Abstract

High-entropy alloys (HEAs) have emerged as a promising class of materials due to their exceptional mechanical properties, thermal stability, and corrosion resistance. The application of HEAs in Wire Arc Additive Manufacturing (WAAM) presents new opportunities for large-scale component fabrication with customized material properties. This paper reviews recent developments in WAAM processing of HEAs, focusing on the influence of process parameters on microstructure evolution, mechanical performance, and potential industrial applications. Challenges such as segregation, porosity, and residual stresses are also discussed, along with strategies for optimizing HEA properties through alloy design and process control. Furthermore, the potential industrial applications of WAAM-fabricated HEAs in aerospace, marine, and energy sectors are highlighted, demonstrating their relevance in high-performance environments. The insights presented in this review contribute to a deeper understanding of WAAM-based HEAs, guiding future research toward process optimization and industrial adoption.

Highlights

- Reviews the current status of high-entropy alloys (HEAs) in WAAM processing.

- Identifies key challenges in process optimization and alloy design.

- Highlights microstructural features and mechanical behavior of WAAM-processed HEAs.

- Discusses future perspectives and potential industrial applications.

1. Introduction

Additive manufacturing (AM) has transformed material processing by allowing the fabrication of complex geometries [1]. Among the AM techniques, wire arc additive manufacturing (WAAM) presents superior deposition rates, material efficiency and low cost [2]. WAAM is one of the metal additive manufacturing techniques that uses an electric arc as a heat source and a metal wire as feedstock. On the other hand, selective laser melting (SLM) and electron beam melting (EBM) rely on powder-bed fusion where a laser or electron beam selectively melts metal powder with higher precision and finer finishes. Both SLM and EBM entail the utilization of powder-spreading equipment, which will lead to material loss and additional costs [3]. Compared to all other additive manufacturing techniques, the most distinctive advantages of WAAM are its extremely high deposition rate, much economic process and capability of treating a wide group of metals, while residual stresses, porosity and anisotropy in microstructures also characterize such processes. In addition, residual stress, porosity and microstructural inhomogeneities are some of the challenges presented via WAAM, impacting mechanical performances [4]. These need proper understanding of material behaviors and optimization of the process parameters. The principal difference also carries over into the developed microstructure and mechanical properties. WAAM parts tend to have coarse grain structures due to severe thermal gradients, often needing post-processing treatment to obtain enhanced mechanical properties. SLM is aided by rapid cooling rates, producing fine microstructure with enhanced strength, whereas EBM has coarse grains but maintains good mechanical properties, particularly well-suited for high-temperature applications. WAAM is ultimately the most effective at mass-producing large cost-effective parts, whereas SLM and EBM are best suited to precision-critical uses such as implants in the medical industry and avionics components. This is based on required part size, resolution, and costs of manufacture constraints [3-4].

High entropy alloys (HEAs) have a special phase stability that enables them to retain their mechanical properties within a wide range of temperatures and under severe environmental conditions. The entropy-driven stability of solid solutions suppresses the tendency to form intermetallic compounds, which in turn may improve toughness and enhance structural integrity [5]. Due to their distinctive microstructures, HEAs also possess outstanding properties such as high strength and hardness, excellent corrosion and oxidation resistance, superior thermal stability and improved wear and creep resistance [6-8]. The properties described above result from lattice distortion because of the great variety of elements in HEAs, giving rise to solid solution strengthening. The excellent corrosion and oxidation characteristics arise from Cr, Al and other protective elements in metal alloys [9]. HEAs applications can be seen in Table 1.

Table 1Some HEA application areas [10-13]

Industry | Applications |

Aerospace and defense applications | High-strength, lightweight HEAs for turbine blades and structural components |

Energy | Wear-resistant coatings and heat-resistant components in nuclear and thermal power plants |

Biomedical | Biocompatible HEAs for implants and prosthetics |

Additive manufacturing | Custom-designed HEAs for complex and high-performance structures |

Extreme environment materials | HEAs designed for high radiation, extreme temperatures, and harsh environments, maintaining structural integrity and stability. |

Electronics and magnetic applications | HEAs with tunable electrical and magnetic properties for use in electronic components and magnetic devices. |

HEAs continue to be a rapidly growing research field, with ongoing studies focused on optimizing compositions, processing methods and applications in emerging technologies. The following paper discusses the synergy between HEAs and WAAM, establishing key developments and research gaps and covers aspects like processing techniques, microstructural characteristics, mechanical properties and potential applications, critically examining the latest advancements. By systematically reviewing current findings, this study provides a thorough understanding of the state-of-the-art developments in additive manufacturing and highlight areas that require further exploration.

2. Fundamentals of HEAs

HEAs can be one of the ways of enhancing the properties in WAAM-produced components [14]. Multicomponent composition is the hallmark of HEAs, characterized by their exceptional strength, good corrosion resistance and thermal stability. WAAM will unleash new frontiers of performance, reliability and applicability in critical industries such as aerospace, energy and defense through the judicious leveraging of HEAs.

HEAs are unique due to the high-entropy effect of multi-principal element composition, hence their superior mechanical and functional properties. HEAs are special class of metallic materials that conventionally have been prepared with more than five principal elements in near-equal atomic proportions [15]. Contrary to conventional alloys which are based on one dominant element with small additions of other elements, HEAs use a high configurational entropy that is responsible for stabilizing single-phase solid solutions instead of intermetallic compounds, which makes their mechanical, thermal and chemical properties exceptional compared to those of conventional alloys [16]. However, the formation of simple solid solution phases with FCC, BCC or HCP discourages complicated intermetallic structures, lattice distortion and slow atomic diffusion [17]. Some of the commonly used elements in the preparation of HEAs are Fe, Ni, Co, Cr, Al, Ti, Mo, Mn, Cu and V [18]. In the case of HEAs, the increase in entropy of mixing due to the presence of multiple elements in near-equal atomic fractions stabilizes simple solid solution phases, such as FCC, BCC and dual-phase structures [19].

Another key property of the HEAs is sluggish diffusion, a title given to the lowered atomic mobility in the alloy matrix [20]. This may be attributed to the variety of elements present with different atomic sizes and bonding energies that enhance the energy landscape in terms of complexity and retard the atomic mobility. Sluggish diffusion has several critical implications [21]. HEAs do not depict severe deformation under extremely high temperatures, hence their application in aerospace and power generation is very vital [22]. Conventional alloys have a problem with grain coarsening at high temperatures, whereas HEAs exhibit a more refined microstructure, which remains stable over relatively longer times. Many classical alloys undergo phase separation or precipitation after long-term annealing, HEAs very often retain their single-phase structures which improve long-term performance. With these properties. HEAs become specifically attractive in those applications at high temperatures-for example, turbine blades, heat exchangers and nuclear reactor components [23].

