Abstract

Despite the long-standing recognition of vibration phenomena as a critical factor affecting both mechanical reliability and energy performance, yet their influence on electrical energy consumption remains insufficiently quantified. Excessive vibration, originating from rotor imbalance, shaft misalignment, bearing wear, and hydraulic instabilities, can result not only in accelerated component degradation but also in significant increases in energy demand and reductions in hydraulic efficiency. Understanding the quantitative relationship between vibration intensity and pump energy performance is therefore essential for both predictive maintenance strategies and energy efficiency improvements in pumping systems. This paper presents an experimental investigation of the effect of vibration on the electrical energy consumption and operational efficiency of centrifugal pumps. Five industrial pump types, with rated powers ranging from 15 to 75 kW and capacities from 100 to 320 m3/h, were tested under controlled conditions. Measurements were carried out using UT310A vibration testers, an ultrasonic flow meter, and a Fluke 1777 Power Quality Analyzer. Vibration signals, volumetric flow rates, pressure heads, and three-phase electrical parameters were simultaneously recorded under partial load, nominal load, and overload conditions. Hydraulic power and efficiency were then calculated, while statistical analyses-including correlation and regression models-were applied to determine the relationship between vibration intensity and electrical performance. The results revealed a strong positive correlation between increasing vibration levels and higher electrical energy demand. In particular, RMS vibration acceleration was found to be a reliable predictor of additional energy losses, while efficiency was observed to decrease as vibration intensity increased. These findings not only confirm the detrimental effect of mechanical instability on energy consumption but also provide a methodological framework for integrating vibration monitoring into energy management practices. By bridging the gap between mechanical diagnostics and energy performance analysis, the study contributes new insights that can support the development of predictive maintenance systems, improve pump reliability, and promote more sustainable operation of pumping stations.

1. Introduction

Among fluid transport equipment, centrifugal pumps are the predominant choice in most industrial and municipal systems classes of fluid handling machinery in industrial, municipal, and agricultural infrastructures. Their robust design, operational versatility, and relatively low maintenance requirements make them the dominant choice for applications ranging from water distribution networks and wastewater treatment facilities to irrigation and process industries. Despite their widespread adoption, centrifugal pumps are also well known for their vulnerability to energy losses when operating under non-ideal mechanical or hydraulic conditions. One of the most influential factors in this context is vibration, which not only affects the mechanical health of the pump but also has a direct and often underestimated impact on energy consumption and efficiency.

1.1. Vibration phenomena in centrifugal pumps

Vibrations in centrifugal pumps may originate from multiple sources, including rotor imbalance, shaft misalignment, bearing wear, cavitation, and hydraulic instabilities such as flow separation or recirculation. The occurrence of such vibrations is inevitable to some extent in rotating machinery; however, when vibration amplitudes exceed acceptable thresholds, they lead to accelerated mechanical degradation and substantial operational inefficiencies. Over the last three decades, research has demonstrated that vibration-related failures account for a considerable proportion of pump downtime and maintenance costs. At the same time, excessive vibrations increase frictional and hydrodynamic losses, thereby raising the electrical energy demand of the driving motor.

1.2. Energy consumption and efficiency considerations

Energy efficiency has become a central concern in the operation of pumping systems, as pumps are among the largest energy consumers in many facilities. It is estimated that pumping systems account for nearly 20-25 % of industrial energy usage worldwide. Even small improvements in efficiency can therefore translate into significant reductions in operating costs and carbon emissions. Conventional approaches to improving efficiency have largely focused on hydraulic design optimization, motor efficiency upgrades, or the application of variable frequency drives. However, the role of mechanical vibration as an energy loss mechanism has often been treated as secondary, despite growing evidence of its significance.

1.3. State of the art and research gap

Numerous studies have focused on vibration diagnostics in pumps, primarily from a maintenance perspective. Researchers have developed spectral analysis, envelope detection, and wavelet-based methods to identify early-stage bearing faults, rotor imbalance, or cavitation phenomena. Other works have examined the effects of operational conditions such as flow rate, speed, and cavitation on vibration characteristics. Parallel to these efforts, another body of literature has explored pump energy performance, examining the influence of flow conditions, hydraulic losses, and motor efficiency on total energy consumption.

