Abstract

A method is proposed for quantitative assessment and justification of the criterion of the rationing indicators of external and boost air temperature factors on the qualitative component of the working process of two-stroke supercharged diesel engines under various load conditions of the traction power plant of operating diesel locomotives. The results of the study were obtained in the numerical values and graphs, as well as analytical dependencies (equations) designed to substantiate the parameters under study, including their average values under different operating mode diesel and ambient temperatures. These studies are recommended to continue with the aim of studying the intensity of the dynamics of the decrease or increase in the relative filling coefficients of the 10D100 diesel cylinders with air and developing a methodology for predicting the criterion of the influence of the rationing of boost indicators and outside (external) air on the operating process of diesel locomotives diesels.

Highlights

- The obtained results of the study will be useful in the practical work of locomotive complex specialists in terms of providing him opportunities by optimizing thermodynamic operating cycles and by theoretical modeling of the speed and load characteristics of their diesel engines.

- It is recommended to continue these studies in order to study changes in the intensity of the relative filling factors of diesel cylinders with air taking into account the ambient temperature and various operating modes of the power plant of diesel locomotives.

- An original method for assessing and substantiating the influence of outside air temperature, taking into account the parameters of the boost air, on the quantitative and qualitative characteristics of the diesel engine operating process under operating conditions is proposed.

- An improved methodology for substantiating the parameters of temperature factors of the supercharged air and the environment that affect the quality of diesel fuel combustion under various load conditions of the main (traction) generator of operating diesel locomotives is proposed.

1. Introduction

Currently, against the backdrop of the replenishment of the operating fleet of locomotives of JSC “Uzbekistan Temir Yollari” with modern Chinese and Russian electric locomotives and a noticeable increase in the total length of electrified railway sections, the level of demand for mainline locomotives of diesel traction (diesel locomotives) is not weakening and will be continue to remain quite high.

The main purpose of diesel locomotives is to carry out railway freight and passenger transportation on all views (types) of railway sections, including electrified ones.

In this regard, increasing the efficiency of the transportation work of these locomotives, including freight diesel locomotives TE10M, structurally formed in two to four sections, concludes of conducting large-scale theoretical and experimental studies to study issues aimed at improving the compatibility of the fuel characteristic and air characteristics of diesel engines, improving their fuel efficiency and improvement their fuel efficiency and improving the quality of the technological repair process, with ensuring guaranteed reliability of rolling stock along the route.

Naturally, research related to the substantiation of the efficiency of using the specified locomotives in operating conditions by improving the quality of the work process and the operational reliability of the units (parts) of their diesel engines, depending on the type and kind of railways sections, differing in the degree of complexity, is timely and relevant.

2. Objects and methods of research

The main performance indicators transportation works of locomotives of diesel traction take be conditionally divided into operational and working indicators, moreover, if the former are characterized by kinematic parameters and indicators of traction and energy characteristics of the movement of freight trains and locomotives on the studied section of the railway, then the latter are characterized by the parameters and fuel efficiency of the operating process of diesel locomotive engines in use.

A large number of works [1-15] by foreign scientists are devoted to theoretical and experimental studies of the working process of internal combustion engines, including diesel engines, some of which of studies aviation [1-4] engines with spark ignition of fuel, of diesel locomotive [5-11] and of automobile-tractor [12-15] diesel engines.

Here, all foreign scientists agreed on one opinion and were unanimous in the fact that the efficiency of using internal combustion engines directly depends on the constant improvement of the quality component of each local process of the diesel engine operating cycle, from the totality of which its thermodynamic cycle and work process as a whole consists. The above concerns the quality of the processes of filling the diesel cylinders with air and burning diesel or other types of alternative fuel, taking into account its injection into the cylinder at maximum crankshaft speed of the diesel, corresponding to the maximum load of its main (traction) generator.

It should be noted that over the entire period of the transportation process of freight, the work time of diesel locomotives in non-nominal (intermediate) operating modes of their diesel engines is approximately 70 percent, and at maximum positions usually it amounts to no more than 15 percent. A diesel locomotive is a complex structure of interconnected among themselves various systems and units, and the fuel efficiency and durability of a diesel locomotive significantly depend on the operating mode (nominal or intermediate) of the diesel generator set.