HEAs have high lattice distortion owing to the size mismatch of different constituent elements atomic size. Lattices are usually uniform in conventional alloys [24]. HEAs possess a rather strong local strain hardening because the elements are distributed randomly with a different atomic radius. The unit irregular lattice acts like a barrier to dislocation movement, which should increase its yield strength and hardness [25]. Contrary to the conventional materials that usually suffer rapid softening right after initial deformation, HEAs have often demonstrated a continued strain-hardening effect that extends their mechanical durability. The distorted lattice structure reduces friction and mechanically induced material loss, making the HEAs suitable for wear-resistant coatings and structural components [26]. This leads to the conjunction of these factors, hence leading HEAs to exhibit outstanding mechanical properties often beyond conventional alloys like stainless steel and superalloys.

HEAs have garnered great interest due to their unique combination of mechanical strength, thermal stability and corrosion resistance. Such properties make HEAs useful in a wide range of industrial applications, from aerospace to biomedical engineering. Due to their complex composition and unique properties, the fabrication of HEAs requires advanced manufacturing techniques, each affecting the microstructure and performance of the alloy in different ways including casting-based methods [27], powder metallurgy [28], AM technologies [29]. Accordingly, HEAs have attracted much attention in additive manufacturing due to their ability to form stable microstructures under rapid solidification. Especially, WAAM offers high deposition rates and cost-effective HEA processing.

Table 2Key examples of cocktail effect [30-33]

Effect | Description |

Improved strength-ductility trade-off | The presence of both FCC and BCC phases in many HEAs allows an unusual combination of high strength and good ductility, overcoming the typical trade-off observed in conventional alloys |

Superior corrosion and oxidation resistance | The synergistic interaction of elements such as Cr, Al and Ni in forming protective oxide layers greatly enhances corrosion resistance |

Magnetic and electrical properties | Some of the HEAs are found with some unique magnetic behaviors, namely CoCrFeNi-based alloys, appropriate for electronic applications, such as sensors |

One of the strongest reasons that HEAs contain exceptional properties is the cocktail effect. This is caused by the complex atomic interactions between multiple significant elements, leading to higher strength, stability and wear and corrosion resistance. The cocktail effect results in better mechanical properties due to a superior solid solution strengthening, lattice strain, and stability of the phase [22]. All of these have extensive roles in controlling the hardness, tensile strength, and abrasion resistance of HEAs and are hence fully apt for harsh applications. In order to fully utilize the cocktail effect, fabrication methods must be properly selected. Techniques such as additive manufacturing, arc melting and mechanical alloying control the elemental distribution and phase stability, and therefore the occurrence of the cocktail effect in the final structure of the alloy. The cocktail effect involves emergent properties in HEAs that cannot be predicted based solely on the contribution of each participating element, however their combined influence gives rise to the phenomenon through complex interactions at the atomic level with influence on phase stability, mechanical performance and resistance to corrosion [30]. Key examples of cocktail effect can be seen in Table 2.

3. Wire arc additive manufacturing of HEAs, microstructure and mechanical properties

WAAM is one of DED processes using an electric arc to melt and deposit metallic wire layer by layer [34]. Compared to the powder-based AM processes, WAAM features higher deposition rates and lower material costs, therefore enabling the fabrication of large-sized HEA components. Some key process parameters affecting the properties of HEAs in WAAM can be seen in Table 3.

Table 3Important process parameters of HEA-WAAM [35-36]

Parameter | Effect |

Wire composition | Choice of elements controls phase stability and mechanical response |

Heat input | Responsible for microstructural refinement and defect formation |

Interpass temperature | Influences residual stress development and grain growth |

Deposition strategy | Decides the texture and anisotropy of the component |

The rapid solidification and thermal cycling in WAAM processing greatly influence the microstructure of HEAs. Depending on the composition and cooling rate, the formation of phases in HEAs can be single-phase FCC, single-phase BCC or multi-phase. Columnar and equiaxed grains are normally encountered, controlled conditions during processing might affect grain size [37]. Non-equilibrium solidification can lead to elemental segregation, porosity and cracks; hence, post-processing treatments might be required [38]. High strength with accompanying ductility has resulted from grain refinement and work-hardening mechanisms. Resistance to wear and corrosion is related to the stable oxide layers formed along with solid solution strengthening. There is a realization that heat treatments, and thermomechanical processing could enhance mechanical behavior further, possibly through the homogenization of composition and residual stress relieving [39].

Within the extended research on WAAM of HEAs, different works have focused on various alloy systems and/or processing strategies that allow for the manufacturability and the optimization of microstructure and mechanical properties. Studies on HEA materials produced via WAAM are given in Table 4. Some ultimate tensile strength results of HEAs produced via WAAM can be seen in Fig. 1.

Table 4Studies on HEA materials produced via WAAM

High-entropy alloy (HEA) | Composition (at.%) | Reference |

TaMoNbZrTi | Ta (20), Mo (20), Nb (20), Zr (20), Ti (20) | [40] |

AlCoCrNi | Al (16–38.6), Co (21.7-38.6), Cr (21.7–22.7), Ni (22.7-39.2) | [41] |

TaNbHfZrTi | Ta (20), Nb (20), Hf (20), Zr (20), Ti (20) | [42] |

AlCoCrFeNi | Al (35.67), Co (4.99), Cr (8.28), Fe (17.28), Ni (33.79) | [43] |

FeMnCrNi | Fe (50), Mn (30), Cr (10), Ni (10) | [44] |

SiCrMnFeCoNi | Si (1.4), Cr (15), Mn (3.5), Fe (37.9), Co (25.4), Ni (16.8) | [46] |

TiNbMoTaW | Ti (20), Nb (20), Mo (20), Ta (20), W (20) | [47] |

AlCoCrCuFeNi | Al (16.6), Co (16.6), Cr (16.6), Cu (16.6), Fe (16.6), Ni (16.6) | [48] |

