Abstract

The technology of creating a bimetallic compound steel 20GL – a hard alloy of the Fe-Cr-C system, formed during the casting process by melting the carbide powder of the PG-C27 alloy due to the heat of the crystallizing melt, is investigated in this article. The resulting bimetallic compound on the working surfaces of the crawler makes it possible to increase the abrasive wear resistance. The production of bimetallic castings in the casting process involves the complete or partial penetration of inserts made of wear-resistant material placed on the working surface of the casting during its crystallization. Upon contact with the melt, the melt penetrates and partially melts the particles of the inserts to form a single bimetallic composition. Based on the above and in order to increase the durability and wear resistance of cast parts of road construction and agricultural machinery, we have developed a technology for bimetallic steel - hard alloy PG-C27 type “sormite”. The obtained bimetallic compound makes it possible to increase the abrasive wear resistance on the working surfaces of the crawler.

Highlights

- The wear-resistant coating is created directly upon receipt of castings.

- A technology has been developed for the production of a bimetallic compound steel 20GL – a hard alloy of the Fe-Cr-C system, which is formed during the casting process by melting PG-C27 alloy powder due to the heat of the crystallizing melt.

- The created bimetallic compound on the working surfaces of the crawler engine operating under conditions of intense abrasive wear makes it possible to increase their wear resistance and service life.

- In order to increase the durability and wear resistance of cast parts of road construction and agricultural machinery, we have developed a technology for bimetallic steel - hard alloy PG-C27 type "sormite".

- The obtained bimetallic compound makes it possible to increase the abrasive wear resistance on the working surfaces of the crawler.

1. Introduction

The competitive ability of modern road construction and agricultural machinery largely depends on the performance and reliability of the parts, assemblies and mechanisms used. The effectiveness of a particular part or assembly largely depends on technological interruptions, which are most associated with wear. The main problems faced by economic enterprises in the process of operation include: a small resource of parts, assemblies and mechanisms; large downtime of road construction and agricultural machinery associated with planned and emergency repairs; reduced productivity of machines and aggregates; increased consumption of spare parts. These problems lead to a decrease in the technical and economic indicators of economic enterprises and, as a result, increases the cost of the service provided (i.e., the development of soil or the performance of one or another road construction work). Therefore, increasing the wear resistance and durability of machines and components is an important task of science and production. One of the main problems associated with the insufficient service life of agricultural and road construction machinery parts are the abrasive wear of component parts. Its consequences can be both directly and indirectly related to stopping the car. For example, when operating excavators and bulldozers, wear directly affects the decrease in productivity of these machines due to intensive wear and reshaping of parts.

2. Materials and methods

The concept of bimetal is understood as a composite material consisting of two or more different layers of metals or their alloys [1]-[4]. Currently, the use of bimetallic compounds is becoming increasingly used in the production and restoration of parts in many industries due to the addition of components and machines such properties as: strength, wear resistance, heat resistance, corrosion resistance, manufacturability, etc.

According to their intended purpose, bimetallic materials are divided into three groups: wear-resistant, corrosion-resistant and antifriction. Bimetals also differ in the chemical composition of the layers, in the shape of the products, in the method of production, in the geometric parameters of the layers, etc.

The authors of the works [2] claim that when obtaining bimetallic compounds in the contact zone of the components, there can be three aggregate states of the components: solid with solid, solid with liquid and liquid with liquid.

It is noted in [1]-[5] that bimetals can be classified on the basis of the presence or absence of plastic deformation in the joint zones. The most widespread method of creating bimetals using plastic deformation, i.e.: pressing, rolling, explosion welding, etc. Processes such as casting, welding, surfacing, and spraying are characteristic of the method without plastic deformation. These claim a wide range of methods and technological techniques for the manufacture of bimetallic products.

It is stated in [6] that the main factor in the production of bimetals, in the case of stainless steel and gray cast iron, is the mass transfer of carbon from one material to another, in contrast to the diffusion of Fe, Cr or Ni. When two-layer castings of aluminum and copper are obtained by casting onto a solid billet, Al2Cu intermetallides are formed at the junction boundary, which greatly reduce the strength of the connection of the layers [7].

There are also known methods for obtaining a bimetallic compound of two metals and alloys by centrifugal casting [8], [9]. At the same time, the absence of impurities and metal oxides at their junction is very important to create a strong metallurgical bond between the two metals [9].

When obtaining a bimetallic compound, welding has recently become widespread [10]. Currently, such methods as fusion welding, pressure welding, arc welding, diffusion welding, explosion welding and others are used among welding methods [11]-[14].