In addition, the studies mentioned [1-15] do not sufficiently cover the issues of selecting optimal diesel engine power and there is no consensus on the fuel efficiency and operational reliability of a diesel locomotive depending on the various operating modes of its diesel generator set.

Consequently, the operating modes of diesel engines, including diesel of diesel locomotives, directly depend on and change according to variable loads over a wide range. This applies to changes in the parameters of such indicators as effective power, rotational speed and torque of the crankshaft, thermal and mechanical loads, fuel supply and, naturally, subsequently, economic indicators.

The dependence of parameters in one or another combination under steady-state operating conditions of a diesel engine, that is, when the specified indicators remain unchanged, is called the characteristics of a diesel engine, the value of the parameters of which significantly affects the traction and operational properties and economic efficiency of the diesel engine.

Diesel engines are classified into speed and load characteristics. The speed characteristic of a locomotive diesel engine describes the relationship between effective power, torque, and fuel consumption and crankshaft speed, which shows how these parameters change at different engine crankshaft speeds and a constant fuel supply, that is, with a fixed position of the fuel pump rack. The load characteristic diesel of a diesel locomotive is a graphical representation of the dependence of its power or tangential traction force on the speed of the locomotive, which, in essence, is a performance graph showing how much power the diesel can develop at a certain speed movement. Also, the specified load characteristic shows how the diesel engine operates under different loads (speeds movement) and allows one to evaluate its operating indicators (parameters), such as power and torque, which are important for the operation of the locomotive.

In addition, diesel engines can be classified by design features (frame design, where the cylinder block and crankcase can be one-piece or separate; the number and arrangement of cylinders - in-line or V-shaped), by working cycle (two-stroke or four-stroke), by combustion chamber type (non-separate or separate), by the type of cooling system (air or liquid), by the presence or absence of air boost, and by purpose - automotive, marine, diesel locomotive, stationary, agricultural and others.

Research presented continues work [16, 17] and concerns about the locomotives of diesel traction, through which cargo traffic (movement) is carried out on sections of the Uzbek railways of varying complexity.

The purpose of the research is to substantiate the influence of some indicators of the working cycle of two-stroke diesel engines with supercharging and counter-moving pistons, associated with the processes of filling the cylinders with a fresh charge of air, injection and combustion of fuel in cylinders in various operating modes of a diesel generator set at different ambient temperatures and charge air temperatures after the air cooler.

Here, the author relies on the methodology he developed [17] for performing a numerical calculation of the parameters of the diesel engine operating process, the initial data [18] on the two-stroke diesel engine 10D100 under study, taking into account the object of study and local components the subject of study.

Here, a TE10M type cargo diesel locomotive, formed from two sections with a diesel engine with counter-moving pistons and with the processes of filling the cylinders with air, injection and combustion of fuel in the cylinders of this diesel engine, is taken as the object of research.

The values of the indicators of supercharging air, atmospheric (surrounding) environment and the coefficient of filling of the diesel cylinder with air charge are taken as the subject of the research.

The influence of atmospheric conditions and boost air conditions is assessed based on the value of the criterion, which characterizes the amount of fresh air in the diesel cylinders and is produced using the following analytical expressions [19]:

– For boost conditions:

– For atmospheric conditions (environment):

where – weight of air at the beginning of compression, kg/cycle; – weight of air in a diesel cylinder, taking into account supercharging, kg/cycle; – weight of air in a diesel cylinder under atmospheric conditions, kg/cycle.

The specified values of the fresh air weight charge according to the boost parameters and according to the atmospheric condition parameters are calculated using the following well-known formulas [20]:

where – working volume of the diesel cylinder, liter; – pressure after centrifugal supercharger, Pa (kg/sm2); – temperature of the air entering the diesel cylinder, °K.

The weight charge air in cylinder at beginning of compression , related to the values of and ‚ is determined by calculation at different temperatures of the charge air and atmospheric air .

The values of the specified parameters of boost and atmospheric conditions (environment) were determined during rheostat (bench) tests by measuring their values using widely known methods [21, 22] using electronic devices and appropriate sensors. To measure the pressure value after the driven centrifugal supercharger and the air temperature values in the purge receiver after the air cooler, an electronic pressure gauge, which was installed at the outlet of the supercharger, and a pyrometer installed on the pipeline were used, respectively.