MoNbHfZrTi | Mo (20), Nb (20), Hf (20), Zr (20), Ti (20) | [49] |

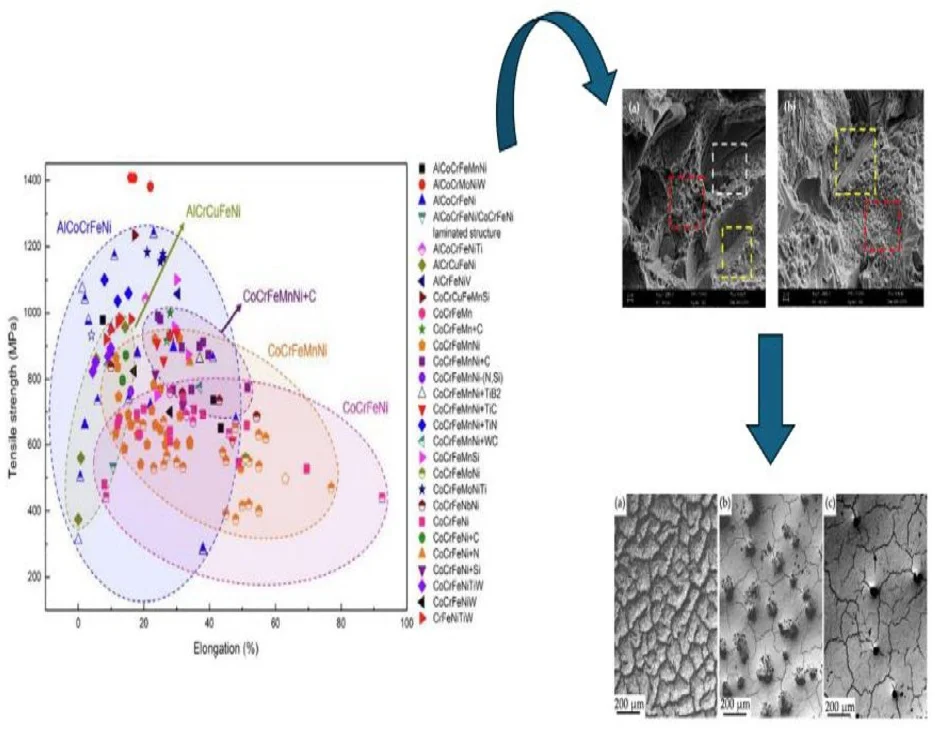

Fig. 1 shows the relationship between the ultimate tensile strength and fracture elongation of different additively manufactured HEAs according to Zhang et al. [50]. Different HEA compositions are marked by different symbols and colors. Solid, top half-solid, open and bottom half-solid symbols are used to represent HEAs fabricated using selective laser melting (SLM), laser melting deposition (LMD), electron beam melting (EBM) and WAAM, respectively. The findings reveal that the mechanical properties of HEAs are very different depending on their composition and processing route. For instance, AlCoCrFeNi and AlCrCuFeNi alloys are ductile while CoCrFeMnNi and CoCrFeNi alloys have high strength. The effects of alloying elements such as carbon (C), silicon (Si) and nitrogen (N) on mechanical properties are also highlighted using the graph. Generally, this study demonstrates that HEAs exhibit a wide range of mechanical properties which might be tailored for specific applications.

Fig. 1The relationship between the ultimate tensile strength and fracture elongation of different additively manufactured HEAs. The solid, top half-solid, open and bottom half-solid symbols represent HEAs fabricated by SLM, LMD, EBM and WAAM, respectively (only considering the as-fabricated state) [50]

![The relationship between the ultimate tensile strength and fracture elongation of different additively manufactured HEAs. The solid, top half-solid, open and bottom half-solid symbols represent HEAs fabricated by SLM, LMD, EBM and WAAM, respectively (only considering the as-fabricated state) [50]](https://static-01.extrica.com/articles/24828/24828-img1.jpg)

The morphological analysis of the fracture provides important information regarding the fracture mechanisms of WAAM fabricated HEAs. Liu et al. [47] studied TiNbMoTaW HEAs at different temperatures. The fracture surface, at 500 °C, is largely covered with cleavage steps and visible cracks, implying a cleavage fracture mode with brittleness. This implies that the material undergoes little or no plastic deformation at low temperatures prior to failure, which can be attributed to restricted dislocation motion within the microstructure. As the temperature increases to 1000 °C, the fracture behavior is dramatically altered (Fig. 2). The presence of small dimples and tearing edges suggests a transition towards a composite mode of fracture, involving both ductile and quasi-cleavage fracture. This change is a result of enhanced plasticity and fracture toughness at elevated temperatures due to enhanced atomic mobility and dislocation activity which favors energy dissipation during deformation. The microstructural evolution indicated by the reduced cleavage steps and the acquisition of ductile nature highlights the temperature-sensitive mechanical behavior of the surfacing formed HEAs layers.

Zhou et al. [40] developed a WAAM process to fabricate TaMoNbZrTi refractory HEA. For the first time, a pre-alloyed droplet transfer mode was developed, ensuring much better element diffusion and metallurgical bonding and explored the microstructure-property relationship of WAAM-fabricated refractory HEAs. Meanwhile, the authors obtain a dual-phase BCC structure characterized by TaMoNb-rich dendrites with ZrTi-rich interdendritic regions. Their work proves the possibility of using WAAM to fabricate refractory HEAs with better properties. Accordingly, the yield strength increased by ~158 % from 920 MPa to 2025 MPa as the strain rate rose from 920 to 4100 s-1. Fracture strain also increased by ~72 %, showing enhanced ductility. High dislocation density in the Zr-Ti-rich region contributed to strain hardening.

Based on the idea of multi-material HEA fabrication, a dual arc WAAM with a CMT system was applied to fabricate compositionally graded AlxCoCrNi HEAs by Lu et al. [41], The authors observed a continuous FCC-to-FCC+B2 phase transformation due to the compositionally graded addition of Al. In the meantime, the microstructure evolved from columnar grains to dendrites as increasing the Al content and the AlNi-rich B2 precipitated in the interdendritic regions. This work highlights the capability of WAAM in controlling the properties of HEAs through compositional tailoring. Yield strength increased from 257 MPa to 640 MPa. Hardness increased from 170 HV to 450 HV. Fracture mode transitioned from ductile to brittle due to excessive B2 phase formation. In-situ alloying capability of WAAM was also demonstrated with this study.

Fig. 2Fracture morphology of compressive deformation for TiNbMoTaW HEA at high temperatures: a) T= 500 °C and b) T= 1000 °C [47]

![Fracture morphology of compressive deformation for TiNbMoTaW HEA at high temperatures: a) T= 500 °C and b) T= 1000 °C [47]](https://static-01.extrica.com/articles/24828/24828-img2.jpg)

Hu et al. [42] identified very strong resistance in TaNbHfZrTi HEAs to adiabatic shear banding; this holds an important function especially for such an alloy with impact application requirements. Its unique properties are dependent not just on materials but also on advanced manufacturing processes such as WAAM. In this sense, alloys like TaNbHfZrTi are of crucial importance regarding mechanical properties and facility of production. Further, the application of such alloys is expected to make an important step in the elaboration of long-living materials especially in very aggressive environments.

WAAM fabricated HEAs possess complex microstructures controlled by thermal gradients and solidification kinetics. Zhang et al. [44] demonstrated this by producing FeMnCrNi HEA where the microstructure is predominantly dendritic, with grain morphology varying from the bottom to the top of the build due to differences in heat dissipation due to variations in heat dissipation (Fig. 3). The fusion lines between layers show the layer-wise deposition process, and grain size reduces gradually towards the top. This deviation is closely related to critical solidification parameters such as temperature gradient (), solidification rate (), degree of subcooling (), and diffusion coefficient (). The interaction among these parameters decides the columnar or equiaxed microstructure, which ultimately affects the mechanical properties of the final product.