In addition, laser welding is known [15], which can be considered as a promising method for obtaining bimetallic compounds, since the technological process is easily automated and allows joining metals of various combinations in a wide range of thicknesses. However, the mechanical properties of such welding are low, so heat treatment is used if necessary.

Now, increasing the wear resistance of the working surfaces of parts by surfacing and spraying is widely used in mechanical engineering [16]-[18]. However, the high labor and energy intensity of the surfacing and spraying processes, the poor surface quality of the coating, as well as the possibility of formation of gas shells, pores, slag inclusions, cracks and other defects reduce the efficiency and widespread use of these technologies.

Evaluating these methods in general, it should be noted that the common disadvantages are, firstly, the need to organize and implement a complete independent cycle of the technological process of forming a wear-resistant coating, and secondly, the depth of the hardened zone in most variants, except for surfacing, do not meet the requirements. In this regard, the technology of obtaining wear-resistant bimetallic coatings directly in the process of producing castings is considered the most preferable [19], [24], [25].

The production of bimetallic castings in the casting process involves the complete or partial penetration of inserts made of wear-resistant material placed on the working surface of the casting during its crystallization [20]. Upon contact with the melt, the melt penetrates and partially melts the particles of the inserts to form a single bimetallic composition.

Several factors have been established that directly affect the degree of abrasive wear:

– Impact velocity.

– Attack angle.

– The abrasive particles size.

– The moisture content in the soil.

– Solid inclusions.

– Abrasive particles concentration.

– The hardness ratio of abrasive particles and the working part of the part.

The wear rate of the parts of the tracked running gear when the excavator is operating with the brakes on and at the same time the development of the soil is 1.4 times greater than when the excavator is moving. This shows that the working conditions of the parts in this mode are basic, especially since 90 % of the working time is spent on work, and 10 % on movement.

The temperature conditions of agricultural and road construction machinery in the Republic of Uzbekistan vary widely from +45 ℃ to +55 ℃ in the southern regions in summer, up to –30 ℃ in the northern regions in winter, summers are dry, hot, without precipitation. Researches conducted on working machines have shown that the temperature of individual components and parts can reach 85-90 ℃ [21], [24], [27].

A detailed study of the worn links of the crawler movers of excavators made of 20GL steel revealed the following:

– For 1000 hours of excavator operation, the treadmill wear of the caterpillar engine links is more than 5 mm.

– The wear on the working surface of the links of the crawler is unevenly distributed, i.e. the middle of the treadmill is more worn and plastically deformed than that of the comb and edge.

To ensure the optimal service life of the crawler engine of the excavator chassis, the wear resistance should be increased within 3.0-5.0 times [22], [23].

25GL steel is used as the material for the link. In order to increase the wear resistance of the caterpillar link, the well-known PG-C27 sormite type hard alloys (GOST 21448-78) were used as a coating (Table 1). The bimetallic compound was formed directly during the formation of castings. Steel was smelted in an electric arc furnace DSP-1.5, acid lining, spill temperature 1570-1600 ℃.

The macro- and microstructure of coatings, base metal and transition layers were researched on polished sections cut from the track link.

The macrostructure of bimetal using MBS-2. The microstructure was researched using an OLYMPUS BXM microscope. Microhardness was determined using the MICRO-VICKERS CV 400-AAT device. A 4 % solution of nitric acid in ethyl alcohol and a saturated solution of FeCI in HCl were used as an etchant.

Table 1The composition of PG-C27 type “sormite” hard alloy according to GOST 21448-78

The components percentage, % | |||||||

Base | C | Cr | Si | Mn | Ni | W | Mo |

Fe | 3.3-4.5 | 25-28 | 1.0-2.0 | 0.8-1.5 | 1.5-2.0 | 0.2-0.4 | 0.08-0.15 |

The chemical composition of the bimetallic coating was researched using microrentgenospectral analysis and secondary mass ion spectrometry.

3. Results and discussion

We propose the creation of a wear-resistant coating on the working surfaces of an excavator crawler mover based on a powdered hard alloy of the Fe-Cr-C system of the “sormite” PG-C27 type (GOST 21448-75) for the development of technical solutions to increase the resistance to abrasive wear of the links of crawler movers of excavators working on agriculture and irrigation systems. The wear-resistant coating is created directly upon receipt of castings.

To do this, two options for applying powdered hard alloy to the mold were investigated:

– Applying a treadmill shape with a powdered hard alloy of the “sormite” type with a brush or spatula.

