Abstract

The article presents the results of the development and research of self-compacting fine-grained concrete mixes for energy-efficient vibration-free construction technologies. The main focus is on selecting optimal compositions that ensure the required level of mobility and self-compaction through a rational ratio of components and the use of complex modifying additives. The results of research into the rheological characteristics of concrete mixtures, as well as the physical and mechanical parameters of the materials obtained, are presented. The patterns of the influence of the composition and structure of concrete on its density, strength, water absorption and deformability have been established. The results obtained confirm the possibility of creating effective self-compacting fine-grained concretes with high structural homogeneity and reduced energy consumption during production and laying.

1. Introduction

Modern developments in construction technology are aimed at ensuring high efficiency of production processes, reducing energy consumption and increasing the durability of structures. In this regard, particular attention is paid to improving the properties of cement composites, which remain the main construction material due to their versatility, availability and. Traditional methods of compacting concrete mixtures using vibration are associated with increased energy consumption, labour intensity, and the risk of disrupting the homogeneity of the material structure [1].

One of the most promising areas of development in concrete technology is the creation of self-compacting fine-grained concretes (SCFC), which provide the necessary degree of compaction under their own weight, without the use of external vibration. The effectiveness of this class of concrete is determined primarily by its rheological properties, which determine the mixture's ability to spread, self-compact and maintain structural stability. Optimisation of rheological characteristics allows for simultaneous improvement of the concrete mixture’s workability, improvement of the cement stone structure and, as a result, improvement of the operational characteristics of the finished material – strength, density, frost resistance and water resistance [2].

The rheological properties of self-compacting fine-grained mixtures are improved by comprehensively modifying their composition. The combined use of highly effective plasticising additives and mineral microfillers allows the water-cement ratio to be adjusted, hydration processes to be activated, and a denser, fine-pored cement stone structure to be formed. This significantly improves not only the workability of the mixtures, but also their structural homogeneity, which ensures stable concrete quality with minimal energy consumption and the elimination of vibration equipment.

A number of studies confirm that the use of complex modifying systems contributes to the intensification of physicochemical processes in the cement matrix, improves particle dispersion, reduces internal friction in the system and forms a more stable structure. This not only improves the technological properties of concrete mixtures, but also increases the strength and performance characteristics of hardened concrete, including frost resistance, water resistance and durability [3-5].

The development of vibration-free and low-vibration technologies is particularly relevant for modern construction, where energy efficiency, environmental friendliness and technological efficiency of production processes must be combined. In the context of the priority areas of development of the construction industry in the Republic of Uzbekistan and the implementation of strategic programmes to improve the quality and seismic resistance of capital construction projects, the creation of self-compacting fine-grained concretes based on local mineral resources is of particular importance [6-10].

The aim of this study is to develop compositions and investigate the properties of self-compacting fine-grained concrete mixtures using complex modifying additives that provide improved rheological and operational properties of materials for energy-efficient vibration-free construction technologies.

The scientific novelty of the work lies in establishing the patterns of influence of chemical and mineral additives of various nature on the rheological behaviour of mixtures, structure and physical and mechanical characteristics of self-compacting fine-grained concretes, as well as in optimising the composition parameters that ensure a combination of high mobility and strength with reduced energy consumption in the production cycle.

2. Research methods and materials used

Materials widely available in the Republic of Uzbekistan were used to conduct experimental research on the development of self-compacting fine-grained concrete. The main binder was Portland cement grade CEMI 32.5N, produced by “Kizilkumcement” LLC.

The mineral filler used was a metallurgical waste product from “Uzbekistan Temir Yollari” JSC, which is a finely dispersed grey-brown material with a high specific surface area and the presence of amorphous phases. Before use, the filler was dried at a temperature of (105±5) °C to a constant mass and then ground in a ShLM-100 laboratory ball mill. The grinding time and load were determined experimentally in order to achieve optimal dispersion.

The dispersion of the mineral filler was controlled by the specific surface area using the Kozeni-Karmann air permeability method with the PSKh-11A device, which allowed quantitative assessment of the degree of fineness of grinding. In addition, the morphology of the particles and the degree of aggregation were assessed using a sieve No. 008.

