Abstract

This study examines the methodology for producing 3D-printing filaments from industrial polyamides. Novel compositions and a modification technique were developed for semi-finished products using an aqueous polymer solution based on tall oil rosin amides and a polycondensation product of adipic acid with diethylenetriamine, along with dispersed byproducts from electroerosive processing of tool steels with a graphite electrode. The results demonstrate that the developed filaments enhance the stress-strain properties of 3D-printed products due to the implementation of a multilevel polymer matrix modification concept through the introduced components.

Highlights

- Among the various 3D prototyping (3D printing) methods, Fused Deposition Modeling (FDM) stands out due to its accessibility, parameter flexibility, and compatibility with a wide range of thermoplastic composites, making it a key tool for creating prototypes.

- The objective of this study is to investigate the structural features and performance parameters of composite materials based on industrial polyamides used in the production of 3D printing filaments.

- Methodological approaches for creating filaments from industrial polyamide-based composite materials for modern 3D printing technology have been examined.

- Novel compositions and manufacturing technology have been developed for industrial polyamide-based filaments that enable 3D printing of products with enhanced performance characteristics.

- Obtained results create opportunities for industrial implementation of the developed composites, production cost reduction, and expansion of polymer filament varieties.

1. Introduction

The implementation of the Concept of Sustainable Socio-Economic Development of the Republic of Belarus and the Innovative Development Strategy of the Republic of Uzbekistan is based on the development of new technologies for the production and processing of engineering materials to manufacture products with tailored functional properties, as well as technologies for the efficient recycling of end-of-life products to obtain high-quality components for subsequent practical use [1]-[3].

Among the promising technologies for manufacturing functional products are so-called additive technologies. Modern additive manufacturing (AM) technologies, with their unique capabilities for digital design and layer-by-layer synthesis of complex-profile components, are becoming particularly relevant in the engineering industry. These technologies not only accelerate prototyping but also enable the production of lightweight, high-strength, and functionally graded polymer structures that cannot be manufactured using traditional processing methods [4]-[9].

Among the various 3D prototyping (3D printing) methods, Fused Deposition Modeling (FDM) stands out due to its accessibility, parameter flexibility, and compatibility with a wide range of thermoplastic composites, making it a key tool for creating prototypes and small-batch products with customizable performance characteristics [10], [11].

Modern composite materials for FDM technology are multicomponent systems based on thermoplastic matrices modified with functional additives. The most widely used composites are those based on polylactic acid (PLA), acrylonitrile butadiene styrene (ABS), polyether ether ketone (PEEK), and thermoplastic polyurethanes (TPU), which exhibit an optimal balance of rheological and mechanical properties for extrusion-based forming.

A promising direction is the development of adaptive composites with tunable properties, including shape-memory polymers and heat-resistant formulations, which expand the functionality of FDM-printed parts in engineering, robotics, biomedicine, and electronics [12]-[17]. However, to effectively apply FDM in critical engineering applications, it is essential to develop specialized materials that offer high strength, thermal stability, and extrusion-optimized rheological behavior. Achieving this goal requires a thorough analysis of current material compositions and processing equipment to ensure their suitability for such applications. Among the matrices used for 3D printing filaments, industrial thermoplastics are particularly promising due to their high processability and relatively low cost, aligning with the demands of the modern economy [1]-[3].

The objective of this study is to investigate the structural features and performance parameters of composite materials based on industrial polyamides used in the production of 3D printing filaments.

2. Materials and methods

The study objects were composite materials based on aliphatic polyamides. To prepare the polyamide-based composites, polyamide 6 (PA6) produced by Khimvolokno Plant (a subsidiary of Grodno Azot OJSC, Grodno, Belarus) in the form of strands was used as the matrix. The strands were diffusion-modified with dispersed electroerosion byproducts (EEBPs) obtained from the electroerosive processing of tool steels 4Kh5MFS, 40Kh13, and 40Kh using an MPG-7 graphite electrode. Plasticization of the polymeric semi-finished products (PA6 strands) was performed using ProChem DUO (LLC ProKhimTekhnologii, Belarus), a strengthening additive consisting of a 10 % aqueous solution of a polymer based on tall oil rosin amides and the polycondensation product of adipic acid with diethylenetriamine [18], [19].