Fig. 3Microstructure of different position of WAAM HEA: a) bottom, b) middle, c) top [44]

![Microstructure of different position of WAAM HEA: a) bottom, b) middle, c) top [44]](https://static-01.extrica.com/articles/24828/24828-img3.jpg)

Shen et al. [43] designed a combined cable wire for arc additive manufacturing of non-equiatomic AlCoCrFeNi HEA. BCC and FCC dual-phase structure reported with good interlayer bonding and defect-free microstructure. Therefore, their focus was more on optimizing wire feedstock design. It was concluded that custom-designed wire feedstocks have the potential for better phase constituent control in the WAAM fabrication of HEAs. The obtained results also shed light on how different heat treatment temperatures alter the microstructure and mechanical properties of Al-Co-Cr-Fe-Ni HEAs. Thus, heat treatment at 600 °C provided improved strength and hardness due to precipitation strengthening, while 800 °C resulted in improved elongation and 1000 °C yielded a softer material that is more ductile. These findings add to the understanding of how the properties of HEAs can be tailored for various applications by exploiting controlled heat treatments.

While most of the above studies focused on their objectives with a controlled phase structure, Zhang et al. [44], developed an efficient and cost-effective WAAM method to fabricate a Fe50Mn30Cr10Ni10 high-entropy alloy. The main phase of the produced alloy consisted of a face-centered cubic single phase, with a minor amount of σ phase. It is mentioned that such formation of the σ phase in the alloy differs from those alloys prepared by other methods. The microstructure of the alloy exhibited mainly dendritic and inter-dendritic crystals. It was observed that the grain size increased from the bottom to the top of the sample, and this might relate to dissipation of heat. This study emphasizes the capability of WAAM as a possible process to fabricate complex structural parts made of HEAs rather than laser additive manufacturing processes which are expensive and time-consuming. The mechanical strength of the WAAM HEA reached as high as about 448 MPa with a high fracture elongation of 80 %. Corrosion tests showed that a protective layer formed on the alloy surface, hence offering better corrosion resistance compared to 45 steel material. Tensile testing showed a plastic fracture mechanism with lots of dimples.

Further exploring the fabrication of non-equiatomic HEAs, Ivanov et al. [45], fabricated a non-equiatomic AlCoCrFeNi HEA using WAAM in an argon atmosphere. The SEM analysis revealed a dendritic structure with second-phase particles at grain boundaries. Grain interiors were enriched with Al and Ni, while the grain boundaries contained Cr and Fe; Co was distributed quasi-uniformly. This study further validated the capability of WAAM in tailoring microstructural characteristics through controlled elemental distribution. Tensile testing showed that the material had fractured as a result of an intragranular cleavage mechanism. The brittle cracks were propagating along the grain boundaries and their junctions, especially in those regions with second-phase inclusions. The authors believed that increased brittleness in the WAAM-manufactured HEA could be associated with either an inhomogeneous elemental distribution, second-phase formation at the grain boundary and/or discontinuities (pores) within the material. The tensile testing also showed low strength and ductility for the alloy that could be associated with microcracking and embrittlement. Fracture surface analysis confirmed the intragranular cleavage mechanism, observing a grooved pattern inside the grains with second phase particles acting as local fracture initiators.

Osintsev et al. [51], investigated the fabrication of a non-equiatomic CoCrFeMnNi HEA. They used cable-type wire as feedstock that consisted of a single pure Co wire and two wires containing Cr, Fe, Mn, and Ni (Fig. 4). CoCrFeMnNi HEA microstructure exhibited grain variations and dotted lines were specifically drawn based on the deposition sequence rather than grain boundaries, in figure 4. XRD analysis confirmed single-phase face-centered cubic (FCC) crystal structure with elemental homogeneous distribution. Microstructural examination showed a dendritic microstructure with heat propagation directions, typical of WAAM-made materials. Mechanical performance was similar to other HEAs, with compressive yield strength of ~279 MPa, ultimate compressive strength of ~1689 MPa and tensile elongation of ~63 %. There were small non-metallic inclusions and porosity which may affect mechanical performance. In spite of such defects, the research pointed to the possible application of WAAM in the production of HEAs with acceptable mechanical properties at lower cost compared to powder-based additive manufacturing techniques.

While WAAM has a wonderful advantage in deposition rate and material efficiency, it creates rough surface finishes and residual stresses due to rapid solidification and layer by layer deposition. To enhance the mechanical properties and surface finish of WAAM-fabricated components, post-processing treatments undertaken. Ivanov et al. [52] highlights post-processing as vital in optimizing the microstructure and relieving the residual stresses, particularly in maintaining the structural integrity of WAAM-fabricated components via examining the structure and properties of AlCoCrFeNi high-entropy alloy and processing with electron–ion plasma. Fig. 5 demonstrates how post-processing techniques influence the final properties of WAAM parts, validating the necessity of the treatments as a component of the manufacturing process rather than an isolated step. The study focused on surface treatment by deposition of a (B + Cr) film and irradiation of the samples with a pulsed electron beam (figure 5). XRD investigation confirmed a simple cubic crystal lattice, and microstructural analysis revealed a dendritic structure in the as-manufactured state. The microhardness of the HEA nearly doubled after treatment, its wear resistance increased more than five times and the friction coefficient decreased by 1.3 times. All these properties were attributed to grain refinement, formation of borides and oxyborides. And dissolution of boron atoms in the crystal lattice. The results show that electron-ion plasma treatment can effectively improve the mechanical and tribological performance of WAAM-processed HEAs, rendering them better candidates for wear-resistant applications.

Fig. 4a) Cross-sectional view of the stranded wire and b) an optical micrograph of CoCrFeMnNi HEA sample produced via WAAM (right). The dotted lines indicate the boundaries between layers [51]

![a) Cross-sectional view of the stranded wire and b) an optical micrograph of CoCrFeMnNi HEA sample produced via WAAM (right). The dotted lines indicate the boundaries between layers [51]](https://static-01.extrica.com/articles/24828/24828-img4.jpg)

a)

![a) Cross-sectional view of the stranded wire and b) an optical micrograph of CoCrFeMnNi HEA sample produced via WAAM (right). The dotted lines indicate the boundaries between layers [51]](https://static-01.extrica.com/articles/24828/24828-img5.jpg)

b)

Fig. 5Electron microscopic image of the surface structure of the film (Cr + B)/(HEA) substrate system after irradiation with a pulsed electron beam at an electron beam energy density of a) 20 J/cm2, b) 30 J/cm2, and c) 40 J/cm2 [52]

![Electron microscopic image of the surface structure of the film (Cr + B)/(HEA) substrate system after irradiation with a pulsed electron beam at an electron beam energy density of a) 20 J/cm2, b) 30 J/cm2, and c) 40 J/cm2 [52]](https://static-01.extrica.com/articles/24828/24828-img6.jpg)

These studies bring evidence on the growth of WAAM interest in fabrication techniques, also the pronounced influences that processing condition, wire feedstock design and compositional control have effect on microstructure and mechanical properties. New WAAM techniques, including pre-alloyed droplet transfer, dual-wire deposition and compositionally graded approaches are expanding the additive manufacture of HEAs into new territory.

