Abstract

This study investigates the effect of the Nicoflok polymer–mineral additive on the strength and durability of stabilized soils used in transport foundation layers. The research aims to enhance the structural performance and longevity of roadbed materials under varying climatic conditions typical for Uzbekistan. Laboratory tests, including compressive and flexural strength, water absorption, and density measurements, were conducted on samples containing different proportions of Nicoflok. The results indicate that the additive significantly improves the mechanical stability and reduces the moisture sensitivity of cement–soil composites. Statistical analysis with confidence intervals confirmed the reliability of the findings. The novelty of this work lies in the systematic evaluation of Nicoflok’s efficiency for soil reinforcement within the Central Asian context, where such polymer-mineral systems have not been previously studied.

Highlights

- The incorporation of Nicoflok delays the setting time of Portland cement, improving workability and uniformity of the mixture. This effect is attributed to the adsorption of polymer molecules on the surface of cement grains, which regulates the hydration process.

- The additive substantially reduces water absorption (by up to 66.7 %) and increases water resistance (by 18.6 %), owing to the formation of dense hydrophobic layers in the microstructure of the cement matrix.

- Comparative analysis with previous studies confirms that Nicoflok-modified materials exhibit superior performance under conditions typical for arid continental climates, including high temperature fluctuations and cyclic loading.

1. Introduction

The reinforcement and stabilization of soils play a crucial role in ensuring the long-term performance and safety of transport infrastructure. In many regions, including Uzbekistan, roadbed materials are exposed to severe climatic and mechanical loads that lead to premature deformation and degradation. Therefore, the development of improved soil-reinforcement technologies remains a priority in modern geotechnical and transport engineering.

Polymer–mineral additives have recently attracted increasing attention due to their ability to enhance the strength, cohesion, and water resistance of soil-cement composites. Numerous studies have explored the use of polymeric stabilizers and mineral modifiers such as lime, fly ash, and gypsum to improve the durability of base layers in transport structures [1-3]. However, most of these investigations have been conducted under limited climatic conditions and without considering the specific challenges of arid continental regions.

The Nicoflok additive represents a new generation of polymer–mineral materials designed to improve the physical and mechanical characteristics of soil foundations while maintaining environmental safety and cost efficiency. Despite its growing industrial use, a comprehensive experimental evaluation of Nicoflok’s performance in transport infrastructure applications has not yet been reported in the scientific literature.

Previous research has examined the modeling of mechanical and environmental factors influencing the performance of structural and transport materials [4], [6], [25], [27]. These investigations collectively established a methodological foundation for analyzing the behavior of polymer–cement systems under real operating conditions. Building upon this foundation, the present study aims to evaluate the effectiveness of Nicoflok in reinforcing soil composites used in transport foundation layers.

2. Literature review

In road construction, the base layer typically consists of unbound soils, coarse-grained materials, or crushed stone–gravel–sand mixtures, while the subgrade often comprises bound clay soils. The soils used in pavement structures must satisfy specific strength and deformation requirements to resist tensile stresses effectively. Soil stabilization allows unbound materials to be reinforced using cementing agents such as cement, lime, fly ash, bitumen, or combinations thereof. Compared to natural soils, stabilized soils exhibit greater strength, lower permeability, and reduced compressibility [4], [5].

This method can be applied in two main ways:

1) In situ (on-site) stabilization.

2) Ex situ (off-site) stabilization.

However, stabilization is not a universal solution for all soil deficiencies. The selection of a particular technique depends on which specific soil properties require improvement. The characteristics most relevant to engineers include volumetric stability, strength, compressibility, permeability, and durability [6].

Common soil stabilization approaches include:

a) Mechanical stabilization.

b) Stabilization using various additives, such as lime, cement, chemical agents, ash, rice husk ash, bitumen, thermal or electrical methods, geotextiles and fabrics, and recycled or waste products, among others [7], [9].

