Abstract

In order to promote the resource utilization of the byproducts of municipal solid waste incineration in asphalt pavement materials, this study selected different types of waste incineration fly ash as fillers and prepared waste fly ash-asphalt mastic materials. The Brookfield viscosity test was used to investigate the variation in apparent viscosity of the waste fly ash-asphalt mastic at different temperatures. The dynamic shear rheological test was employed to study the effects of fly ash content on the viscoelastic properties of asphalt under different frequencies. The low-temperature bending beam rheological test was used to analyze the changes in creep stiffness and creep rate of the waste fly ash-asphalt mastic. Based on this, the rotating film oven aging test was conducted to investigate the mass loss and softening point increment of the waste fly ash-asphalt mastic. The results indicated that the small particle size and developed pore structure of fly ash contributed to the adsorption of asphalt components, enhancing the volume of the mastic. As the fly ash content increased, its specific surface area also increased, further promoting the increase in the viscosity of the asphalt mastic. Under low-temperature conditions, the asphalt mastic became more prone to hardening and brittleness, which resulted in poorer low-temperature cracking resistance, consistent with the ductility results.

Highlights

- The fly ash possesses fine particle size and well-developed porous structure.

- In the high-frequency region, the phase angle of fly ash-modified asphalt mastic decreases with increasing frequency.

- Replacing mineral filler with municipal solid waste incineration (MSWI) fly ash in asphalt mastics compromises their low-temperature cracking resistance.

1. Introduction

With the continuous increase in global waste generation and the growing demand for sustainable waste management, waste incineration has become a primary method of waste disposal. However, the substantial amount of fly ash produced during the incineration process poses significant challenges to the environment and disposal systems [1]. Although municipal solid waste incineration (MSWI) fly ash may contain hazardous elements, its incorporation into asphalt materials not only alleviates disposal pressures but also has the potential to enhance the performance of asphalt mixtures, thereby promoting the sustainable development of asphalt pavement materials [2]. In recent years, research on the resource utilization of waste-derived fly ash has gradually become a hotspot in the field of asphalt pavement materials [3]. The unique properties of MSWI fly ash, such as its fine particle size, high specific surface area, and well-developed porous structure, contribute to its excellent adsorption capacity, which can improve the rheological properties of asphalt [4]. Previous studies have shown that asphalt materials incorporating fly ash exhibit certain improvements in high-temperature stability, aging resistance, and mechanical performance. However, the potential presence of heavy metals and harmful substances in fly ash raises safety concerns regarding its application in asphalt materials. Current research primarily focuses on performance optimization of fly ash-modified asphalt pavement materials, while systematic studies on the rheological behavior of asphalt binders incorporating fly ash from different sources remain limited.

To address this gap, this study selects various types of MSWI fly ash as fillers to prepare fly ash-modified asphalt binders. The Brookfield viscosity test is employed to investigate the variation in apparent viscosity of the binders at different temperatures. Dynamic shear rheometer (DSR) tests are conducted to examine the influence of fly ash content on the viscoelastic properties of asphalt under varying frequencies. The bending beam rheometer (BBR) test is used to analyze the creep stiffness and creep rate of the fly ash-modified asphalt binders at low temperatures. Additionally, the rolling thin film oven (RTFO) aging test is applied to evaluate the mass loss and softening point increment of the binders after aging.

2. Materials and methods

2.1. Materials

2.1.1. Fly ash

The fly ash was sourced from waste-to-energy plants in Guangzhou, while the mineral filler used was limestone powder. The fly ash-modified asphalt binders were prepared by incorporating MSWI fly ash at different mass fractions (0 %, 25 %, 50 %, 75 %, 100 %) based on a filler-bitumen ratio of 0.8. The asphalt binders were blended using a high-speed shearing method to ensure homogeneous mixing.

2.1.2. Asphalt

AH-70# base asphalt was selected as the binder, and the fly ash-asphalt mastic was prepared via melt blending. The asphalt exhibited a softening point of 47.8 °C, a penetration of 6.5 mm (0.1 mm), and a ductility of 20.6 cm at 10 °C.