The chemical additive used was PRO500 superplasticiser based on polycarboxylate esters, which has a high water-reducing capacity (up to 25-30 %) and provides the required mobility of cement systems with minimum water consumption.

Experimental studies were conducted to determine the effect of the composition and complex of modifying additives on the rheological, physical-mechanical and operational characteristics of self-compacting fine-grained concretes. All tests were performed in accordance with applicable regulatory documents and standards.

The rheological properties of concrete mixtures were evaluated in accordance with the requirements of GOST 10181–2021 ‘Concrete mixtures. Test methods’. The mobility of the mixture was determined by the flow of the Abrams cone, which made it possible to evaluate the degree of spreadability, viscosity and workability of the composition. In addition, fluidity and the ability to pass through obstacles were investigated using a V-shaped cone and an L-shaped box (V-funnel and L-box) in accordance with the recommendations of EFNARC (European Guidelines for Self-Compacting Concrete, 2005), adapted to the requirements of GOST 10181-2021. These tests provided a comprehensive assessment of the concrete mix's ability to self-compact under its own weight without delamination or loss of homogeneity.

The physical and mechanical characteristics were studied on control samples manufactured in accordance with GOST 10180-2012 “Concrete. Methods for determining strength using control samples”. Compressive strength was determined on cubic samples measuring 100×100×100 mm after 3, 7 and 28 days of hardening. Prismatic strength was determined on 100×100×400 mm samples in accordance with GOST 24452-2021 “Concrete. Methods for testing bending and tensile strength in bending”, which made it possible to evaluate the crack resistance and deformability of the material.

The operational properties of concrete were determined using standard methods. Water impermeability was assessed in accordance with GOST 12730.5-2021 “Concrete. Methods for determining water impermeability” with a gradual increase in water pressure until the first signs of filtration appeared. Frost resistance was determined in accordance with GOST 10060.0-2012 “Concrete. Methods for determining frost resistance” by the number of freezing and thawing cycles until the strength decreased by no more than 5 %. Water absorption was measured in accordance with GOST 12730.3-2020 “Concrete. Methods for determining water absorption” by saturating the samples with water to a constant mass, which made it possible to estimate the volume of the open-pore structure and the degree of capillary activity of the material.

Porosity was investigated using mercury porosimetry with a Thermo Scientific Pascal 240 EVO device, which provides high accuracy in analysing the distribution of pores by size and their total volume. The testing methodology was based on international standards ISO 15901-1:2016 and DIN 66133. The results obtained made it possible to establish a relationship between the microstructure of cement stone, the composition of modifying additives and the performance properties of concrete, in particular strength, water absorption and frost resistance.

3. Results and discussions

During the experimental research stages, the effectiveness of using a complex modifying additive in self-compacting fine-grained concrete mixtures and concretes was studied. The main task was to determine the optimal dosages of components that would ensure the required rheological and physical-mechanical characteristics with a minimum water-cement ratio [11].

The dosage of chemical-mineral modifiers was determined on the basis of preliminary experimental studies and amounted to 1 % of the total mass of the binder for the SP system and 25% of the total mass of the binder for the system using BWS. The amount of mixing water was adjusted depending on the slump values of the mixture, determined by the Abrams method, in order to achieve a workability class of PK2. This approach ensured the production of concrete mixtures capable of self-compacting under their own weight without the need for vibration, which meets the requirements of energy-efficient and vibration-free moulding technologies [12-15].

The detailed compositions of the mixtures studied and their physical and technical characteristics are given in Table 1.

Table 1Composition and properties of concrete mixtures with modifying additives

No. | Cement, kg | Sand, kg | Water, l | BWS, kg | SP, % | W/C | CS, sm |

1 | 550 | 1375 | 275 | – | – | 0.51 | P5 (≥20 sm) |

2 | 413 | 1597 | 190 | – | 1.0 | 0.34 | |

3 | 413 | 1460 | 190 | 137 | 1.0 | 0.34 |

The main technological parameters of self-compacting fine-grained concrete mixtures include the preservation of mobility over time and resistance to segregation, which together determine the mixture's ability to self-compact stably during transport and placement. To evaluate these indicators, tests were conducted on the retention of mobility in accordance with the requirements of GOST 10181-2014 “Concrete mixtures. Test methods” and GOST 30459-2008 “Concrete mixtures. Methods for determining delamination”.

