Abstract

In this study, a technology for producing high-strength spheroidal graphite cast iron of grade VCh50 using secondary steel scrap in an induction crucible furnace was developed. During the research, the efficiency of using complex modifiers in the ladle and mold gating system was investigated. The influence of elements such as magnesium, calcium, aluminum, barium, cerium, and lanthanum contained in these modifiers on the graphite morphology, structure, and mechanical properties of the molten cast iron was analyzed.

1. Introduction

The chemical composition of high-strength spherical graphite cast iron grade VCh50, the composition of alloying elements, modifiers, and the technology of ladle modification were thoroughly studied. The technologies for using molding and core sands from several large foundries specializing in the production of cast parts abroad were also analyzed. A technology for melting synthetic spherical graphite cast iron by carburization using secondary metal feedstock in induction crucible furnaces was developed and evaluated. The combined effects of magnesium, calcium, and rare earth metals contained in modifiers on the structure, mechanical, and performance properties of high-strength spherical graphite cast iron were studied.

During the study, the research works of foreign and domestic scientists on the composition of modifiers for the production of high-strength spherical graphite cast iron grade VCh50, the purpose of each element in it, as well as improving its mechanical and operational characteristics were analyzed and implemented. It is recommended to add magnesium in an amount of 0.03-0.06 % Mg as the main modifier, using magnesium to convert graphite from a lamellar form to a spherical one, calcium (Ca) as an additional modifier in the cast iron modification, increasing the degree of spheroidization of graphite, promoting the formation of a finely dispersed and uniformly distributed structure, as well as forming calcium sulfides CaS and neutralizing sulfur (S < 0.02%), when used as a complex modifier, the amount of calcium should be 0.5-2.0% Ca. The combined use of cerium (Ce) and lanthanum (La) with magnesium improves the shape of graphite. The use of aluminum (Al) as a secondary modifier in cast iron modification and the formation of aluminum nitride particles in solution, which act as graphite crystallization centers, promotes a fine and uniform distribution of graphite crystals. When combined with magnesium, aluminum prevents the lamellar transformation of graphite [1]. The optimal amount is between 0.01-0.05 % Al, and excessive additions risk evaporation and carbide formation. Silicon (Si) is used as the primary alloying and modifying agent in cast iron production [2]. Silicon enhances graphitization, increases the carbon equivalent, and accelerates the release of carbon from solution as graphite, ensuring good casting properties. If the Si content increases excessively (> 3 %), the cast iron may become hard and brittle. Therefore, it is recommended to store it within 2.2-2.8 %. Barium (Ba) is added as a powerful complex modifier in VCh50 ductile irons. The optimal amount of barium is 0.005-0.02 % Ba; excess amounts can lead to the formation of carbides, which increases hardness and reduces flexibility. Together with Ba, Mg, and Ca, it ensures the formation of stable spheroidal graphite and prevents the graphite from returning to a lamellar form. Ba reacts with sulfur (S) and oxygen (O2) in solution to form harmless BaS and BaO, which reduces Mg loss, since Mg is directly consumed in the spheroidization of the graphite without first reacting with S and O2. Methods for improving the mechanical and operational properties of the finished product due to the quantity and action of complex modifiers in the production of high-strength cast iron are described [3, 4].

To obtain high-strength VCh50 cast iron, the cast iron was pre-smelted in a medium-frequency induction crucible furnace (IFC) from OTTO JUNKER with a capacity of 6 tons at the Foundry and Mechanical Plant JSC [5]. A computer program was used to determine the key performance indicators of induction crucible furnaces. The material balance and charge materials for the smelting process were calculated. The total charge material consumption per ton of liquid iron is 4.158.8 kg, of which 2.800 kg is secondary steel waste. Carbon steel scrap, such as worn-out wheelsets used in railway transport, was used as secondary steel raw material. The chemical composition of the secondary steel raw material is shown in Table 1.