2.2. Methods

2.2.1. Brookfield viscosity test

In accordance with the “Test Methods for Asphalt and Asphalt Mixtures in Highway Engineering” (JTG E20-2019), the Brookfield viscosity test was conducted on the fly ash-asphalt mastic with different replacement ratios. The test temperatures were set at 135 °C, 150 °C, and 175 °C, respectively.

2.2.2. Dynamic shear rheometer (DSR) test

The dynamic shear rheometer (DSR) test was conducted to investigate the rheological properties of fly ash-modified asphalt mastic with different replacement ratios of fly ash. The testing was carried out at 60 °C using 25 mm parallel plates with a 1mm gap setting. A frequency sweep from 0.1 rad/s to 100 rad/s was applied under a controlled strain amplitude of 1 %, in accordance with standard rheological testing protocols for asphalt binders.

2.2.3. Low-temperature bending beam rheometer (BBR) test

The low-temperature rheological properties of the fly ash-asphalt mastic were investigated using a TE-BBR bending beam rheometer. The tests were conducted at three temperatures: –6 °C, –12 °C, and –18 °C, to comprehensively evaluate the binder's performance under cold climate conditions.

2.2.4. Rolling thin film oven (RTFO) aging test

The RTFO aging test of fly ash-asphalt mastics with different replacement ratios was conducted according to JTG E20-2019 “Test Methods for Asphalt and Asphalt Mixtures in Highway Engineering”. The thermal aging properties were evaluated based on the mass change and softening point increment before and after aging.