The experiments were conducted under controlled environmental conditions at a temperature of (22±2) °C. The mobility of the concrete mix was determined by the diameter of the spread of a standard cone, which made it possible to quantitatively assess the degree of mobility and self-compaction ability without loss of structural homogeneity.

Measurements of the concrete mix’s mobility indicators began immediately after its preparation and were carried out at 60-minute intervals throughout the observation period. A new, pre-mixed sample was used for each test cycle, which excluded the influence of structure formation and partial hydration processes on the measurement results.

The data obtained made it possible to assess the dynamics of changes in the mobility of self-compacting fine-grained concrete mixtures (SCM) over time and to establish the degree of preservation of their rheological characteristics at various dosages and types of complex modifying additives [16, 17].

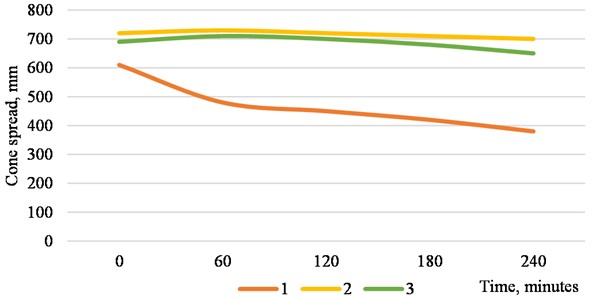

The results of the study of the mobility of self-compacting fine-grained concretes (SCF) with the introduction of various modifying systems are presented in Fig. 1, which clearly illustrates the influence of chemical-mineral additives on the mobility and ability of mixtures to maintain self-compacting properties during curing.

Fig. 1Change in the spread ability of concrete mix over time in the compositions studied

Analysis of the results showed that compositions without additives quickly lose their mobility, becoming unsuitable for use. The introduction of SP ensures long-term fluidity retention due to steric repulsion of particles, while the combined use of SP and BWS stabilises the structure of the mixture and reduces water separation. The use of a complex additive allows PK2 class mobility to be maintained for over 3 hours, improving uniformity and enabling laying without vibratory compaction.

The main difference between self-compacting fine-grained concrete (SCFC) and traditional concrete mixtures is their unique rheological characteristics and high degree of grain density. Thanks to the optimal ratio of components and the action of complex modifying additives, SCFC is characterised by its ability to compact itself under its own weight without the use of external vibration. This ability ensures uniform filling of the formwork, absence of voids and defects, as well as increased adhesion to the reinforcement cage, which contributes to the formation of a dense, homogeneous structure and improves the quality of finished concrete structures [18].

At the production stage, the quality of self-compacting mixtures was assessed according to a number of key technological parameters that determine their self-compacting ability. The viscosity of the mixture was determined using a V-funnel, which made it possible to establish the flow rate and resistance of the composition to delamination. This indicator is one of the most important criteria characterising the stability and uniformity of the concrete mixture.

The ability of the mixture to fill the form and pass through reinforcement obstacles was assessed using an L-shaped box (L-box test). This method allows determining the ratio of the height of the concrete mixture after passing through the reinforcement barrier to the initial level, as well as the flow time. The test reflects the fluidity, homogeneity and self-compacting ability of the composition when simulating real concreting conditions. These criteria serve as the basis for confirming the compliance of self-compacting mixtures with established requirements and guarantee their high technological efficiency, effectiveness and reliability in practical application (Table 2).

