Abstract

The primary objective of this research is to modify the composition of SKN-18 by altering its components and the sequence of their incorporation, as well as to establish the optimal proportion of P803 in the formulation using locally available raw materials. Furthermore, the study examines the feasibility of utilizing secondary waste from local acetylene production as an additive, with the aim of enhancing vibration resistance and load-bearing capacity of the final product. The influence of this secondary waste on the vulcanization network was justified through scientific analysis of variations in the material’s physico-mechanical properties.

Highlights

- It was established that secondary acetylene fillers increase cross-link density, reduce heat build-up, and lower permanent deformation, resulting in improved dynamic endurance under cyclic loading conditions.

- The developed rubber compositions increase the service life of vibration-damping elements by up to 40% while enabling cost-effective production using locally available secondary raw materials.

- This study investigates NBR-based rubber compounds modified with secondary raw materials from acetylene production to improve mechanical, dynamic, and service-life properties of vibration-damping elements used in transport vehicles.

- For the first time, acetylene production by-products were proven to act as effective reinforcing fillers in NBR compounds, forming strong interfacial bonds that significantly enhance strength, fatigue resistance, and durability.

- A novel NBR-based rubber compound containing 40–60 phr of secondary acetylene production raw materials instead of carbon black P803 is proposed for vibration-damping rubber–metal and rubber–fabric components.

1. Introduction

Today, in the world, special importance is attached to increasing the service life of transport vehicles, increasing their productivity, creating and increasing the effectiveness of vibration damping elements that arise under the influence of vertical and horizontal forces in the main responsible nodes and details. Currently, in our country as well as in developed countries, it is required to conduct scientific research aimed at creating a new generation of transport vehicles and increasing the service life of components and parts. In this regard, great importance is attached to the creation of internal combustion engines of transport vehicles and the connecting element of the body frame, i.e. vibration-absorbing cushions, using local raw materials [1-3].

Fig. 1Bearings of locomotives

Fig. 2Car cushions

Engine mounts for internal combustion engines of locomotives, which are repaired at the JSC “Uztemiryolmashtamir” enterprise within the JSC “O’zbekiston temir yo’llari” (Uzbekistan Railways) system, are shown in Figs. 1 and 2. Depending on the construction and technical parameters of the internal combustion engine and frame connecting pads of transport vehicles, they have different appearance (Figs. 1 and 2).

It is necessary to increase the service life by making changes to the standard material composition in the creation of cushions that dampen the vibration of the internal combustion engines, which are the main energy source of the transport vehicles presented in Figs. 1 and 2, and connect them to the body frame.

2. Material and methods

The study focused on secondary raw materials intended for acetylene production, with the standard rubber compound formulated on the basis of nitrile butadiene rubber (NBR). Preparation of the rubber mixtures was carried out using RC-WW 150/330 laboratory mixing rolls (Rubicon, Germany). The Mooney viscosity of the compounds was determined with a Mooney MV 2000 viscometer (Alpha Technologies, UK). Stress relaxation tests were conducted on the same specimens directly after viscosity measurement, by rapidly stopping the rotor and recording the decrease in Mooney viscosity over time. Vulcanization kinetics of the rubber blends was analyzed using an ODR 2000 rheometer (Alpha Technologies, UK).

Technological and mechanical properties were evaluated in accordance with the corresponding GOST standards: 10201-2015 – stiffness and elastic recovery (Defoe method), 415-2015 – plasticity, 10722-2016 – Mooney viscosity (ML 4-373 K), 38.05244-91 – free sulfur content, 262-2013 – tear resistance, 263-1973 – Shore A hardness, 270-2015 – tensile strength and elastic properties, SEV1217-78 – residual deformation under constant compression, 261-2014 – cyclic tensile testing at constant strain, 2048-2015 – heat buildup, residual deformation, and fatigue endurance under repeated compression, and 6950-2013 – rebound resilience measured using a Schob-type device.