For the electroerosive processing of tool steel semi-finished products, high-density fine-grained graphite MPG-7 ( 1.7 g/cm3) was primarily used. This artificial carbon material is synthesized via cold isostatic pressing of low-ash petroleum coke and is characterized by a monolithic fine-crystalline structure, minimal porosity, and extremely low metallic impurity content (Al, Mn, Cu, Fe, B). It complies with ISO 9000/9001 standards and domestic technical specifications (including TS 1915-109-081-2004, TS 48-4807-297-00). Due to its structural homogeneity, enhanced mechanical strength, and thermal stability, MPG-7 graphite is widely used as an electrode tool for electrospark machining of dies and molds, high-temperature structural components (e.g., crystallizers, crucibles), and process tooling in semiconductor manufacturing.

Electroerosive processing of the tool steel samples was performed on an Agie Integral 2 die-sinking (electrode) machine by GF AgieCharmilles (Switzerland). The study focused on the mechanisms of diffusion saturation of the surface layer of polyamide semi-finished products with dispersed carbon-containing particles obtained during the electroerosive processing of tool steels using a graphite electrode. For the fabrication of model specimens, a standard 1.75±0.05 mm diameter filament based on polyamide-6 (PA6) was used. Prior to processing, the samples underwent thermal treatment (100 °C, 4 h) to remove sorbed moisture.

Plasticization and modification of the polyamide filaments were carried out in a 10% aqueous solution of polyamide resin containing 0.1 wt.% dispersed electroerosion byproducts (EEBPs) from the electroerosive processing of tool steels with a graphite electrode. The thermal diffusion saturation of the model specimens was performed at 50 °C for 1 h. After modification, the specimens were dried at 100 °C for 4 h.

Additive manufacturing of the experimental samples was conducted on an FDM printer (Qidi Q1 Pro, 0.4 mm nozzle diameter) under the following optimized parameters:

– Extruder temperature: 260 °C.

– Platform temperature: 60 °C.

– Extrusion speed: 20 mm/s.

– Layer thickness: 256 µm (first layer: 330 µm).

– Infill density: 100 % (air gap = 0).

– Infill pattern: Linear (line pattern).

Tensile strength parameters were determined according to standard methods [20] using standard specimens at a crosshead speed of 20 mm/min.

The melt flow index (MFI) of the thermoplastic composites was measured following GOST 11645-73 [21] using a PTR-LAB-02 extrusion plastometer at 230 °C, a piston load of 21.19 N, a capillary diameter of 2.095 mm, and an extrudate cutoff time of 5 s.

The energetic state of modifier particles was evaluated via thermally stimulated current (TSC) spectroscopy using an ST-1 setup (developed by V.A. Belyi Metal-Polymer Research Institute of National Academy of Sciences of Belarus) in accordance with the methodology outlined in [22].

Microstructural and compositional analysis of the modifier was performed using scanning electron microscopy (SEM) on a SUPRA 55WDS microscope equipped with an INCA Energy 350 X-ray microanalysis system. Statistical processing of the experimental data was conducted using modern computational methods and specialized software.

3. Results and discussion

In modern nanomaterials science, modifiers of various compositions produced by different technologies are widely used [23], [24]. Of particular interest is the utilization of byproducts generated during advanced manufacturing processes of machine-building components, which represent residual materials. These byproducts, with controlled composition and dispersion, are promising polymer matrix modifiers due to their unique structural features, composition, and energetic state. Among such materials are electroerosion byproducts (EEBPs) obtained from the electroerosive processing of tool steels of various compositions, produced via the aforementioned methodology.