3. Results and their discussion

The results of calculations performed using Eqs. (1-4), the dynamics of changes in the mentioned coefficients in relative units for some operating modes (working process) of the 10D100 diesel engine in the range of changes in the values of the indicators entering the diesel engine cylinders air and atmospheric (outside) air adopted by authors are given in Table 1. The following notations are used here:

– , …, – outside (atmospheric) air temperature, °K.

– , …, – air temperature after the air cooler, °K.

– and – accordingly, the ratio of the values of the indicated parameters and to similar parameters under normal atmospheric conditions (indicated by the index ), when the pressure and temperature of the outside air are, respectively, = 760 mm Hg and = 293°K, that is, and .

The variation range for the outside (atmospheric) air temperature is from 233 °K to 313 °K with a variation interval of 40 °K, and for the air temperature after the air cooler – from 260 °K to 380 ° K with a variation interval of 20 °K.

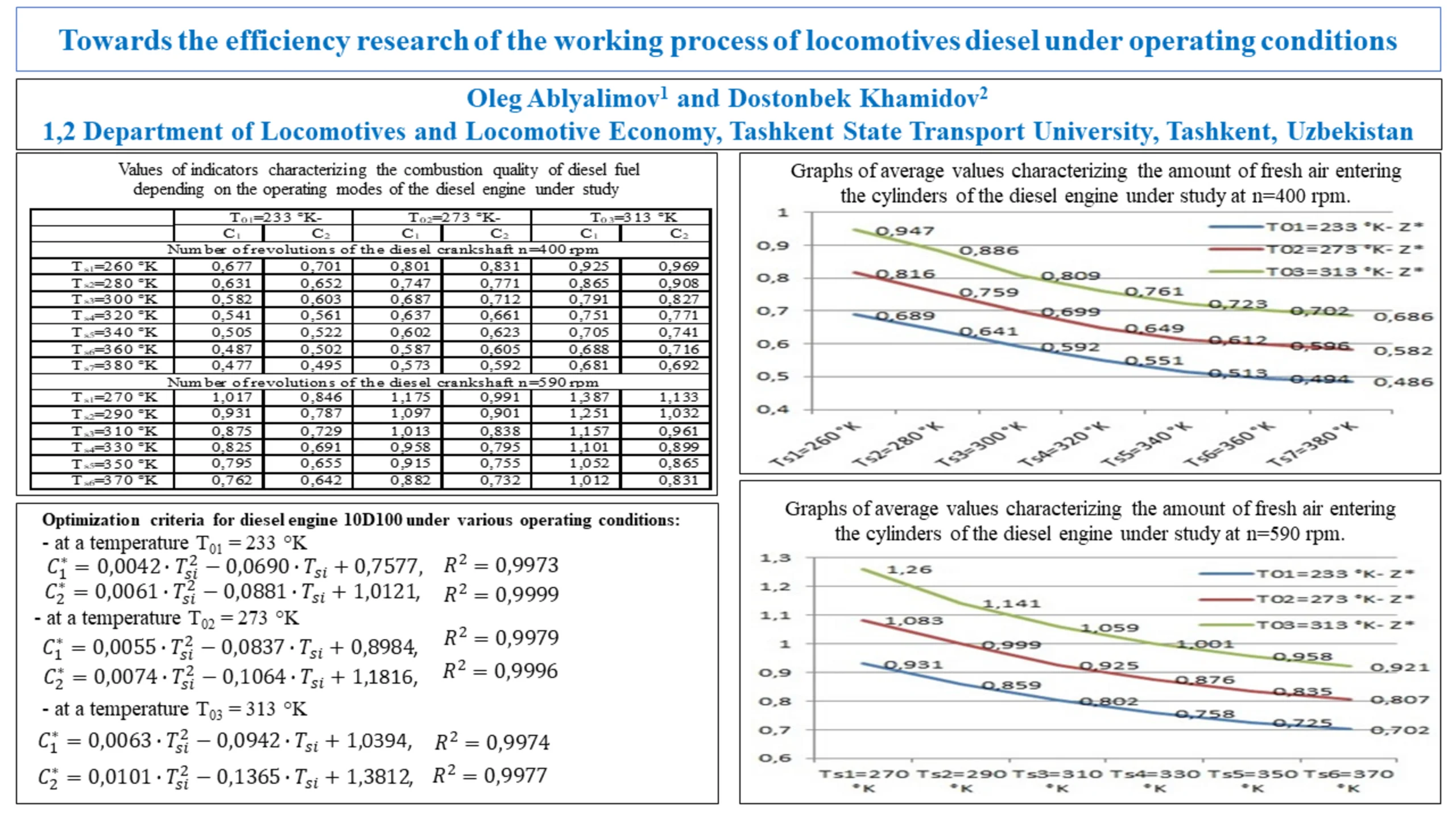

Table 1Values of indicators characterizing the combustion quality of diesel fuel depending on the operating modes of the diesel engine under study