Table 2Permissible deviations in indicators and quality indicators for self-compacting concrete mixtures

Name of concrete mix quality indicator | The interval in which the specified indicator value falls | Permissible deviation of the indicator from the specified value | Compositions | ||

1 | 2 | 3 | |||

Average density, kg/m3 | 2200-2600 | ±20 | 2225 | 2354 | 2306 |

Viscosity index using a V-shaped funnel, with | 9-25 | ±3 | 61 | 9 | 11 |

An indicator of the ability to overcome obstacles in tests using an L-shaped box, with | According to the project | ±0.05 | Failed to overcome completely | 6 | 10 |

Analysis of the test results showed a direct correlation between the flow time from the V-shaped funnel and the viscosity of the concrete mix. It was found that as the flow time decreases, the fluidity increases and the viscosity of the mix decreases, which is a favourable factor for self-compacting concrete. In the modified compositions studied, the flow time varied from 9 to 11 seconds, which meets the requirements for self-compacting fine-grained concrete. The minimum flow time (9 seconds) was recorded for the composition with the optimal dosage of the modifying additive, which indicates a balanced ratio between fluidity and structural stability. In the control composition, which did not contain a modifier, the flow time was 61 seconds, which significantly exceeds the permissible regulatory limits and indicates insufficient mobility and increased viscosity of the mixture.

The results of tests conducted using the L-box test showed that the time taken for the mixture to pass through the obstacles varied from 6 to 19 seconds. The minimum time (6 seconds) was observed for the most technologically advanced composition and indicates high mobility and the ability of the mixture to evenly fill the mould without forming voids and delamination. Compositions No. 2 and No. 3 demonstrated an optimal combination of fluidity and viscosity parameters, confirming that their rheological properties meet the requirements for self-compacting fine-grained concrete (SCFC).

The next stage involved studying the effect of the complex additive on the physical and mechanical properties of self-compacting fine-grained concretes (Table 3). It was found that the addition of the additive improves strength and deformation characteristics. The prismatic strength () of composition No. 3 increased by 14.6 % compared to the control (No. 1) and by 6.7 % compared to composition No. 2. The modulus of elasticity () increased by 6.5 % and 5.2 %, respectively.

The use of a complex additive also increased the density of the concrete by reducing capillary porosity, which led to improved performance characteristics. Frost resistance increased from F300 to F450, and water resistance from W8 to W12. Water absorption decreased from 6.1 % to 4.5 % by mass and from 14.2 % to 8.3 % by volume, confirming the reduction in porosity and improvement in material durability.

The physical and mechanical properties of concrete, including strength, deformability, permeability and frost resistance, are determined by its porous structure, which depends on the size, shape and volume of the pores [18-20].

A Thermo Scientific Pascal 240 mercury porosimeter was used to analyse the porous structure. Concrete samples, hardened for 28 days, were vacuum-treated and filled with mercury after drying at 105 °C. Based on the obtained porograms (Table 4), the quantitative characteristics of the porous structure of the studied compositions were determined.

Table 3Properties of concrete with modifying additives

No | Concrete class | Prismatic strength, MPa | Modulus of elasticity, 103, MPa | Water resistance, Atm | Frost resistance, cycle | Water absorption, % | |

By mass, % | By volume, % | ||||||

Composition No. 1 | В35 | 35.49 | 35.5 | W8 | 300 | 6.1 | 14.2 |

Composition No. 2 | 38.7 | 35.8 | W10 | 400 | 4.9 | 9.1 | |

Composition No. 3 | 41.3 | 37.8 | W12 | 450 | 4.5 | 8.3 | |

Table 4Porous structure indicators of the samples studied

Name of indicators | Composition No. 1 | Composition No. 2 | Composition No. 3 |

Relative pore volume (mm3/g) | 51.11 | 44.12 | 41.78 |

Total pore area (m3/g) | 5.16 | 4.822 | 4.3 |

Average pore size (μm) | 0.024 | 0.022 | 0.021 |

Total porosity of samples, % | 9.81 | 8.89 | 8.42 |

The results of porosimetric analysis of three compositions of fine-grained concrete revealed a regular improvement in the porous structure when modifying additives were introduced. In composition No. 3, containing KK, the total porosity decreased by 9.4 % compared to composition No. 2 and by 14.2 % compared to composition No. 1, which indicates an increase in density and a decrease in the volume of voids.

The relative pore volume in composition No. 3 decreased to 41.78 mm3/g, which is 18.2 % and 5.3 % lower than the values for compositions No. 1 and No. 2, respectively. The average pore size was 0.021 μm, the minimum value among the mixtures studied. The reduction in porosity and pore size increases the density, strength and frost resistance of concrete.