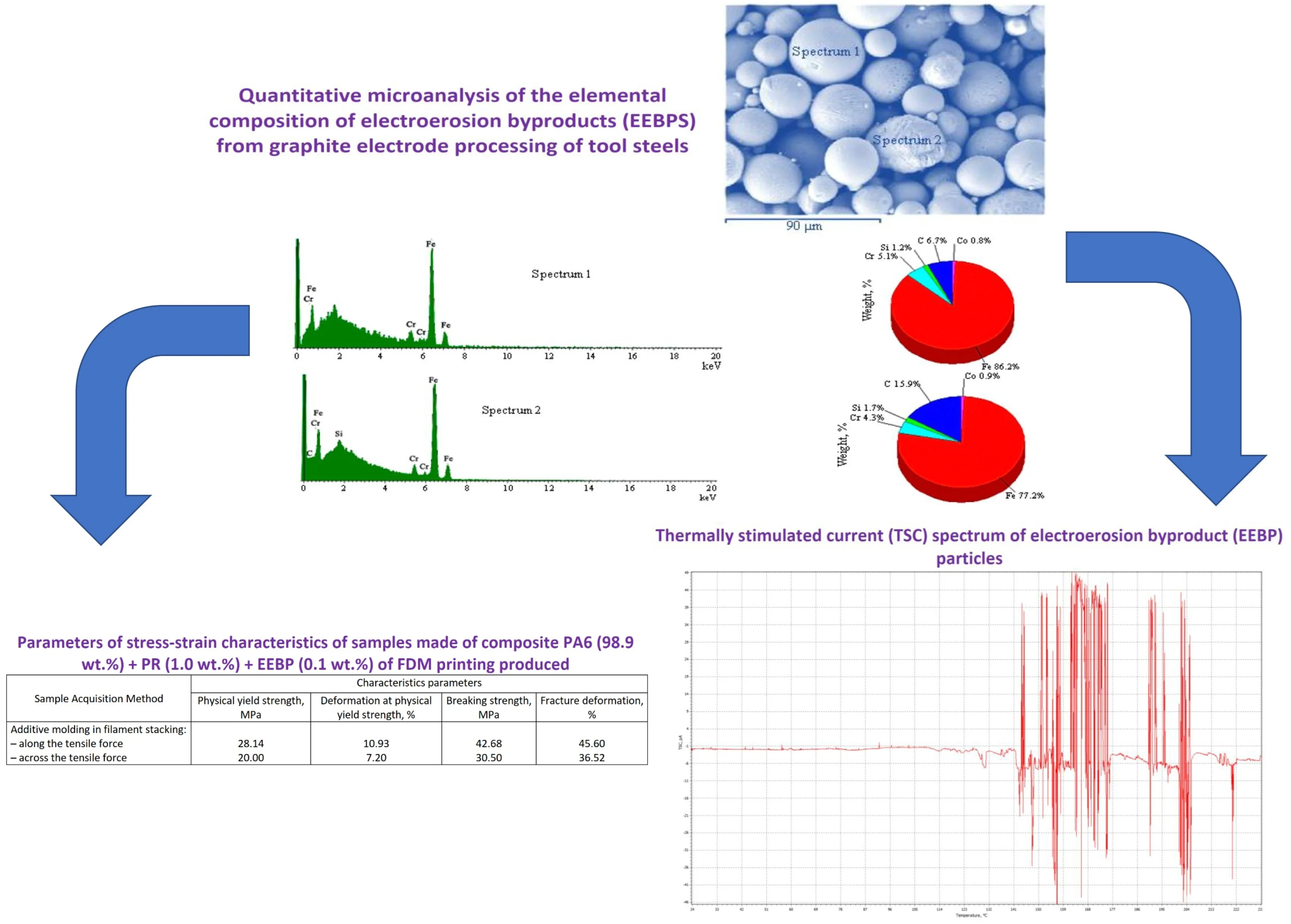

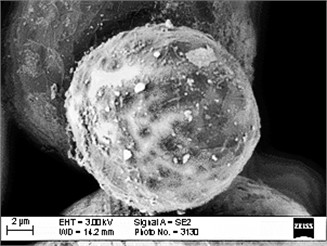

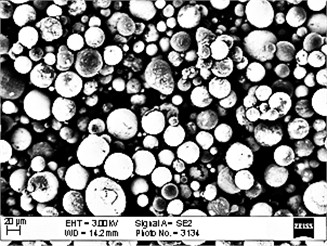

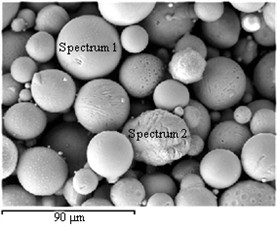

The morphology of the surface layers of dispersed EEBPs from the electroerosive processing of tool steels with a graphite electrode, as revealed by scanning electron microscopy (SEM), is shown in Fig. 1.