3. Results and discussion

3.1. Brookfield viscosity test

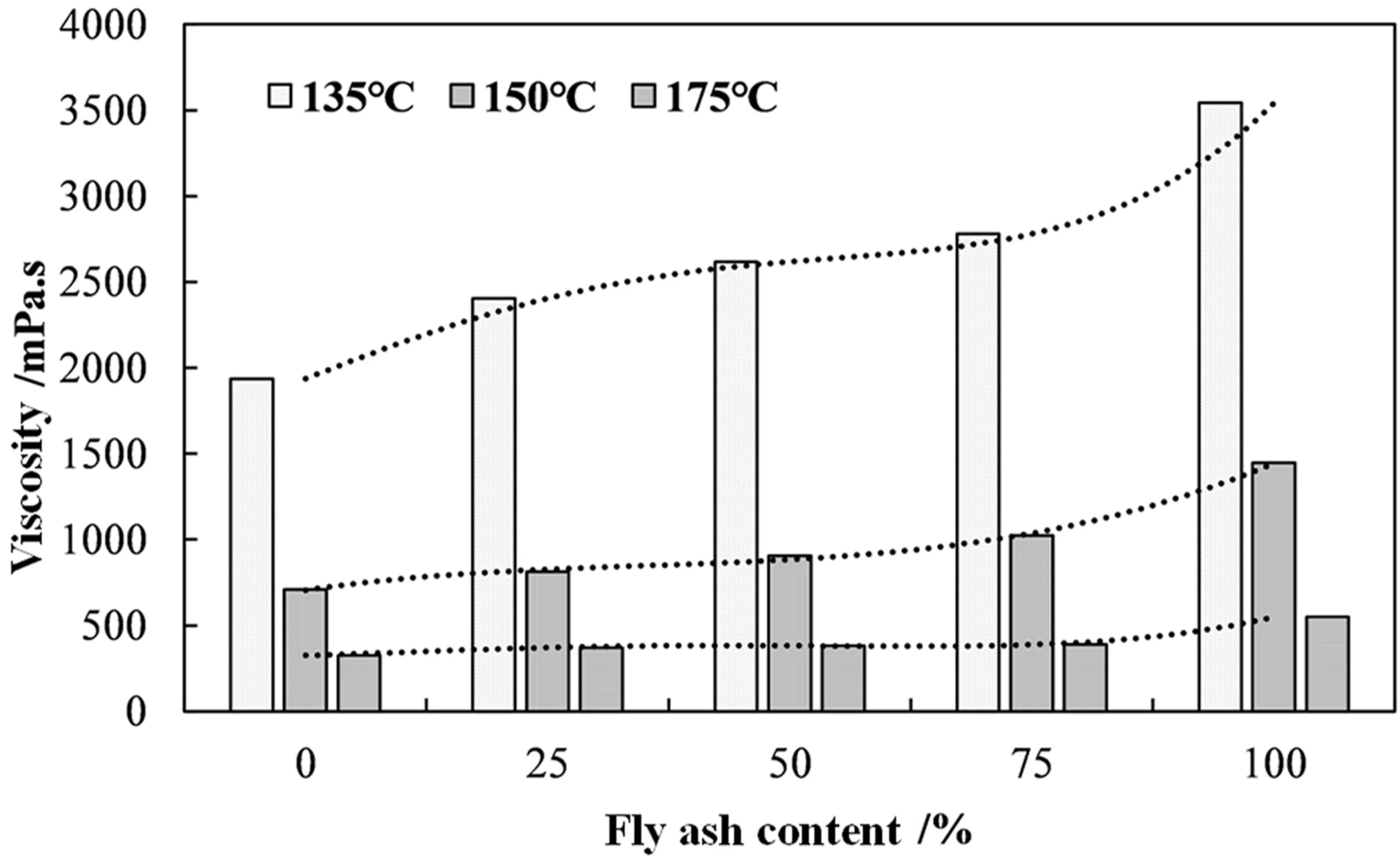

Fig. 1 shows the Brookfield viscosity test results of MSWI fly ash-modified asphalt mastics with different replacement ratios. Under a constant filler-bitumen ratio of 0.8, the Brookfield viscosity of all fly ash-modified asphalt mastics exhibited a general decreasing trend with increasing temperature. Notably, the viscosity differences between different samples became less significant when the temperature reached 175 °C. At any given test temperature, the viscosity of the asphalt mastics increased progressively with higher fly ash content. For instance, at 135 °C, the viscosity of the control sample (with pure mineral filler) was measured at 1937 mPa·s, while the sample containing 100 % fly ash replacement showed a substantially higher viscosity of 4105 mPa·s. This marked viscosity enhancement demonstrates the superior effect of fly ash compared to conventional mineral filler. The observed viscosity improvement may be attributed to the unique physical characteristics of fly ash, including its finer particle size distribution and well-developed porous structure. As the fly ash content increases, its larger specific surface area provides more active sites for interaction with the asphalt binder, thereby significantly enhancing the overall viscosity of the mastic system.

Fig. 1Brookfield viscosity test results for fly ash- asphalt mastics at different temperatures

3.2. Frequency sweep test

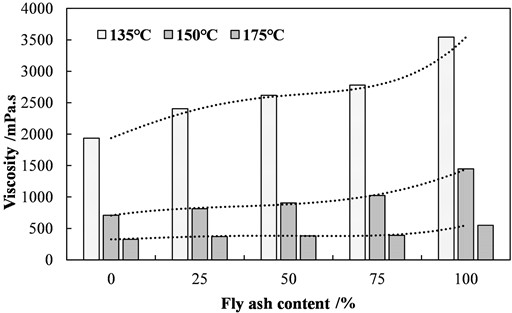

The frequency sweep test results of fly ash-asphalt mastics with different replacement ratios are shown in Fig. 2. Fig. 2 displays the curves of complex shear modulus (*) and phase angle () versus frequency for fly ash-asphalt mastics. Analysis of Fig. 2 reveals that the complex shear modulus () of all fly ash-asphalt mastics gradually increases with increasing frequency. Since all curves exhibit similar growth trends under different frequencies, a specific frequency point (10 rad/s) was selected for comparative analysis. The bar chart in Fig. 2 shows that the complex modulus () of fly ash-asphalt mastics increases with higher fly ash replacement ratios. Specifically, when the fly ash replacement ratio reaches 100 %, the value increases by 6 kPa compared to mineral filler-asphalt mastic, demonstrating that replacing mineral filler with fly ash can effectively enhance the complex modulus of asphalt mastics.