The reduction in porosity and average pore size results in a denser and more uniform concrete structure, which increases its strength, modulus of elasticity, water resistance and frost resistance. Thus, the use of a complex modifying additive contributes to the intensification of the cement stone structure formation processes, increases its compactness and durability, which confirms the effectiveness of the developed approach to modifying self-compacting fine-grained concretes.

4. Conclusions

Experimental studies have shown that the use of a complex modifying additive in self-compacting fine-grained concretes significantly improves their rheological and physical-mechanical characteristics. Optimisation of the component composition made it possible to ensure the required fluidity and resistance to delamination while maintaining a high density structure without the need for vibration compaction.

Rheological tests showed that the modified compositions are characterised by a flow time from a V-shaped funnel of 9-11 seconds and a passage time through an L-box of 6-19 seconds, which indicates high mobility and self-compacting ability. The control composition without additives had significantly worse performance (flow time of 61 seconds), confirming the effectiveness of the complex modifier.

Analysis of the physical and mechanical properties showed that the use of a complex additive increases the prismatic strength of concrete by 14.6 %, increases the modulus of elasticity by 6.5 %, and improves performance indicators: frost resistance increased from F300 to F450, water resistance from W8 to W12, and water absorption decreased from 6.1 % to 4.5 % by mass. The results confirm the formation of a denser and more homogeneous cement stone structure.

Mercury porosimetry data showed a decrease in total porosity and average pore size in the modified compositions, which increases the density, strength and durability of concrete. The total porosity decreased to 8.42 %, and the relative pore volume to 41.78 mm3/g, which corresponds to an improvement in the microstructural characteristics of the material.

Thus, the introduction of complex modifying additives allows for the production of self-compacting fine-grained concretes with improved performance characteristics, ensuring the implementation of vibration-free and energy-efficient construction technologies. The developed compositions can be recommended for monolithic and prefabricated structures, especially in conditions of increased requirements for surface quality, density and durability of concrete.

References

-

C. Yalçınkaya and O. Çopuroğlu, “Elephant skin formation on UHPC surface: Effects of climatic condition and blast furnace slag content,” Construction and Building Materials, Vol. 268, p. 121126, Jan. 2021, https://doi.org/10.1016/j.conbuildmat.2020.121126

-

A. A. Zende et al., “Mechanical properties of high-strength self-compacting concrete,” ACS Omega, Vol. 8, No. 20, pp. 18000–18008, May 2023, https://doi.org/10.1021/acsomega.3c01204

-

J. Ahmad, Z. Zhou, and A. F. Deifalla, “Steel fiber reinforced self-compacting concrete: a comprehensive review,” International Journal of Concrete Structures and Materials, Vol. 17, No. 1, Oct. 2023, https://doi.org/10.1186/s40069-023-00602-7

-

S. Gupta et al., “In situ crack mapping of large-scale self-sensing concrete pavements using electrical resistance tomography,” Cement and Concrete Composites, Vol. 122, p. 104154, Sep. 2021, https://doi.org/10.1016/j.cemconcomp.2021.104154

-

S. Zheng, Q. Liu, F. Han, S. Liu, T. Han, and H. Yan, “Basic mechanical properties of self-compacting concrete prepared with aeolian sand and recycled coarse aggregate,” Buildings, Vol. 14, No. 9, p. 2949, Sep. 2024, https://doi.org/10.3390/buildings14092949

-

M. Marchel, M. P. Rayaroth, C. Wang, L. Kong, J. A. Khan, and G. Boczkaj, “Hydrophobic (deep) eutectic solvents (HDESs) as extractants for removal of pollutants from water and wastewater – a review,” Chemical Engineering Journal, Vol. 475, p. 144971, Nov. 2023, https://doi.org/10.1016/j.cej.2023.144971

-

A. Adilkhodzhaev, I. Kadirov, B. Kudratov, B. Khasanov, M. Radjabov, and V. Kondrashenko, “Some aspects of the processes of obtaining and application of mineral powders as fillers for cement systems,” in E3S Web of Conferences, Vol. 410, p. 01021, Aug. 2023, https://doi.org/10.1051/e3sconf/202341001021