Fig. 1Morphology of electroerosion byproducts (EEBPs) from graphite electrode processing of tool steels

a) Scanning area 1

b) Scanning area 2

c) Scanning area 3

d) Scanning area 4

Notably, the EEBP particles exhibit heterogeneity, originating from the composite structure of tool steels and the graphite electrode, with nanoscale constituents present in their morphology.

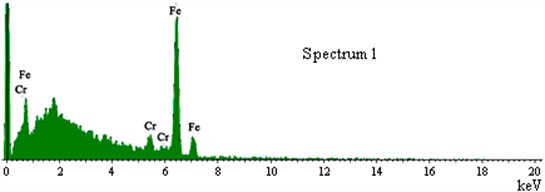

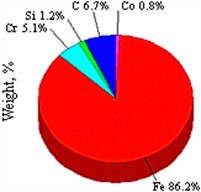

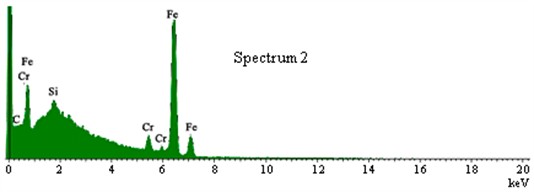

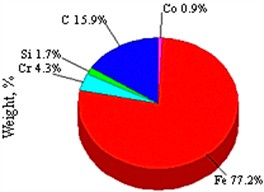

The complex composition of the EEBP particles is further confirmed by microstructural and elemental analysis (Fig. 2).

These data indicate the formation of polydisperse particles dominated by spheroidal and ellipsoidal morphotypes, with Fe, C, and Cr as the primary components.

The research methodology included preliminary purification of the EEBP powders from technological impurities formed during electroerosion, such as hydrocarbon compounds (residual dielectric medium), free carbon, and other associated contaminants. This step ensured the reliability of the obtained data on the morphological characteristics and elemental composition of the processed products.

Fig. 2Quantitative microanalysis of the elemental composition of electroerosion by products (EEBPS) from graphite electrode processing of tool steels

Thus, the conducted studies demonstrate that particles obtained via electroerosion of tool steels with a graphite electrode (EEBPs) exhibit characteristic features of nanoscale components [25]. Consequently, such particles can influence the structural parameters of polymer matrices of varying compositions and production technologies. Clearly, these multicomponent byproducts, containing metal and carbon particles of varying dispersion (including nanoscale fractions), enable the implementation of a multilevel modification principle [26]-[30] when introduced into a polymer matrix. This approach promotes a synergistic effect, enhancing the performance characteristics of composite materials and the resistance of resulting products to thermo-oxidative environments.

To test this hypothesis, formulations and a production technology for PA6-based filaments were developed. To ensure uniform distribution and fixation of the dispersed modifier particles, a 10 % aqueous solution of polyamide resin (PR) was employed. The following composite material formulations were investigated:

1. PA6 (99.0 wt.%) + PR (1.0 wt.%).

2. PA6 (98.9 wt.%) + PR (1.0 wt.%) + EEBP (0.1 wt.%).

The obtained data are consistent with modern concepts of interlayer adhesion mechanisms in FDM printing and confirm the necessity of accounting for property anisotropy when designing components. The conducted research enabled the development of novel compositions and manufacturing technology for filaments used in 3D printing [31].

4. Conclusions

Methodological approaches for creating filaments from industrial polyamide-based composite materials for modern 3D printing technology have been examined. A promising direction and critical consideration in developing composite formulations for semi-finished products used in fused filament fabrication (FFF or FDM) is ensuring sufficient intensity of high-molecular-weight carbon-containing compound formation in surface layers through specialized modifiers exhibiting nano-state phenomena. These form during diffusion saturation of semi-finished products in aqueous solutions of polyamide resin modified with dispersed particles from electroerosive processing of tool steels using graphite electrodes.

