Abstract

This study analyzes the methodological principles of implementing the nano-state phenomenon in the development of high-performance composite materials based on recycled polyolefins. We demonstrate that incorporating carbon-containing modifiers – specifically, carbon-mineral filler (CMF, a byproduct of carbonaceous shale processing) and carbon-silica filler (CSF, synthesized from carbonized rice husks) – into the polymer matrix as doping additives significantly enhances the composites’ structural and functional properties. These modifiers were produced via oxygen-free pyrolysis of biomass. The developed materials were successfully tested in the manufacturing of dowel-type fasteners for construction applications.

Highlights

- The growing use of thermoplastic polymer products highlights the challenge of implementing sustainable development strategies.

- The objective of this study was to develop composite materials based on recycled polyolefins modified with carbon-containing components of different compositions and to establish their manufacturing technology.

- The methodological approaches to achieving the nano-state phenomenon enabled the use of carbon-containing components derived from thermal treatment of plant waste as modifiers for recycled thermoplastic matrices.

- Our study demonstrated that introducing doping quantities of carbon-based modifiers (CMF and CSF) into recycled LDPE, HDPE, and PP matrices allows for controlled structural modifications, altering rheological and stress-strain parameters.

- We have developed composite formulations based on recycled polyolefins for manufacturing construction industry products with enhanced performance characteristics.

1. Introduction

The implementation of the National Strategy for Sustainable Socio-Economic Development of the Republic of Belarus [1], [2] and the Innovation Development Strategy of the Republic of Uzbekistan [3] is based on developing modern technologies for producing functional products with various applications. These technologies focus on reducing residual byproducts during manufacturing and operation to minimize the negative impact of anthropogenic factors on environmental components.

Polymer and composite materials have found widespread application in modern mechanical engineering due to their combination of tailored functional characteristics and highly efficient manufacturing technologies utilizing high-performance equipment [4-11]. In this context, thermoplastic materials show particular promise. Their processing employs advanced technological equipment – injection molding machines, extruders, etc. – which ensures required performance parameters and process productivity [7-9].

The growing use of thermoplastic polymer products highlights the challenge of implementing sustainable development strategies. Increasing quantities of depreciated products negatively impact the environment, necessitating the development of efficient recycling technologies to reintroduce material components with remaining service life back into production. To modify thermoplastic matrices to achieve composite materials with high functional characteristics, components of varying dispersion and structural influence are used [12-16]. Some of these components positively affect the vibrodynamic properties and damping capacity of materials used in transportation systems operating under cyclic and impact loads.

The objective of this study was to develop composite materials based on recycled polyolefins modified with carbon-containing components of different compositions and to establish their manufacturing technology.

2. Materials and methods

The study objects were composite materials based on recycled polyolefins produced by JSC “Belvtorpolimer” (Grodno, Belarus): recycled low-density polyethylene (R-LDPE), recycled high-density polyethylene (R-HDPE), and recycled polypropylene (R-PP).

The recycled polyolefins were obtained through conventional recycling technology involving sorting, cleaning, crushing of recycled products, and subsequent extrusion to produce granulated semi-finished material. For polymer matrix modification, we employed plant-based carbon- and silicon-containing particulate components:

1. Carbon-mineral filler (CMF) with silicon in crystalline state [17].

2. Carbon-silica filler (CSF) [18] containing amorphous silicon.

The carbon-silica filler (CSF) was synthesized by NeoCarbon LLP (Almaty, Kazakhstan). The raw material consisted of biomass from a mixture of rice husks and stems. The CSF production process involved: preliminary raw material treatment by grinding biomass in a rotary knife mill to obtain homogeneous fractions; carbonization in a pyrolysis reactor under inert atmosphere (oxygen-free) at 550-600 °C; thermal decomposition of organic components forming a carbon framework and silicon-containing phases.

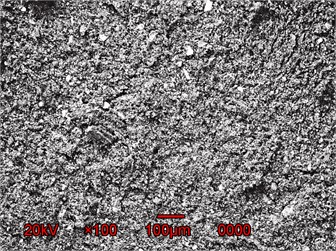

The resulting particulate product features a unique heterophase structure combining a carbon matrix with silicon-containing inclusions. The CSF morphology presents a three-dimensional network of interconnected fibrous elements inherited from the original plant structure, with inclusions of inorganic compounds. To reduce particle aggregation and increase specific surface area, the material underwent mechanochemical treatment using laboratory vibration and planetary ball (PM100) mills in high-energy impact mode [19], [20].