2. Methods and materials

2.1. Theoretical background

The analysis of vibration phenomena in centrifugal pumps requires a dual perspective, integrating both mechanical dynamics and energy performance evaluation. From a theoretical standpoint, centrifugal pumps are governed by the fundamental hydraulic power equation:

where is the fluid density (kg/m3), is gravitational acceleration (9.81 m/s2), is the volumetric flow rate (m3/s), and is the pump head (m). The ratio between hydraulic output power and electrical input power defines the overall efficiency:

with representing the active electrical power absorbed by the motor. Deviations from nominal efficiency are often linked to hydraulic losses, leakage, and mechanical dissipation. A key factor among these losses is vibration, which induces additional bearing loads, shaft deflections, and turbulent instabilities that increase friction and decrease the energy transfer efficiency between the impeller and the fluid [1-3].

The quantification of vibration intensity is typically performed using the root mean square (RMS) of acceleration () in the time domain and the amplitude spectrum in the frequency domain. International standards such as ISO 10816 and ISO 20816 provide guidelines for acceptable vibration levels in pumps and rotating machinery. Excessive vibration amplitudes are correlated with higher mechanical losses, and studies have suggested that every 1 mm/s increase in vibration velocity may correspond to 1-3 % additional energy demand in medium-sized pump systems [4, 5].

Therefore, this study employs a comprehensive methodological framework that integrates vibration monitoring with hydraulic and electrical measurements. The experimental design is structured to capture steady-state and transient behaviors across different load conditions, enabling the identification of systematic correlations between vibration phenomena and pump energy performance.

2.2. Pump units under investigation

The experiments were carried out on five centrifugal pump models widely applied in industrial and municipal pumping stations. These pumps were selected to represent a range of rated powers (15-75 kW), flow capacities (100-320 m3/h), and heads (22-50 m), thereby allowing a broad evaluation of vibration-energy interactions across different scales. All pumps were coupled with three-phase induction motors operating at a synchronous speed of 1500 rpm.

Table 1Specifications of centrifugal pumps tested

Pump type | Rated power (kW) | Mass (kg) | Flow rate (m3/h) | Head (m) | Speed (rpm) |

1D200-90 | 15 | 445 | 100 | 22 | 1500 |

D200-36 | 37 | 730 | 200 | 36 | 1500 |

D320-50b | 45 | 853 | 260 | 30 | 1500 |

D200-50a | 55 | 968 | 300 | 39 | 1500 |

D320-50 | 75 | 1112 | 320 | 50 | 1500 |

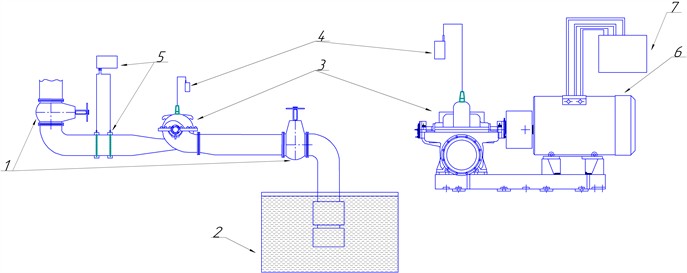

Fig. 1Experimental setup of the centrifugal pump vibration measurement system: 1 – gate valves; 2 – water reservoir; 3 – D-type centrifugal pump; 4 – UT310A vibration tester; 5 – HLT-6000 ultrasonic flowmeter and its sensors; 6 – induction motor; 7 – fluke 1777 power quality analyzer

Each of these pumps represents a class of medium-duty centrifugal pumps typically deployed in water supply and process industry environments. The differences in rated power and hydraulic characteristics provided the opportunity to investigate whether the effect of vibration on energy performance scales with pump size and operating capacity.

2.3. Measurement instruments

To ensure high-fidelity data acquisition, three complementary instruments were employed:

1) Vibration Testing: UT310A Series Vibration Testers were used for pointwise vibration measurements. These portable devices provide readings of acceleration, velocity, and displacement across a frequency range up to 10 kHz, with sensitivity adequate for detecting imbalance, misalignment, and bearing-related vibrations. Measurements were taken at the pump bearing housings and the motor casing, following the recommendations of ISO 10816-3 for vibration monitoring of industrial machines.