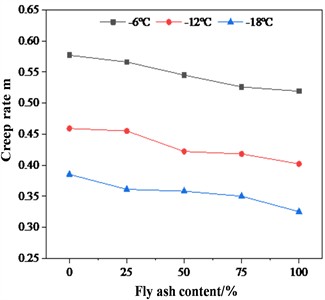

3.3. Low-temperature rheological properties of MSWI fly ash-modified asphalt mastics

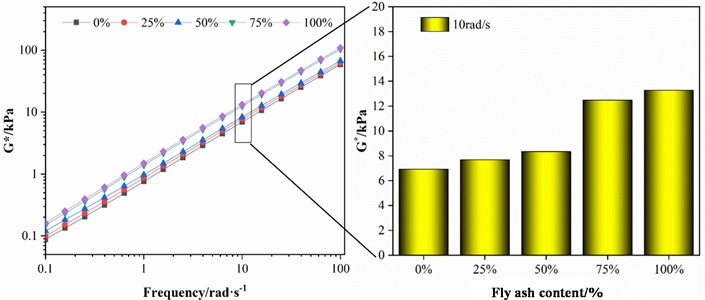

Fig. 3 shows the creep stiffness (S) and creep rate (m) of two types of MSWI fly ash-modified asphalt mastics with different replacement ratios. As shown in Fig. 3, at the same replacement ratio, the creep stiffness S of all fly ash-modified asphalt mastics increased with decreasing temperature, indicating poorer low-temperature cracking resistance at lower temperatures. Under identical temperature conditions, the S value gradually rose with increasing fly ash content. Both temperature change and fly ash replacement ratios significantly affected the S values of the asphalt mastics. Specifically, when the temperature was –6 °C and the fly ash replacement ratio increased from 25 % to 100 %, the S value increased by 4.7 % to 25.25 % compared to the pure mineral filler asphalt mastic. At –12 °C, the S value increased by 7.1 % to 34.3 %, while at –18 °C, the increase ranged from 0.3 % to 7.3 %.

Fig. 2Complex shear modulus of MSWI fly ash-modified asphalt mastics

Fig. 3Creep stiffness (S) and creep rate (m) of MSWI fly ash-modified asphalt mastics

As evidenced by Fig. 3, all fly ash-modified asphalt mastics exhibited lower m-values compared to pure mineral filler mastics under identical testing conditions. The analysis demonstrates three critical findings: At any given temperature, the m-value showed a progressive decline with higher fly ash replacement ratios. For each fixed replacement ratio, the m-value decreased consistently with reduced temperature. These trends collectively indicate that fly ash incorporation diminishes the low-temperature cracking resistance of asphalt mastics. The underlying mechanism involves the fly ash’s adsorption of certain asphalt components, which produces more pronounced hardening effects than limestone mineral filler. This results in impaired stress relaxation capacity (quantified by reduced m-values) and consequently poorer resistance to thermal cracking at low temperatures.