233 °K | 273 °K | 313 °K | ||||

Number of revolutions of the diesel crankshaft 400 rpm | ||||||

260 °K | 0.677 | 0.701 | 0.801 | 0.831 | 0.925 | 0.969 |

280 °K | 0.631 | 0.652 | 0.747 | 0.771 | 0.865 | 0.908 |

300 °K | 0.582 | 0.603 | 0.687 | 0.712 | 0.791 | 0.827 |

320 °K | 0.541 | 0.561 | 0.637 | 0.661 | 0.751 | 0.771 |

340 °K | 0.505 | 0.522 | 0.602 | 0.623 | 0.705 | 0.741 |

360 °K | 0.487 | 0.502 | 0.587 | 0.605 | 0.688 | 0.716 |

380 °K | 0.477 | 0.495 | 0.573 | 0.592 | 0.681 | 0.692 |

Number of revolutions of the diesel crankshaft 590 rpm | ||||||

270 °K | 1.017 | 0.846 | 1.175 | 0.991 | 1.387 | 1.133 |

290 °K | 0.931 | 0.787 | 1.097 | 0.901 | 1.251 | 1.032 |

310 °K | 0.875 | 0.729 | 1.013 | 0.838 | 1.157 | 0.961 |

330 °K | 0.825 | 0.691 | 0.958 | 0.795 | 1.101 | 0.899 |

350 °K | 0.795 | 0.655 | 0.915 | 0.755 | 1.052 | 0.865 |

370 °K | 0.762 | 0.642 | 0.882 | 0.732 | 1.012 | 0.831 |

For a comprehensive assessment, analysis and calculation of the parameters of the quantitative component of air entering the cylinders of the diesel engine under study, taking into account its temperature after the air-cooler at fixed values of the ambient temperature and boost air using the standard Microsoft Office Excel series program, the authors obtained the corresponding regression equations, namely.

– At a temperature 233 °K:

– At a temperature 273 °K:

– At a temperature 313 °K:

In Eqs. (5-16) the value of the approximation reliability R2 ranges from 0.9970 to 0.9989 units (there must be 0.8 [16]). Eqs. (5), (6), (9), (10), (13), (14) - the number of revolutions of the diesel crankshaft 400 rpm and Eqs. (7), (8), (11), (12), (15), (16) - the number of revolutions of the diesel crankshaft 590 rpm, and the magnitude = 1, 2, 3,..., 7, here indicates on the serial number of the calculation option.

Analysis of the tabular data and the obtained Eqs. (5-16) for the studied 10D100 diesel engines shows that a decrease in the temperature of the air entering the cylinder and an increase in the ambient temperature with an increase in the number of revolutions of the diesel crankshaft ensures an increase in the indicators of the boost and outside air criteria during the working process of the specified diesels of diesel locomotives.

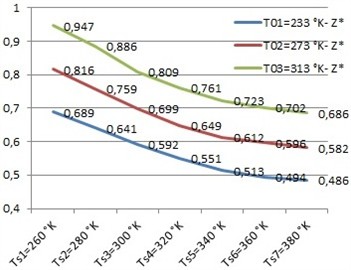

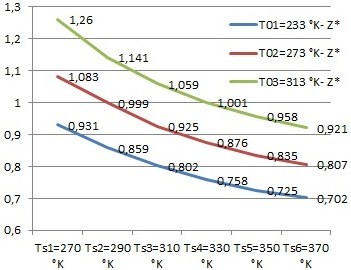

To graphically illustrate what was said by the author, the averaged values (the arithmetic mean of two values and ) of of the studied parameters were determined, the dynamics of change of which, depending on the mentioned of air temperature , is presented in the form of graphs in Fig. 1 and Fig. 2, respectively, at the diesel crankshaft speed 400 rpm and 590 rpm.

