid MRF-2.

4. Conclusions

Experimental study of inhomogeneous magnetic field action on the oxide layer thickness of MRF has been done. Acoustical impedance method was used at ultrasonic wave frequencies 7, 9 and 10 MHz. It was firstly discovered that amplitude and angular phase shift of ultrasonic wave impulse reflected from boundary of oxide and magnetic particles layers in MRF are increasing function vs. magnetic field value. So, to be increased up to by 3-4 time, and angular phase shift – up to 35-65°. There are shown that in the result of magnetic field separation the oxide layer thickness of MRF is increasing with the field value and can be determined by 2-3 µm and lesser. The obtained results are of interest to control parameters of the oxide layer in MRF polishing technology of solids.

References

-

Korobko E. V., Rubanov A. C. Electrosensitive fluids as a basis of acoustic devices of a new type. Sensory Phemomen and Measurement Instrumentation for Smart Structures and Materials, Vol. 4328, 2001, p. 249-258.

-

Baev A. R., Korobko E. V., Novikova Z. A. Acoustical properties of magnetorheological fluids under applied magnetic field. Journal of Intelligent Material Systems and Structures, Vol. 26, Issue 14, 2015, p. 1913-1919.

-

Mendeleev V. S., Ivanov A. O. Ferrofluid aggregation in chains under the influence of a magnetic field. Physics Review E, Vol. 70, 2004, p. 051502.

-

Baev A. R., Prokhorenko P. P., Alekseyuk N. Influence of the concentration of a dispersed phase and of the magnetic field on the attenuation of ultrasonic waves in magnetic fluids. Journal of Engineering and Thermophysics, Vol. 80, Issue 5, 2007, p. 989-999.

-

Bloom E., Mayorov M. M., Tchebers A. Magnetic Fluids. Zinatne, Riga, 1989.

-

Skumiel A. The effect of temperature on the anisotropy of ultrasound attenuation in a ferrofluid. Journal of Physics D: Applied Physics, Vol. 37, Issue 3073, 2004.

-

Brehovsky L. M., Godin O. A. Acoustic of Nonhomogeneous Materials. Nauka, Moscow, 1989, (in Russian).

-

Rosensweig R. Ferrohydrodynamic. Cambridge University Press, 1985.