3. Results and discussion

For the purposes of this study, the standard SKN-18 composition based on butadiene-nitrile rubber was chosen (Table 1). The primary objective was to substitute its components with locally sourced raw materials

Table 1Butadiene-nitrile rubber-based SKN-18 standard composition of mixing sequence and amount of ingredients

Name of rubber and ingredients | Amount of rubber and ingredients, wt.unit | |

Standard composition | Recommended composition | |

Sulfur | 2.0 | 2.0 |

Zinc oxide | 5.0 | 5.0 |

Mercaptobenzthiazole | 1.5 | 1.5 |

Carbon P803 | 20, 40, 60 | – |

Recycled raw materials acetylene production (SRMAP) | – | 20, 40, 60 |

Stearic acid | 1.5 | 1.5 |

Dibutyl phthalate (DBF) | 5, 10, 15 | 5, 10, 15 |

In this study, the composition of rubber technical materials was developed on a theoretical and experimental basis. The amount of each component used in the composition was analyzed and determined as follows (wt. %).

The purpose of the research is to analyze the influence of the amount of various components on the physicochemical and mechanical properties of rubber products. Through this composition, the hardening process, elasticity, strength, and production capacity of the rubber material are assessed on a scientific basis.

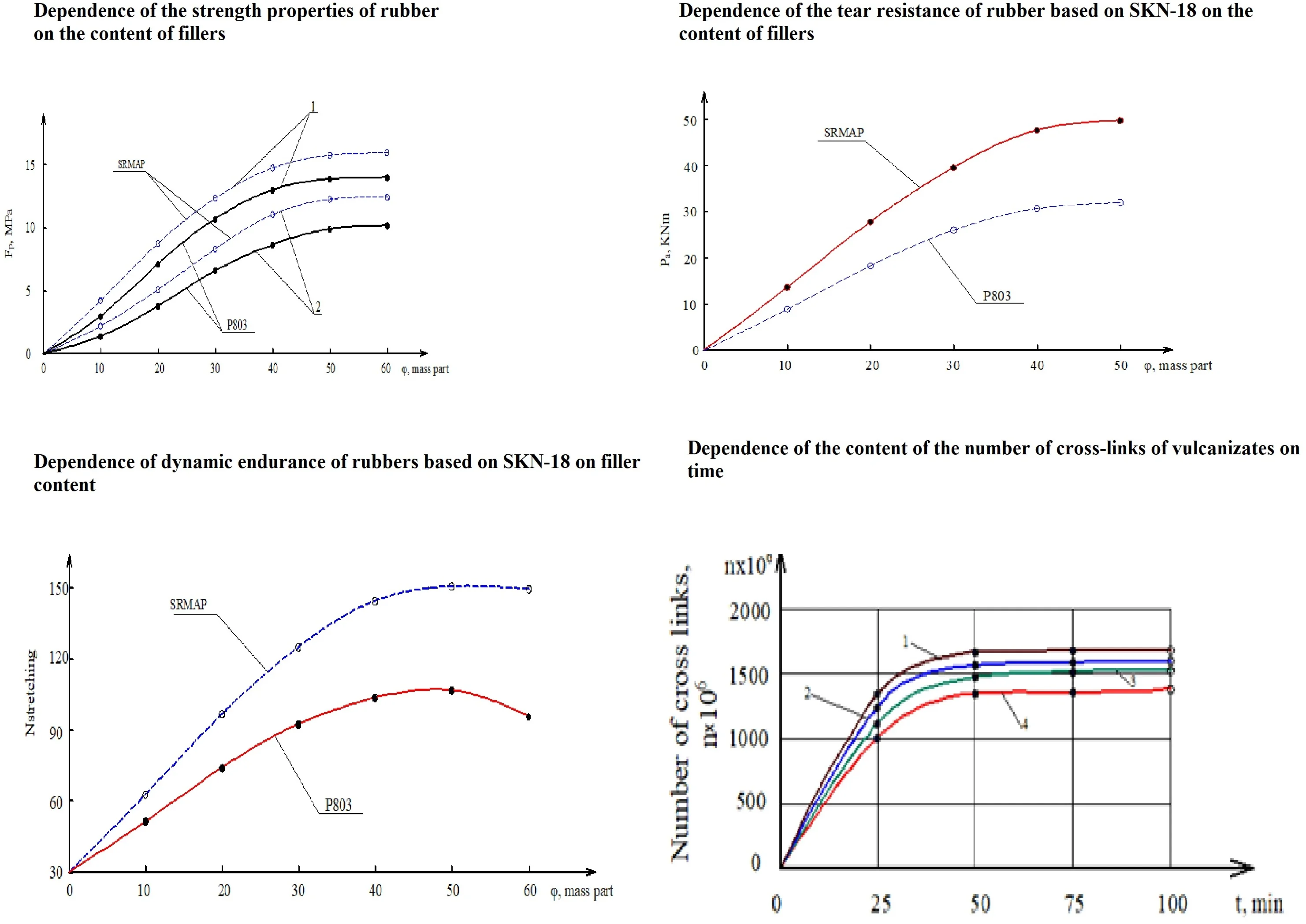

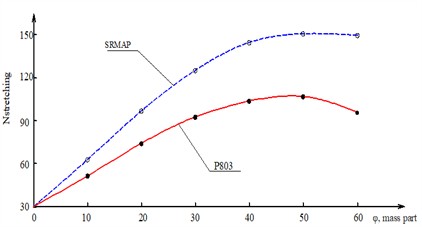

In this study, the effect of secondary raw materials from acetylene production (SRMAP) on the physical and mechanical performance of composite materials was investigated, with particular focus on the elastic and strength characteristics of filled rubbers. The results showed that incorporating SRMAP into vulcanizates leads to a higher tensile strength () compared to rubbers filled with carbon black P803 [4-6].

For instance, when 40 phr of SRMAP and P803 were introduced into elastomeric systems based on SKN-18 and SKN-40, the obtained Fp values were 12.9 and 10.7 MPa, and 13.4 and 12.6 MPa, respectively. The improvement in tensile strength with SRMAP can be explained by the oligomeric coating present on the surface of its carbon particles, which enhances the interaction between the rubber matrix and the filler (Fig. 3).

Fig. 3Dependence of the strength properties of rubber on the content of fillers

a) Tensile strength

b) Elongation at break

c) Permanent elongation at break

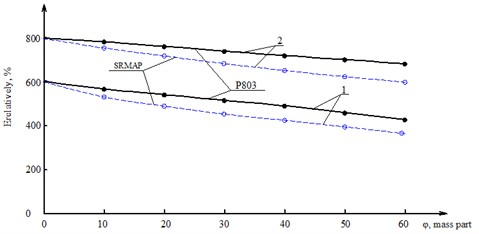