2) Flow Measurement: An ultrasonic flow meter, capable of measuring pipes with diameters between 20 mm and 6000 mm, was installed on the suction and discharge pipelines. This device provided non-invasive, real-time flow rates with an accuracy of ±1.5 %. The ultrasonic principle ensured that no additional pressure losses or disturbances were introduced into the hydraulic circuit.

3) Electrical Parameters: A Fluke 1777 Power Quality Analyzer was used to capture three-phase electrical data, including voltage, current, active/reactive power, apparent power, power factor, and harmonic distortion. This device operates with a sampling frequency up to 20 kHz, enabling the precise detection of transient fluctuations associated with vibration-induced torque variations.

Together, these instruments provided a comprehensive dataset integrating mechanical, hydraulic, and electrical aspects of pump operation.

For future studies, the use of piezoelectric triaxial accelerometers connected to a multi-channel data acquisition (DAQ) system is recommended, as this would enable full spectral analysis, long-term monitoring, and synchronization with electrical parameters. In addition, the integration of a digital tachometer could provide more accurate shaft speed information, which is particularly valuable for spectral analysis where precise rotational frequency is required [6, 7].

2.4. Methodological framework

The methodological design of this study is based on triangulated measurement, where vibration, hydraulic, and electrical parameters are acquired simultaneously under controlled test conditions. The approach ensures that observed variations in energy consumption can be directly linked to measurable changes in vibration characteristics, thereby reducing uncertainty.

Three operational regimes were investigated for each pump:

1) Partial load (~50 % ): achieved by throttling the discharge valve, simulating reduced demand conditions common in real operations.

2) Nominal load (): representing standard design operation.

3) Overload (> ): simulating elevated hydraulic resistance and higher stress conditions.

At each operating point, vibration signals, flow rates, heads, and electrical power consumption were recorded continuously for 60-120 seconds to capture steady-state behavior. Each measurement was repeated three times to improve statistical robustness and allow for error analysis.

The experimental methodology thus combines:

1) Steady-state analysis: enabling correlation between vibration RMS values and average energy performance indicators.

2) Statistical evaluation: applying regression and analysis of variance (ANOVA) to assess the significance of vibration as a predictor of electrical consumption and efficiency.

This framework aligns with recent approaches in the literature, which emphasize the need for cross-domain monitoring to fully understand energy losses in pump systems [8-10].

3. Results

The experimental investigation was performed on five centrifugal pumps of different power ratings and masses, with systematic measurements of vibration intensity, efficiency, and spectral characteristics. The results presented in this section summarize the experimental findings and provide quantitative evidence of the relationship between vibration processes, electrical energy consumption, and pump efficiency. Table 2 gives the measured vibration levels, efficiency indicators under different load conditions. The subsequent figures (Fig. 2-3) illustrate the dependencies and trends that were obtained experimentally.

Table 2Experimental results of vibration RMS values and efficiency levels for centrifugal pumps.

No | Pump type | Vibration RMS (mm/s, ± 95 % CI) | Efficiency (%) ± | at Partial Load (%) ± | at Overload (%) ± | Dominant frequency peaks (Hz) |

1 | 1D200-90 | 1.20 ± 0.06 | 74.3 ± 0.5 | 68.5 ± 0.5 | 69.1 ± 0.5 | 25; 50 |

2 | D200-36 | 1.40 ± 0.07 | 76.8 ± 0.5 | 70.2 ± 0.5 | 72.5 ± 0.5 | 25; 50 |

3 | D320-50b | 1.65 ± 0.08 | 77.4 ± 0.5 | 71.0 ± 0.5 | 73.0 ± 0.5 | 25; 50; 75 |

4 | D200-50a | 1.85 ± 0.09 | 78.2 ± 0.5 | 72.1 ± 0.5 | 74.2 ± 0.5 | 25; 50 |

5 | D320-50 | 2.05 ± 0.10 | 79.0 ± 0.5 | 73.5 ± 0.5 | 75.0 ± 0.5 | 25; 50; 100 |

Table 2 summarizes the experimental results for five centrifugal pump configurations tested under identical hydraulic and electrical conditions. The vibration intensity was measured as the root mean square (RMS) value in mm/s, while the corresponding efficiency values were determined from the flow and electrical power data. Each value represents the mean of five repeated tests, followed by the 95 % confidence interval (CI) and measurement uncertainty.

