Abstract

This article studies specific methods for reducing harmful gases, noise and vibration levels from gasoline light-duty vehicles. For this purpose, scientific research on the rational selection of the composition of complex oxygenated additives in gasoline and the efficiency of vehicle operation on this fuel was studied. Also, changes in the operational performance of light-duty vehicles as a result of the selection and use of the concentration of complex oxygenated gasoline were determined based on the results of experimental research. The use of oxygenated gasoline with a complex composition in automobiles compared to the base gasoline – AI-92, has resulted in a reduction in exhaust gas emissions by CO – 28-36 %, CH – 13-32 %, NOx – 47-49 %, CO2 – 70-81 %, and a reduction in noise level by 4-6 dB due to reduced detonation.

Highlights

- Systematic presentation of studies of motor fuels with oxygen-containing additives.

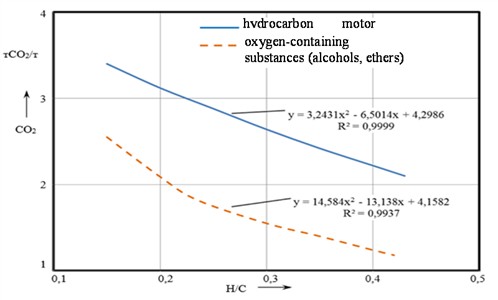

- Changes in carbon dioxide emissions in the exhaust gases of internal combustion engines depending on the H/C ratio in the fuel composition.

- Comparative results of calculated and experimental studies of base gasoline - AI-92 and gasoline with an oxygen-containing additive.

- Main traction-speed and fuel-efficiency indicators of a passenger automobile.

1. Introduction

The use of fuel-efficient technologies and environmentally friendly fuels is becoming a necessity in all sectors of the world. In particular, the use of alternative fuels to petroleum fuels in vehicles is an urgent issue, as their efficiency can be improved and harmful exhaust gases, noise and vibrations can be reduced.

Statistical studies show that road transport generates approximately 72 % (60 % passenger vehicles) of the total CO2 emissions. According to the International Energy Agency (IEA), the average vehicle is allowed to emit CO2 of 148 g of carbon dioxide in CO2 equivalent per passenger km over its life cycle, which should decrease to 95 g/km and then by 55 % in 2030-2034 [1, 2].

Road vehicles cause acoustic discomfort in 80 % of cities. Many highways pass near residential areas, where noise and vibration levels currently exceed the established standard standards by 5-30 dB. On the main highways of large cities, the noise level exceeds 90 dB, and this indicator is increasing by 0,5 dB every year [3], which is the greatest environmental hazard for areas adjacent to the road.

2. Analysis of publications

In recent decades, a significant number of scientific and technical studies in the field of motor gasoline production and internal combustion engine (ICE) design have focused on improving detonation resistance and enhancing the compression ratio of engines. These advancements aim to increase fuel efficiency, reduce specific fuel consumption, and minimize the environmental impact of automotive emissions. The optimization of engine operating modes through the electronic control unit (ECU) has also been identified as a crucial factor influencing both the energy efficiency and environmental safety of gas-cylinder vehicles [2, 4, 5].

Considerable research attention has been devoted to the use of aliphatic alcohols and ethers as additives in motor gasoline. These compounds have been shown to improve various fuel characteristics, including higher octane numbers, improved combustion stability, reduced sulfur and carbon monoxide (CO) emissions, and better cleaning and anti-knock performance. Studies such as those reported in [1, 4, 6] indicate that oxygenated fuel components – particularly ethanol, methanol, methyl tert-butyl ether (MTBE), and ethyl tert-butyl ether (ETBE) – not only enhance fuel quality but also contribute to a cleaner and more complete combustion process.

Oxygen-containing compounds, or oxygenates, possess notable advantages over other additive types. They can be derived from renewable and biodegradable raw materials, including municipal waste, thus offering both ecological and economic benefits. In addition, oxygenated fuels are characterized by improved volatility, lower toxicity, and superior cleaning properties. These features contribute to enhanced fuel atomization and more uniform combustion, which, in turn, reduce harmful exhaust emissions and improve thermal efficiency.

