Abstract

To clarify the impact of resin modifier fineness on the performance and interaction of modified asphalt, this study selects resin modifiers to prepare modified asphalts. The effects of the fineness parameters of resin modifiers on the road performance of modified asphalts are investigated. The segregation tests and Han curves are employed to analyze the influence of modifier on the compatibility of modified asphalt. The scanning electron microscopy is utilized to characterize the interaction between resin modifiers and asphalt. The results indicate that resin modifiers improve the high-temperature performance and deformation resistance of asphalt binder but lead to the adverse effect on low-temperature performance. Adjusting the particle size of the modifier could improve the modification effect of resin modifiers on asphalt binder.

Highlights

- The resin modifier improves both the high-temperature performance and deformation resistance of asphalt binder at ambient temperature, while adversely affecting its low-temperature performance.

- Larger modifier particles not only intensify the phase separation degree in modified asphalt systems but also induce phase separation phenomena at lower temperatures.

- The interface between 0.075mm modifier and base asphalt binder shows smooth and continuous bonding, with asphalt achieving excellent infiltration of the 0.075mm modifier.

1. Introduction

Asphalt has long faced challenges such as thermal deformation and aging, which significantly impair its durability and performance. Resin modifiers could enhance asphalt’s high-temperature stability and low-temperature crack resistance, improving its mechanical properties and anti-aging capabilities, thereby ensuring better long-term performance in transportation infrastructure. Resin modifiers exhibit excellent thermal stability, chemical resistance, and adhesion, optimizing the mechanical behavior. Studies indicate that resin modifiers could improve asphalt’s high-temperature performance by reducing its flowability and enhancing rutting resistance under elevated temperatures [1]. Additionally, they improve low-temperature crack resistance, mitigating the risk of brittle fracture in cold conditions. However, the particle size of resin modifiers plays a critical role in the performance of modified asphalt. Finer resin modifiers disperse more uniformly inside the asphalt matrix, thereby enhancing modification efficacy [2]. In contrast, coarser resin modifiers may form larger aggregates within the asphalt, reducing compatibility and adversely affecting mechanical performance and durability. Nevertheless, the precise relationship between resin modifier fineness and asphalt performance remains incompletely understood [3, 4]. Thus, investigating the influence of resin modifier particle size-particularly its effects on high-temperature stability, low-temperature crack resistance, and compatibility is crucial for optimizing the application of resin modifiers. Accordingly, this study selects resin modifiers to prepare modified asphalt, investigating the influence of modifier fineness on the high-temperature stability and low-temperature crack resistance of resin-modified asphalt. Furthermore, the effect of modifier particle size on the compatibility between the modifier and asphalt is analyzed, and the interaction behavior between resin modifiers of varying sizes and the asphalt binder is characterized.

2. Materials and methods

2.1. Materials and preparation

This study utilized 70# grade A base asphalt with a softening point of 47 °C, penetration of 6.7 mm, and ductility (10 °C) of 60 cm as the base material, with polyester-based resin serving as the primary asphalt modifier to prepare modified asphalt. The modifier’s key technical specifications are shown in Table 1, with three particle sizes (0.075 mm, 0.15 mm, and 0.3 mm) investigated at a fixed dosage of 6 % by asphalt mass. The modified asphalt was prepared through high-speed shear mixing (3500 rpm, 160 ℃ and 20 min), with the resulting samples designated as SPMA-756 (0.075 mm modifier, 6 % dosage), SPMA-156 (0.15 mm modifier, 6 % dosage), and SPMA-306 (0.3 mm modifier, 6 % dosage).

Table 1Technical performance indicators of resin modifier

Modifier | Solid content / % | Viscosity / cps | Tensile strength / MPa | Elongation /% |

SPUA | 81~85 | ≤ 800 | 28 | 375 |

2.2. Method

2.2.1. Pavement performance

The softening point test was initiated at 5 °C with a heating rate of 5 °C/min. The penetration test was conducted at 25 °C with a penetration duration of 5 seconds. The ductility test was performed at 15 °C using a tensile speed of 5 cm/min.

2.2.2. PG grading test

The performance grade (PG) testing was conducted in accordance with AASHTO M320-15 specifications. The applied strain and frequency were set at 12 % and 10 rad/s, respectively, with the testing temperature range spanning from 46 °C to 76 °C.

2.2.3. Segregation test

The test specimens were prepared according to the segregation test method specified in ASTM D7173, with the degree of modified asphalt segregation quantitatively evaluated by comparing the physical properties of samples taken from the top and bottom third-length positions of the specimen.

2.2.4. Han curve analysis

This study employed frequency sweep test data to construct Han plots for different modified asphalt specimens to evaluate their compatibility characteristics.