Fig. 1Graphs of average values characterizing the amount of fresh air entering the cylinders of the diesel engine under study at n= 400 rpm

Fig. 2Graphs of average values characterizing the amount of fresh air entering the cylinders of the diesel engine under study at n= 590 rpm

Taking into account the Microsoft Office Excel environment and the constructed graphs of average values characterizing the amount of fresh air entering the cylinders of the diesel engine under study, the authors obtained the corresponding criteria for standardizing for the 10D100 diesel engine under various operating modes, in which the “values” of parameters and relate, respectively, to the operation of the diesel engine at a crankshaft speed of 400 rpm and 590 rpm, we have:

– At a temperature 233 °K:

– At a temperature 273 °K:

– At a temperature 313 °K:

As a result of this stage of research, the corresponding numerical values, graphs and analytical dependencies (equations) were obtained, including for the average values of some parameters of the working process of diesel locomotives, on the basis of which it is possible to predict in advance the degree of rationing of the boost indicators and ambient (outside) temperature on the qualitative component of the fuel injection and combustion process in diesel cylinders.

4. Conclusions

The authors obtained the following general conclusions and recommendations.

1) An original method for assessing and substantiating the influence of outside air temperature, taking into account the parameters of the boost air, on the quantitative and qualitative characteristics of the diesel engine operating process under operating conditions is proposed.

2) A methodology is proposed for substantiating the parameters of temperature factors of the supercharged air and the environment that affect the quality of combustion of diesel fuel under various load conditions of the main (traction) generator of operating diesel locomotives.

3) Numerical values of the indicators (coefficients) characterizing the amount of fresh air entering the cylinders of a two-stroke diesel engine 10D100 were obtained depending on the range of change in the rotation frequency of its crankshaft and the outside air temperature, respectively, at 400 rpm and 590 rpm and from 233 °K to 333 °K.

4) A discrepancy was found between the quantitative ratio of boost air and fuel supplied to the diesel cylinders, which leads to poor mixture formation and, as a consequence, causes incomplete combustion of the working mixture with a subsequent decrease in the power and fuel efficiency of diesel locomotives.

5) Despite the fact that the research methodology is confirmed by high correlation coefficients, however, from a thermodynamic point of view, additional uncertainty assessments will allow obtaining reliable and valuable information that predicts (forecasts) ways to improve operational reliability, economic efficiency and the qualitative component of the environmental performance of diesel locomotives under the operational activities of various sections of railways, taking into account the ever-changing freight flow and climatic conditions.

6) The obtained results of the study will be useful in the practical work of locomotive complex specialists and operators of other types of mainline diesel locomotives in terms of providing him opportunities by optimizing thermodynamic operating cycles and by theoretical modeling of the speed and load characteristics of their diesel engines.

These studies it is recommended to be continued on a wider range of items of two-stroke internal combustion engines of this type, for the purpose study of intensity (tempo) changes in relative coefficients of filling diesel cylinders with air and a wide range of variations in ambient temperature and various loads modes of operation of the power plant of diesel locomotives.

References

-

M. D. Garipov, R. Y. Sakulin, and D. R. Rezvanov, “Characteristics of a two-stroke spark-ignition engine when running on diesel fuel,” Vestnik UGATU, Vol. 21, No. 2(76), pp. 30–41, 2017.

-

S. Guo et al., “Optimizing hydrogen and ammonia injection timing for enhanced mixture formation in internal combustion engines,” Journal of Engineering Research and Reports, Vol. 26, No. 4, pp. 152–164, Mar. 2024, https://doi.org/10.9734/jerr/2024/v26i41122

-

M. Yao, B. Zhang, Z. Zheng, Z. Chen, and Y. Xing, “Effects of exhaust gas recirculation on combustion and emissions of a homogeneous charge compression ignition engine fuelled with primary reference fuels,” Proceedings of the Institution of Mechanical Engineers, Part D: Journal of Automobile Engineering, Vol. 221, No. 2, pp. 197–213, Feb. 2007, https://doi.org/10.1243/09544070jauto102

-

R. Singh and R. Mcchesney, “Development of multi-fuel spark ignition engine,” in Small Engine Technology Conference and Exposition, Sep. 2004, https://doi.org/10.4271/2004-32-0038

-

V. A. Ryzhov, “Prospects for the development of highly accelerated diesel locomotive diesel engines of the Kolomna Plant,” Heavy Engineering: Monthly Scientific, Technical and Production Magazine, No. 2, pp. 51–54, 2002.