– Placement of a pre-made insert made of powdered “sormite” directly on the foundry model of the crawler, in the treadmill area (Fig. 1), followed by molding in a sandy-clay form.

The conducted research has shown that the second option of applying powdered hard alloy to the mold has several advantages:

– Firstly, the process of manufacturing inserts from powdered “sormite” can be automated.

– Secondly, the insertion operation guarantees the production of high-quality bimetallic casting.

Therefore, in further research, the second option was taken as a basis – the production of bimetallic castings.

The technology of manufacturing inserts includes the following operations: preparation of a coated mixture and manufacture of inserts using the “hot box” method.

The cladding of a powdered hard alloy of the PG-C27 brand (GOST 21448-75) was carried out in a paddle mixer.

Phenolic powdered binder resin of the SF-011L (OST 6-11-441-78) type was introduced as cladding additives in an amount of 3-5 %.

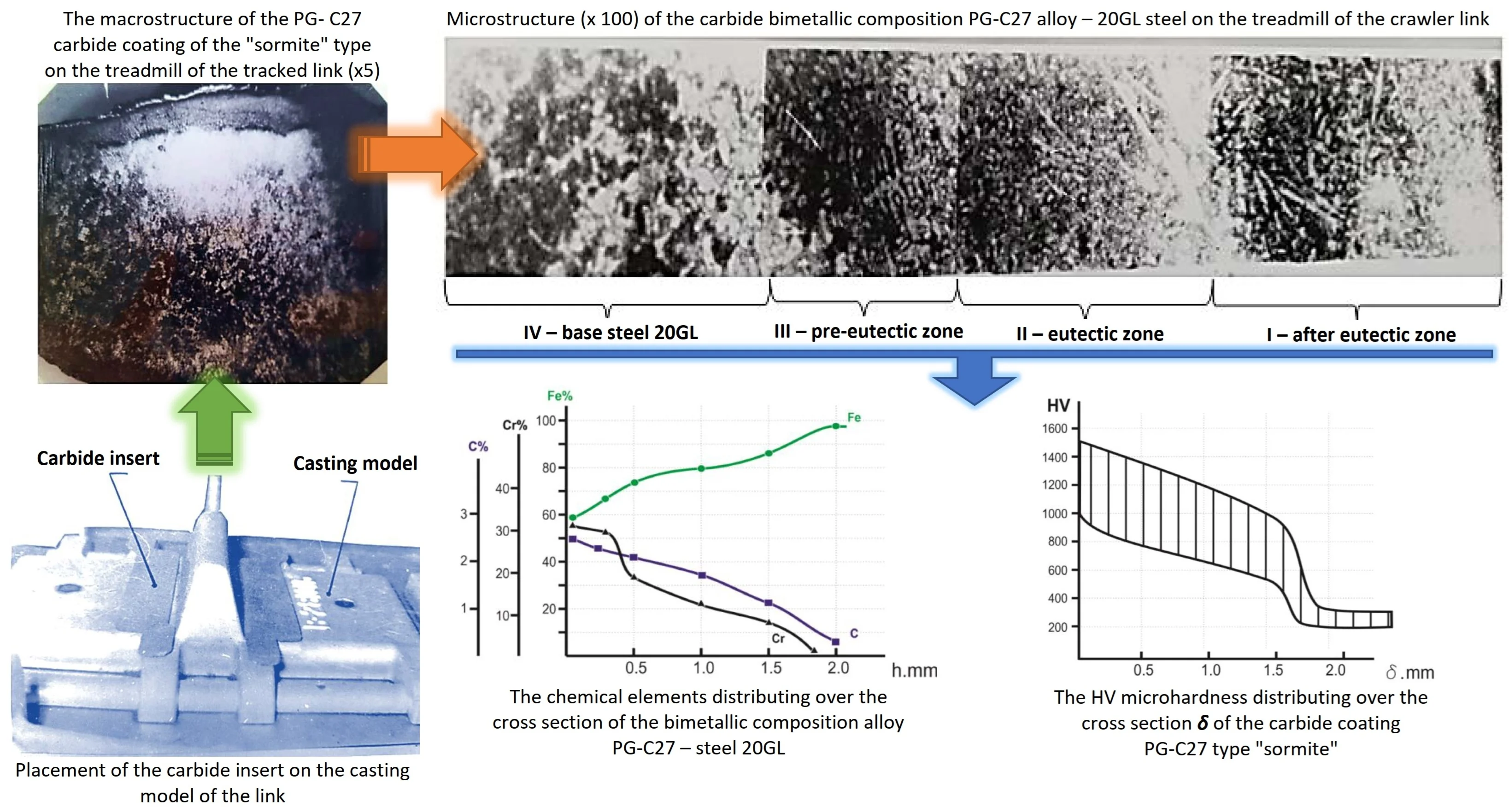

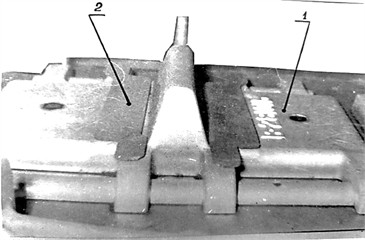

Fig. 1Placement of the carbide insert on the casting model of the link: 1 – casting model; 2 – carbide insert

Based on the results of the experiments, the best method of “hot” cladding was established, which was performed at a mixing temperature of 130-140 ℃ and required a minimum amount of binder.

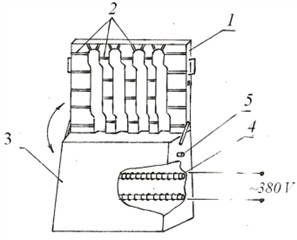

The inserts were manufactured on a sandblasting machine using a specially designed and manufactured “hot” box (Fig. 2).

Fig. 2Placement of the carbide insert on the casting model of the link

a) Open position: 1 – lid; 2 – ventilation ducts; 3 – drawer body; 4 –heater; 5 – thermocouple; 6 – hook

b) Working position

The installation of ready-made carbide inserts into the mold was carried out with the help of clamps, by installing their casting model, followed by filling with a molding compound. The displacement of the inserts during the sealing of the mold was prevented by two clamps with a diameter of 1.5 mm, installed according to the dimensions of the insert with a height of 2.0 mm above the surface level of the model.