Table 1Chemical composition of secondary steel scrap

Material name | Mass fraction of elements, % | |||||||||

C | Si | Mn | S | P | Ni | Cr | Cu | Mg | Fe | |

Scrap steel | 0.6 | 0.31 | 0.7 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | 0.04 | 98.24 |

Iron scrap accounts for approximately 30 % of the total charge during casting, or 300 kg. This amount is generated by remelting risers and gating systems generated during the casting of ductile iron parts [6]. During the iron production process, alloying with electrode scrap, ferrosilicomanganese (MnS17), and ferrosilicon (FS65) was performed to bring the carbon, manganese, and silicon content into compliance with the chemical composition of ductile iron grade VCh50, as required by ГОСТ 7293-85 [1]. The use of melt desulfurization technology using the DS-BKM-Si40Mg11Ca6Al1.5(Cе+La)5 complex modifier at an average consumption of 20 kg per 1 ton of liquid iron during iron refining allows for a reduction in the sulfur concentration in the metal. The chemical composition of the briquetted DS-BKM-Si40Mg11Ca6Al1.5(Cе+La)5 complex modifier is shown in Table 2.

Table 2Chemical composition of briquette complex modifier

Modifier brand | Mass fraction of main elements, % | |||||

Mg | Ca | Al | Cе+La | Si | Fe | |

DS-BKM Si40Mg11Ca6Al1.5(Cе+La)5 | 10.0-12.0 | ≤ 6.0 | ≤ 1.5 | ≤ 5.0 | 35.0 – 44.8 | rest |

To eliminate cementite and improve the cross-sectional structure of castings to ensure early graphitization, a complex barium modifier with the fraction SXBEG-KM-Si70Al1.5Ca0.65Ba4 was used. The chemical composition of the spheroidizing modifier GSH-KM-Si46Mg6AlCa2(Cе+La)0.5 and the barium complex modifier SXBEG-KM-Si70Al1.5Ca0.65Ba4 is given in Table 3.

Experimental studies of the process for producing high-strength cast iron grade VCh50 were conducted using six variants. The first and second variants represent the traditional ladle modification technology used worldwide, namely, modification with magnesium ferroalloy alone (FSMg5 – 2 %) or magnesium ferroalloy and silicocalcium (FSMg5 – 2 % + SK30 – 0.5 %). To improve the operational and mechanical properties of high-strength spheroidal graphite cast iron, unlike existing technology, the proposed method involved loading complex modifiers into the reaction chamber of a 0.5-ton ladle using the “sandwich process” in a specific sequence.

Table 3Chemical composition of complex modifiers

Modifier brand | Mass fraction of main elements, % | ||||||

Si | Mg | Al | Ca | Ba | Ce+La | Fe | |

GSH-KM-Si46Mg6AlCa2(Cе+La)0.5 | 44.0-49.0 | 5.7-6.5 | 0.6-1.2 | 1.6-2.5 | - | 0.35-0.6 | rest |

SXBEG-KM -Si70Al.5Ca0.65Ba4 | 65.0-75.0 | – | 1.0-2.0 | 0.8-1.5 | 3.5-5.0 | - | rest |

In order to determine the rational amount of complex modifiers, experiments were conducted with various composition options. In particular, the third and fourth options were tested using the following modifiers: GSH-KM-Si46Mg6AlCa₂(Cе+La)0.5 – as a spheroidizing modifier; SXBEG-KM-Si70Al1.5Ca0.65Ba4 – as a modifier activating early graphite formation. These modifiers were used in the following quantities per ton of liquid iron: GSH-KM-Si46Mg6AlCa2(Cе+La)0.5-1.4 % and 2.0 %; SXBEG-KM-Si70Al1.5Ca0.65Ba4-0.15 % and 0.35 %. Based on the experiment results, the efficiency of the modification process, the optimal amount, the degree of graphite formation and the mechanical properties of the casting were assessed.