Recent studies have also explored the secondary effects of fuel composition on acoustic and dynamic parameters such as engine noise and vibration. Oxygenated additives facilitate smoother combustion by shortening ignition delay and stabilizing flame propagation, leading to lower cyclic variability. As a result, the amplitude of engine block vibrations and the intensity of emitted noise are significantly reduced, improving both environmental and mechanical performance indicators. Researchers have confirmed that optimized oxygenate concentrations not only mitigate toxic emissions but also enhance the comfort and operational reliability of internal combustion engines.

Overall, the existing body of literature underscores the multifaceted benefits of using oxygen-containing additives in motor gasolines. These additives contribute not only to emission reduction and improved energy conversion efficiency but also to a measurable decrease in vibration and noise levels – parameters that are increasingly important for modern sustainable transportation systems.

3. Review methodology

There are well-established techniques for determining an automobile’s traction-speed and fuel-economy characteristics. One such method involves the thermal analysis of the internal combustion engine (ICE), which accounts for the specific physical and chemical properties of the motor fuels being used. Preliminary evaluations of vehicle performance on both conventional and alternative fuels are carried out by performing a comprehensive set of calculations, including engine thermal analysis, traction performance.

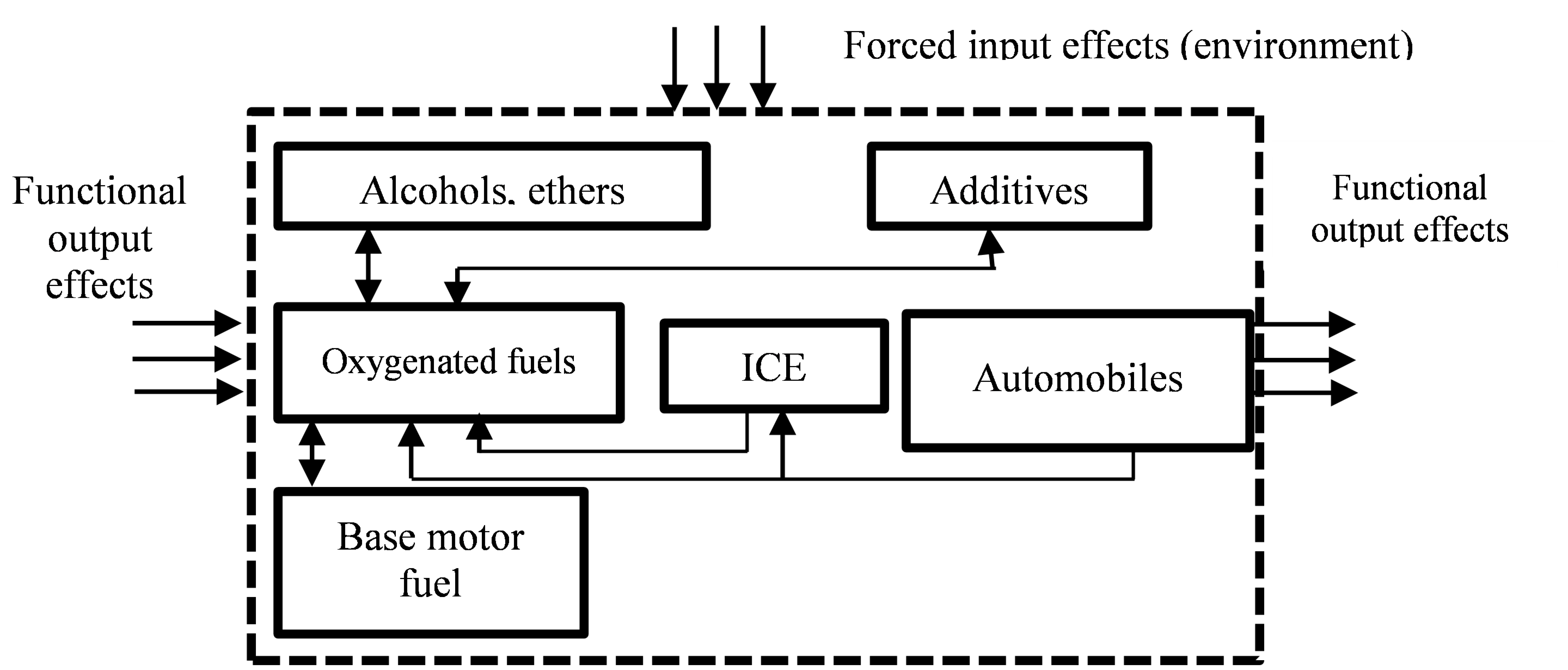

All experimental procedures were conducted in accordance with the relevant national and international standards and regulatory documents to ensure accuracy and repeatability. From a systems perspective, the use of oxygenated motor fuels for spark-ignition ICEs represents a complex multi-component structure consisting of several interrelated subsystems and elements. A systematic study of this structure enables the identification of all key components and interdependencies, thereby facilitating a rational approach (Fig. 1).