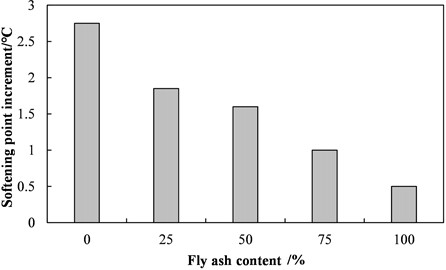

3.4. Rolling thin film oven (RTFO) aging test

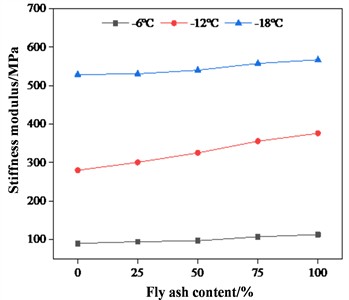

Fig. 4 displays the softening point changes of fly ash-asphalt mastics before and after thin film oven aging. The test results show that after undergoing thin film oven aging, the softening points of all fly ash-asphalt mastics increased, and the magnitude of softening point increment gradually decreased with higher fly ash replacement ratios. The softening point increment of Dongguan fly ash-asphalt mastics was slightly smaller than that of Guangzhou fly ash-asphalt mastics. When the replacement ratio reached 100 %, the softening point increments of Dongguan and Guangzhou fly ash-asphalt mastics decreased to 0.45 °C and 0.5 °C respectively, compared to pure mineral filler-asphalt mastics. This phenomenon may be explained by the following reasons: under high-temperature oxidation, the light components in asphalt partially volatilize while resins transform into asphaltenes, causing the asphalt to exhibit reduced plasticity and consequently an increased softening point. As the fly ash content increases, its microporous structure and larger specific surface area can adsorb more light fractions, increasing the asphaltene content and thereby improving the high-temperature stability of asphalt, which leads to the gradual reduction in softening point increment.

Fig. 4Softening point increment of fly ash- asphalt mastics before and after aging

4. Conclusions

1) The fly ash possesses fine particle size and well-developed porous structure, which facilitates the adsorption of asphalt components and consequently provides volumetric reinforcement in the asphalt mastic. As the fly ash content increases, its specific surface area expands, further enhancing the viscosity of the asphalt mastic.

2) In the high-frequency region, the phase angle of fly ash-modified asphalt mastic decreases with increasing frequency. At any given frequency, higher fly ash replacement ratios result in progressively smaller phase angles. A reduced phase angle indicates greater elastic components in the asphalt mastic, demonstrating that increased fly ash content enhances the elastic proportion in the viscoelastic composition of the asphalt mastic.

3) Replacing mineral filler with municipal solid waste incineration (MSWI) fly ash in asphalt mastics compromises their low-temperature cracking resistance. This phenomenon may be attributed to the fly ash's adsorption of certain asphalt components, which produces more pronounced hardening effects compared to limestone mineral filler. Consequently, the fly ash-asphalt mastic exhibits reduced stress relaxation capacity, increased creep stiffness (S), and decreased creep rate (m-value). These changes render the asphalt mastic more prone to hardening and embrittlement under low-temperature conditions, ultimately impairing its resistance to thermal cracking.

4) After thin film oven aging, all fly ash-modified asphalt mastics showed increased softening points. However, the magnitude of softening point increment gradually diminished with higher fly ash replacement ratios.

References

-

Y. Sun, Y. Zhong, J. Liao, Y. Gao, and C. Huang, “Life cycle assessment of asphalt pavement containing MSWI bottom ash,” Scientific Reports, Vol. 15, No. 1, p. 12481, Apr. 2025, https://doi.org/10.1038/s41598-025-97241-7

-

X. Sun, H. Xu, X. Qin, Y. Zhu, and J. Jin, “Cross-scale study on the interaction behaviour of municipal solid waste incineration fly ash-asphalt mortar: a macro-micro approach,” International Journal of Pavement Engineering, Vol. 26, No. 1, p. 2469114, Dec. 2025, https://doi.org/10.1080/10298436.2025.2469114

-

H.-S. Han, B. Golestani, K. Park, B. Cho, and B. H. Nam, “Utilization of multiple recycled materials in asphalt concrete: mechanical characterization and cost-benefit analysis,” Materials, Vol. 17, No. 19, p. 4742, Sep. 2024, https://doi.org/10.3390/ma17194742

-

D. T. Melese, G. Jida, R. Beyene, T. T. Woldesenbet, A. E. Meshesha, and W. S. Geleta, “Expansive clay subgrade soil improvement using municipal solid waste fly ash: Experimental and numerical approach,” Environmental Challenges, Vol. 16, p. 100998, Aug. 2024, https://doi.org/10.1016/j.envc.2024.100998

About this article

This paper describes research activities mainly requested and sponsored by Guangzhou Road Affairs Center.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.