Abstract

In the course of the research, the authors studied the formation of structures of cast blanks on various alloys, depending on the conditions of metal crystallization, including under the influence of vibration. An analysis of the structures of the control samples (blanks) confirmed that solidification under normal conditions occurs mainly according to the sequential crystallization scheme, as evidenced by the width of the structural zones in them. The external vibration effect on solidifying alloys leads to a significant change in the conditions of their crystallization, in particular, to a significant grinding of the macrostructure of the workpieces and a change in the size of the structural zones, which indicates a volume-sequential scheme of their crystallization. It is established that vibration increases the physico-mechanical properties of cast metal and significantly reduces their anisotropy over the section of the workpieces.

1. Introduction

At the present stage of development, the machine-building industry is characterized by increasing demands on the quality of metal blanks and products used, which cannot be improved without improving the technologies of smelting and casting metals and their alloys [1]. In this case, the most important task is to obtain cast blanks with high physical, chemical uniformity and a dispersed crystal structure of the metal. The conditions of melt solidification determine the formation of the internal structure of the workpieces, since crystallization is accompanied by a complex interaction of hydrodynamic, heat exchange, diffusion and capillary processes [2]. At this stage, internal defects (structural and chemical heterogeneity, shrinkage defects, etc.) are formed, which cannot be eliminated by subsequent treatment [3].

To improve the structure of cast blanks, methods of external dynamic effects on the melt are being actively developed: ultrasonic and vibration treatment, electromagnetic and gas pulse mixing, thermal treatment, etc. These methods affect the crystallization processes, but their effective application requires further development of the theory of metal structure formation under external influences [4, 5].

The most common method is low-frequency vibration pulse treatment ( 200 Hz, 3 mm), due to its versatility, efficiency, low energy consumption and the ability to process melts of various weights. However, the widespread use of vibration methods is limited by the lack of specialized equipment and the lack of general research on their use in metallurgy [6].

Nevertheless, there is a sufficient number of studies confirming the positive effect of vibration on the grinding of the crystal structure, a reduction in the zone of transcrystallization, a decrease in zonal and dendritic heterogeneity, and an increase in the mechanical properties of metals and their alloys [7]. However, there are some disagreements on this issue due to the variety of effects of vibration on crystallization processes, which depend on a large number of difficult-to-control factors (conditions of crystal nucleation and growth, supercooling and the magnitude of the temperature gradient across the section of the solidifying melt, the development and width of the zone of the two-phase state, etc.). Differences in views boil down to two main provisions [8]:

1) Vibration increases the number of crystallization centers due to the destruction of the crystallization front and dendrites under the action of elastic waves and cavitation;

2) Vibration increases the rate of crystal nucleation due to periodic pressure, a decrease in viscosity and surface tension of the melt, as well as the appearance of nuclei during viscous friction.

The differences are explained by the use of different types of vibration, different chemical composition and mass of the melt, as well as different approaches to interpreting the processes occurring during solidification. In this regard, in this work, systematic studies have been conducted under strictly controlled conditions aimed at identifying the effect of vibration on the crystallization and structure formation processes of model and metal alloys [9].

2. Materials and research methods

Conducting systematic studies of the crystallization and structure formation of cast blanks in real production is extremely difficult, therefore, indirect methods, including physical modeling in the laboratory, are most effective. One of these methods is modeling using transparent model alloys, which makes it possible to reproduce the solidification processes and study them under controlled conditions [9].

The physical model replaces the real object with the maximum possible compliance with the conditions of the processes. This makes it possible to study the crystallization of various alloys in a laboratory facility, followed by the recalculation of the results for real systems using transition coefficients – scale modeling.

The absolute similarity of the model and the natural object is unattainable, therefore, the principles of incomplete, approximate or local similarity are used [9]. In this work, modeling with incomplete similarity is applied, when only the key criteria determining the development of the phenomenon are met. Geometric, temperature, velocity, and force scales are chosen as such criteria. The remaining processes are considered secondary and are within the limits of self-similarity [9].

