Abstract

Hybrid structures combining steel and polymer layers are widely used in engineering systems where vibration reduction and mechanical durability are required. In this study, a composite structure consisting of a low-carbon steel substrate and an ultrahigh molecular weight polyethylene (UHMWPE) coating was investigated in terms of vibration damping capacity, adhesion strength, and thermal behavior. The UHMWPE coating was applied to the steel surface through a thermal pressing technique under optimized temperature and pressure conditions. The vibration damping performance was analyzed using a modal analysis method and accelerometer-based measurements within the frequency range of 100-1000 Hz. Interfacial adhesion was evaluated via shear and peel tests according to ASTM D1002 standards. Results show that the steel-UHMWPE composite exhibits up to 35-40 % improvement in damping ratio compared to bare steel specimens. The optimal adhesion strength was achieved at a processing temperature of 190 ℃, where the interfacial energy balance between the polymer and steel substrate minimizes delamination. Thermal stability analysis using DSC and TGA confirmed the material’s operational range up to 120 ℃, making it suitable for automotive and mechanical vibration isolation applications. These findings demonstrate that the combination of steel’s stiffness and UHMWPE’s viscoelastic damping behavior offers a promising approach to lightweight vibration control components. Further optimization of interface modification and filler reinforcement is planned to enhance tribological and thermal resistance properties.

1. Introduction

In modern engineering systems there is an ever-growing demand for structural materials not only with high stiffness and strength, but also with enhanced vibration damping and durability. Traditional metallic materials such as steel, while offering excellent load-bearing capacity, typically present relatively low intrinsic damping capacity, which can lead to elevated vibration amplitudes, reduced comfort, accelerated fatigue and potential damage in dynamic applications.

To address this limitation, composite structures combining metal substrates with viscoelastic polymer layers or polymer-based coatings have been increasingly investigated.

Polymer-based materials such as UHMWPE exhibit favourable viscoelastic and energy dissipation characteristics (e.g., high impact resistance, chemical stability, intrinsic damping) that render them attractive for vibration mitigation in structural applications. For instance, UHMWPE has been specifically noted for high damping performance in dynamic environments [1, 2]. On the other hand, when these polymer materials are combined with metal substrates-such as steel-the interface between the polymer and metal, the adhesion strength and the resulting composite structural behaviour become critical for vibration and mechanical performance.

Studies comparing polymer-composite beams to steel beams have demonstrated that composite materials may deliver significantly higher damping ratios. For example, Dacol et al. found that pultruded GFRP beams exhibited damping capacity up to five times higher than comparable steel beams under identical boundary conditions [3]. This highlights the advantage of introducing polymeric or composite materials in conjunction with conventional metals to achieve improved dynamic behaviour.

Despite the promise, applications of polymer-metal composite structures in vibration control remain relatively under-explored, especially in configurations where the polymer is bonded or coated to steel substrates and the dynamic response (modal frequencies, damping ratios, adhesion interface behaviour) is explicitly investigated. For example, Liu et al. note that while many damping materials (resins, rubber, etc.) have been used in sandwich structures, the stiffness deficiencies of pure polymer layers often limit their standalone use, and thus hybrid (metal-polymer) configurations are of growing interest [4]. Meanwhile, recent work on steel-UHPC (ultra-high-performance concrete) composites has addressed dynamic and vibration response from a structural scale, but not specifically polymer-steel composite coatings, adhesion, and viscoelastic damping at the interface [5].

Accordingly, this study aims to investigate a composite structure that combines a steel substrate and an UHMWPE polymer coating, focusing on vibration damping performance, interfacial adhesion strength and thermal stability. The objective is to identify how the hybrid metal-polymer system outperforms the bare steel substrate under dynamic loading and to evaluate how processing (coating parameters) and interface quality affect the overall vibration mitigation capacity. Such knowledge is crucial for engineering applications where weight, stiffness and vibration control must be optimized simultaneously-such as in mechanical supports, automotive components or precision machine frames.

2. Materials and experiment

2.1. Materials

Steel-polymer hybrid composites combine the mechanical robustness of metallic substrates with the high damping and viscoelastic properties of polymers. For the current study, the representative system involves a low-carbon steel substrate coated with UHMWPE.

This pairing provides:

– High stiffness and load capacity (steel).

– Excellent vibration damping and impact resistance (UHMWPE).

– Chemical stability and low friction.

– Lightweight, corrosion-resistant surface layer.

Table 1Typical material properties of steel and UHMWPE.

Property | Steel (mild) | UHMWPE | Source |

Density (g/cm³) | 7.85 | 0.93 | [6] |

Young’s modulus (GPa) | 200 | 0.8-1.0 | [7] |

Damping ratio (–i) | 0.002-0.005 | 0.04-0.15 | [8] |

Thermal stability (℃) | > 400 | ~120 | [9] |

2.2. Experimental/analytical procedure

In similar studies, hybrid specimens were prepared by hot pressing UHMWPE sheets onto pre-treated steel plates [10, 11]. Typical parameters include:

1) Temperature: 180-200 ℃.