-

H. Ul Haq, A. Wali, F. Safi, M. B. Arain, L. Kong, and G. Boczkaj, “Natural deep eutectic solvent based ultrasound assisted liquid-liquid micro-extraction method for methyl violet dye determination in contaminated river water,” Water Resources and Industry, Vol. 29, p. 100210, Jun. 2023, https://doi.org/10.1016/j.wri.2023.100210

-

A. Patil et al., “Performance analysis of self-compacting concrete with use of artificial aggregate and partial replacement of cement by fly ash,” Buildings, Vol. 14, No. 1, p. 143, Jan. 2024, https://doi.org/10.3390/buildings14010143

-

A. Adilkhodjaev, I. Kadyrov, and Rasulmukhamedov, “Research of porosity of a cement stone with a zeolite containing filler and a superplastic stificator,” in E3S Web of Conferences, Vol. 264, p. 02007, Jun. 2021, https://doi.org/10.1051/e3sconf/202126402007

-

J. Ahmad, Z. Zhou, and A. F. Deifalla, “Self-compacting concrete with partially substitution of waste marble: a review,” International Journal of Concrete Structures and Materials, Vol. 17, No. 1, Apr. 2023, https://doi.org/10.1186/s40069-023-00585-5

-

X. Liu et al., “Mix design and performance study of high-strength self-compacting concrete with manufactured sand,” Materials, Vol. 18, No. 1, p. 55, Dec. 2024, https://doi.org/10.3390/ma18010055

-

K. C. Onyelowe et al., “Mechanical properties of self compacting concrete reinforced with hybrid fibers and industrial wastes under elevated heat treatment,” Scientific Reports, Vol. 15, No. 1, Apr. 2025, https://doi.org/10.1038/s41598-025-96899-3

-

O. Gencel, C. Ozel, W. Brostow, and G. Martínez-Barrera, “Mechanical properties of self-compacting concrete reinforced with polypropylene fibres,” Materials Research Innovations, Vol. 15, No. 3, pp. 216–225, Nov. 2013, https://doi.org/10.1179/143307511x13018917925900

-

R. B. Ardalan, Z. N. Emamzadeh, H. Rasekh, A. Joshaghani, and B. Samali, “Physical and mechanical properties of polymer modified self-compacting concrete (SCC) using natural and recycled aggregates,” Journal of Sustainable Cement-Based Materials, Vol. 9, No. 1, pp. 1–16, Jan. 2020, https://doi.org/10.1080/21650373.2019.1666060

-

J. Rashidov, R. Narov, K. Yusupov, and I. Kadyrov, “Unraveling the effects of compound additives on the strength of cast concrete,” Revista de Gestão Social e Ambiental, Vol. 18, No. 5, p. e05599, Mar. 2024, https://doi.org/10.24857/rgsa.v18n5-076

-

M. H. R. Sobuz et al., “High-strength self-compacting concrete production incorporating supplementary cementitious materials: experimental evaluations and machine learning modelling,” International Journal of Concrete Structures and Materials, Vol. 18, No. 1, Oct. 2024, https://doi.org/10.1186/s40069-024-00707-7

-

A. Adylkhodzhaev, I. Makhamataliev, I. Kadyrov, S. Shaumarov, and F. Ruzmetov, “To the question of the influence of the intensity of active centers on the surface of mineral fillers on the properties of fine-grained concrete,” International Journal of Innovative Technology and Exploring Engineering, Vol. 8, No. 9S2, pp. 219–222, Aug. 2019, https://doi.org/10.35940/ijitee.i1044.0789s219

-

S. Gao, Q. Liu, F. Han, and Y. Fu, “Mix design of recycled coarse aggregate self‐compacting concrete based on orthogonal test and analysis of mercury intrusion porosimetry,” Advances in Materials Science and Engineering, Vol. 2021, No. 1, Jul. 2021, https://doi.org/10.1155/2021/4829673

-

A. I. Adilkhodzhaev, I. A. Kadirov, D. T. Azimov, and B. S. Kudratov, “Thermodynamic analysis of mineral powder grinding processes,” In Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060003, Jan. 2024, https://doi.org/10.1063/5.0197549

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.