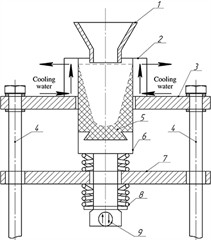

Based on certain scales of physical modeling, a laboratory installation for semi-continuous casting of metals and alloys was created (Fig. 1). The installation consisted of the following main components: a filling funnel (1), a mold (2), a working platform (3), racks (4), a shank (6), a traverse with an extraction mechanism (7), springs to ensure the mobility of the shank (8) and a vibrator (9). The object of research was varietal blanks with a diameter of 50 mm and a length of up to 2 m made of various alloys cast at this laboratory facility. Model and metal alloys were used as materials for research (Table 1). An alloy of camphene (with tricyclene) was chosen for physical modeling, and the metal materials were aluminum alloy AD35 and stainless steel 12X18H9T [9, 11].

Experiments to study the effect of vibration on the processes of crystallization and structure formation were carried out using the following methodology. At the beginning, the required volume of the alloy under study was smelted: steel was smelted in an induction furnace ITS 0.05 / 75; aluminum alloy – in an electric furnace resistance CAT-0.25; camphene alloy – in a muffle furnace SNOL-54/1200 [10]. The liquid alloy was fed through a casting funnel into a water–cooled copper mold with a certain casting temperature, which for metal alloys was 50 °C above their liquidus temperatures, and for camphene alloy –5 °C. As the mold was filled with melt, an extraction mechanism was turned on with a set drawing speed of the cast billet (the drawing speed for each alloy was determined empirically) and vibration. The eccentric-type vibrator was rigidly fixed to the shank from the bottom (Fig. 1(a)) and the pulses from it through the shank were transmitted directly to the workpiece along the axial vertical plane from bottom to top. The vibration parameters were adjusted depending on the alloy being poured within the following limits: frequency 40...120 Hz, amplitude 0.5...1.5 mm. Thus, two continuously cast blanks with a diameter of 50 mm were obtained from each alloy under study: control (i.e., without vibration) and experimental (under the influence of vibration).

Table 1Physical properties of the studied materials

Material | , °C | , °C | , J/kg | , W/m·K | , kJ/kg·K | , kg/m3 | , m2/s | , 1/K | , m2/s |

Stainless steel 12X18H9T | 1460 | 50 | 276×103 | 725 – | 0.46 0,71 | 7920 7250 | 725×10-6 – | – 0.75×10-4 | – |

Aluminum alloy AD35 | 605 | 25 | 390×105 | 188 136 | 1.075 1.24 | 2632 2425 | 140×10-6 40×10-6 | 24×10-6 12×10-6 | – 6.0×10-7 |

Camphene alloy | 45 | 3 | 14 | – 1.85 | – | 845 815 | – 14.2×10-8 | – | – |

Note: the numerators are in the solid state; the denominator is in the liquid state | |||||||||

In order to carry out a structural analysis and determine the mechanical characteristics of the studied alloys in cast form, corresponding samples of identical dimensions in length were cut from the same areas of the workpieces in height. The structures of cast blanks (control and experimental) along their axial vertical plane were subjected to comparative analysis. The macro- and microstructures of the studied metal alloys were manifested using standard reagents, and their mechanical characteristics were determined by appropriate tests according to ГОСТ 1497-84 and ГОСТ 9454-78. To reveal the structures of the camphene alloy blanks, given its nature and transparency, it was enough to wash the sanded surface of the template (sample) with alcohol. Residual stresses in metal workpieces were determined by laser interferometry – electron speckle interferometry [12, 13].

Fig. 1Diagram and photo of a laboratory installation for semi-continuous casting of workpieces. The photograph was first taken by Uzdieva N. S. and Vakhidova K. L. in 2019 at the “Nanotechnology and Nanomaterials” Collective Use Research Center of the Groznian State Oil Technical University

a)

b)

3. Analysis of research results

Before analyzing the results of these studies, let us briefly consider the theoretical foundations of the mechanism of vibration action on the processes of crystallization and structure formation of alloys. So, when vibration is applied to the melt, an instantaneous change in mass forces occurs in the volume of the solidifying metal. This is due to the fact that vibration treatment is, in fact, the introduction of elastic wave energy () into the melt of a solidifying metal, which is equal to [11]:

where is the density of the liquid metal; is the local volume of the metal melt; , and is the frequency and amplitude of vibration (elastic waves).