2.2.5. Scanning electron microscopy test

The specimens were subjected to gold sputtering treatment to stabilize imaging quality. The magnification range for microscopic characterization was set between 1,000× and 5,000×.

3. Results and discussion

3.1. Pavement performance

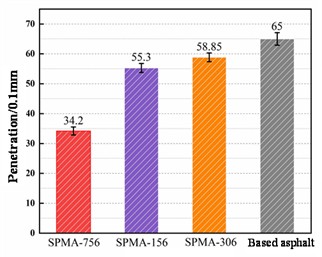

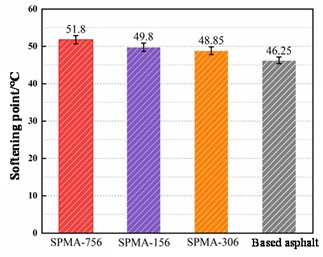

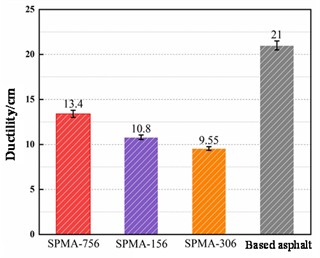

Fig. 1 presents the road performance of resin-modified asphalt binders with different modifier particle sizes. SPMA samples exhibited lower penetration values than the base asphalt binder, indicating that the resin modifier increased the binder’s viscosity. The softening points of SPMA samples were consistently higher than those of the base binder, demonstrating that reducing modifier particle size enhances the high-temperature performance of asphalt binders. However, the addition of modifiers adversely affected low-temperature performance.

Fig. 1Road performance test results modified asphalt with modifiers of different particle sizes

a) Penetration

b) Softening point

c) Ductility

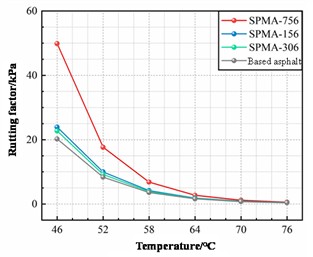

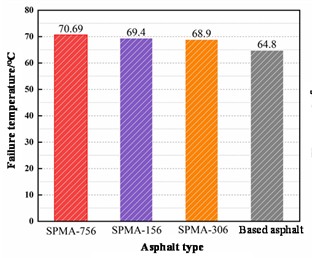

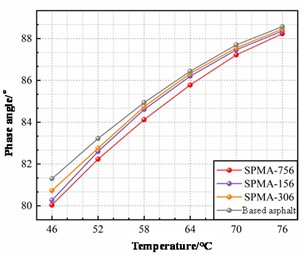

3.2. PG grading

Fig. 2 presents the rutting factor (/), phase angle (), and high-temperature failure temperatures of the asphalt binders at different temperatures. As anticipated, the incorporation of modifiers enhanced the / values of the asphalt binders, indicating improved rutting resistance. Compared to the base asphalt binder, SPMA-756, SPMA-156, and SPMA-306 demonstrated that failure temperature was increased by 9.1 %, 7.1 %, and 6.3 %, respectively. These results confirm that the resin modifiers enhance the high-temperature rutting resistance of asphalt binders effectively, with smaller modifier particles exhibiting more pronounced improvement effects.

Fig. 2PG grading test results of modified asphalt with modifiers of different particle sizes

a) Rutting factor

b) Failure temperature

c) Phase angle

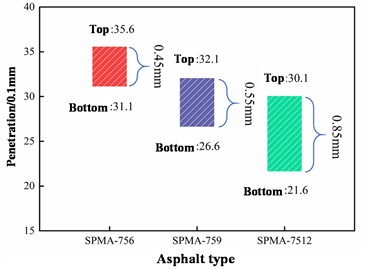

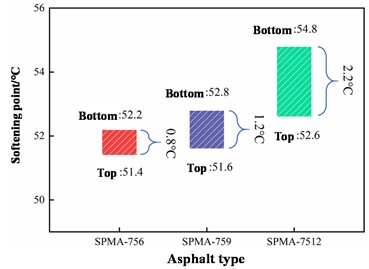

3.3. Segregation test

Fig. 3 presents the segregation test results of modified asphalt with different modifier particle sizes. In penetration tests, SPMA-756 exhibited a minimal penetration difference of 0.45 mm, while SPMA-156 and SPMA-306 showed larger differences of 0.51 mm (+13.3%) and 0.63 mm (+40 %), respectively. Similarly, softening point tests revealed differences of 0.8 °C for SPMA-756, increasing to 1.1 °C and 1.4 °C for SPMA-156 and SPMA-306. These findings clearly indicate that the compatibility of resin-modified asphalt systems improves with decreasing modifier particle size, as finer particles promote more uniform dispersion within the asphalt matrix.