The research showed that the lower position of the inserts in the mold is convenient from the position of placing the inserts during the assembly of the flasks and when pouring the melt. However, gas pores form in the coating due to the difficulty of removing gases. Therefore, in the future, only the upper position of the inserts in the molds was used, in addition, it turned out that the inserts in the mold were firmly fixed.

During the pouring of liquid steel 20GL (GOST 977-88) into the mold, there was an interaction between the solidifying base of the casting and the carbide composition PG-C27 of the “sormite” type. As a result, the carbide composition PG-C27 of the “sormite” type undergoes the following stages:

– Melting of the carbide powder due to the heat released from the crystallizing metal.

– Solidification of a hard alloy, which is formed between a sandy-clay mold, and an already hardened steel casting.

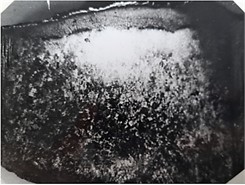

Macrostructural analysis has shown that a wear-resistant, durable, relatively even rough bimetallic coating with a thickness of 1.5 mm to 2.0 mm is formed on the treadmill of the crawler (Fig. 3).

Fig. 3The macrostructure of the PG-27C carbide coating of the “sormite” type on the treadmill of the tracked link (x5)

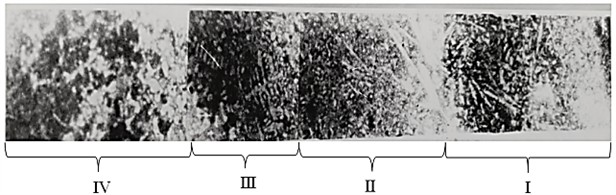

The microstructure of the bimetallic compound is a combination of a carbide coating with a dendrite structure characteristic of “sormite” type alloys and a ferrite-pearlite structure of pre-eutectoid steel, which is the bearing base of the composition (Fig. 4).

Fig. 4Microstructure of the carbide bimetallic composition PG-C27 alloy – 20GL steel on the treadmill of the crawler link: I – after eutectic zone; II – eutectic zone; III – pre-eutectic zone; IV – base steel 20GL (x 100)

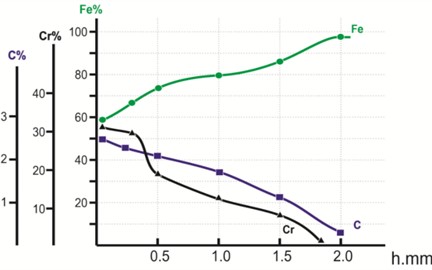

The chemical composition of the carbide coating was studied using microrentgenospectral analysis for iron and chromium, and for carbon using secondary mass ion spectrometry at the SMIS device, the results of which are shown in Fig. 5.