The research subjects included: structure and performance parameters of various composite formulations based on recycled polyolefins.

The investigation employed standard methods: infrared (IR) spectroscopy; thermally stimulated current (TSC) analysis; rheological and stress-strain characterization methods; statistical processing of results.

3. Results and discussion

In the development of composite materials based on virgin and recycled thermoplastics, carbon-containing components have gained widespread use – graphite, carbon black, detonation synthesis products (ultradispersed diamonds (UDD) and diamond-graphite (UDDG), fullerenes, and nanotubes [4], [9]-[12], [16]-[23]. The application of certain carbon-containing components requires the development of highly efficient production technologies to enable industrial-scale manufacturing of functional products. Therefore, despite the effective structure-forming action of nanoscale particles like UDD, UDDG, fullerenes, and nanotubes, their practical use remains limited to specialty composite applications. In this context, technologies for producing dispersed carbon-containing polymer matrix modifiers from plant-derived components show particular promise, as they enable large-scale production at costs permitting widespread industrial application.

A critical feature of polymeric modifiers is the active influence of particles on matrix structuring at various levels [24]. The most significant factor in this process is the energetic state of the particle surface layer, which determines structuring mechanisms at molecular, supramolecular, and intermolecular levels. This aspect is particularly important for developing nanostructured composite materials with enhanced deformation-strength, tribotechnical, thermophysical, and other characteristics.