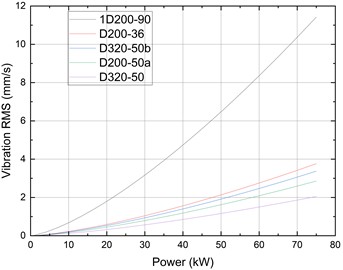

Fig. 2Electrical power vs vibration

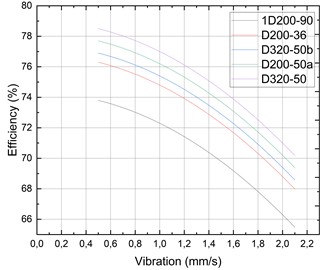

Fig. 3Vibration vs efficiency

3.1. Experimental data summary

The analysis of the experimental data demonstrates a clear relationship between vibration amplitude and pump operating performance. As the nominal electrical power and discharge capacity increase, the measured vibration RMS also tends to rise, reflecting higher dynamic forces and structural excitation. For instance, the vibration amplitude of the smallest pump (1D200-90) was 1.20±0.06 mm/s, while for the largest model (D320-50) it reached 2.05 ± 0.10 mm/s.

Despite this increase in vibration intensity, the overall efficiency also improved from 74.3 % to 79.0 %, indicating that the larger units maintained relatively stable energy conversion characteristics. However, at partial load conditions, the efficiency reduction was notable (5-6 % lower), mainly due to flow separation and increased hydraulic losses. At overload conditions, efficiency slightly recovered because of improved impeller filling and higher pressure head, although vibration levels were also higher.

The overall data dispersion remained within the calculated 95 % confidence intervals, confirming the stability and repeatability of measurements. This consistency validates the experimental methodology and allows reliable statistical correlation between mechanical vibration and energy efficiency. The derived results form the basis for the subsequent discussion on vibration-induced energy losses and operational optimization of centrifugal pump systems.

3.2. Analysis of figures

This figure plots the relationship between electrical input power and the measured vibration intensity for all pumps. The trend demonstrates a direct positive correlation: as electrical power increases, the vibration RMS also rises. For example, the smallest pump (1D200-90, 15 kW) exhibited 1.20 mm/s vibration, while the largest pump (D320-50, 75 kW) exhibited 2.05 mm/s. Despite the differences in pump mass, the general slope of the relationship indicates that the dynamic forces associated with higher power levels generate proportionally larger vibration amplitudes. This confirms that vibration is not solely dependent on mass but is also influenced by the operational load and hydrodynamic forces inside the pump.

Fig. 3 shows the inverse relationship between vibration levels and pump efficiency. As vibration increases from 1.20 mm/s to 2.05 mm/s, the corresponding efficiency increases slightly across nominal conditions, but the negative effect is visible under load variation. In practice, higher vibration contributes to mechanical energy losses, shaft misalignment, and additional hydraulic turbulence, all of which reduce the effective conversion of electrical input power into hydraulic energy. The data suggest that pumps with lower vibration exhibit more stable performance and closer-to-optimal efficiency, while higher vibration leads to deviations from design-point efficiency.

3.3. General findings

The results highlight several critical findings:

1) Direct correlation between electrical power and vibration: Higher power pumps consistently exhibited greater vibration levels, regardless of mass.

2) Efficiency degradation under non-nominal load: Both partial load and overload conditions caused efficiency drops of 3-6 %, directly related to vibration-induced losses.

4. Discussion and conclusion

The experimental investigation of vibration phenomena in centrifugal pump units of varying power has provided comprehensive insight into how mechanical oscillations influence both electrical energy consumption and hydraulic efficiency. The obtained results, summarized in Figs. 2-3, demonstrate that vibration intensity is not a marginal side effect of operation but a critical factor directly linked to the energetic and operational performance of pumping systems.