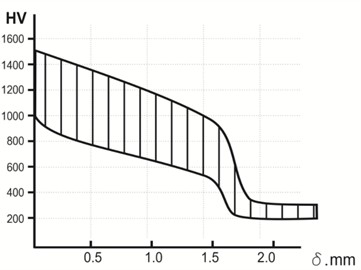

Microhardness researches by the cross section of coatings have shown (Fig. 6) that the microhardness of the carbide coating varies from 1000 to 1500 HV. The maximum hardness value falls on the surface area, the minimum on the area of connection of the coating with the substrate. The decrease in the microhardness of the coating occurs smoothly, and a sharp drop in microhardness is observed during the transition to the base.

A layered phase analysis was performed on the DRON-2.0 X-ray machine using iron Fe radiation in 0.5 mm increments. The results of the layered phase analysis are shown in Table 2.

Fig. 5The chemical elements distributing over the cross section of the bimetallic composition alloy PG-C27 – steel 20GL

Fig. 6The HV microhardness distributing over the cross section δ of the carbide coating PG-C27 type “sormite”

Table 2Phase distribution over the cross section of the carbide composition PG-C27 – steel 20GL

Coating depth, mm | Amount of phases, in % | ||

-Fe | Fe3C | Cr3C2 | |

0 | 53-57 | 12-14 | 29-32 |

0.5 | 68-71 | 9-11 | 18-20 |

1.0 | 75-78 | 10-12 | 12-14 |

1.5 | 80-84 | 8-10 | 6-8 |

2.0 | 96-97 | 2-4 | – |

4. Conclusions

Thus, a technology has been developed for the production of a bimetallic compound steel 20GL – a hard alloy of the Fe-Cr-C system, which is formed during the casting process by melting PG-C27 alloy powder due to the heat of the crystallizing melt. The created bimetallic compound on the working surfaces of the crawler engine operating under conditions of intense abrasive wear makes it possible to increase their wear resistance and service life.

In order to increase the durability and wear resistance of cast parts of road construction and agricultural machinery, we have developed a technology for bimetallic steel - hard alloy PG-C27 type “sormite”. The obtained bimetallic compound makes it possible to increase the abrasive wear resistance on the working surfaces of the crawler.

References

-

V. O. Sklyar, Innovative and Resource-Saving Technologies in Metallurgy. A Study Guide. (in Russian), Donetsk: DonNTU, 2014.

-

M. I. Chepurko, V. Y. Ostrenko, and N. Y. Gluskin, Bimetallic Materials. (in Russian), Leningrad: Shipbuilding, 1984.

-

L. D. Sirotenko, E. S. Shlykov, and T. R. Ablyaz, “Application of bimetallic materials in mechanical engineering,” (in Russian), Modern Problems of Science and Education, No. 2, 2015.

-

V. K. Korol and M. S. Gindelhorn, Fundamentals of Technology for the Production of Multilayer Metals. (in Russian), Moscow: Metallurgy, 1970.

-

A. A. Bykov, “Bimetal production and applications,” Steel in Translation, Vol. 41, No. 9, pp. 778–786, Dec. 2011, https://doi.org/10.3103/s096709121109004x

-

T. Wróbel and J. Szajnar, “Bimetallic casting: ferritic stainless steel – grey cast iron,” Archives of Metallurgy and Materials, Vol. 60, No. 3, pp. 2361–2365, Sep. 2015, https://doi.org/10.1515/amm-2015-0385

-

Y. Hu, Y.-Q. Chen, L. Li, H.-D. Hu, and Z.-A. Zhu, “Microstructure and properties of Al/Cu bimetal in liquid-solid compound casting process,” Transactions of Nonferrous Metals Society of China, Vol. 26, No. 6, pp. 1555–1563, Jun. 2016, https://doi.org/10.1016/s1003-6326(16)64261-9

-

V. V. Shiryaev, O. A. Pelikan, I. O. Shinsky, D. V. Glushkov, and Y. N. Romanenko, “Technological features of the production of bimetallic (multilayer) castings of increased wear resistance,” (in Russian), Metal and Casting of Ukraine, No. 7-8, pp. 52–56, 2009.

-

J. Nazari, M. Yousefi, M. S. Amiri Kerahroodi, N. S. Bahrololoumi Mofrad, and S. H. Alavi Abhari, “Production of copper-aluminum bimetal by using centrifugal casting and evaluation of metal interface,” International Journal of Materials Lifetime, Vol. 1, No. 1, pp. 20–28, 2015.

