Abstract

This article investigates the influence of the tedder’s angular speed on the kinematic and power characteristics of the drive system of the 5LP linter machine. The linter machine is a complex technological unit used to remove residual fibres from the surface of cotton seeds. One of the key factors determining linting efficiency is the interaction between the tedder and the seed roller inside the machine’s working chamber. A detailed kinematic and force analysis is presented, taking into account the resistance forces generated by the seed roller during its movement and processing. Particular attention is given to the development of a calculation model that describes the interaction between the tedder blades and the seed roller. In this model, each blade is treated as a cantilever beam subjected to variable loads resulting from the non-uniform mass and density distribution of the seed material. The analysis demonstrates that variations in the mass and density of the seed roller significantly affect the load transmitted to the drive and the stability of the saw cylinder. The obtained results enable more accurate selection of drive parameters and optimisation of the operating modes of the linter machine. These findings are crucial for improving the productivity and reliability of the equipment, as well as for accounting for both transient and steady-state operating conditions in real industrial environments.

1. Introduction

The development of high-performance cotton ginning machinery can only be achieved through a deep understanding of the physical processes occurring inside the machines under various loading conditions, along with the creation of advanced methods for calculating operational loads. These calculations form the basis for the strength and durability analysis of machine components and assemblies. The refinement of calculation methods for the drives and shafts of high-capacity machines remains particularly important, as it allows more accurate parameter selection during production testing.

The growing global and domestic demand for high-quality cotton fibre requires not only improvements in the technological processes of raw cotton processing but also the continuous modernisation of equipment. One of the priority areas of the cotton industry is the enhancement of the seed lintering process, which plays a key role in increasing production efficiency and improving the quality of both seeds and linter.

A crucial factor in achieving sustainable growth in this sector is the deeper processing of raw cotton within the textile and light industries. By focusing not only on fibre production but also on the manufacture of value-added products-such as dyed yarn, knitted fabrics, and finished textiles-combined with the adoption of modern technologies and innovative design solutions, the cotton industry can generate substantial economic benefits. Since independence, the Republic of Uzbekistan has prioritised the development of the cotton cleaning sector, focusing on increasing the global competitiveness of cotton products, reducing production costs, and maximising fibre and linter yields [1, 2].

In recent years, cotton processing plants across the country have undergone gradual modernisation. The main objectives of this process are to improve machine productivity and ensure the production of high-grade cotton fibre and linter that meet international market standards. One of the most effective strategies for achieving these objectives is the technical re-equipment of enterprises through the integration of advanced scientific and technological developments.

The parameters of the linter machine’s working chamber are of particular importance, as they largely determine the seed lintering process. In currently employed 5LP-series linter machines, the configuration of the working chamber and operating units leads to the formation of a high-density seed roll. This results in significant dynamic loads on the seeds, increased seed damage, higher energy consumption during rotation, and a deterioration in linter quality. As the seed roll density increases, the quality of seeds and linter decreases, while energy consumption and drive load intensify.

The main shortcomings of existing linter designs can be summarised as follows:

– low operational reliability;

– high energy consumption for saw cylinder rotation, especially at startup due to large inertia torques;

– excessive seed roll density, leading to increased seed damage and reduced linter quality.

Recent advances in both lintering technology and machine design have improved seed and linter quality indicators. However, one promising approach involves using additional devices to mix and rotate the seed roll (stirrers). Their application helps reduce seed roll density, lower loads on the working components, and ultimately improve product quality.

The novelty of this study lies in the development of a new design of the seed tedder and the performance of a detailed kinematic analysis for this innovative configuration. This allows for more accurate determination of the drive parameters and operating modes of the linter machine, contributing to increased productivity and reliability.

One such machine in the cotton processing industry is the linting machine, which replaces less productive linting machines of the PMP-160M brand and provides production with better quality indicators [1-6].