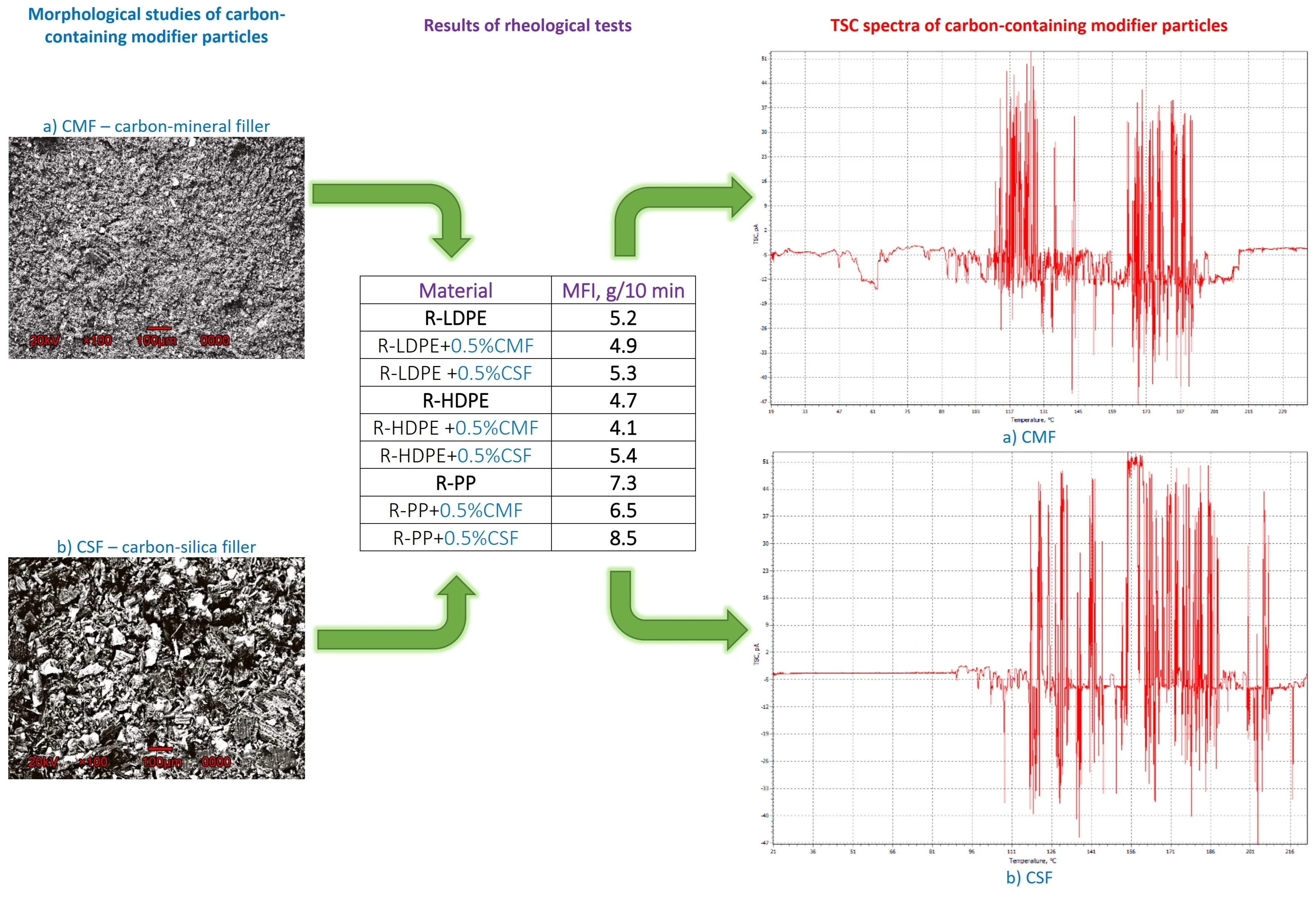

Evaluation of particle size distribution in the carbon-containing modifiers (CMF, CSF) using microscopy revealed predominantly micro-scale particles with nanoscale fragments present (Fig. 1). However, as shown in [17]-[20], the production technology involving thermal treatment at 550-600 °C in an oxygen-free environment results in unique crystalline structure and energetic state [25]-[27].

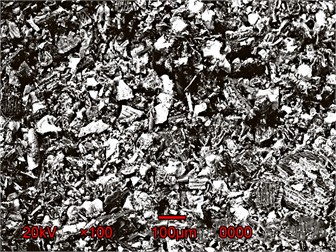

TSC analysis of CMF and CSF particles clearly demonstrates charge activity in their surface layers within the 388-473 K temperature range (Fig. 2). Notably, increased particle activity occurs in temperature ranges correlating with thermoplastic processing conditions (injection molding or extrusion), significantly influencing matrix structure formation in composites.

Fig. 1Morphological studies of carbon-containing modifier particles

a) CMF [16]

b) CSF [17]

Fig. 2TSC spectra of carbon-containing modifier particles

a) CMF

b) CSF

Our research, summarized in monographs [10], [11], classifies CMF and CSF modifier particles as exhibiting the nanostate phenomenon – characterized by special surface layer energetic states resulting from their dispersion and production technology, which enables effective multi-level polymer matrix structuring. Applying our previously proposed methodology [10], [11] for implementing the nano-state phenomenon in polymer matrix composites, we developed technological approaches for optimizing the structure of recycled polymer-based composites to achieve target performance characteristics (Fig. 3).

Fig. 3Methodological principles for implementing the nano-state phenomenon in materials science and composite technology based on polymer matrices and metal-polymer systems [10], [11]

![Methodological principles for implementing the nano-state phenomenon in materials science and composite technology based on polymer matrices and metal-polymer systems [10], [11]](https://static-01.extrica.com/articles/25690/25690-img5.jpg)

These methodological principles utilize standard polymer composite processing equipment, significantly simplifying and reducing costs for manufacturing functional products while supporting of the National Strategy for Sustainable Socio-Economic Development of the Republic of Belarus [1], [2] and the Innovation Development Strategy of the Republic of Uzbekistan [3]. To evaluate the effectiveness of the nano-state phenomenon implementation, we investigated the structure and properties of recycled polyolefins modified with CMF and CSF carbon-containing components. Test samples were produced using conventional thermoplastic processing methods.

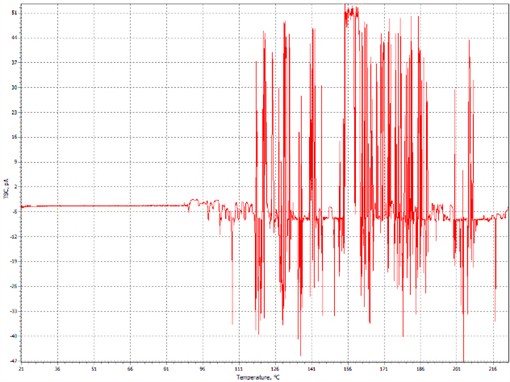

Rheological characterization results (Table 1) demonstrate significant influence of silicon morphology (crystalline/amorphous) in fillers on the melt flow index (MFI) of developed recycled polyolefin composites containing carbon-silicon particles.