To ensure optimal mixing of the complex inoculant with the molten iron, it is crucial to place the reaction chamber inside the ladle, ensuring a consistent and controlled reaction process. This ensures that the inoculant mixes evenly with the metal, and the necessary chemical reactions occur completely [7]. Therefore, the ladle shape and dimensions are designed based on the precise technological requirements of the casting process [13]. The developed technology was used to calculate the material balance for smelting high-strength cast iron grade VCh50 (Fig. 1).

Fig. 1Modification of liquid metal at the junction using the sandwich method: a) khaki view of the placement of modifiers in the bucket, b) schematic view of the sandwich method, c) the pouring of liquid metal from the oven into the bucket and the reaction process. The original photographs were obtained in the laboratory of JSC “Foundry and Mechanical Plant”, in Tashkent, the images were obtained in 2024-2025, the author is U.T. Rakhimov

a)

b)

c)

Table 4Results of experimental studies of the process of cast iron processing in a ladle and casting system

Processing options | Property category | |||

Tensile strength ,MPa, kg/mm2 | Yield strength ,MPa, kg/mm2 | Relative elongation, 𝛿, % | Brinell hardness, HB | |

GOST 7293-85 | No less | |||

500 | 320 | 7.0 | 153-245 | |

1 (CT) | 480/485 | 300 | 5.8 | 180/183 |

2 (CT) | 500/503 | 325 | 6.1 | 190/192 |

3 (PT) | 557/560 | 678 | 7.5 | 205/206 |

4 (PT) | 606/600 | 370 | 7.7 | 228/226 |

5 (PT) | 610/615 | 375 | 8.5 | 230/232 |

6 (PT) | 620/630 | 380 | 6 | 250/255 |

After each treatment was held for 5 minutes, samples were collected for mechanical properties. The data presented in Table 4 demonstrate that the proposed technology, compared to the traditional method, reduces the sulfur content in the cast iron from 0.025 % to 0.010 %, and the total oxygen content from 40 ppm to 15 ppm (in the fifth treatment).

As can be seen from the data presented in the table, the highest values of mechanical properties were obtained when processing the metal with complex modifiers GSH-KM-Si46Mg6AlCa₂(Cе+La)0.5. SXBEG-KM-Si70Al1.5Ca0.65Ba4 and B-BKM-Si75Al4Ca0.9 according to options 3. 4. 5 and 6. However, the results of option 6 do not meet the requirements of GOST 7293-85 for hardness and relative elongation, therefore options 4 and 5 gave the best results, of which option 5 is the most optimal. The results of the studies showed that when adding complex modifiers GSH-KM-Si46Mg6AlCa2(Cе+La)0.5. SXBEG-KM-Si70Al1.5Ca0.65Ba4 and B-BKM-Si75Al4Ca0.9 to cast iron in an amount of 1.8 %, 0.3 % and 1 %, respectively, of the mass of liquid metal, the mechanical properties of high-strength cast iron grade VCh50 increase: tensile strength – up to 27 %, yield strength – up to 25 %, hardness – up to 28 %.

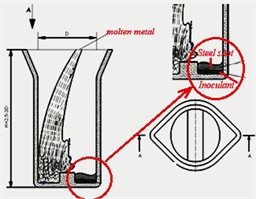

Fig. 2Improved process flow chart for casting high-strength cast iron grade VCh50