2. Research methods

The process of lintering is carried out on lintering machines, in which the main working organ is a saw cylinder. Significant power in machine consumes exactly the drive of the saw cylinder of linter machines 18,5 kWt [2-6]. The process of lintering is mainly due to the rotary motion of the saw cylinder and the seed roller tedder. We are interested in how the change of seed roll mass will influence the torque of the working shaft of the saw cylinder and the tedder, as the linting process cannot be studied separately. Here we have to consider the two drives (including the seed roller) as one single system.

From the theory of linting, changes in the mass of the seed roller will influence the productivity and the quality of the removal as well as the load of the drives [2, 3]. It is these drives that account for the main power consumption. Let's consider kinematic diagrams of these drives, which are shown in Fig. 1.

Fig. 1Kinematic diagrams of linter machine drives

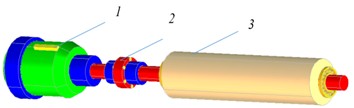

a) Saw cylinder drive: 1 – electric motor, 2 – coupling, 3 – saw cylinder

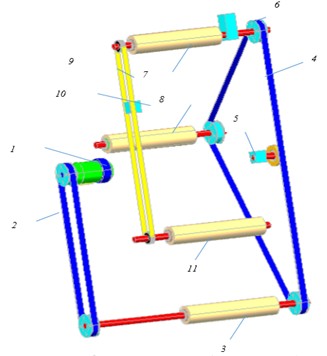

b) Tedder and feed drum drive: 1 – electric motor, 2 – belt transmission, 3 – driver, 4 – belt transmission, 5 – tensioner, 6 – variator IVA, 7 – sawing drum, 8 – levelling drum, 9 – chain transmission, 10 – tensioner, 11 – sawing drum

Fig. 1(a) shows the kinematic diagram of the saw cylinder drive. If we take into account that the drive uses a motor with a power of = 18.5 kW (4A200M8) and the turnover of which is = 735 min [3, 4]. Using the method of drive calculation applied [7], it is possible to determine with what power the saw cylinder rotates (without taking into account the seed roller):

where, , – power (kW) of the working shaft and the shaft of the electric motor, – drive’s overall efficiency, which in turn is determined using the following formula:

where, is the efficiency coefficient for mechanical transmissions.

We can also determine the torque of the shaft [6]:

Let’s calculate the drive for the saw cylinder of the linter machine. Firstly, we determine the total efficiency of the drive using Eq. (2). at the same time, – the value of the efficiency is taken from the standard [3-6]:

Now we can determine the power consumption of the saw cylinder shaft using Eq. (1):

Substituting the data obtained by Eq. (3) we obtain the saw cylinder shaft torque:

These calculations were made without taking into account the resistance of the seed roller. Next, let’s carry out kinematic calculation of the drive of the seed roller tedder, which is shown in Fig. 2(b).

From the kinematic diagram shows that with the help of one electric motor rotate several shafts, including the 1st shaft on the drive shaft tedder. The drive uses an = 11 kW motor (4A160S6) with speed = 960 min-1 [3-6].

Using the above methodology, we determine the power consumption and torque of the tedder shaft (without taking into account the seed roller). With the help of Eq. (3) we calculate the power consumption:

Using Eq. (3) we will calculate the torque of the sead roller shaft:

3. Results and discussion

It should be noted that, when the tedder rotation speed increases, the mass of the seed roller will decrease. Table 1 summarises the calculated data, the speed of rotation of the tedder shaft affects the torque of the shaft.

Table 1Dependence of shaft torque on tedder shaft rotational speed

min -1 | 400 | 450 | 500 | 550 |

Nm | 245.9 | 218.5 | 197.5 | 178.9 |

The main question facing us is how the change in the seed roller mass will affect the load of the linter drives. For this purpose it is necessary to consider these two drives in one system taking into account the change of seed roller mass.