Fig. 3Segregation test results of modified asphalt with modifiers of different particle sizes

a) Penetration difference

b) Softening point difference

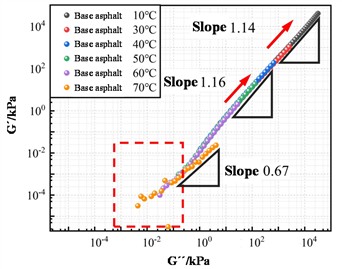

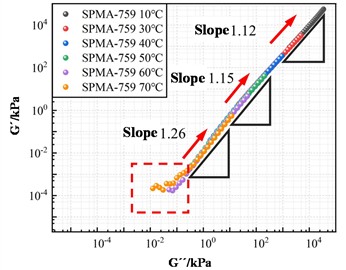

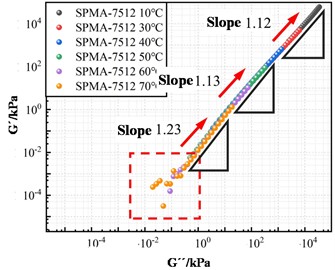

3.4. Han curve analysis

Fig. 4 presents the Han curves of modified asphalt binders with different modifier particle sizes. The results show that all modified asphalt binders maintain excellent linear relationships (slope < 2) in the temperature range of 10-40 °C, confirming their characteristics as multiphase polymer systems with good dispersion stability. Comparative analysis reveals that the slope of Han curves decreases with increasing modifier particle size in the 10-50 °C range, suggesting that larger particles adversely affect the compatibility of modified asphalt, which may be attributed to their surface microstructure and swelling behavior. Notably, the terminal portions of Han curves exhibit varying degrees of dispersion (as highlighted in red boxes). Specifically, SPMA-756 (0.075 mm) shows slight dispersion at 60-70 °C, while SPMA-156 (0.15 mm) begins to display observable dispersion at 50 °C. Most significantly, SPMA-306 (0.3 mm) demonstrates severe dispersion at 50 °C. This temperature-dependent phenomenon primarily results from the gradual weakening of interfacial bonding strength between the modifier and asphalt matrix at elevated temperatures, which facilitates relative displacement and eventual phase separation of the modifier particles.