Fig. 2 shows an improved process flow chart for casting high-strength cast iron grade VCh50. The total consumption of charge materials to produce one ton of liquid cast iron in an induction crucible furnace is 4158.8 kg. To produce cast iron, 600 kg of recycled cast iron scrap, 100 kg of electrode scrap, and 2800 kg of locally produced secondary steel scrap are initially loaded. Solid slag mixture (SSM) is loaded in an amount of 56 kg at a CaO:CaF2 ratio of 1:0.4. The melting process lasts 60 minutes at a temperature of 1.500 °C, after which sample No. 1 was selected for a rapid determination of the metal’s chemical composition. By adjusting the carbon content to the required amount of 3.608 %, cast iron was obtained. To ensure the sulfur content of 0.02 % in the refining process, a briquette complex modifier DS-BKM-Si40Mg11Ca6Al1.5(Cе+La)5 was used, where “Si” is a silicon-containing material replacing ФС45. In addition to alloying, it has a refining effect by removing sulfur and phosphorus from the metal. It contains magnesium, active alkaline earth and rare earth elements. When the liquid metal level in the furnace reached 3/4 of the volume, the briquette complex modifier was loaded in an average amount of 20 kg per 1 ton of liquid cast iron. Then the remaining 600 kg of recycled cast iron scrap was loaded, ensuring full coverage of the modifier briquettes. This allows you to use the modifier most effectively. The desulfurization process lasted 15-20 minutes at a temperature of 1550 °C. During this process, the sulfur was converted to slag, after which the slag was removed and the final No. 2 sample was taken. During desulfurization, a decrease in the sulfur concentration in the metal was achieved from 0.025 to 0.010. Then, based on the chemical composition of cast iron, the number of ferroalloys was calculated. The reduction and alloying process was carried out at a temperature of 1500 °C for 25-30 minutes. At the same time, MnS17 – 5.42 kg and FS65 – 36 kg were added, taking into account the amount of silicon coming from the complex modifiers, after which the slag was drained and a sample of No. 3 was taken. To increase the efficiency of complex modification of cast iron in a 0.5 ton bucket, strict adherence to an improved design solution and technological process is required. The bottom of the bucket is divided into two functional chambers using refractory bricks: the reaction chamber is a zone where a preliminary reaction with modifiers takes place; the metal receiving chamber is a part collecting modified liquid metal [8, 9].

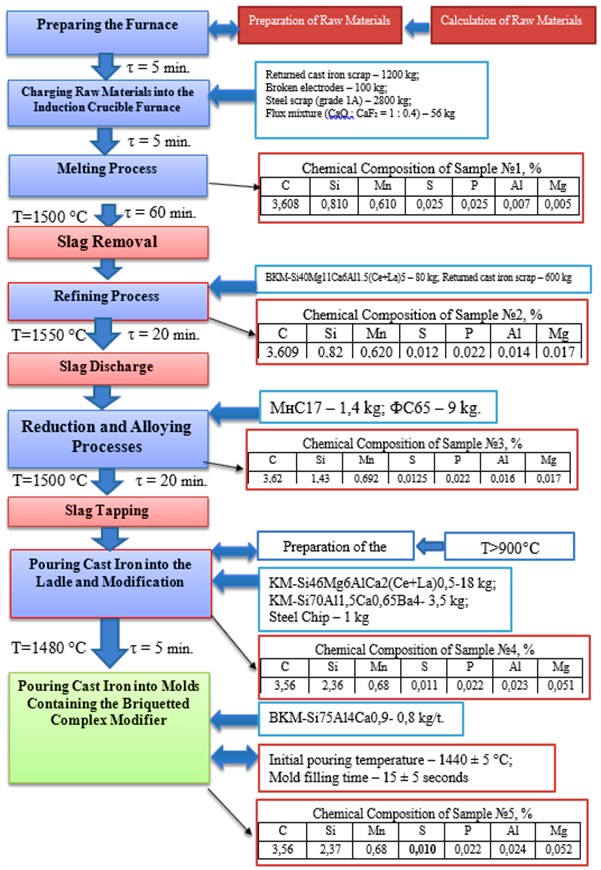

Analysis of the Effect of Magnesium Content on Tensile Strength is shown in Fig. 3. The above graph illustrates how changes in the magnesium (Mg) content in the alloy affect the material’s tensile strength ( < sub > < /sub >, MPa). The study was conducted based on six different samples, with the magnesium concentration varying in the range of 0.04 % to 0.054 %. During the study, the effect of magnesium content on the mechanical properties, particularly on the tensile strength of the alloy, was investigated [2]. The following graph shows the relationship between magnesium concentration and tensile strength.

Fig. 3Effect of magnesium content on tensile strength

The points on the graph represent the results of experimental measurements, while the dashed line indicates the quadratic regression curve constructed based on these data. From the shape of the curve, it is evident that as the magnesium content increases, the tensile strength of the material also increases steadily.