The study demonstrates that modifying PA6 semi-finished products with functional components based on tall oil rosin amides and adipic acid-diethylenetriamine polycondensation products, combined with dispersed electroerosion byproducts (EEBPs) from graphite electrode processing of tool steels, enhances stress-strain parameters of filaments. This creates a multilevel matrix structuring effect that improves strength characteristics of 3D-printed products across different orientations.

Novel compositions and manufacturing technology have been developed for industrial polyamide-based filaments that enable 3D printing of products with enhanced performance characteristics. These results create opportunities for industrial implementation of the developed composites, production cost reduction, and expansion of polymer filament varieties. Their production will support the growing additive manufacturing market – a cornerstone technology of post-industrial economies.

References

-

“On the national strategy for circular economy development of the Republic of Belarus until 2035: Decree of the council of ministers of the Republic of Belarus No. 393 dated May 29, 2024.” National Legal Internet Portal of the Republic of Belarus, 2024, https://pravo.by/document/?guid=12551&p0=c22400393.

-

“Draft national strategy for sustainable development of the Republic of Belarus until 2040,” (in Russian), Research Institute of Economics of the Ministry of Economy of the Republic of Belarus, 2025.

-

“Strategy for innovative development of the Republic of Uzbekistan for 2022-2026: Appendix No. 1 to the decree of the president of the Republic of Uzbekistan No. UP-165 dated July 6, 2022.” National Legal Information Center Adolat of the Ministry of Justice of the Republic of Uzbekistan, 2022, https://lex.uz/docs/6102464.

-

B. Redwood, F. Schoffer, and B. Garret, The 3D Printing Handbook: Technologies, Design and Applications. London: 3D Hubs, 2017.

-

N. Shahrubudin, T. C. Lee, and R. Ramlan, “An overview on 3D printing technology: technological, materials, and applications,” Procedia Manufacturing, Vol. 35, pp. 1286–1296, Jan. 2019, https://doi.org/10.1016/j.promfg.2019.06.089

-

M. Picard, A. K. Mohanty, and M. Misra, “Recent advances in additive manufacturing of engineering thermoplastics: challenges and opportunities,” RSC Advances, Vol. 10, No. 59, pp. 36058–36089, Oct. 2020, https://doi.org/10.1039/d0ra04857g

-

S. T. Gobena and A. D. Woldeyohannes, “Comparative review on the application of smart material in additive manufacturing: 3D and 4D printing,” Discover Applied Sciences, Vol. 6, No. 7, Jun. 2024, https://doi.org/10.1007/s42452-024-05999-8

-

G. Prashar, H. Vasudev, and D. Bhuddhi, “Additive manufacturing: expanding 3D printing horizon in industry 4.0,” International Journal on Interactive Design and Manufacturing (IJIDeM), Vol. 17, No. 5, pp. 2221–2235, Jul. 2022, https://doi.org/10.1007/s12008-022-00956-4

-

T. A. Yeshiwas, A. B. Tiruneh, and M. A. Sisay, “A review article on the assessment of additive manufacturing,” Journal of Materials Science: Materials in Engineering, Vol. 20, No. 1, Jul. 2025, https://doi.org/10.1186/s40712-025-00306-8

-

E. V. Igorina and O. V. Druzhinina, “Features of development and application of FDM technology in creation and prototyping of 3D objects,” (in Russian), Modern Information Technologies and IT Education, Vol. 13, No. 2, pp. 185–193, 2017.

-

S. V. Kondrashev, A. A. Pykhtin, S. A. Larionov, and A. E. Sorokin, “Influence of FDM printing parameters and material composition on physical-mechanical characteristics of FDM models,” (in Russian), Technology of Materials, No. 5, pp. 44–45, 2019.