-

B. E. Paton, “Selected works,” Paton Institute of the National Academy of Sciences of Ukraine, Kiev, 2008.

-

B. A. Grinberg, M. A. Ivanov, and V. V. Rybin, “Inhomogeneities of the interface during explosion welding,” Physics of Metals and Metallology, Vol. 113, No. 2, pp. 187–200, 2012.

-

A. Y. Malakhov, I. V. Saikov, and A. B. Pervukhin, “Features of pipe explosion welding according to the “reverse” scheme,” (in Russian), Bulletin of the Tambov University, Vol. 21, No. 3, pp. 1139–1140, 2016.

-

B. S. Zlobin, “Explosion welding of steel with aluminum,” Combustion, Explosion and Shock Waves, Vol. 38, No. 3, pp. 374–377, May 2002, https://doi.org/10.1023/a:1015674407898

-

M. Prazmowski, M. Najwer, H. Paul, and D. Andrzejewski, “Influence of explosive welding parameters on properties of bimetal Ti-carbon steel,” in MATEC Web of Conferences, Vol. 94, p. 02012, Jan. 2017, https://doi.org/10.1051/matecconf/20179402012

-

M. Schmidt and S. V. Kuryntsev, “Obtaining bimetallic blanks using laser welding with a weld seam,” Automatic Welding, No. 4, pp. 47–51, 2014.

-

I. A. Ryabtsev, I. A. Kondratiev, and E. F. Bookbinders, Surfacing, Technologies, Materials, Equipment. (in Russian), Kiev: E.O. Paton NPP of the National Academy of Sciences of Ukraine, 2015.

-

N. A. Sosnin, S. A. Ermakov, and P. A. Topolyansky, Plasma Technologies. Handbook for Engineers. (in Russian), St. Petersburg: Publishing House of the Polytechnic University, 2013.

-

D. H. Babaev, “Plasma surfacing, hardening and the choice of a method for restoring machine parts,” in Materials of the 6th International Scientific Conference, pp. 65–68, 2016.

-

N. X. Bekmurzaev, F. R. Norkhudjaev, and S. P. Alimukhamedov, “Development of the optimal composition of the alloying mixture for surface boration of cast parts,” ACADEMICIA: An International Multidisciplinary Research Journal, Vol. 12, No. 5, pp. 152–159, Jan. 2022, https://doi.org/10.5958/2249-7137.2022.00368.8

-

N. Bekmurzaev, F. Norkhudjaev, and S. Alimukhamedov, “Energy aspects of conjugated heterophase surfaces wear operating in a free abrasive medium,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060018, Jan. 2024, https://doi.org/10.1063/5.0197469

-

M. Rakhmatov, A. Riskulov, and K. Nurmetov, “Abrasive-resistant composite materials with specified functional characteristics based on thermoplastics,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030040, Jan. 2025, https://doi.org/10.1063/5.0266781

-

L. Kuchkorov, S. Alimukhamedov, N. Tursunov, and O. Toirov, “Effect of different additives on the physical and mechanical properties of liquid-glass core mixtures,” in E3S Web of Conferences, Vol. 365, p. 05009, Jan. 2023, https://doi.org/10.1051/e3sconf/202336505009

-

S. Z. Yunusov, S. N. Kenjayev, S. A. Makhmudova, and G. X. Islamova, “Full factorial experiment in research the parameters of a combined shaft of technological machines,” in E3S Web of Conferences, Vol. 401, p. 03043, Jul. 2023, https://doi.org/10.1051/e3sconf/202340103043

-

S. Z. Yunusov, S. A. Makhmudova, D. A. Kasimova, and M. M. Agzamov, “The influence of changes in technological loads on the deflection of the saw cylinder shaft of a linting machine,” Material and Mechanical Engineering Technology, pp. 8–13, 2025.

-

S. Mamayev, A. Ibadullayev, E. Teshabayeva, M. Tursunaliev, and M.-A. Ikromov, “Creation of elastomer-based compositions with special characteristics for the wheel-engine block of thermal locomotives,” in E3S Web of Conferences, Vol. 452, p. 04013, Nov. 2023, https://doi.org/10.1051/e3sconf/202345204013

-

S. Z. Yunusov, S. N. Kenjayev, and S. A. Makhmudova, “Shafts of technological machines with combined supports,” in E3S Web of Conferences, Vol. 401, p. 01059, Jul. 2023, https://doi.org/10.1051/e3sconf/202340101059

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.