This demonstrates the positive effect of magnesium as a modifying element [14]. The addition of magnesium leads to solid-solution strengthening, restriction of dislocation motion, and phase transformations along grain boundaries within the alloy [10]. As a result, the alloy becomes more resistant to internal stresses and less prone to deformation. According to the regression analysis, the determination coefficient ( 0.9693) indicates a very high degree of accuracy. Therefore, approximately 97 % of the variation in tensile strength can be explained by the change in magnesium content.

Based on an effective design scheme and an improved technological process, a special recess (cavity) measuring 80×80 mm and 30 mm deep was formed in the casting system of the cast valve body of the D49 diesel camshaft. A briquette complex modifier B-BKM-Si75Al4Ca0.9 in an amount of 0.4 kg/ton for late graphitization was installed in this recess. The mold was filled at an initial temperature of 1440 °C. Samples were cast to determine the final chemical composition, metallographic and mechanical properties of high-strength cast iron of the VCh50 grade.

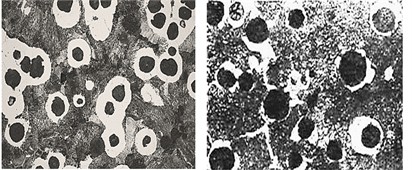

Fig. 4 shows the results of the microstructure of high-strength cast iron of the VCh50 grade under various types of processing.

Fig. 4Microstructure of high-strength cast iron of the VCh50 grade during various types of processing: a) FSMg5 – 2 %; b) GSH-KM-Si46Mg6AlCa2(Cе+La)0.5 – 1.8 %; SXBEG-KM-Si70Al1, 5Ca0.65Ba4-0.3 %; B-BKM-Si75Al4Ca0.9 – 1 %. The original photographs were obtained in the laboratory of JSC “Foundry and Mechanical Plant”, in Tashkent, the images were obtained in 2024-2025, the author is U.T. Rakhimov

a)

b)

As can be seen from Fig. 3, the best results for the 5th variant were obtained when processing cast iron with complex modifiers B-BKM-Si75Al4Ca0.9. SXBEG-KM-Si70Al1, 5Ca0, 65Ba4 and B-BKM-Si75Al4Ca0.9. The magnesium contained in the complex modifier provides the release of graphite particles in a spherical shape, calcium and aluminum react with oxygen and sulfur to form inert compounds, which eliminates elements that prevent graphitization, cerium and lanthanum stabilize the crystallization process, contributing to the ideal formation of the graphite shape [11]. As a result, the graphite shape is 90-95 % spheroidal, perfect, smooth and permanent, graphite balls are evenly distributed and have the same size, as well as a ferrite-pearlite matrix with a relatively high ferrite content, which indicates high strength, heat resistance and mechanical stability [12, 15].

2. Conclusions

For the first time, an improved technology for cast iron production based on selectively chosen secondary steel raw materials using an induction crucible furnace has been developed. As a result, the production cost of cast products was reduced by 50 %, the alloy grade was improved, and the yield of usable products increased by 20 %. In the casting of D49-type diesel distribution valve housings intended for railway transport, a mold and core mixture based on the “Alpha-Set” process was applied. This technology made it possible to increase the compressive and bending strength of the mixture by 7 times, improve its gas permeability by 2 times, reduce surface roughness by 4 times, and decrease moisture content by 10 times. An effective constructive solution for the complex modification of cast iron in the ladle and mold gating system was developed, which, compared to the conventional technology, made it possible to reduce the sulfur content in the cast iron from 0.025 % to 0.010 % and the total oxygen content from 40 ppm to 15 ppm. As a result of the improved technology, the mechanical properties of high-strength spheroidal graphite cast iron of grade VCh50 were significantly enhanced: the tensile strength increased by 27 %, the yield strength by 25 %, and the hardness by 28 %. Moreover, the graphite structure achieved 90-95 % perfect sphericity, with smooth, uniformly distributed, and evenly sized graphite nodules.