4. Challenges and future directions

The application of high-entropy alloys to wire arc additive manufacturing brings in a transformation possibility for the fabrication of high-performance and customized components. Yet, several important challenges exist that need to be overcome for the full exploitation of the integration benefits of HEAs with WAAM material selection, control of processing, refinement of microstructure, optimization of mechanical properties and industrialization of the process [53]. Overcoming these limitations requires further study in feedstock development, process monitoring, computational modeling and techniques for post-processing.

The general problem with fabricating HEAs via WAAM is the very limited availability of commercial HEA wire feedstock. Unlike conventional alloys where established methods of wire production have been developed, the preparation of HEA feedstock requires strict control of elemental composition and homogenization. Most research on HEAs has thus far depended on customized wires, which are costly to fabricate and difficult to produce in large amounts. Variations in the quality of wire feedstocks may introduce compositional inconsistencies which can influence microstructural evolution and mechanical properties. Further efforts are needed to develop cost-effective and commercially viable HEA wire feedstocks with compositions designed for WAAM processing.

Different bimetallic parts can also be manufactured via WAAM process using solid and metal-cored wires [54-56]. In addition to welding wire type, several welding parameters, including heat input, interpass temperature and deposition strategy should be taken into consideration for the final properties. High thermal input and cyclic heating/cooling cycles in WAAM lead to some challenges such as residual stress, anisotropic grain structures and undesirable phase formations [57]. Without precise process control, porosity, cracking and compositional segregation are possible defects that may arise. Real-time monitoring and adaptive control strategies will be necessary to assure process stability and reproducibility, possibly mediated by machine learning algorithms. HEAs gain their unique properties from the multicomponent nature which encourages single-phase solid solutions. Rapid solidification via WAAM and nonuniform thermal gradients induce element segregation increase localized phase transformations [58]. Most of these heterogeneities are related to brittle phases, compromising structural integrity. Advanced solidification modeling and subsequent thermomechanical treatments hold the potential for suppressing these and offering a uniform microstructure.

Anisotropy is one of the general problems in WAAM, because the directional heat flow influences grain growth [59]. Mechanical properties are anisotropic for columnar and dendritic microstructures aligned along the build direction, showing strength and ductility different in different orientations [60]. Besides, high residual stresses induced via WAAM can result in distortion of the component and crack formation. In-situ stress-relief techniques, optimized deposition strategies, and post-deposition heat treatments shall be developed to enhance isotropic mechanical performance.

The increasing research on HEAs in WAAM has yet to see much industrial adoption due to the absence of standardized testing protocols and certification frameworks. Most mechanical and corrosion resistance studies are carried out in idealistic ways under laboratory conditions. Extensive testing under realistic service conditions will be necessary to enable the introduction of HEA-WAAM components into critical applications such as aerospace, energy and biomedical. This will involve fatigue testing, long-term oxidation/corrosion studies and impact resistance evaluations. The establishment of industrial standards regarding processing and performance validation will be necessary for the wider commercialization of HEA-WAAM.

Future studies should focus more on the formulation of HEA compositions for WAAM processing. Most of the available HEA formulations have been borrowed from research into casting or powder metallurgy, probably not best suited to the thermal environment of WAAM. Computationally intensive thermodynamic calculations and high-throughput screening are potent approaches to identifying new compositions with improved printability, phase stability and mechanical properties [61]. Further, alloying strategies are required which could provide minimum segregation tendency and optimize solid solution strengthening. Real-time monitoring with infrared thermal imaging, high-speed cameras and acoustic sensors integrated into WAAM can derive valuable insight into the WAAM process dynamics [62]. In this regard, AI and machine learning algorithms will be able to optimize processing parameters and enable active control to avoid defects, further improving part quality [63]. Digital twins can be virtual models mimicking the processes involved in WAAM and may possess predictive capabilities to avoid defects and enhance processes [64]. These will be pursued in the direction of hybrid approaches, such as WAAM combined with post-processing treatments which would bring an improved mechanical performance of the WAAM-processed HEAs. Thermomechanical processing, HIP and surface treatments like laser shock peening or ultrasonic impact treatment will be adopted to reduce porosity, homogenize the microstructure and release residual stresses; these will contribute to structural integrity [65]. WAAM will be combined with other additive/subtractive manufacturing techniques, enabling multi material fabrication and functionally graded structures.

Computational tools, such as finite element modeling and phase-field simulations will enhance the understanding of WAAM-induced microstructural evolution. These models predict thermal gradient, stress distribution and phase transformation, hence offering better optimization of the process [66]. Experimental validation coupled with computational approaches will hasten the development of WAAM-processed HEAs with tailored properties. Future research should be directed toward the design of application-specific HEA-based WAAM components and assessment of their performance for long-term operational conditions. For instance, lightweight, high-strength HEA structures could be used in the next generation of aircraft and space crafts, while corrosion-resistant HEA coatings might extend the life of offshore and nuclear power components. Another exciting direction of the research relates to biomedical applications: patient-specific HEA implants, with much-improved biocompatibility [67].

5. Conclusions

High-entropy alloys represent an innovative category of materials characterized by outstanding mechanical, thermal, and chemical capabilities. When combined with WAAM, HEAs provide exceptional prospects for producing high-performance components characterized by improved structural integrity, customized compositions, and increased mechanical properties. HEAs have great mechanical strength, corrosion resistance, and thermal stability, while WAAM provides cost-effective and scalable processing. Compositional segregation, anisotropy, and residual stresses are some of the challenges that need to be overcome through process optimization, advanced monitoring, and post-processing techniques for perfect functionality.

Future research should concentrate on optimizing the composition of high-entropy alloys for WAAM process, improving real-time process control, and expanding hybrid manufacturing techniques. Ongoing advancements in these areas will broaden applications within the aerospace, energy, and medical sectors. Addressing these challenges will realize the whole potential of WAAM-based HEAs, driving advancements in next-generation manufacturing methods.