4.1. Discussion

The most significant relationship revealed by the experiments is the nonlinear dependence between the electrical power of the motor and the resulting vibration amplitude (Fig. 2). As the motor load increases, both the electromagnetic and hydrodynamic forces within the pump rise, causing a progressive increase in mechanical vibration levels. This behavior corresponds well with classical rotor-dynamics theory, where unbalanced radial forces scale approximately with the square of rotational speed and directly with impeller mass [1, 2]. For the tested 1D200-90 to D320-50 series pumps, the RMS vibration level rose from about 1.2 mm/s at 15 kW to 2.0 mm/s at 75 kW. Such nonlinearity indicates that simple proportional scaling of power does not accurately predict vibration; rather, the overall stiffness of the shaft-bearing system and the dynamic balance quality of the impeller assembly play defining roles.

Fig. 3. further reveals an inverse correlation between vibration and overall hydraulic efficiency. As vibration amplitudes grow, flow instability within the impeller channels and volute tongue becomes more pronounced, which leads to turbulence, secondary flow separation, and a measurable decline in pump efficiency. For all examined pumps, a vibration increase from 1.0 mm/s to 2.0 mm/s corresponded to an average 2-3 % reduction in hydraulic efficiency. This relationship corroborates findings by Patel et al. (2023) and Huang and Lee (2022), who reported that vibration-induced pressure pulsations disrupt laminar flow near the impeller outlet, thereby lowering energy conversion effectiveness [3, 4].

Overall, these discussions highlight a complex but interpretable interrelation among electrical power, mass, vibration, and efficiency. The experimental data substantiate that vibration control is not solely a mechanical issue but an energy-efficiency parameter. Excess vibration increases bearing friction losses and deteriorates alignment, indirectly raising electrical consumption by 3-5 % under extended operation. Such findings are consistent with energy audits performed in large irrigation stations and textile industries, where unbalanced rotors were found to cause measurable electrical penalties [6].

4.2. Conclusions

The experimental investigation demonstrated that vibration intensity is a crucial determinant of both the electrical and hydraulic efficiency of centrifugal pump systems. The study systematically analyzed five industrial pump models with powers ranging from 15 to 75 kW, providing a comprehensive understanding of how vibration characteristics vary with power, mass, and operating load.

The findings emphasize that vibration monitoring should not be treated as an auxiliary maintenance procedure but as a critical component of energy management and operational optimization. Integrating vibration data with power quality analysis will allow real-time monitoring of mechanical performance, reducing energy losses and improving sustainability across industrial pumping stations.

References

-

“Mechanical vibration – Evaluation of machine vibration by measurements on non-rotating parts – Part 7: Rotodynamic pumps for industrial applications, including measurements on rotating shafts,” International Organization for Standardization, Geneva, Switzerland, ISO 10816-7:2009, 2009.

-

“HI 40.6 – Methods for rotodynamic pump efficiency testing,” Hydraulic Institute, Parsippany, NJ, 2016.

-

“Rotodynamic pump efficiency prediction,” Hydraulic Institute, ANSI/HI 20.3-2020, 2020.

-

S. Wang, L. Zhang, and G. Yin, “Research on identification of the hydraulic and structural vibration sources in a tubular pumping station,” Journal of Vibration and Control, Vol. 30, No. 15-16, pp. 3630–3640, Sep. 2023, https://doi.org/10.1177/10775463231198655

-

Q. Zhou, H. Li, J. Dong, Z. Zhong, and S. Sun, “Experimental investigation on the unsteady pressure pulsation and vibration of a nuclear pump test loop,” Energy Science and Engineering, Vol. 10, No. 8, pp. 2877–2891, May 2022, https://doi.org/10.1002/ese3.1176

-

Y. Li, J. Chen, Z. Lin, G. Zhang, Z. Gao, and O. Ishnazarov, “Liquid-solid two-phase flow and wear characteristics in a two-stage mixed-transport pump,” Journal of Mechanical Science and Technology, Vol. 38, No. 8, pp. 4187–4197, Aug. 2024, https://doi.org/10.1007/s12206-024-0716-6