The experimental determination of the octane number of fuel mixtures containing oxygenated additives was carried out using the standardized motor method with a single-cylinder UIT-65 (UIT-85) engine unit. Phase stability was evaluated through the cloud point temperature using a KR10-VT low-temperature thermostat. The saturated vapor pressure of the fuel mixtures was measured with a MINIVAP VPSH device, while the fractional composition was determined using both a Wurtz flask-based distillation apparatus.

Engine bench tests were conducted using a B15D2 engine (1.5 L displacement) on a LanmecTest dynamometer bench (Lanmec Electromechanical Technology Co., Ltd.) with a rated power of 100 kW and a torque capacity of 400 Nm. Exhaust gas composition was analyzed using a five-component gas analyzer, HORIBA MEXA-584L. Field experiments were performed on a Chevrolet Gentra (Lacetti) equipped with the B15D2 engine, using the KORSYS-DATRON test complex (CORSYS-DATRON Sensor system GmbH).

In addition to the thermal and emission analyses, the experimental setup was extended to evaluate noise and vibration characteristics under different fuel compositions. Vibration levels were measured using tri-axial accelerometers mounted on the cylinder block and cylinder head, allowing the detection of both vertical and lateral oscillations. The data were recorded at varying engine speeds and loads to capture resonance frequencies and transient effects. Noise intensity was simultaneously measured using conventional.

The acquired vibration and acoustic data were analyzed using spectral analysis and Fast Fourier Transform (FFT) methods to identify dominant frequency ranges associated with combustion irregularities. Statistical filtering was applied to eliminate background interference, providing a precise correlation between combustion efficiency, emission reduction, and mechanical stability. This integrated methodology enabled a comprehensive assessment of the energetic, ecological, and acoustic performance of gasoline engines.

Fig. 1Systematic presentation of studies of motor fuels with oxygen-containing additives

4. Results and discussion

The octane number (ON) of the pre-set concentrations of the components of gasoline with oxygen-containing additives were determined by the following calculation methods:

1. Using the average value of the sum of the RON of the constituent components:

where is the volume fraction of components in the fuel mixture; is the octane number of the components of the fuel mixture.

2. Using the values of the propagation speeds of ultrasonic waves in gasoline at two different fixed temperatures:

where and are the propagation speed of the ultrasonic wave at 20 and 40 °С, respectively.

3. Using the boiling point values:

where – average boiling point , – initial boiling point temperature, °С; – temperature at which boiling ends, °С; – gasoline’s density at 20 °С.

4. Using the engine CPG parameters:

or:

where – the cylinder diameter; – the compression ratio

In these studies, the calculation of the octane number of the fuel mixture was performed using the average value of the sum of the octane numbers of the constituent components without taking into account the possible energizing effects of antiknock properties:

According to the calculated data, it was established that the average values of the sum of the octane number for the flight type of gasoline with oxygen-containing additives of gasoline (OCA-1) are RON = 95.31 and for the winter type TKD-2 RON = 96.23.

A conclusion about the presence of senergetic effects of antiknock properties of the fuel mixture can be made based on the results of experimental studies of these fuels on a single-cylinder UIT-65 unit.

Studies of the properties of gasoline with oxygen-containing additives (OCA) were vehicleried out with different contents of the constituent components (ethanol, butanol, MTBE, Monomethylaniline) based on AI-92 gasoline, according to the results of which the volume concentrations of ethanol (no more than 5 %), butanol (no more than 20 %), MTBE (4-8 % depending on the season), and Monomethylaniline (no more than 0,5 % – below the limits) were selected. The obtained data shows that on the basis of AI-92 gasoline, it is possible to obtain AI-95 and AI-98 of eco-class not less than EVRO 4 (K4).