The figure illustrates the influence of filler content on the mechanical properties of rubber compositions. Tensile strength (a) is determined by the elasticity and viscosity of the rubber, while elongation at break (b) serves as a key indicator of the material’s overall elasticity. Residual elongation (c) reflects the plasticity of the rubber and its ability to recover following curing. As shown in the figure, variations in filler content significantly affect both tensile strength and elasticity, highlighting the critical role of fillers in optimizing the formulation and performance of rubber compositions. It has been shown that incorporating secondary raw materials from acetylene production into nitrile–butadiene rubber (NBR) compounds significantly enhances the tear strength of the material (Fig. 4) when compared with conventional P803 carbon black fillers. The effect is most pronounced at loadings of 40-60 phr (parts per hundred rubber), where tear resistance improves markedly from 42.6 to 74.2 kN/m [7-8].

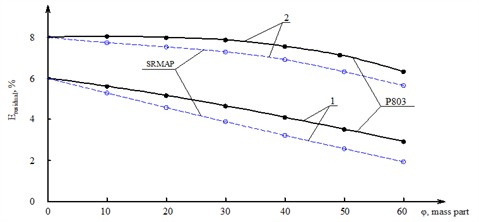

Investigations into the effect of acetylene production by-products on the dynamic behavior of rubber under cyclic compression (Fig. 5) revealed that their inclusion in NBR-based elastomeric formulations leads to reduced heat build-up and lower permanent deformation. This, in turn, influences the fatigue life of rubber under repeated tensile loading (Nras). The endurance reaches its maximum value at filler concentrations of 40-60 phr.

Fig. 4Dependence of the tear resistance of rubber based on SKN-18 on the content of fillers

Fig. 5Dependence of dynamic endurance of rubbers based on SKN-18 on filler content

Fig. 4 shows how the tear resistance of rubber compositions based on SKN-18 varies depending on the amount and type of various fillers. Tear resistance is an important mechanical indicator that assesses the ability of rubber to resist cutting and tearing along its length or under load. As can be seen from the figure, with an increase in the amount of fillers, significant changes are observed in the tear resistance of SKN-18 rubber. Fillers strengthen the internal structure of rubber, increasing its tensile strength. At the same time, an excess of fillers or an incorrectly chosen type can negatively affect elasticity and lead to material defects. These results indicate the importance of optimizing the type and amount of fillers in the development of rubber compositions.