As a result of the introduction of this additional energy of elastic waves into a limited volume of the solidifying metal melt, pressure gradients arise at the phase boundary, which will exert a cyclic bending effect on growing crystals (branches of dendrites). The magnitude of this pressure, as is known, is directly proportional to the amplitude () and frequency () of the elastic wave and is determined by the dependence [11]:

where is the distance from the open surface of the melt to the point under consideration.

From this elementary analysis, we see that the main effect of vibration on the formation of crystalline structures of cast blanks should be the breaking off of growing crystals (branches of dendrites) under the influence of bending stresses caused by the pressure of an elastic wave. At the same time, the release of supercooled melt micro-volumes ) around each floating dendrite fragment is an additional (side) effect of vibration, which should contribute to the appearance of additional crystallization centers in the volume of the solidifying metal due to its faster cooling [11]:

where is the interfacial tension; is the equilibrium crystallization temperature of the alloy; is the size of the floating crystal; and are the density of the melt and the specific heat of crystallization.

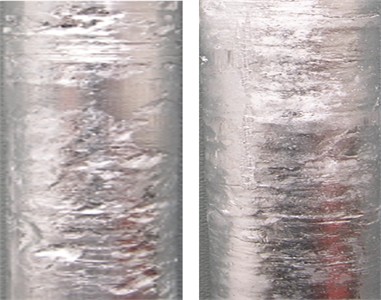

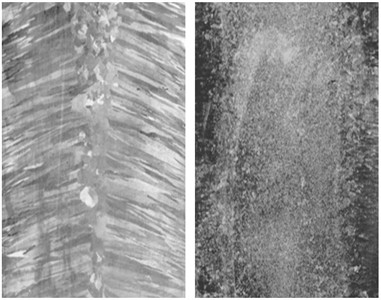

The obtained research results confirmed the effectiveness of vibration effects on the formation of structures and properties of cast blanks from the tested alloys. First of all, it is necessary to note the higher surface quality of the workpieces cast under the influence of vibration (Fig. 2). It can be seen that on the surface of the control blank we clearly observe such defects as non-plates, nadirs and oxide films (Fig. 2, left), while on the surface of the experimental blank (i.e. under the influence of vibrations), such defects are practically not observed (Fig. 2, right).

Fig. 2Surface quality of control and experimental blanks made of AD35 alloy. The photograph was first taken by Uzdieva N.S. and Vakhidova K.L. in 2019 at the “Nanotechnology and Nanomaterials” Collective Use Research Center of the Groznian State Oil Technical University

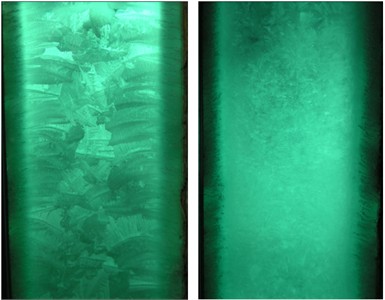

Fig. 3Macrostructures of the control and experimental camphene alloy blanks in the longitudinal axial plane. The photograph was first taken by Uzdieva N.S. and Vakhidova K.L. in 2019 at the “Nanotechnology and Nanomaterials” Collective Use Research Center of the Groznian State Oil Technical University

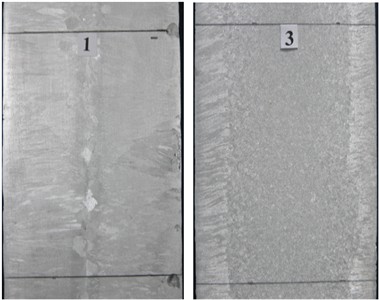

One of the most important criteria for assessing the quality of cast blanks is the characteristics of their primary crystalline structures (shape and dispersion of the cast grain, size of structural zones, etc.), which determine the level of physical and mechanical properties of the final metal products and products made from them [14]. A comparative macrostructural analysis of the obtained blanks for all tested alloys shows that vibration has a significant effect on their formation (Figs. 3-5). We see that the macrostructures of all blanks consist of “standard” zones: the cortical zone, the transcrystallization zone, and the zone of equiaxed crystals. The difference between the structures of the control and experimental blanks is the change in the widths of the corresponding zones and the dispersion of crystals in them.