In accordance with the Intergovernmental Panel on Climate Change (IPCC) Guidelines for National Greenhouse Gas Inventories, carbon dioxide emissions from fuel combustion in internal combustion engines are calculated by multiplying the amount of fuel consumed by the emission factor for each fuel type and transport type using the formula:

where – annual emissions of CO2 in mass units, or t/year; – actual screw fuel consumption, t or t/year; – coefficient of oxidation of carbon and fuel; – low-temperature heating capacity, TDj/tys.t or TDj/tys.m3; – coefficient of vibration of carbon, t C/Dj; 44/12 is the coefficient for the exchange of vibrating carbon C and carbon dioxide CO2.

The conducted studies showed that changes in carbon dioxide emissions, a greenhouse gas in internal combustion engine exhaust gases, largely depend on the H/C ratio of the motor fuels used (Fig. 1). The resulting graphical data allows us to predict greenhouse gas emissions depending on the H/C ratio in the gasoline formulation used or adopted with complex oxygen-containing additives (alcohols, ethers).

Fig. 2Changes in carbon dioxide emissions in the exhaust gases of internal combustion engines depending on the H/C ratio in the fuel composition

All this shows the need for a calculated determination of the characteristics of engines converted to gasoline with oxygen-containing additives in order to predict their output indicators, as well as emissions of harmful substances and other indicators, in advance. The heat of combustion of fuel with oxygen-containing additives of complex composition can be calculated based on the concentration of the constituent components of the fuel mixture:

The experimental external speed characteristic of the B15D2 engine, running on base gasoline AI-92 and on gasoline with oxygen-containing additives (OCA), obtained during bench studies, shows that a rational concentration of OCA components ensures practically identical engine performance on the fuels under study.

The external speed characteristics of the internal combustion engine have characteristic points such as:

– Minimum operating speed – .

– Nominal speed – .

– Rotation speed corresponding to the maximum engine torque –.

– Idle speed – .

Table 1Comparative results of calculated and experimental studies of base gasoline – AI-92 and gasoline with an oxygen-containing additive

No. | Indicators | Fuels | |||||

Gasoline AI-92 | OCA | ||||||

Calc.* | Exp.** | , % | Calc. | Exp. | , % | ||

1 | Power, kW | 77.85 | 84.77 | 8.9 | 79.86 | 83.29 | 4.3 |

2 | Torque, Nm | 126.07 | 137.27 | 8.9 | 129.32 | 134.81 | 4.25 |

3 | Specific fuel (energy) consumption, g/kW×h (MJ/kW×h) | 270.24 | 245.17 | 10.22 | 262.39 | 241.6 | 8.6 |

* Calculations ** Experimental | |||||||

The operating mode of automobile engines under operating conditions mainly occurs in the range between and . It is in this range that the speed of the automobile is controlled and the minimum specific fuel (heat) consumption and emissions of explosives are achieved, which is the main goal of many studies, including the present one. However, when assessing the operational properties of a vehicle and the characteristics of its engine, the torque value has a higher priority than power.

Comparative results of calculated and experimental studies of base gasoline – AI-92 and gasoline with an oxygen-containing additive are given in Table 1.

The maximum speed, acceleration time to 100 km/h, and fuel consumption of a vehicle running on different fuels, obtained in the process of comparative field studies, confirm the scientific validity of the decisions taken on the use of gasoline with an oxygen-containing additive (Table 2).

Table 2Main traction-speed and fuel-efficiency indicators of a passenger automobile

Name of the indicator | Chevrolet Gentra automobile | ||

Fuels | |||

Gasoline AI-92 | OCA* | ||

Maximum travel speed, km/h | Calc. | 182 | 183.2 |

Exp. | 150.0 | 159.8 | |

Acceleration time to 100 km/h | Exp. | 23.26 | 20.82 |

Fuel consumption at 90 km/h, l/100 km (MJ/100 km) | Exp. | 9.6 (312.6) | 9.7 (312.56) |

* Gasoline AI-92 (70.5 %) + Ethanol 5% + Butanol 20% + Methyl tert-butyl ether 4% + Monomethylaniline 0.5 % | |||

5. Discussion of the results of calculated and experimental studies of the main traction and fuel-economic indicators of the automobile

Previously conducted operational studies of automobile gasoline with oxygen-containing additives showed the need to improve their phase stability at negative ambient temperatures.