From Table 1 we can conclude that the change in rotation speed of the tedder will affect the density of the seed roller. If we take into account that from the density of the seed roller will be the moment of resistance to the drive from the seed roller, it is advisable to calculate the effect of the speed of rotation of the tedder shaft on the forces of resistance of the mass of the seed roller.

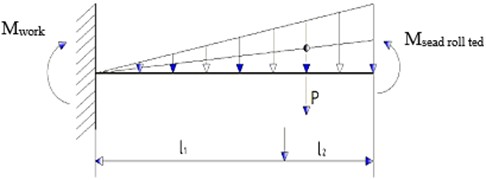

Fig. 2a) Seed roller tedder in contact with seeds in the working chamber; b) calculation scheme of the influence of the seed roller mass on the tedder blades linter machine, where, Msead roll ted – torque of the sead roller shaft (Nm), P – the mass of the seed roller (N), Mwork – the moment of resistance of the seed roller (Nm)

а)

b)

In order to make a mathematical description of the object of calculation and to solve the problem as simply as possible, in calculations real constructions are replaced by idealised models or calculation schemes [9]. In this case, the calculation becomes approximate, with the help of this method we have calculated the tedder of the seed roller of the linter machine in Fig. 2. We assume the torque of the tedder shaft to be constant and investigate the influence of the mass of the seed roller on the operation of the drive.

In Fig. 2(a) a simplified version of the tedder sector is proposed. The seeds in the working chamber will resist the rotation of the tedder shaft. Here the density (mass) of the seed roller will play an important role. From the theory of linting, a reduction in density (mass) will have a positive effect on the rotation speed of the tedder shaft and the drive itself. An excessive reduction of density will lead to a stop of the tedding or linting process.

Fig. 2(b) a scheme of influence of density (mass) of the seed roller on the resistance moment of the system is proposed. A tedder blade in the form of a cantilever beam is considered.

The scheme shows the forces affecting the beam (tedder blade). Let us consider a system of balanced forces applied to the beam. The action of the links on the structure is replaced by their reactions. To find out in which case the moment in the system is the smallest, let us find it for each case (substituting the data given in Table 1):

The obtained results of calculations for determining the moment of resistance from the seed roller to the drive depending on the angular speed of the tedder are summarised in Table 2.

Table 2Dependence of the resistance moment from the seed roller on the angular speed of the tedder

, (min-1) | 400 | 450 | 500 | 550 |

, (Nm) | 245.9 | 218.5 | 197.5 | 178.9 |

, (kg) | 46 | 42 | 39 | 36 |

, (N) | 450 | 411 | 382 | 353 |

., (Nm) | 115 | 111 | 108 | 103 |

In the majority of production processes, including the lintering process, the load on the engine of machine units is variable. As it is known, the main structural elements of machine units used in technology for driving the working organ are: engine; clutch; gearbox or gearbox (or variator); working organ drive mechanism (belt transmissions). It has been found that due to varying loads, many machine units operate at varying energy inputs to the engine and varying engine speeds [9-12].

Usually, the working shafts of machine units in the cotton industry are influenced by the parameters (weight, moisture, etc.) of the processed raw material (raw cotton, fibre, seeds) [14, 15]. In [16] it is noted that the maximum load modes in the drive of cotton processing machines are characteristic in the acceleration mode, performed either by changing the operating mode of the machine unit at a constant speed of movement, or by changing the speed of the machine unit without changing the operating mode. At the same time the dynamics of the machine unit at each stage of its motion (acceleration, steady motion, gear shifts, stops) have peculiarities in the load modes of both the electric motor and the drive.

4. Conclusions

The study analysed the dynamic behaviour of the linter machine drive, focusing on the influence of the tedder’s angular speed on the kinematic and power characteristics of the system. The main findings can be summarised as follows:

1) The required motor power must significantly exceed the power calculated for steady-state external loads in order to compensate for the effects of transient processes and the recovery of kinetic energy lost during periodic load fluctuations.

2) An increase in the frequency and amplitude of variable loads and higher operational speeds lead to greater motor power demand and higher energy losses in transient regimes.