This Fig. 5 shows how dynamic endurance changes when various amounts and types of fillers are added to SKN-18 rubber. Dynamic durability is an important indicator for assessing the stability and test resistance of rubber under repeated loading and continuous movement.

As can be seen from the figure, the amount and type of fillers significantly affect the dynamic resistance of SKN-18 rubber. The amount and correct type of target fillers increase the ability of rubber to recover under long-term loading and reduce fatigue of the material. These results are important for optimizing rubber compositions under various production and operating conditions.

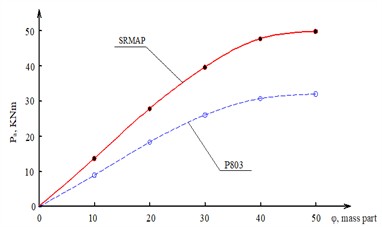

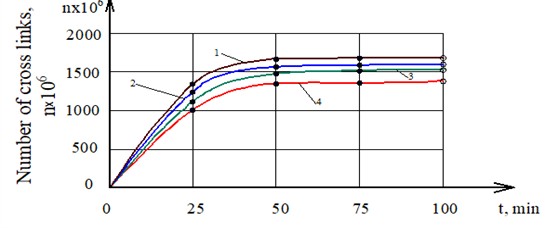

The effect of secondary raw materials derived from acetylene production on the electrophysical and radiation characteristics of elastomeric compositions has been investigated. The findings show that vulcanizates incorporating these secondary materials exhibit higher values of volume electrical resistivity 13-16) and enhanced dielectric strength (5×106-2×107 Ω/m) (see Fig. 6).

Fig. 6 shows how the number of cross-linking in rubber vulcanizers changes over time in rubber compositions of different compositions. The following compositions were used in the study: 20 (2) and 40 (2) parts, as well as 20 (4) and 40 (4) parts of filler P803 were added to 100 parts of base rubber. As can be seen from the figure, during the vulcanization process, a rapid increase in the number of transverse bonds is observed over time. The amount and type of filler significantly influence this process: compositions with a higher amount of fillers harden faster, and the number of transverse bonds is also higher. Such connections strengthen the mechanical and elastic properties of the rubber, but a very high amount of filler can negatively affect elasticity. These data are important for controlling the vulcanization process of rubber compositions and choosing optimal compositions. The number of transverse connections and their change over time serve as the main indicator in assessing the properties of mechanical stability, elasticity, and ductility.

The improved performance is primarily explained by the fact that the coated surface layer on particles derived from acetylene production waste isolates the particles from one another. This leads to the creation of conductive soot structures and enhances their protective function. Such effects are associated with the development of an extended interphase boundary characterized by strong, high-energy bonds.

Consequently, the potential and practical value of using secondary raw materials from acetylene production in rubber compound formulations for specialized rubber products have been confirmed [9-12]. Investigations into their dynamic behavior revealed advantages over currently applied materials, including a 40 % increase in service life. Incorporating acetylene production by-products (BPAP) into product compositions provided rubber materials with novel properties suitable for challenging operating environments [13-17].

Fig. 6Dependence of the content of the number of cross-links of vulcanizates on time: 20 (2), 40 (2) and P803 20 (4) and 40 (4) parts by weight per 100 parts by weight rubber

Table 2Performance properties of rubber products containing 40 parts by weight. secondary raw materials production of acetylene instead of carbon black P803 rubber compounds based on nitrile butadiene rubbers

Indicators | Rubber textile products | Rubber-metal products | ||

According to GOST | Recommended composition | According to GOST | Recommended composition | |

Plasticity (), conventional units | мах. 0.2 | 0.2 | 0.3-0.4 | 0.33 |

Density (), kg/m3 | 2400-1700 | 2550 | 2200-2400 | 2350 |

Tensile strength (), MPa | 22-25 | 27.3 | min. 21 | 23.3 |

Elongation at break (), % | – | – | 200-300 | 200 |

Residual elongation at break (), % | 13-15 | 15 | 12-16 | 14 |

Relative viscosity, kJ/f | 3-12 | 7 | – | – |

Hardness according to TIR, conventional units | 95-100 | 99 | 40-50 | 44 |

Remaining in heat, % | 0.2-0.6 min. 0.8 | 0.55 0.97 | min. 0.84 min. 0.95 | 0.96 0.99 |