-

Y. L. Moshentsev and A. A. Gogorenko, “Possible trends in the development of cooling systems for modern mainline diesel locomotives,” Lokomotiv-Inform: International Information and Technical Magazine, No. 7, pp. 20–24, 2011.

-

A. V. Gorin, “Diagnostics of cooling system parameters as a means to increase the reliability and service life of a locomotive diesel engine,” Modern Technologies, System Analysis, Modeling, Vol. 41, No. 1, pp. 112–118, 2014.

-

V. R. Vedruchenko, V. V. Krainov, and E. S. Lazarev, “Development of an approximate mathematical model for the connection of fuel injection and combustion processes in diesel power plants of locomotives,” Journal of Transsib Railway Studies, No. 4, pp. 18–28, 2014.

-

P. N. Blinov and A. P. Blinov, “Model of the process of fuel supply by fuel equipment of diesel locomotive diesel engines, taking into account the technological characteristics of its details,” Journal of Transsib Railway Studies, Vol. 1, No. 1, pp. 35–40, 2010.

-

D. V. Balagin, “Study of operational reliability and means of diagnosing the technical condition of diesel fuel equipment,” Journal of Transsib Railway Studies, Vol. 3, No. 11, pp. 12–19, 2012.

-

S. M. Ovcharenko, I. S. Ring, and S. S. Ovcharenko, “Study of temperature conditions of operation of cooling systems of diesel locomotives during operation,” Scientific journal of Izvestia Transsib, Vol. 50, No. 2, pp. 116–123, 2022.

-

R. M. Bashirov, F. R. Safin, and R. Z. Magafurov, “Improving the method of regulating diesel fuel equipment,” Vestnik AGAU, Vol. 6, No. 152, pp. 158–163, 2017.

-

E. Tausenev, “On the possibility of increasing the power of an automotive diesel engine when cooling the fuel,” Bulletin of Altai State Agrarian University, Vol. 234, No. 4, pp. 93–96, Apr. 2024, https://doi.org/10.53083/1996-4277-2024-234-4-93-96

-

S. A. Plotnikov, D. V. Plekhov, A. N. Kartashevich, and P. Y. Malyshkin, “Study of the effective performance of a tractor diesel engine on fuels with promoter additives,” Bulletin of NGIEI, Vol. 7, No. 170, pp. 36–47, 2025, https://doi.org/10.24412/2227-9407-2025-7-36-47

-

E. V. Ovchinnikov, S. Y. Coziness, K. S. Dmitriev, and A. S. Ovcharenko, “Analysis of ways to adapt automotive diesel engines to work on gas fuel,” Agricultural Machinery: Service and Repair, No. 8, pp. 23–27, Aug. 2020, https://doi.org/10.33920/sel-10-2008-02

-

O. Ablyalimov, “Indicators of transport logistics of locomotives of diesel traction on Kattakurgan-Navoi section in operation,” in E3S Web of Conferences, Vol. 401, p. 05022, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105022

-

O. Ablyalimov, “To the substantiation of charge air parameters on different operating modes of diesel engines of diesel locomotives,” in E3S Web of Conferences, Vol. 460, p. 06010, Dec. 2023, https://doi.org/10.1051/e3sconf/202346006010

-

B. A. Sharoglazov, M. F. Farafontov, and V. V. Klementyev, Internal combustion engines: theory, modeling and calculation of processes. Chelyabinsk: Publishing house. SUSU, 2005.

-

O. Ablyalimov, “Optimization of transport operation of diesel locomotives,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 060002, Jan. 2025, https://doi.org/10.1063/5.0266946

-

O. Ablyalimov, “Towards substantiation of optimal train traffic control modes on various sections of railway,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 060030, Jan. 2025, https://doi.org/10.1063/5.0266949

-

S. A. Prishvin, P. V. Safronov, and P. V. Dushkin, Thermal Measurements in Internal Combustion Engines. Measurement of Temperatures, Pressures, Deformations: Textbook. M.: MADI, 2023.

-

K. Latyshenko, Technical Measurements and Devices: Methods of Analysis and Control. Litres, 2025.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.