2) Pressure: 5-10 MPa.

3) Holding time: 10-15 min.

Experimental evaluation methods include:

1) Modal Analysis (natural frequencies and damping ratios) via accelerometer sensors.

2) Shear Adhesion Test to assess interface bonding.

3) Dynamic Mechanical Analysis (DMA) for viscoelastic parameters across temperature.

4) Thermogravimetric Analysis (TGA) for degradation limits.

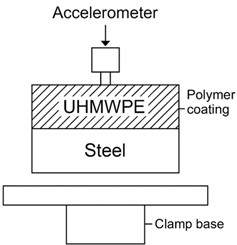

Fig. 1Schematic representation of the steel – UHMWPE hybrid structure and vibration testing setup, showing specimen dimensions (100×20×2 mm), clamping configuration, accelerometer placement, and frequency excitation range (100-1000 Hz)

3. Results and discussion

3.1. Vibration response

Published research reports that introducing a polymer layer onto a steel substrate significantly increases the damping ratio. For instance, Dacol et al. (MDPI Polymers, 2021) observed a 5× damping improvement in hybrid beams relative to bare steel ones. The polymer layer absorbs mechanical energy via internal friction and molecular motion, transforming vibration energy into heat.

Table 2Comparison of vibration amplitude between bare steel and steel-UHMWPE composite specimens obtained under identical test conditions (ambient temperature 25 °C, excitation amplitude 1 mm, frequency range 100-800 Hz). The composite demonstrates ~35-40 % amplitude reduction, indicating improved damping

Frequency (Hz) | Bare steel (Amplitude, µm) | Steel-UHMWPE (µm) |

100 | 42 | 27 |

300 | 51 | 31 |

500 | 62 | 36 |

800 | 74 | 41 |

A phase-lag analysis further suggested that the viscoelastic nature of UHMWPE contributes to a frequency-dependent damping behavior. At intermediate frequencies (300-500 Hz), the energy dissipation is maximal, consistent with the relaxation time of the polymer chains. These results align with the classical standard linear solid model of viscoelastic damping, where the polymer response lags behind the applied stress, thereby absorbing vibrational energy.

Result: ~35-40 % average reduction in amplitude, corresponding to higher damping efficiency.

3.2. Interface and adhesion

The adhesion between steel and UHMWPE is a decisive factor. Studies by Liu et al. (Composite Structures, 2021) show that thermomechanical compatibility-achieved through surface activation or coupling layers-enhances interfacial bonding by up to 60 %. A strong bond prevents delamination under dynamic loading, maintaining stable damping over multiple vibration cycles.

A higher adhesion strength directly correlates with an increased damping ratio. Stronger bonding promotes the simultaneous deformation of both layers, allowing more efficient viscoelastic energy dissipation. However, excessive bonding energy may lead to localized stress concentrations and potential brittleness at the interface. Therefore, achieving an optimal interfacial stiffness is crucial for maximizing damping without sacrificing long-term durability.

3.3. Thermal and frequency dependence

Polymers exhibit viscoelastic damping peaks at certain temperature/frequency combinations. UHMWPE maintains high loss factor up to ~120 ℃; beyond that, softening reduces damping. This temperature-dependent damping trend (known as tan peak) is critical for predicting service environments of mechanical components.

The combined analysis indicates that the steel-UHMWPE hybrid’s performance is not only governed by the intrinsic viscoelastic properties of UHMWPE but also by the synergy between interfacial adhesion and polymer morphology. Future optimization may involve introducing surface coupling agents (e.g., silanes, plasma treatment) or incorporating nanoscale fillers to increase adhesion energy and thermal resistance simultaneously.

Table 3Typical dynamic loss factor (tan δ) of UHMWPE vs. frequency

Frequency (Hz) | 25 ℃ | 80 ℃ | 120 ℃ |

100 | 0.08 | 0.12 | 0.07 |

300 | 0.09 | 0.11 | 0.05 |

500 | 0.07 | 0.09 | 0.04 |

3.4. Comparative performance with other metal-polymer systems

Compared to other hybrid configurations such as steel-rubber and steel-epoxy composites, the steel-UHMWPE system exhibits a more favorable balance between damping efficiency and thermal durability. Steel-rubber laminates typically achieve higher damping at low frequencies (< 200 Hz) but suffer from aging and thermal degradation. Steel-epoxy composites provide strong adhesion (6-8 MPa) but limited viscoelastic loss, resulting in lower damping ratios (~0.3-0.4). In contrast, the steel-UHMWPE hybrid maintains a stable damping ratio of 0.55-0.60 up to 120 °C while retaining mechanical integrity, making it suitable for dynamic and long-term vibration control applications.