Fig. 4Macrostructures of the control and experimental blanks made of aluminum alloy AD35 in the longitudinal axial plane. The photograph was first taken by Uzdieva N.S. and Vakhidova K.L. in 2019 at the “Nanotechnology and Nanomaterials” Collective Use Research Center of the Groznian State Oil Technical University

Fig. 5Macrostructures of control and experimental blanks made of 12X18H9T steel in the longitudinal axial plane. The photograph was first taken by Uzdieva N. S. and Vakhidova K. L. in 2019 at the “Nanotechnology and Nanomaterials” Collective Use Research Center of the Groznian State Oil Technical University

In the control blanks, uneven transcrystallization zones are visible in their height, as a result of which bridges (“bridges”) may form in some places, below which solidification will occur with insufficient liquid metal supply and, as a result, axial cracks, shrinkage shells, pores, etc. may form. In experimental blanks, cyclic bending pressures of elastic waves destroy dendrites in the zone of columnar crystals and, thus, eliminate the likelihood of the formation of “bridges” along their height, resulting in a reduction (or elimination) of internal defects in their structure.

The structure of a cast metal depends on the conditions of its crystallization and, as is known, three schemes of solidification of workpieces are possible (including during continuous casting of metals), namely: sequential crystallization, approximate sequential crystallization and volume sequential crystallization [15]. Thus, from the analysis of the structures of the control blanks, it can be assumed that solidification in them mainly proceeds according to the sequential crystallization scheme, and this is indicated by the insignificant width of the zones of equiaxed crystals in them (Fig. 3-5, left). An analysis of the crystalline structure of the experimental blanks indicates that the external vibration effect on the hardening alloys leads to a drastic change in the conditions of their crystallization. This is indicated by a significant reduction in the transcrystallization zones in the experimental blanks and a significant increase in the widths of the zones of equiaxed crystals, which indicates a volume-sequential pattern of their crystallization (Fig. 3-5, right; Table 2).

The change in the size of structural zones in experimental blanks under the influence of vibration is due, as noted above, to the destruction of dendrite branches at the crystallization front (columnar crystal zones) and an increase in the rate of nucleation in the melt volume. At the same time, the dispersion of the dendritic structure increases significantly (Table 3) due to the destruction of their branches by vibration pulses, a higher structural uniformity of the workpieces is ensured (Fig. 3-5, right). In addition, the vibration effect on the cast workpiece leads to an improvement in the quality of its surface (Fig. 2) and, practically, complete elimination of subcortical defects (Fig. 4).

Table 2The sizes of the structural zones of cast blanks depending on the conditions of their crystallization

Alloy | Crystallization conditions | Cortical area, mm | The zone of columnar crystals, mm | The zone of equiaxed crystals, mm |

Camphene | Free | 1 | 20-21 | 6-10 |

With vibration | 1 | 5-7 | 38-40 | |

Aluminum alloy AD35 | Free | 1 | 22-24 | 4-6 |

With vibration | 1 | 8-10 | 35-37 | |

Stainless steel 12X18H9T | Free | 1 | 20-22 | 8-10 |

With vibration | 1 | 7-9 | 38-40 |

Table 3Parameters of the dendritic structure of blanks depending on the conditions of their crystallization

Alloy | Crystallization conditions | Dimensions of columnar dendrites, mm | Dimensions of equiaxed dendrites, mm | ||