Particles containing crystalline silicon (CMF) in the studied compositions reduce the melt flow index (MFI), increasing melt viscosity. This effect may be attributed to enhanced filler-matrix interactions and the formation of additional crosslinking points in the polymer chains.

Table 1Results of rheological tests

Material | MFI, g/10 min |

R-LDPE | 5.2 |

R-LDPE+0.5%CMF | 4.9 |

R-LDPE +0.5%CSF | 5.3 |

R-HDPE | 4.7 |

R-HDPE +0.5%CMF | 4.1 |

R-HDPE+0.5%CSF | 5.4 |

R-PP | 7.3 |

R-PP+0.5%CMF | 6.5 |

R-PP+0.5%CSF | 8.5 |

Particles with amorphous silicon (CSF) demonstrate the opposite effect: for R-LDPE and R-PP, a significant increase in MFI is observed, facilitating processing; while for R-HDPE the effect is minimal, likely due to differences in matrix structure.

Crystalline silicon-containing particles (CMF) restrict the mobility of polyolefin chain segments, whereas amorphous silicon-containing particles (CSF) appear to plasticize the system, improving composite flow characteristics.

R-LDPE-based materials showed the highest sensitivity to fillers (–12.8 % and +14.9 % respectively), which can be explained by its higher density and linear chain structure.

A comparative analysis of stress-strain parameters for the developed composite formulations under uniaxial tension is presented in Table 2. The results demonstrate that introducing doping quantities (0.5 %) of carbon-silica fillers into the matrix component enables targeted property modification: CMF increases stiffness parameters but reduces plasticity, while CSF particles provide a balanced combination of strength and deformability.

Table 2Stress-strain characteristics of composites based on regenerated polyolefins (uniaxial tension)

Material | Physical yield strength, MPa | Deformation at physical yield strength, % | Strength at maximum force, MPa | Deformation at maximum force, % | Breaking strength, MPa | Deformation at break, % | Temporal Resistance, MPa | Upper yield strength, MPa | Lower yield strength, MPa |

R-LDPE | 16.58 | 69.42 | 17.13 | 98.01 | 17.13 | 98.01 | 17.1 | 11.2 | 11.2 |

R-LDPE + 0.5%CMF | 19.32 | 64.47 | 19.89 | 86.81 | 19.89 | 86.81 | 19.8 | 13.4 | 13.4 |

R-LDPE + 0.5%CSF | 19.83 | 48.75 | 20.31 | 70.50 | 20.31 | 70.50 | 20.3 | 15.8 | 15.8 |

R-HDPE | 24.55 | 9.94 | 24.55 | 9.94 | 18.475 | 43.80 | 24.5 | 23.9 | 23.9 |

R-HDPE + 0.5%CMF | 26.46 | 8.47 | 26.46 | 8.47 | 19.33 | 36.29 | 26.4 | 26.1 | 25.9 |

R-HDPE + 0.5%CSF | 25.77 | 8.87 | 25.77 | 8.87 | 19.05 | 29.88 | 25.7 | 25.6 | 25.6 |

R-PP | 11.60 | 1.10 | 22.85 | 7.83 | 22.85 | 7.83 | 22.8 | 22.7 | 22.7 |

R-PP + 0.5%CMF | 13.38 | 1.17 | 22.53 | 5.93 | 22.53 | 5.93 | 22.5 | – | – |

R-PP + 0.5%CSF | 13.56 | 1.17 | 24.42 | 8.28 | 24.42 | 8.28 | 24.4 | 24.2 | 24.1 |

Comparative results of stress-strain parameters for the developed composite materials under bending are presented in Table 3.

Analysis of stress-strain parameters revealed that modification with doping quantities of carbon-silica fillers significantly affects the bending properties of recycled polyolefins: CMF enhances stiffness but increases brittleness, while CSF provides balanced improvement in both strength and plasticity. Notably, CMF particles containing crystalline silicon increased the yield strength for all materials by 5.2 %-21.0 % while reducing deformability, particularly for R-PP-based composites (up to 64.8 %). In contrast, CSF with amorphous silicon delivered maximum strength improvement (up to 45.22 MPa for R-PP) while maintaining higher plasticity compared to CMF.