Wear by severity, mg/hour | min. 0.9 | 0.98 | min. 0.78 | 0.97 |

Acid resistance coefficient, con.units | min.0.7 | 0.94 | min. 0.70 | 0.95 |

Alkali resistance coefficient, con. units | min 0.75 | 0.92 | min. 0.70 | 0.91 |

Oil resistance coefficient, con.units | min. 0.60 | 0.86 | min. 0.60 | 0.84 |

The findings also demonstrate the feasibility of producing rubber-fabric and rubber-metal components for mechanical engineering applications under demanding conditions. The resulting products meet the necessary performance standards, consistent with previously reported data on the influence of 12 % BPAP-containing oligomers on elastomer properties [18-20].

In conclusion, it was established that the addition of these materials makes it possible to develop elastomeric compounds intended for specific applications. When used in combination within rubber mixtures during vulcanization, they exhibit a synergistic effect, leading to improved properties of the resulting vulcanizates (see Table 2).

Experimental investigations were conducted in the laboratory of the “First Rubber Technician” plant in Angren to evaluate the physical, mechanical, thermal, and chemical properties of various rubber compositions. Mechanical properties were assessed using an Instron 5969 universal testing machine, while hardness measurements were performed with a Shore A/D hardness tester. Thermal behavior was characterized using a TGA/DSC thermal analyzer, and chemical resistance was evaluated with specialized laboratory stations. The results demonstrate that the mechanical and chemical characteristics of rubber compositions are strongly dependent on their formulation and the concentrations of individual additives. In particular, the content of carbon P803 and SRMAP significantly affects tensile strength and viscosity, whereas dibutyl phthalate (DBF) and stearic acid are critical for controlling the curing process and optimizing the elasticity of the rubber. These findings provide valuable insights for the design and optimization of rubber materials with tailored performance characteristics for industrial applications.

4. Conclusions

It has been established that the surface layer formed on particles obtained from secondary acetylene production acts as an insulating barrier for individual particles, thereby facilitating the formation of conductive carbon structures and enhancing their protective functionality. This behavior is attributed to the development of an extensive interphase boundary characterized by strong energy interactions. Experimental studies have demonstrated the feasibility and potential of incorporating secondary raw materials from acetylene production into rubber compound formulations intended for specialized rubber products. Evaluation of their dynamic properties revealed significant improvements compared to conventional materials, including an extension of service life by up to 40 %. The utilization of elastomeric compositions derived as by-products of acetylene manufacturing enables the production of rubber items with novel mechanical and functional properties, making them well-suited for demanding operational conditions.

References

-

E. Teshabayeva, A. Ibadullayev, U. Chorshanbiyev, and M. Vapayev, “Modification of composite elastomeric materials for polyfunctional purposes,” in Asia-Pacific Conference on Applied Mathematics and Statistics, Vol. 2471, p. 030082, Jan. 2022, https://doi.org/10.1063/5.0090317

-

A. Ibadullaev, E. Teshabayeva, B. Kakharov, and A. Babaev, “Elastomeric materials based on new ingredients,” in Asia-Pacific Conference on Applied Mathematics and Statistics, Vol. 2471, p. 030021, Jan. 2022, https://doi.org/10.1063/5.0089726

-

A. Ibadullaev, D. Nigmatova, and E. Teshabaeva, “Radiation resistance of filled elastomer compositions,” in IOP Conference Series: Earth and Environmental Science, Vol. 808, No. 1, p. 012043, Jul. 2021, https://doi.org/10.1088/1755-1315/808/1/012043

-

A. Ibadullayev, E. Teshabayeva, B. Kakharov, and D. Nigmatova, “Composite elastomeric materials filled with modified mineral fillers,” in E3S Web of Conferences, Vol. 264, p. 05006, Jun. 2021, https://doi.org/10.1051/e3sconf/202126405006

-

B. B. Yoqubov, A. Ibadullaev, D. Q. Yoqubova, and E. U. Teshabaeva, “Prospects and development of research of composite elastomer materials,” Journal of Siberian Federal University. Chemistry, Vol. 14, No. 4, pp. 464–476, Dec. 2021, https://doi.org/10.17516/1998-2836-0255