References

-

M. Armstrong, H. Mehrabi, and N. Naveed, “An overview of modern metal additive manufacturing technology,” Journal of Manufacturing Processes, Vol. 84, pp. 1001–1029, Dec. 2022, https://doi.org/10.1016/j.jmapro.2022.10.060

-

L. P. Raut and R. V. Taiwade, “Wire arc additive manufacturing: a comprehensive review and research directions,” Journal of Materials Engineering and Performance, Vol. 30, No. 7, pp. 4768–4791, Jun. 2021, https://doi.org/10.1007/s11665-021-05871-5

-

M. Srinivas and B. S. Babu, “A critical review on recent research methodologies in additive manufacturing,” Materials Today: Proceedings, Vol. 4, No. 8, pp. 9049–9059, Jan. 2017, https://doi.org/10.1016/j.matpr.2017.07.258

-

D. Chakraborty, N. A. Khan, A. Prajapati, K. Palanchu, and A. Kumar, “The state-of-the-art on properties enhancement by post-heat treatment of WAAM fabricated alloys,” in International Conference on Processing and Fabrication of Advanced Materials, pp. 155–192, Nov. 2024, https://doi.org/10.1007/978-981-97-5963-7_12

-

L. Han et al., “Multifunctional high-entropy materials,” Nature Reviews Materials, Vol. 9, No. 12, pp. 846–865, Sep. 2024, https://doi.org/10.1038/s41578-024-00720-y

-

W. Li, D. Xie, D. Li, Y. Zhang, Y. Gao, and P. K. Liaw, “Mechanical behavior of high-entropy alloys,” Progress in Materials Science, Vol. 118, p. 100777, May 2021, https://doi.org/10.1016/j.pmatsci.2021.100777

-

X. Liu, J. Zhang, and Z. Pei, “Machine learning for high-entropy alloys: Progress, challenges and opportunities,” Progress in Materials Science, Vol. 131, p. 101018, Jan. 2023, https://doi.org/10.1016/j.pmatsci.2022.101018

-

Y. Tang et al., “A review on the dynamic-mechanical behaviors of high-entropy alloys,” Progress in Materials Science, Vol. 135, p. 101090, Jun. 2023, https://doi.org/10.1016/j.pmatsci.2023.101090

-

B. R. Gelchinski, I. A. Balyakin, A. A. Yuryev, and A. A. Rempel, “High-entropy alloys: properties and prospects of application as protective coatings,” Russian Chemical Reviews, Vol. 91, No. 6, p. RCR5023, Jun. 2022, https://doi.org/10.1070/rcr5023

-

S. Dixit et al., “Refractory high-entropy alloy coatings for high-temperature aerospace and energy applications,” Journal of Thermal Spray Technology, Vol. 31, No. 4, pp. 1021–1031, Feb. 2022, https://doi.org/10.1007/s11666-022-01324-0

-

A. Rashidy Ahmady, A. Ekhlasi, A. Nouri, M. Haghbin Nazarpak, P. Gong, and A. Solouk, “High entropy alloy coatings for biomedical applications: A review,” Smart Materials in Manufacturing, Vol. 1, p. 100009, Jan. 2023, https://doi.org/10.1016/j.smmf.2022.100009

-

D. Miracle, “Unlocking the potential of high entropy alloys with new TMS study,” JOM, Vol. 74, No. 1, pp. 14–17, Dec. 2021, https://doi.org/10.1007/s11837-021-05069-z

-

A. Ostovari Moghaddam, N. A. Shaburova, M. N. Samodurova, A. Abdollahzadeh, and E. A. Trofimov, “Additive manufacturing of high entropy alloys: A practical review,” Journal of Materials Science and Technology, Vol. 77, pp. 131–162, Jun. 2021, https://doi.org/10.1016/j.jmst.2020.11.029

-

S. Chen, Y. Tong, and P. K. Liaw, “Additive manufacturing of high-entropy alloys: a review,” Entropy, Vol. 20, No. 12, p. 937, Dec. 2018, https://doi.org/10.3390/e20120937

-

Y. A. Alshataif, S. Sivasankaran, F. A. Al-Mufadi, A. S. Alaboodi, and H. R. Ammar, “Manufacturing methods, microstructural and mechanical properties evolutions of high-entropy alloys: a review,” Metals and Materials International, Vol. 26, No. 8, pp. 1099–1133, Dec. 2019, https://doi.org/10.1007/s12540-019-00565-z

-

Y. Zhang, D. Wang, and S. Wang, “High‐entropy alloys for electrocatalysis: design, characterization, and applications,” Small, Vol. 18, No. 7, p. 2104339, Nov. 2021, https://doi.org/10.1002/smll.202104339

-

Y.-C. Wu and J.-L. Shao, “FCC-BCC phase transformation induced simultaneous enhancement of tensile strength and ductility at high strain rate in high-entropy alloy,” International Journal of Plasticity, Vol. 169, p. 103730, Oct. 2023, https://doi.org/10.1016/j.ijplas.2023.103730

-

T. Yoshizaki and T. Fujita, “Thermal stability and phase separation of nanoporous high-entropy alloys containing 23 elements,” Journal of Alloys and Compounds, Vol. 968, p. 172056, Dec. 2023, https://doi.org/10.1016/j.jallcom.2023.172056

-

J.-T. Ren, L. Chen, H.-Y. Wang, and Z.-Y. Yuan, “High-entropy alloys in electrocatalysis: from fundamentals to applications,” Chemical Society Reviews, Vol. 52, No. 23, pp. 8319–8373, Nov. 2023, https://doi.org/10.1039/d3cs00557g

-

E. J. Pickering, A. W. Carruthers, P. J. Barron, S. C. Middleburgh, D. E. J. Armstrong, and A. S. Gandy, “High-entropy alloys for advanced nuclear applications,” Entropy, Vol. 23, No. 1, p. 98, Jan. 2021, https://doi.org/10.3390/e23010098

-

M. Z. Farias, “Molecular Dynamics study of atomic diffusion in cantor high entropy alloy in the selective laser melting process,” The University of Texas Rio Grande Valley, 2021.

-

A. Mehta and Y. H. Sohn, “Fundamental core effects in transition metal high-entropy alloys: “high-entropy” and “Sluggish diffusion” effects,” Diffusion Foundations, Vol. 29, pp. 75–93, Apr. 2021, https://doi.org/10.4028/www.scientific.net/df.29.75

-

P. Jovičević-Klug and M. Rohwerder, “Sustainable new technology for the improvement of metallic materials for future energy applications,” Coatings, Vol. 13, No. 11, p. 1822, Oct. 2023, https://doi.org/10.3390/coatings13111822

-

R. S. Mishra, R. S. Haridas, and P. Agrawal, “High entropy alloys – tunability of deformation mechanisms through integration of compositional and microstructural domains,” Materials Science and Engineering: A, Vol. 812, p. 141085, Apr. 2021, https://doi.org/10.1016/j.msea.2021.141085

-

E. P. George, W. A. Curtin, and C. C. Tasan, “High entropy alloys: a focused review of mechanical properties and deformation mechanisms,” Acta Materialia, Vol. 188, pp. 435–474, Apr. 2020, https://doi.org/10.1016/j.actamat.2019.12.015