Table 3Stress-strain characteristics of composites based on regenerated polyolefins (bending)

Material | Physical yield strength, MPa | Deformation at physical yield strength, mm | Breaking strength, MPa | Fracture deformation, mm |

R-LDPE | 25.24 | 12.90 | 25.54 | 12.90 |

R-LDPE+0.5%CMF | 29.75 | 10.19 | 27.32 | 26.31 |

R-LDPE+0.5%CSF | 30.54 | 11.20 | 28.12 | 27.66 |

R-HDPE | 37.81 | 13.92 | 37.81 | 13.92 |

R-HDPE+0.5%CMF | 40.75 | 13.25 | 35.42 | 22.74 |

R-HDPE+0.5%CSF | 38.68 | 13.09 | 33.45 | 22.75 |

R-PP | 40.26 | 9.17 | 38.30 | 12.73 |

R-PP+0.5%CMF | 42.35 | 3.23 | 42.35 | 3.23 |

R-PP+0.5%CSF | 45.22 | 8.16 | 44.80 | 9.35 |

This research has enabled the development of new composite materials based on recycled polyolefins for manufacturing products with various functional applications. The developed composite compositions are particularly effective for producing dowel-type fasteners used in the construction industry.

4. Conclusions

The practical implementation of the Sustainable Socio-Economic Development Concept of the Republic of Belarus and the Innovation Development Strategy of the Republic of Uzbekistan is based on developing efficient resource-saving technologies for processing base materials into functional products and their subsequent recycling. The methodological approaches to achieving the nano-state phenomenon enabled the use of carbon-containing components derived from thermal treatment of plant waste as modifiers for recycled thermoplastic matrices.

Our study demonstrated that introducing doping quantities of carbon-based modifiers (CMF and CSF) into recycled LDPE, HDPE, and PP matrices allows for controlled structural modifications, altering rheological and stress-strain parameters. We have developed composite formulations based on recycled polyolefins for manufacturing construction industry products with enhanced performance characteristics.

Furthermore, the developed composites show promise for manufacturing components of transport systems, such as protective covers for cardan shafts in agricultural and special machinery transmissions, or damping pads in mining equipment. These applications require a simultaneous combination of vibration resistance, impact toughness, and service durability.

References

-

“On the national strategy for circular economy development of the Republic of Belarus until 2035: resolution of the council of ministers of the Republic of Belarus No. 393 dated May 29, 2024.” National Legal Internet Portal of the Republic of Belarus, https://pravo.by/document/?guid=12551&p0=c22400393.

-

“Draft national strategy for sustainable development of the Republic of Belarus until 2040,” (in Russian), Research Institute of the Ministry of Economy of the Republic of Belarus, Aug. 2025.

-

“Strategy for innovative development of the Republic of Uzbekistan for 2022-2026: Appendix No. 1 to the decree of the president of the Republic of Uzbekistan No. UP-165 dated July 6, 2022.” National Legal Information Center Adolat of the Ministry of Justice of the Republic of Uzbekistan, https://lex.uz/docs/6102464.

-

V. A. Goldade, V. A. Struk, A. S. Vorontsov, and S. V. Avdeychik, Materials Science and Technology of Polymers and Composites. (in Russian), Grodno: Yanka Kupala State University of Grodno, 2018.

-

N. I. Baurova and V. A. Zorin, Application of Polymer Composite Materials in Mechanical Engineering. (in Russian), Moscow: Infra-M, 2018.

-

K. Friedrich, S. Fakirov, and Z. Zhang, “Polymer composites: from nano – to macro-scale,” Choice Reviews Online, Vol. 43, No. 5, pp. 43–2821-43-2821, Jan. 2006, https://doi.org/10.5860/choice.43-2821

-

V. A. Struk, “Tribochemical concept of creating antifriction materials based on mass-produced polymer binders,” (in Russian), Minsk, 1988.

-

M. Rakhmatov, A. Riskulov, and K. Nurmetov, “Composite materials with enhanced abrasion resistance and certain functional characteristics based on thermoplastics,” Material and Mechanical Engineering Technology, Vol. 2025, No. 2, pp. 86–93, 2025.

-

A. S. Antonov, “Composite materials based on thermoplastic blends for extending service life of technological equipment components,” (in Russian), Belarusian State Technological University, Minsk, 2018.