References

-

U. Rakhimov and N. Tursunov, “Development of technology for high-strength cast iron for manufacturing D49 head of cylinder,” in E3S Web of Conferences, Vol. 401, p. 05013, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105013

-

U. T. Rakhimov, N. K. Tursunov, and S. E. Tursunov, “Improvement of production technology for spheroidal graphite cast iron with increased strength,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060024, Jan. 2024, https://doi.org/10.1063/5.0197475

-

A. L. Rutkovskiy, E. M. Bakhteev, Z. G. Salikhov, and M. A. Kovaleva, “An optimized process of drying titanium pellets in a tunnel kiln,” Tsvetnye Metally, Vol. 2021, No. 5, pp. 89–94, May 2021, https://doi.org/10.17580/tsm.2021.05.12

-

T. Tursunov, N. Tursunov, and T. Urazbayev, “Investigation of heat exchange processes in the lining of induction furnaces,” in E3S Web of Conferences, Vol. 401, p. 05029, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105029

-

T. Urazbayev, N. Tursunov, and T. Tursunov, “Steel modification modes for improving the cast parts quality of the rolling stock couplers,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060015, Jan. 2024, https://doi.org/10.1063/5.0197361

-

S. Absattarov, N. Tursunov, and O. Toirov, “Analysis of heat treatment parameters of 60Si2CrV steel to enhance the mechanical properties of elastic structural elements,” Vibroengineering Procedia, Vol. 58, pp. 320–326, May 2025, https://doi.org/10.21595/vp.2025.24991

-

S. Absattarov, A. Riskulov, and J. Avliyokulov, “Dependence establishment of mass transfer coefficient in third kind boundary condition on temperature during vacuum carburizing of steels,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030035, Jan. 2025, https://doi.org/10.1063/5.0266787

-

N. Tursunov, S. Absattarov, and M. D. Abdulazizovna, “Enhancing the mechanical and functional characteristics of structural spring steel through the advancement of heat treatment technologies,” Vibroengineering Procedia, Vol. 58, pp. 327–332, May 2025, https://doi.org/10.21595/vp.2025.24992

-

D. Valieva, S. Yunusov, and N. Tursunov, “Study of the operational properties of the bolster of a freight car bogie,” in E3S Web of Conferences, Vol. 401, p. 05017, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105017

-

M. Rakhmatov, A. Riskulov, and K. Nurmetov, “Composite materials with enhanced abrasion resistance and certain functional characteristics based on thermoplastics,” Material and Mechanical Engineering Technology, Vol. 2025, No. 2, pp. 86–93, 2025.

-

M. Rakhmatov, A. Riskulov, and K. Nurmetov, “Abrasive-resistant composite materials with specified functional characteristics based on thermoplastics,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030040, Jan. 2025, https://doi.org/10.1063/5.0266781

-

N. Bekmurzaev, F. Norkhudjaev, and S. Alimukhamedov, “Energy aspects of conjugated heterophase surfaces wear operating in a free abrasive medium,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060018, Jan. 2024, https://doi.org/10.1063/5.0197469

-

S. Mamayev, A. Ibadullayev, E. Teshabayeva, M. Tursunaliev, and M.-A. Ikromov, “Creation of elastomer-based compositions with special characteristics for the wheel-engine block of thermal locomotives,” in E3S Web of Conferences, Vol. 452, p. 04013, Nov. 2023, https://doi.org/10.1051/e3sconf/202345204013

-

A. Avdeeva, S. Mamaev, and G. Bakyt, “Determination of the resource of wheel pairs of locomotives during operation on the railways of Uzbekistan,” Vibroengineering Procedia, Vol. 58, pp. 347–353, May 2025, https://doi.org/10.21595/vp.2025.25005

-

S. Azimov, O. Toirov, B. Xalmurzayev, S. Tursunov, and K. Khujakhmedova, “Using a cooling hole to improve the performance of transport brakes,” Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060016, Jan. 2024, https://doi.org/10.1063/5.0197365

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.