3) The effective operation of the tedder depends mainly on the dynamic properties of the machine unit, including the moments of inertia, elastic and dissipative characteristics of the belt transmission, and the nature of the technological loads generated by raw cotton.

4) A comprehensive analysis of both transient and steady-state operating modes is essential for optimising the design and selecting drive parameters of the linter machine tedder.

The novelty of this work lies in the development of a new tedder design and the implementation of a detailed kinematic analysis for this configuration. The obtained results provide a basis for more accurate determination of drive power requirements and can be applied to improve the efficiency and reliability of cotton processing equipment.

References

-

U. Norboyev and R. Sulaymonov, “Ways to increase the efficiency of the seed linting process,” in E3S Web of Conferences 434 (ICECAE 2023), Vol. 434, pp. 03021–3021, 2023, https://doi.org/202343403021

-

S. Novruzov, A. Djuraev, I. Abbazov, B. Sharopov, N. Toshpulatov, and K. Aripov, “Friction force determination between the inclined piles of the cotton gin drum from small impurities and seed of the fiber,” in E3S Web of Conferences, Vol. 377, p. 03015, Apr. 2023, https://doi.org/10.1051/e3sconf/202337703015

-

E. G. Kedisso, J. Guenthner, K. Maredia, T. Elagib, B. Oloo, and S. Assefa, “Sustainable access of quality seeds of genetically engineered crops in Eastern Africa – case study of Bt cotton,” GM Crops and Food, Vol. 14, No. 1, pp. 1–23, Dec. 2023, https://doi.org/10.1080/21645698.2023.2210134

-

S. Z. Yunusov, S. A. Makhmudova, and D. A. Kasimova, “Increasing the efficiency of the seed shaft turber of the linter machine,” Technologies and Quality, Vol. 65, No. 3, pp. 37–41, Nov. 2024, https://doi.org/10.34216/2587-6147-2024-3-65-37-41

-

S. Z. Yunusov et al., “The influence of changes in technological loads on the deflection of the saw cylinder shaft of a linting machine,” Material and Mechanical Engineering Technology, No. 1, 2025.

-

E. Zikriyoyev, “Primary processing of raw cotton,” in Collection Primary Processing of Cotton, 1999.

-

S. A. Chernavsky, Course design of machine parts. Moscow: Alliance, 2005.

-

P. G. Guzenkov, Machine Parts. Moscow: Higher School, 1982.

-

R. K. Byler, “Historical Review on the effect of moisture content and the addition of moisture to seed cotton before ginning on fiber length,” Journal of Cotton Science, Vol. 10, pp. 300–310, 2006.

-

S. Z. Yunusov, S. N. Kenjayev, and S. A. Makhmudova, “Shafts of technological machines with combined supports,” in E3S Web of Conferences, Vol. 401, p. 01059, Jul. 2023, https://doi.org/10.1051/e3sconf/202340101059

-

A. Djuraev, Dynamics of Working Mechanisms of Cotton Processing Machines. Tashkent, 1987.

-

S. Z. Yunusov, S. N. Kenjayev, S. A. Makhmudova, and G. K. Islamova, “Full factorial experiment in the study of the parameters of a combined shaft of technological machines,” in E3S Web of Conferences, Vol. 401, p. 03043, 2023.

-

A. E. Kravchik, Asynchronous Motors of the 4AM Series. Energoizdat, 1982.

-

V. V. Dyachkov, “Improving the efficiency of cleaning cotton seeds in the 5LP linter feeder,” Cotton Industry.

-

R. V. Korabelnikov and O. K. Nuraliev, Influence of Linter Mixer Parameters on Seed Roller Compaction. Tashkent, 1983.

-

U. Norboyev and R. Sulaymonov, “Investigation of the effect of linter mixer blade on seed lintering process,” International Journal on Orange Technology, Vol. 4, pp. 70–76, 2022.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.