-

S. V. Avdeychik, V. A. Struk, and A. S. Antonov, The Nanostate Factor in Materials Science of Polymer Nanocomposites. (in Russian), Saarbrücken: LAP LAMBERT Academic Publishing, 2017.

-

V. A. Struk, V. A. Liopo, S. V. Avdeychik, V. A. Goldade, A. S. Antonov, and Y. R. Beityuk, Nanomaterials and Nanotechnologies for Mechanical Engineering. (in Russian), Minsk: RIVSH, 2021.

-

M. L. Kerber and A. A. Berlin, Polymer Composite Materials: Structure, Properties, Technology. (in Russian), St. Petersburg: Professiya, 2008.

-

V. N. Kuleznev, Polymer Blends and Alloys: Lecture Notes. (in Russian), St. Petersburg: Scientific Foundations and Technologies, 2013.

-

D. R. Paul and C. B. Bucknall, Polymer Blends. Vol. 1: Systematics. (in Russian), St. Petersburg: Scientific Foundations and Technologies, 2009.

-

D. R. Paul and C. B. Bucknall, Polymer Blends. Vol. 2: Functional Properties. (in Russian), St. Petersburg: Scientific Foundations and Technologies, 2009.

-

P. M. Ajayan, L. S. Schalder, and A. V. Braun, Nanocomposite Science and Technology. Weinheim: Wiley, 2003, https://doi.org/10.1002/3527602127

-

A. V. Kasperovich, V. V. Bobrova, A. A. Kadyko, S. A. Efremov, and S. V. Nechipurenko, “Carbon-mineral filler for elastomeric compositions,” (in Russian), in Technology of Organic Substances: Proceedings of the 87th Scientific and Technical Conference of Faculty, Researchers and Postgraduates, pp. 146–149, 2023.

-

V. V. Bobrova, N. R. Prokopchuk, S. A. Efremov, and S. V. Nechipurenko, “Carbon-silica filler for elastomeric compositions,” (in Russian), Proceedings of BSTU. Series 2: Chemical Technology, Biotechnology, Geoecology, Vol. 1, No. 253, pp. 89–95, 2022.

-

S. N. Rusanova, K. B. Vernigorov, V. V. Bushkov, Y. M. Kazakov, S. A. Efremov, and O. V. Stoyanov, “Comparative characteristics of thermal stability of polyethylene in the presence of complex fillers based on natural raw materials,” (in Russian), Plastic Masses, No. 4, pp. 48–52, Sep. 2024, https://doi.org/10.35164/0554-2901-2024-04-48-52

-

V. V. Bobrova, “Elastomeric compositions with carbon-silica filler based on plant raw materials,” (in Russian), Belarusian State Technological University, Minsk, 2023.

-

H. Fu et al., “Overview of injection molding technology for processing polymers and their composites,” ES Materials and Manufacturing, Vol. 8, pp. 3–23, Jan. 2020, https://doi.org/10.30919/esmm5f713

-

M. E. Dirckx and D. E. Hardt, “Analysis and characterization of demolding of hot embossed polymer microstructures,” Journal of Micromechanics and Microengineering, Vol. 21, No. 8, p. 085024, Aug. 2011, https://doi.org/10.1088/0960-1317/21/8/085024

-

Z. S. Shashok, “Modification of elastomeric compositions with carbon nanostructured materials,” (in Russian), Belarusian State Technological University, Minsk, 2020.

-

V. Kravchenko, G. Kostyukovich, and V. Struk, Cardan Transmissions: Materials, Designs, Applications. (in Russian), Minsk: Technology, 2006.

-

M. Rakhmatov, A. Riskulov, and K. Nurmetov, “Abrasive-resistant composite materials with specified functional characteristics based on thermoplastics,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030040, Jan. 2025, https://doi.org/10.1063/5.0266781

-

N. Bekmurzaev, F. Norkhudjaev, and S. Alimukhamedov, “Energy aspects of conjugated heterophase surfaces wear operating in a free abrasive medium,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060018, Jan. 2024, https://doi.org/10.1063/5.0197469

-

S. Absattarov, A. Riskulov, and J. Avliyokulov, “Dependence establishment of mass transfer coefficient in third kind boundary condition on temperature during vacuum carburizing of steels,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030035, Jan. 2025, https://doi.org/10.1063/5.0266787

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.