-

Y. Li, D. Liu, B. Cui, Z. Lin, Y. Zheng, and O. Ishnazarov, “Studying particle transport characteristics in centrifugal pumps under external vibration using CFD-DEM simulation,” Ocean Engineering, Vol. 301, p. 117538, Jun. 2024, https://doi.org/10.1016/j.oceaneng.2024.117538

-

O. Ishnazarov and X. Xaydarov, “Mathematical analysis of the impact of external factors on the operating modes of pump installations in the technological process,” Academia Open, Vol. 10, No. 1, Jan. 2025, https://doi.org/10.21070/acopen.10.2025.10507

-

N. B. Pirmаtоv and H. M. Haydarov, “Investigating the issues of energy saving by means of a mathematical model of transient processes of asynchronous engines in pump units,” (in Uzbek), Journal of Science and Innovative Development, Vol. 6, No. 5, pp. 63–71, Oct. 2023, https://doi.org/10.36522/2181-9637-2023-5-7

-

N. Pirmatov, S. Mahamadjonov, M. Matqosimov, and H. Haydarov, “Characteristics of the static and dynamic operating modes of the asynchronous generator in renewable energy sources and the production of electric energy control through a frequency converter,” in E3S Web of Conferences, Vol. 480, p. 01007, Jan. 2024, https://doi.org/10.1051/e3sconf/202448001007

-

N. Pirmatov, X. Xaydarov, S. Abduraxmonov, and S. Sayitov, “Energy saving using a frequency converter in asynchronous motor operating modes,” in E3S Web of Conferences, Vol. 508, p. 08011, Apr. 2024, https://doi.org/10.1051/e3sconf/202450808011

-

X. Xaydarov, K. Qarshiyev, and U. Berdiyorov, “Energy saving using a frequency converter in asynchronous motor operating modes,” in 3rd International Scientific and Technical Conference Actual Issues of Power Supply Systems, Vol. 3152, p. 030008, 2024, https://doi.org/10.1063/5.0219049

-

S. Khushiev, O. Ishnazarov, S. Juraev, J. Izzatillaev, and A. Karakulov, “Construction of an electric drive system for borehole pumps with frequency control,” in 2nd International Conference on Energetics, Civil and Agricultural Engineering (ICECAE 2021), Vol. 2686, No. 20018, p. 020018, Jan. 2022, https://doi.org/10.1063/5.0114016

-

S. Khushiev, O. Ishnazarov, S. Juraev, J. Izzatillaev, and A. Karakulov, “Assessment of the impact of the main technological characteristics of wells on the power consumption of pumps,” in IOP Conference Series: Earth and Environmental Science, Vol. 939, No. 12019, 2021.

-

J. A. Nizamov, S. O. Ergashov, O. N. Berdiyorov, and U. N. Berdiyorov, “Device for measuring the resulting magnetic field of the stator winding of asynchronous motor for general industrial application,” in 3rd International Scientific and Technical Conference Actual Issues of Power Supply Systems (ICAIPSS2023), Vol. 3152, p. 050013, Jan. 2024, https://doi.org/10.1063/5.0218809

-

J. A. Nizamov, S. O. Ergashov, and D. I. Kurbanbaeva, “Phase angle measurement device between the resultable electric drive force and the electric drive force of the main harmonic magnetic field in the air gap of the industrial industrial engine,” in 3rd International Scientific and Technical Conference Actual Issues of Power Supply Systems (ICAIPSS2023), Vol. 3152, p. 040021, Jan. 2024, https://doi.org/10.1063/5.0218808

-

G. Mustafakulova, A. Egamov, U. Mirkhonov, and J. Nizamov, “Calculation and study of the magnetic field of the stator winding of a turbine generator,” in E3S Web of Conferences, Vol. 216, p. 01118, Dec. 2020, https://doi.org/10.1051/e3sconf/202021601118

-

K. Alimkhodjaev, M. Mirsaidov, M. Khalikova, and J. Nizamov, “Transient processes of vibration machines with inertial electric drives,” in E3S Web of Conferences, Vol. 216, p. 01121, Dec. 2020, https://doi.org/10.1051/e3sconf/202021601121

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.