-

A. C. Feltrin, Q. Xing, A. D. Akinwekomi, O. A. Waseem, and F. Akhtar, “Review of novel high-entropy protective materials: wear, irradiation, and erosion resistance properties,” Entropy, Vol. 25, No. 1, p. 73, Dec. 2022, https://doi.org/10.3390/e25010073

-

T. Nagase et al., “Development of Fe-Co-Cr-Mn-Ni-C high entropy cast iron (HE cast iron) available for casting in air atmosphere,” Materials and Design, Vol. 184, p. 108172, Dec. 2019, https://doi.org/10.1016/j.matdes.2019.108172

-

N. Eißmann, B. Klöden, T. Weißgärber, and B. Kieback, “High-entropy alloy CoCrFeMnNi produced by powder metallurgy,” Powder Metallurgy, Vol. 60, No. 3, pp. 184–197, May 2017, https://doi.org/10.1080/00325899.2017.1318480

-

T. Ron, A. Shirizly, and E. Aghion, “Additive manufacturing technologies of high entropy alloys (HEA): Review and Prospects,” Materials, Vol. 16, No. 6, p. 2454, Mar. 2023, https://doi.org/10.3390/ma16062454

-

L. Wang et al., “Surprising cocktail effect in high entropy alloys on catalyzing magnesium hydride for solid-state hydrogen storage,” Chemical Engineering Journal, Vol. 465, p. 142766, Jun. 2023, https://doi.org/10.1016/j.cej.2023.142766

-

C. Jin, X. Li, J. Kang, and H. Wang, “Achieving excellent strength-ductility balance in the lightweight refractory high-entropy alloy by incorporating aluminum,” Materials Science and Engineering: A, Vol. 915, p. 147248, Nov. 2024, https://doi.org/10.1016/j.msea.2024.147248

-

Y. Fu, J. Li, H. Luo, C. Du, and X. Li, “Recent advances on environmental corrosion behavior and mechanism of high-entropy alloys,” Journal of Materials Science and Technology, Vol. 80, pp. 217–233, Jul. 2021, https://doi.org/10.1016/j.jmst.2020.11.044

-

G. Li et al., “Enhanced microwave absorption performances of FeCoNiCuCr high entropy alloy by optimizing particle size dehomogenization,” Journal of Alloys and Compounds, Vol. 941, p. 168822, Apr. 2023, https://doi.org/10.1016/j.jallcom.2023.168822

-

S. C. A. Costello, C. R. Cunningham, F. Xu, A. Shokrani, V. Dhokia, and S. T. Newman, “The state-of-the-art of wire arc directed energy deposition (WA-DED) as an additive manufacturing process for large metallic component manufacture,” International Journal of Computer Integrated Manufacturing, Vol. 36, No. 3, pp. 469–510, Mar. 2023, https://doi.org/10.1080/0951192x.2022.2162597

-

M. R. U. Ahsan et al., “Effects of process parameters on bead shape, microstructure, and mechanical properties in wire + arc additive manufacturing of Al0.1CoCrFeNi high-entropy alloy,” Journal of Manufacturing Processes, Vol. 68, pp. 1314–1327, Aug. 2021, https://doi.org/10.1016/j.jmapro.2021.06.047

-

M. Bhuvanesh Kumar, P. Sathiya, and S. M. Senthil, “A critical review of wire arc additive manufacturing of nickel-based alloys: principles, process parameters, microstructure, mechanical properties, heat treatment effects, and defects,” Journal of the Brazilian Society of Mechanical Sciences and Engineering, Vol. 45, No. 3, p. 164, Feb. 2023, https://doi.org/10.1007/s40430-023-04077-1

-

V. P. Narayana Samy, M. Schäfle, F. Brasche, U. Krupp, and C. Haase, “Understanding the mechanism of columnar-to-equiaxed transition and grain refinement in additively manufactured steel during laser powder bed fusion,” Additive Manufacturing, Vol. 73, p. 103702, Jul. 2023, https://doi.org/10.1016/j.addma.2023.103702

-

S. Chandra, J. Radhakrishnan, S. Huang, S. Wei, and U. Ramamurty, “Solidification in metal additive manufacturing: challenges, solutions, and opportunities,” Progress in Materials Science, Vol. 148, p. 101361, Feb. 2025, https://doi.org/10.1016/j.pmatsci.2024.101361

-

X. Zhang et al., “Progress in machining-induced residual stress and microstructural evolution of inhomogeneous materials and composites,” Advanced Composites and Hybrid Materials, Vol. 6, No. 3, p. 122, Jun. 2023, https://doi.org/10.1007/s42114-023-00698-1

-

Y. Zhou, S. Peng, Y. Guo, X. Di, B. Liu, and C. Liu, “Dynamic mechanical response of TaMoNbZrTi refractory high entropy alloy via multi-wire arc additive manufacturing,” Philosophical Magazine, pp. 1–16, Jan. 2025, https://doi.org/10.1080/14786435.2024.2447040

-

H. Lu, M. Wen, X. Chen, and S. Jayalakshmia, “In-situ synthesis of Alx-Co-Cr-Ni high entropy alloys via twin-wire and arc additive manufacturing (T-WAAM): microstructure evolution and mechanical properties,” Journal of Materials Science, Vol. 59, No. 28, pp. 13251–13264, Jul. 2024, https://doi.org/10.1007/s10853-024-09968-9

-

M.-L. Hu, W.-D. Song, D.-B. Duan, and Y. Wu, “Dynamic behavior and microstructure characterization of TaNbHfZrTi high-entropy alloy at a wide range of strain rates and temperatures,” International Journal of Mechanical Sciences, Vol. 182, p. 105738, Sep. 2020, https://doi.org/10.1016/j.ijmecsci.2020.105738

-

Q. Shen, X. Kong, and X. Chen, “Significant transitions of microstructure and mechanical properties in additively manufactured Al-Co-Cr-Fe-Ni high-entropy alloy under heat treatment,” Materials Science and Engineering: A, Vol. 815, p. 141257, May 2021, https://doi.org/10.1016/j.msea.2021.141257

-

X. Zhang et al., “Microstructure and performance of Fe50Mn30Cr10Ni10 high-entropy alloy produced by high-efficiency and low-cost wire arc additive manufacturing,” Lubricants, Vol. 10, No. 12, p. 344, Dec. 2022, https://doi.org/10.3390/lubricants10120344

-

Y. F. Ivanov, K. A. Osintsev, V. E. Gromov, S. V. Konovalov, and I. A. Panchenko, “Deformation behavior of a high-entropy Al-Co-Cr-Fe-Ni alloy fabricated by means of wire-arc additive manufacturing,” Steel in Translation, Vol. 51, No. 1, pp. 27–32, May 2021, https://doi.org/10.3103/s0967091221010046