Length | Width | Length | Width | ||

Camphene | Free | 20-21 | 3-5 | 5-10 | 3-6 |

With vibration | 5-7 | 1-2 | 1-2 | 1-2 | |

Aluminum alloy AD35 | Free | 22-24 | 1-2 | 3-6 | 2-4 |

With vibration | 8-10 | 0.5-1 | 0.5-1 | 0,5-1 | |

Stainless steel 12X18H9T | Free | 20-22 | 1-3 | 6-8 | 4-6 |

With vibration | 7-9 | 0.5-1 | 0.5-1 | 0.5-1 | |

As a result of tests of samples made of metal alloys (AD35, 12X18H9T) according to GOST 1497-84 and ГОСТ 9454-78, it was found that their physical and mechanical characteristics were directly dependent on the parameters of the crystal structures of the workpieces. Changes in the cast structures of the workpieces caused by vibration led to an increase in the physico-mechanical characteristics of the metal while reducing their anisotropy across the zones (Table 4).

Table 4Physico-mechanical characteristics of the metal in the blanks

The structural area of the workpiece | , kg/m3 | , MPa | , MPa | , % | , % | Residual stresses, MPa |

Aluminum alloy AD35 | ||||||

Columnar crystals | 2615 2608 | 88 69 | 76 58 | 30 26 | 38 34 | 123.3 196.8 |

Equiaxial crystals | 2622 2575 | 98 60 | 82 55 | 32 24 | 40 33 | 102.2 155.4 |

Stainless steel 12X18H9T | ||||||

Columnar crystals | 7840 7800 | 550 520 | 370 355 | 42 33 | 46 35 | 234.6 336.4 |

Equiaxial crystals | 7900 7750 | 590 500 | 390 325 | 45 32 | 48 33 | 168.5 205.6 |

Note: the numerator is with vibration; the denominator is without vibration | ||||||

A comparative analysis of the physical and mechanical characteristics of the workpieces shows that under the influence of vibration, the metal density in them increases for both alloys, which implies an increase in strength. Indeed, vibration strength values for stainless steel increase by 6-9 %, and plastic properties by 30-45 %, depending on the structural zone of the workpiece. At the same time, if in the control blanks the strength indicators from the surface to the center decrease to 10 %, then in the experimental ones, on the contrary, they increase by 5-7 %. Vibration has a similar positive effect on the characteristics of metal in blanks made of aluminum alloy AD35, but, unlike steel, the indicators increase more significantly: strength – by 50-63 %, and ductility – by 20-33 %. At the same time, for both alloys (AD35 and 12X18H9T), vibration significantly reduces residual stresses in cast blanks, respectively, by 52-59 % and 28-43 %, depending on the structural zone, which facilitates their further processing (mechanical, deformation, etc.).

4. Conclusions

The conducted studies have shown that the quality of cast metal significantly depends on the crystallization conditions, which can be controlled by external physical influences. It was found that the vibration treatment of the solidifying melt significantly changes the primary crystal structure of the blanks of both studied alloys.

The thickness of the zones of columnar crystals decreases by 3-4 times during vibration, while the zone of equiaxed crystals increases by 5-7 times. The dispersion of macro grains in this zone increases by 5-15 times. These changes lead to a noticeable increase in the physico-mechanical properties and a decrease in the anisotropy of the cross-section characteristics of the workpieces.

A comparison of the physico-mechanical properties of metal alloys has shown that vibration increases the density of the metal and aligns it along the section of the workpieces. For aluminum alloy AD31, the density was 2615 and 2622 kg/m3, for steel 12X18H9T – 7840 and 7900 kg/m3. An increase in density corresponds to an increase in the strength characteristics of the metal. Indeed, vibration strength values for stainless steel increase by 6-9 %, and plastic properties by 30-45 %, depending on the structural zone of the workpiece. At the same time, if in the control blanks the strength indicators from the surface to the center decrease to 10 %, then in the experimental ones, on the contrary, they increase by 5-7 %. Vibration has a similar positive effect on the characteristics of metal in blanks made of aluminum alloy AD35, but, unlike steel, the indicators increase more significantly: strength – by 50-63 %, and ductility – by 20-33 %. At the same time, for both alloys (AD35 and 12X18H9T), vibration significantly reduces residual stresses in cast blanks, respectively, by 52-59 % and 28-43 %, depending on the structural zone, which facilitates their further processing (mechanical, deformation, etc.).