Fig. 4Han plots of modified asphalt with modifiers of different particle sizes

a) Base asphalt

b) SPMA756

c) SPMA759

d) SPMA7512

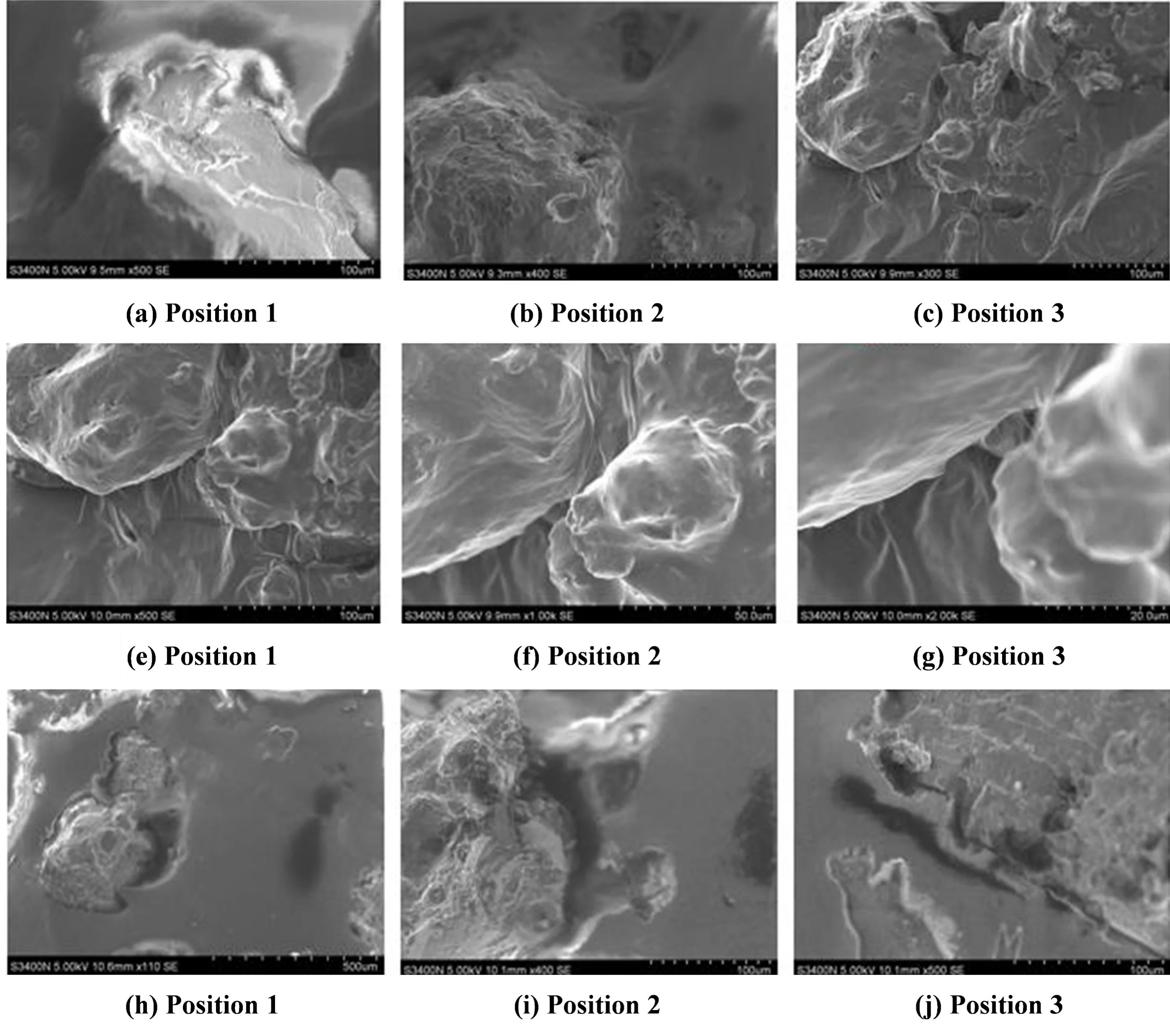

Fig. 5SEM results of interactions between modifiers and base asphalt binders

3.5. Scanning electron microscopy test

Fig. 5 shows SEM results of the interface between modifiers and base asphalt. Analysis of Fig. 5 reveals that the 0.3 mm modifier has a rough and porous surface, with the base asphalt failing to adequately infiltrate the 0.3 mm modifier. A clear gap exists at the interface between the two materials, indicating relatively poor interaction between the 0.3 mm modifier and base asphalt.

Analysis of Fig. 5(e)-(g) shows that the 0.15 mm modifier surface also contains numerous shallow pores. During mixing, the base asphalt can better combine with the 0.15 mm modifier. Furthermore, the abundant pores on the surface of the 0.15 mm modifier increase its surface area, facilitating contact with the base asphalt binder. Analysis of Fig. 5(h)-(j) demonstrates that the interface between the 0.075 mm modifier and base asphalt is smooth and continuous. The asphalt achieves good infiltration of the 0.075 mm modifier, enhancing the bonding between them and reducing the likelihood of compatibility issues in the modified asphalt binder.

4. Conclusions

1) The resin modifier improves both the high-temperature performance and deformation resistance of asphalt binder at ambient temperature, while adversely affecting its low-temperature performance.

2) Larger modifier particles not only intensify the phase separation degree in modified asphalt systems but also induce phase separation phenomena at lower temperatures.

3) The interface between 0.075 mm modifier and base asphalt binder shows smooth and continuous bonding, with asphalt achieving excellent infiltration of the 0.075 mm modifier, resulting in superior interaction effects that significantly reduce the severity of compatibility issues in asphalt binder.

References

-

L. Kregl, G. M. Wallner, R. W. Lang, and G. Mayrhofer, “Effect of resin modifiers on the structural properties of epoxy resins,” Journal of Applied Polymer Science, Vol. 134, No. 44, p. 45348, Nov. 2017, https://doi.org/10.1002/app.45348

-

R. Mezzenga, L. Boogh, and J.-A. E. Månson, “A review of dendritic hyperbranched polymer as modifiers in epoxy composites,” Composites Science and Technology, Vol. 61, No. 5, pp. 787–795, Apr. 2001, https://doi.org/10.1016/s0266-3538(01)00022-7

-

J. Gao, T. Guo, S. Chen, X. Sun, X. Qin, and Y. Zhu, “Compatibility between polyurea resin modifier and asphalt binder based on segregation and rheological parameters,” Reviews on Advanced Materials Science, Vol. 64, No. 1, Apr. 2025, https://doi.org/10.1515/rams-2025-0102

-

W. Zhang, Q. Li, J. Wang, X. Zeng, and B. Yu, “Evaluation of the effect of different preparation processes on the road performance of thermoplastic resin modified porous asphalt mixtures,” Construction and Building Materials, Vol. 428, p. 136256, May 2024, https://doi.org/10.1016/j.conbuildmat.2024.136256

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.