In this regard, in these studies, gasolines with rational concentrations of oxygen-containing additives were also subjected to studies from the point of view of improving the characteristics of phase stability.

Discussion of the results of the calculated and experimental studies of the main traction and fuel-economic indicators of the automobile. The conducted studies confirm the use of gasoline with oxygen-containing additives as a motor fuel for passenger automobiles.

The use of an improved calculation method for the thermal calculation of the internal combustion engine allows, taking into account the known properties of oxygen-containing additives, to establish their required concentrations and predict the engine and vehicle performance. A preliminary calculated assessment of the main traction and fuel-economic indicators of a automobile running on one or another type of motor fuel, and then a comparison of the obtained results with the corresponding experimental data allows, in general, to make a decision on the advisability of using a certain type of energy source.

6. Conclusions

The following conclusions can be drawn from the results of the studies:

1) The assessment of the feasibility of using any energy source as a motor fuel is vehicleried out in stages. The beginning of such work is the calculation of comparative indicators of vehicle power plants using known methods that take into account the distinctive properties of the motor fuel used.

2) The obtained calculated values of traction-speed and fuel-economic properties of vehicles on various fuels are compared with their main indicators (maximum speed, acceleration time to a given speed, fuel consumption) of dynamism and fuel efficiency obtained experimentally.

3) Distinctive values of carbon content or H/C ratio in the composition of gasoline with oxygen-containing additives allow to reduce emissions of greenhouse gas – carbon dioxide.

4) Laboratory, bench and experimental (field) studies of a passenger automobile running on gasoline with oxygen-containing additives from various aliphatic alcohols and ethers were vehicleried out. In this case, the following were obtained:

– Permissible concentration of the constituent components of the fuel mixture as an additive to gasoline, taking into account the immutability of the basic adjustment parameters of the fuel system.

– The use of oxygen-containing additives (aliphatic alcohols, ethers) allows to obtain motor fuel of environmental class not less than K4 for spark ignition engines with improved dynamic properties of the engine and automobile, as well as cleaning properties of the fuel and thereby eliminate the use of expensive additives.

– The use of oxygen-containing additives as an additive to gasoline allows to reduce emissions in exhaust gases (CO by 28-36 %, CH by 13-32 %, NOx by 47-49 %, CO2 by 70-81 %) compared to the base gasoline – AI-92.

– It has been found that using gasoline with oxygenated additives reduces vibrations emitted from car engines, reducing noise levels by 4-6 dB.

References

-

B. I. Bazarov and S. I. Alimov, “Current state and prospects of use oxygenated fuel additives,” Scientific-Technical Journal Railway Transport: Topical Issues and Innovations, No. 2, pp. 68–73, 2022.

-

B. Bazarov, R. Axmatjanov, J. Tojiyev, and A. Azimov, “The concept of improving the performance indicators of gas-cylinder vehicles,” in E3S Web of Conferences, Vol. 434, p. 02008, Oct. 2023, https://doi.org/10.1051/e3sconf/202343402008

-

A. Pascale, C. Guarnaccia, and M. C. Coelho, “Analysis of single vehicle noise emissions in the frequency domain for two different motorizations,” Journal of Environmental Management, Vol. 370, p. 122905, Nov. 2024, https://doi.org/10.1016/j.jenvman.2024.122905

-

Y. Ren and L. Hao, “The influence of gasoline oxygen-containing additives on the emission characteristics of gasoline vehicles,” Energy, Vol. 332, p. 137104, Sep. 2025, https://doi.org/10.1016/j.energy.2025.137104

-

B. I. Bazarov, R. N. Axmatjanov, A. Azimov, and Y. M. Hamraqulov, “The method of improving fuel efficiency indicators and ensuring environmental safety of gas cylinder vehicles in low temperature weather conditions,” in ICTEA: International Conference on Thermal Engineering, Vol. 1, No. 1, Jun. 2024.

-

Y. Liu, Y. B. Jia, X. J. Zhang, Z. C. Liu, Y. C. Ren, and B. Yang, “Noise test and analysis of automobile engine,” Applied Mechanics and Materials, Vol. 307, pp. 196–199, Feb. 2013, https://doi.org/10.4028/www.scientific.net/amm.307.196

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.