References

-

V. A. Efimov and A. S. Eldarkhanov, Physical Methods of Influencing the Hardening Processes of Alloys. (in Russian), Moscow: Metallurgy, 1995.

-

G. F. Balandin, Formation of the Crystalline Structure of Castings. Crystallization in a Casting Mold. (in Russian), Moscow: Mechanical Engineering, 1973.

-

U. Rakhimov and N. Tursunov, “Development of technology for high-strength cast iron for manufacturing D49 head of cylinder,” in E3S Web of Conferences, Vol. 401, p. 05013, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105013

-

A. Ohno, The solidification of metals. Tokyo: Chijin Shokan Co., 1976.

-

A. S. Nuradinov, L. H.-A. Saipova, I. G. Gayrbekov, and S. S.-S. Ahtaev, “Effect of vibration on structure and properties of cast billets,” in IOP Conference Series: Earth and Environmental Science, Vol. 87, p. 092018, Oct. 2017, https://doi.org/10.1088/1755-1315/87/9/092018

-

T. Tursunov, N. Tursunov, and T. Urazbayev, “Investigation of heat exchange processes in the lining of induction furnaces,” in E3S Web of Conferences, Vol. 401, p. 05029, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105029

-

A. S. Nuradinov, A. V. Nogovitsyn, I. A. Nuradinov, N. F. Zubenina, and K. A. Sirenko, “Research of possibility of control of the formation of crystal structure of metal alloys,” Academic and Research journal of the NAS of Ukraine, Vol. 16, No. 4, pp. 71–77, Aug. 2020, https://doi.org/10.15407/scin16.04.071

-

A. L. Rutkovskiy, E. M. Bakhteev, Z. G. Salikhov, and M. A. Kovaleva, “An optimized process of drying titanium pellets in a tunnel kiln,” Non-Ferrous Metals, Vol. 2021, No. 5, pp. 89–94, May 2021, https://doi.org/10.17580/tsm.2021.05.12

-

A. S. El’Darkhanov, A. S. Nuradinov, and S. S.-S. Akhtaev, “Control over the formation of continuously cast billets with the use of vibrating molds in machines for continuous casting,” Metallurgist, Vol. 61, No. 11-12, pp. 1067–1074, Apr. 2018, https://doi.org/10.1007/s11015-018-0608-z

-

J. Campbell, “Effects of vibration during solidification,” International Materials Reviews, Vol. 26, No. 1, pp. 71–108, Jan. 1981, https://doi.org/10.1179/095066081790149249

-

A. S. El’Darkhanov, A. S. Nuradinov, S. S.-S. Akhtaev, and N. S. Uzdieva, “Intensification of heat transfer in continuous casting mold,” Stal, No. 5, pp. 21–25, 2017.

-

S. Absattarov, A. Riskulov, and J. Avliyokulov, “Dependence establishment of mass transfer coefficient in third kind boundary condition on temperature during vacuum carburizing of steels,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030035, Jan. 2025, https://doi.org/10.1063/5.0266787

-

S. Absattarov, N. Tursunov, and O. Toirov, “Analysis of heat treatment parameters of 60Si2CrV steel to enhance the mechanical properties of elastic structural elements,” Vibroengineering Procedia, Vol. 58, pp. 320–326, May 2025, https://doi.org/10.21595/vp.2025.24991

-

A. A. Skvortsov, A. D. Akimenko, and V. A. Ul’Yanov, Influence of External Influences on the Formation of Ingots. (in Russian), Moscow: Metallurgy, 1991.

-

T. Urazbayev, N. Tursunov, and T. Tursunov, “Steel modification modes for improving the cast parts quality of the rolling stock couplers,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060015, Jan. 2024, https://doi.org/10.1063/5.0197361

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.