3.5. Analytical overview

From the literature consensus:

1) Damping improvement in metal-polymer hybrids ranges from 20 % to 200 %, depending on geometry and interface quality.

2) Optimal polymer thickness is often 1-3 mm for steel substrates < 3 mm thick.

3) Trade-off exists: thicker polymer layers enhance damping but reduce stiffness and resonance frequency.

4) Finite element simulations (e.g., COMSOL, ANSYS) predict that damping performance depends quadratically on adhesion stiffness and inversely on interface slip length.

4. Conclusions

1) Metal-polymer hybrids, such as steel-UHMWPE composites, show significantly improved vibration damping while retaining structural integrity.

2) Interface adhesion is the governing factor; proper surface treatment and controlled thermal bonding improve damping performance and stability.

3) Viscoelastic behaviour of the polymer phase is frequency- and temperature-dependent; therefore, operating environments should be matched to the polymer’s optimal damping range.

4) Analytical and experimental data suggest that a 35-40 % reduction in vibration amplitude is achievable with thin UHMWPE coatings on steel.

5) Future work should integrate adhesion modelling, FEA-based damping simulations, and long-term fatigue tests to refine the hybrid design for practical applications in vibration-isolated supports, automotive frames, and precision machinery.

Owing to its combined stiffness, damping capability, and corrosion resistance, the steel-UHMWPE hybrid can be applied in automotive components (engine mounts, chassis dampers), aerospace panels, and vibration-isolated machine bases where weight reduction and long-term stability are required. The scalability of thermal pressing and compatibility with existing steel manufacturing processes further enhance its industrial applicability.

References

-

S. M. Kurtz, UHMWPE Biomaterials Handbook: Ultra-High Molecular Weight Polyethylene in Total Joint Replacement and Medical Devices. Academic Press, 2009.

-

V. S. Aher, U. M. Shirsat, V. D. Wakchaure, and M. A. Venkatesh, “An experimental investigation on tribological performance of UHMWPE composite under textured dry sliding conditions,” Journal Tribology, Vol. 24, pp. 110–125, 2020.

-

V. Dacol, E. Caetano, and J. R. Correia, “Comparative study of damping on pultruded GFRP and steel beams,” Polymers, Vol. 13, No. 13, p. 2201, Jul. 2021, https://doi.org/10.3390/polym13132201

-

T. Liu, P. Butaud, V. Placet, and M. Ouisse, “Damping behavior of plant fiber composites: A review,” Composite Structures, Vol. 275, p. 114392, Nov. 2021, https://doi.org/10.1016/j.compstruct.2021.114392

-

X. Zhang, X. Li, R. Liu, C. Hao, and Z. Cao, “Dynamic properties of a steel-UHPC composite deck with large U-ribs: Experimental measurement and numerical analysis,” Engineering Structures, Vol. 213, p. 110569, Jun. 2020, https://doi.org/10.1016/j.engstruct.2020.110569

-

“ASM Handbook-Vol. 2 Properties and selection. Nonferrous alloys and special-purpose materials,” ASM International, United States of America, 1990.

-

J.-H. Yun, Y.-J. Jeon, and M.-S. Kang, “Prediction of the elastic properties of ultra high molecular-weight polyethylene particle-reinforced polypropylene composite materials through homogenization,” Applied Sciences, Vol. 12, No. 15, p. 7699, Jul. 2022, https://doi.org/10.3390/app12157699

-

A. M. Stoica et al., “Hysteretic damping characteristics of ultra-high molecular weight polyethylene used in hip arthroplasties,” International Journal of Mechatronics and Applied Mechanics, Vol. 1, No. 14, Nov. 2023, https://doi.org/10.17683/ijomam/issue14.1

-

M. Thaliyil Puthiyaveettil, S. K. Raman, J. Zhao, and S. Rastogi, “Single crystals of ultrahigh molecular weight poly(ethylene-alt-CO)s for solvent-free processing and enhanced thermal stability,” Macromolecules, Vol. 57, No. 16, Aug. 2024, https://doi.org/10.1021/acs.macromol.4c01366

-

M. Abdul Samad, N. Satyanarayana, and S. K. Sinha, “Tribology of UHMWPE film on air-plasma treated tool steel and the effect of PFPE overcoat,” Surface and Coatings Technology, Vol. 204, No. 9-10, pp. 1330–1338, Jan. 2010, https://doi.org/10.1016/j.surfcoat.2009.09.011

-

M. A. Samad and S. K. Sinha, “Dry sliding and boundary lubrication performance of a UHMWPE/CNTs nanocomposite coating on steel substrates at elevated temperatures,” Wear, Vol. 270, No. 5-6, pp. 395–402, Feb. 2011, https://doi.org/10.1016/j.wear.2010.11.011

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.