-

K. A. Osintsev, S. V. Konovalov, V. E. Gromov, Y. F. Ivanov, and I. A. Panchenko, “Microstructure and mechanical properties of non-equiatomic Co25.4Cr15Fe37.9Mn3.5Ni16.8Si1.4 high-entropy alloy produced by wire-arc additive manufacturing,” Materials Letters, Vol. 312, p. 131675, Apr. 2022, https://doi.org/10.1016/j.matlet.2022.131675

-

J. Liu et al., “Microstructure and mechanical properties of wire arc additively manufactured MoNbTaWTi high entropy alloys,” Materials, Vol. 14, No. 16, p. 4512, Aug. 2021, https://doi.org/10.3390/ma14164512

-

C.-W. Tsai, Y.-L. Chen, M.-H. Tsai, J.-W. Yeh, T.-T. Shun, and S.-K. Chen, “Deformation and annealing behaviors of high-entropy alloy Al0.5CoCrCuFeNi,” Journal of Alloys and Compounds, Vol. 486, No. 1-2, pp. 427–435, Nov. 2009, https://doi.org/10.1016/j.jallcom.2009.06.182

-

N. N. Guo et al., “Microstructure and mechanical properties of refractory MoNbHfZrTi high-entropy alloy,” Materials and Design, Vol. 81, pp. 87–94, Sep. 2015, https://doi.org/10.1016/j.matdes.2015.05.019

-

W. Zhang, A. Chabok, B. J. Kooi, and Y. Pei, “Additive manufactured high entropy alloys: A review of the microstructure and properties,” Materials and Design, Vol. 220, p. 110875, Aug. 2022, https://doi.org/10.1016/j.matdes.2022.110875

-

K. Osintsev, S. Konovalov, D. Zaguliaev, Y. Ivanov, V. Gromov, and I. Panchenko, “Investigation of Co-Cr-Fe-Mn-Ni non-equiatomic high-entropy alloy fabricated by wire arc additive manufacturing,” Metals, Vol. 12, No. 2, p. 197, Jan. 2022, https://doi.org/10.3390/met12020197

-

Y. Ivanov et al., “Structure and properties of Al-Co-Cr-Fe-Ni high-entropy alloy subjected to electron-ion plasma treatment,” Metals, Vol. 12, No. 11, p. 1987, Nov. 2022, https://doi.org/10.3390/met12111987

-

Q. Shen, J. Xue, Z. Zheng, X. Yu, and N. Ou, “Effects of deposition strategies on microstructure and mechanical properties of wire arc additive manufactured CoCrFeNiMo0.2 high-entropy alloy,” Materials Science and Engineering: A, Vol. 918, p. 147486, Dec. 2024, https://doi.org/10.1016/j.msea.2024.147486

-

U. Gürol, S. Dilibal, B. Turgut, H. Baykal, H. Kümek, and M. Koçak, “Manufacturing and characterizaton of waam-based bimetallic cutting tool,” International Journal of 3D Printing Technologies and Digital Industry, Vol. 6, No. 3, pp. 548–555, Dec. 2022, https://doi.org/10.46519/ij3dptdi.1210836

-

U. Gürol, B. Turgut, H. Kumek, S. Dilibal, and M. Koçak, “Fabrication and characterization of wire arc additively manufactured ferritic-austenitic bimetallic structure,” Metals and Materials International, Vol. 30, No. 5, pp. 1342–1355, Nov. 2023, https://doi.org/10.1007/s12540-023-01568-7

-

U. Gürol, S. Dilibal, B. Turgut, and M. Koçak, “Characterization of a low-alloy steel component produced with wire arc additive manufacturing process using metal-cored wire,” Materials Testing, Vol. 64, No. 6, pp. 755–767, Jun. 2022, https://doi.org/10.1515/mt-2021-2155

-

S. Shi, X. Liu, G. Xie, and X. Chen, “Enhanced cyclic stress response and low-cycle fatigue life of modified 9Cr-1Mo steel by wire-arc additive manufacturing and post-heat treatment,” International Journal of Fatigue, Vol. 184, p. 108333, Jul. 2024, https://doi.org/10.1016/j.ijfatigue.2024.108333

-

M. R. Zahidin et al., “Research challenges, quality control and monitoring strategy for wire arc additive manufacturing,” Journal of Materials Research and Technology, Vol. 24, pp. 2769–2794, May 2023, https://doi.org/10.1016/j.jmrt.2023.03.200

-

M. D. Barath Kumar and M. Manikandan, “Assessment of process, parameters, residual stress mitigation, post treatments and finite element analysis simulations of wire arc additive manufacturing technique,” Metals and Materials International, Vol. 28, No. 1, pp. 54–111, Aug. 2021, https://doi.org/10.1007/s12540-021-01015-5

-

B. Lan et al., “The influence of microstructural anisotropy on the hot deformation of wire arc additive manufactured (WAAM) Inconel 718,” Materials Science and Engineering: A, Vol. 823, p. 141733, Aug. 2021, https://doi.org/10.1016/j.msea.2021.141733

-

I. Aiza et al., “Effects of build orientation and inclined features on physical, microstructural and mechanical properties of powder bed fusion additively manufactured metallic parts,” Progress in Materials Science, Vol. 147, p. 101357, Jan. 2025, https://doi.org/10.1016/j.pmatsci.2024.101357

-

S. Mooraj and W. Chen, “A review on high-throughput development of high-entropy alloys by combinatorial methods,” Journal of Materials Informatics, Vol. 3, Jan. 2023, https://doi.org/10.20517/jmi.2022.41

-

L. Chen, “Multi-sensor monitoring for in-situ defect detection and quality assurance in laser-directed energy deposition,” Nanyang Technological University, Oct. 2024.

-

H. Mu, “Digital Twin of Wire Arc Additive Manufacturing,” University of Wollongong, 2024.

-

S. A. Ojo, “Impact of laser-based ultrasonic vibration on microstructure and mechanical properties of additively manufactured Ti-6Al-4V Alloys,” University of Akron, 2024.

-

J. F. Durodola, “Machine learning for design, phase transformation and mechanical properties of alloys,” Progress in Materials Science, Vol. 123, p. 100797, Jan. 2022, https://doi.org/10.1016/j.pmatsci.2021.100797

-

D. Castro, P. Jaeger, A. C. Baptista, and J. P. Oliveira, “An overview of high-entropy alloys as biomaterials,” Metals, Vol. 11, No. 4, p. 648, Apr. 2021, https://doi.org/10.3390/met11040648

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Doruk Gürkan: conceptualization, data curation, investigation, validation, visualization, writing-original draft preparation. Savas Dilibal: conceptualization, data curation, methodology, supervision, validation, writing-review and editing.

The authors declare that they have no conflict of interest.