-

E. Teshabayeva, S. Axmadjanov, S. Turobdjonov, and M. Tursunaliev, “Properties of elastomer compositions filled with a multifunctional filler,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, No. 1, p. 060007, Jan. 2024, https://doi.org/10.1063/5.0197536

-

D. Ponnamma, K. K. Sadasivuni, Y. Grohens, Q. Guo, and S. Thomas, “Carbon nanotube based elastomer composites – an approach towards multifunctional materials,” Journal of Materials Chemistry C, Vol. 2, No. 40, pp. 8446–8485, Jan. 2014, https://doi.org/10.1039/c4tc01037j

-

U. A. Ziyamukhamedova, T. O. Almataev, A. B. Dzhumabaev, and L. Y. Bakirov, “Improvement of methods and means of testing non-conventional tribosystems,” in Asia-Pacific Conference on Applied Mathematics and Statistics, Vol. 2471, No. 1, p. 030031, Jan. 2022, https://doi.org/10.1063/5.0089984

-

F. Nurkulov, U. Ziyamukhamedova, E. Rakhmatov, and J. Nafasov, “Slowing down the corrosion of metal structures using polymeric materials,” in E3S Web of Conferences, Vol. 264, p. 02055, Jun. 2021, https://doi.org/10.1051/e3sconf/202126402055

-

U. Ziyamukhamedova, A. Djumabaev, B. Urinov, and T. Almatayev, “Features of structural adaptability of polymer composite coatings,” in E3S Web of Conferences, Vol. 264, p. 05011, Jun. 2021, https://doi.org/10.1051/e3sconf/202126405011

-

U. Ziyamukhamedova, E. Rakhmatov, and J. Nafasov, “Optimization of the composition and properties of heterocomposite materials for coatings obtained by the activation-heliotechnological method,” in Journal of Physics: Conference Series, Vol. 1889, No. 2, p. 022056, Apr. 2021, https://doi.org/10.1088/1742-6596/1889/2/022056

-

G. Miradullaeva, E. Rakhmatov, O. Bozorov, U. Ziyamukhamedova, and B. Shodiev, “Mathematical modeling of rheological properties during structure formation of heterocomposite potting materials and coatings and their application,” in Lecture Notes in Civil Engineering, pp. 346–355, Mar. 2021, https://doi.org/10.1007/978-3-030-72404-7_34

-

S. Mamayev, A. Ibadullayev, E. Teshabayeva, M. Tursunaliev, and M.-A. Ikromov, “Creation of elastomer-based compositions with special characteristics for the wheel-engine block of thermal locomotives,” in E3S Web of Conferences, Vol. 452, p. 04013, Nov. 2023, https://doi.org/10.1051/e3sconf/202345204013

-

S. Mamayev, A. Ibadullayev, D. Nigmatova, E. Teshabayeva, and M. Tursunaliev, “Creation of special compositions based on butadiene-nitrile elastomers for diesels,” in E3S Web of Conferences, Vol. 401, p. 03028, Jul. 2023, https://doi.org/10.1051/e3sconf/202340103028

-

S. Fayzibayev, O. Ignotenko, T. Urazbaev, S. Mamayev, and J. Nafasov, “Development of technology for formation of AI-B-N system joints under influence of high pressures and temperatures to create composite tool material,” in E3S Web of Conferences, Vol. 401, p. 05016, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105016

-

T. Urazbayev, N. Tursunov, and T. Tursunov, “Steel modification modes for improving the cast parts quality of the rolling stock couplers,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060015, Jan. 2024, https://doi.org/10.1063/5.0197361

-

T. Tursunov, N. Tursunov, and T. Urazbayev, “Investigation of heat exchange processes in the lining of induction furnaces,” in E3S Web of Conferences, Vol. 401, p. 05029, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105029

-

N. Y. Makhkamov, G. U. Yusupov, T. Tursunov, and K. Djalilov, “Properties of metal-based and nonmetal-based composite materials: A brief review,” in IOP Conference Series: Earth and Environmental Science, Vol. 614, No. 1, p. 012068, Dec. 2020, https://doi.org/10.1088/1755-1315/614/1/012068

-

S. Mamaev, A. Anna, S. Tursunov, D. Nigmatova, and T. Tursunov, “Mathematical modeling of torsional vibrations of the wheel-motor unit of mains diesel locomotive UZTE16M,” in E3S Web of Conferences, Vol. 401, p. 05014, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105014

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.