-

S. D. Brovina, M. Y. Guivan, E. E. Mastalygina, and A. A. Olkhov, “Polymer materials for 3D printing (fused deposition modelling),” Polymer Science, Series D, Vol. 17, No. 2, pp. 450–454, Jun. 2024, https://doi.org/10.1134/s199542122470076x

-

D. V. Stenko, A. A. Khapov, A. B. Kapranova, N. V. Badaeva, and E. R. Novikov, “Study of anisotropic properties of polymer products manufactured by FDM technology,” Theoretical Foundations of Chemical Engineering, Vol. 58, No. 4, pp. 1459–1462, Mar. 2025, https://doi.org/10.1134/s0040579525600561

-

M. K. Aravindan, K. K. Awasthi, P. Shreeraj Nair, A. Mishra, H. Ulla, and A. Barve, “Polymer material framework for 3D printing using fusion deposition modelling,” Progress in Additive Manufacturing, Vol. 10, No. 4, pp. 2317–2333, Sep. 2024, https://doi.org/10.1007/s40964-024-00752-4

-

A. Behera, “Smart materials based additive manufacturing,” in Materials Horizons: From Nature to Nanomaterials, Singapore: Springer Nature Singapore, 2023, pp. 153–175, https://doi.org/10.1007/978-981-99-5949-5_7

-

B. Mallikarjuna, P. Bhargav, S. Hiremath, K. G. Jayachristiyan, and N. Jayanth, “A review on the melt extrusion-based fused deposition modeling (FDM): background, materials, process parameters and military applications,” International Journal on Interactive Design and Manufacturing (IJIDeM), Vol. 19, No. 2, pp. 651–665, May 2023, https://doi.org/10.1007/s12008-023-01354-0

-

A. K. Sahoo and B. Choudhury, “Additive Manufacturing Technologies for Polymer Nanocomposites,” in Engineering Materials, Singapore: Springer Nature Singapore, 2025, pp. 109–134, https://doi.org/10.1007/978-981-96-4214-4_5

-

V. L. Fleisher, N. V. Chernaya, E. P. Shishakov, D. S. Makarova, M. V. Andryukhova, and S. A. Gordeyko, “Method for producing polyamide resin,” (in Russian), Patent BY 21140, 2017.

-

M. Rakhmatov, A. Riskulov, and K. Nurmetov, “Composite materials with enhanced abrasion resistance and certain functional characteristics based on thermoplastics,” Material and Mechanical Engineering Technology, Vol. 2025, No. 2, pp. 86–93, 2025.

-

“Plastics. Tensile test method,” (in Russian), Standartinform, Moscow, GOST 11262-2017, 2018.

-

“Plastics. Method for determination of melt flow rate of thermoplastics,” (in Russian), Russian Institute for Standardization, Moscow, GOST 11645-2021, 2021.

-

S. V. Zotov, Z. V. Kadolich, E. A. Tsvetkova, and A. G. Kravtsov, “Physical method of electret-thermal analysis,” (in Russian), Publishing House Belorusskaya Nauka, Reports of the National Academy of Sciences of Belarus, Jan. 2023.

-

A. A. Eliseev and A. V. Lukashin, Functional Nanomaterials. Moscow: Fizmatlit, 2010.

-

V. A. Struk and V. A. Goldade, Nanomaterials and Nanotechnologies for Mechanical Engineering. (in Russian), Minsk: RIVSh, 2021.

-

S. V. Avdeichik, V. A. Struk, and A. S. Antonov, The Nanostate Factor in Materials Science of Polymer Nanocomposites. (in Russian), Saarbrücken: LAP LAMBERT Academic Publishing RU, 2017.

-

V. A. Struk, “Tribochemical concept of creating antifriction materials based on mass-produced polymer binders,” (in Russian), Minsk, 1988.

-

S. V. Avdeichik, “Implementation of the multilevel modification principle in materials science and technology of polymer composites,” (in Russian), Mining Mechanics and Machine Building, No. 3, pp. 72–86, 2017.

-

S. V. Avdeichik, “Multilevel modification in materials science and polymer nanocomposites technology,” in Non-Equilibrium Phase Transformations: III International Scientific Conference, pp. 98–102, 2017.

-

M. Rakhmatov, A. Riskulov, and K. Nurmetov, “Abrasive-resistant composite materials with specified functional characteristics based on thermoplastics,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030040, Jan. 2025, https://doi.org/10.1063/5.0266781

-

A. S. Antonov, “Composite materials based on thermoplastic blends for increasing service life of technological equipment components,” (in Russian), Belarusian State Technological University, Minsk, 2018.

-

V. A. Struk et al., “Composition and method for processing polymer filaments for 3D prototyping,” (in Russian), Patent Number: 24697, 2025.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.