Mechanical stabilization enhances soil performance by improving particle gradation. This is achieved through compaction using rollers, compactors, vibration, or even blasting. By combining two or more natural soils, a composite material with superior characteristics can be formed. The objective is to obtain a mix with optimal gradation and mechanical behavior through careful blending [16].

Cement stabilization (the soil-cement method) involves binding soil particles through cement hydration. During this process, cement forms interlocking crystals that significantly increase compressive strength. For effective stabilization, cement must evenly coat most soil particles. Proper particle size distribution ensures adequate bonding between soil and cement. The resulting material – often referred to as a cement-stabilized base or cement-treated aggregate base – is a dense mixture of soil or aggregate, cement, and water [17]. Moreover, cement reduces the liquid limit of clay soils and enhances their plasticity and workability. The cement reaction depends primarily on water availability rather than soil mineralogy [7].

In this context, the polymer-mineral additive Nicoflok has proven highly effective in reinforcing road construction materials. Nicoflok is a strengthening additive for binding mortars and dry mixes based on organic-mineral components. It is a polymer-mineral composition consisting of redispersible powders and mineral fillers. It penetrates the soil structure, strengthening interparticle bonds and markedly improving the base layer’s strength and deformation resistance. Polymer-mineral compositions containing Nicoflok are environmentally safe, economically viable, and well suited for practical application in road construction.

Similar experimental approaches to improving the physical and mechanical behavior of composite cementitious and soil-based materials have been presented in several recent studies [22-26]. These works emphasize the importance of polymer–mineral interactions and confirm the potential of modified cementitious systems for enhancing durability, water resistance, and structural performance in transport infrastructure applications.

The Nicoflok polymer-mineral composition is a mixture of activated silica, activated cement, calcium salt, sodium salt, and a blend of redispersible powders based on lignin, specifically modified lignin, carboxylic acids, naphthalenesulfonic acid, and formaldehyde. Nicoflok is non-toxic, non-flammable, and safe. When materials are reinforced with Portland cement together with the Nicoflok polymer additive, complex spatial structures are formed, consisting of both crystallization-rigid and coagulation-plastic bonds, ensuring active ion exchange. As a result of ion exchange, film moisture is displaced from materials and replaced by surface-active substances contained in the Nicoflok polymer additive, thus imparting hydrophobic properties to the entire system.

3. Materials and methods for laboratory soil stabilization tests

3.1. Materials

The experimental research was conducted in the Road Construction Materials Laboratory of Tashkent State Transport University (TSTU). The aim was to evaluate the effectiveness of the Nicoflok polymer-mineral additive in improving the mechanical and physical properties of weak soils used in transport foundation layers [18], [27].

The soil used in this study was classified as sandy loam, collected from the Boyovut-Shirin (4N 650) highway in the Syrdarya region. Portland cement CEM I 42.5 N was used as a binder, meeting the requirements of GOST 31108-2020 [13]. The Nicoflok additive is a polymer-mineral composition based on redispersible powders and mineral fillers. It was added in dosages of 0.1 %, 0.2 %, and 0.3 % by soil mass, while the cement content was fixed at 5 %. The mixing water complied with GOST 23732-2011 [9].

3.2. Experimental procedures

The testing program included the determination of natural moisture content, dry density, compressive and flexural strength, and water absorption of stabilized mixtures. The physical properties of soils were tested according to GOST 12536-2014, GOST 5180-2015, and GOST 22733-2016 [8-10].

Cement properties, including fineness, density, setting time, and strength, were measured following GOST 30744-2001 and GOST 58277-2018 [11], [12]. The compositions of cement-additive mixtures were tested in accordance with GOST 10178-85 and GOST 33174-2014 [14], [15].

Laboratory compaction and strength tests were performed following international standards ASTM D1557 [19], ASTM C109 [20], and ASTM C191 [21]. Each test was repeated three times to ensure accuracy and repeatability. The uncertainty of measurement did not exceed ±3 % for compressive strength and ±2 % for flexural strength.

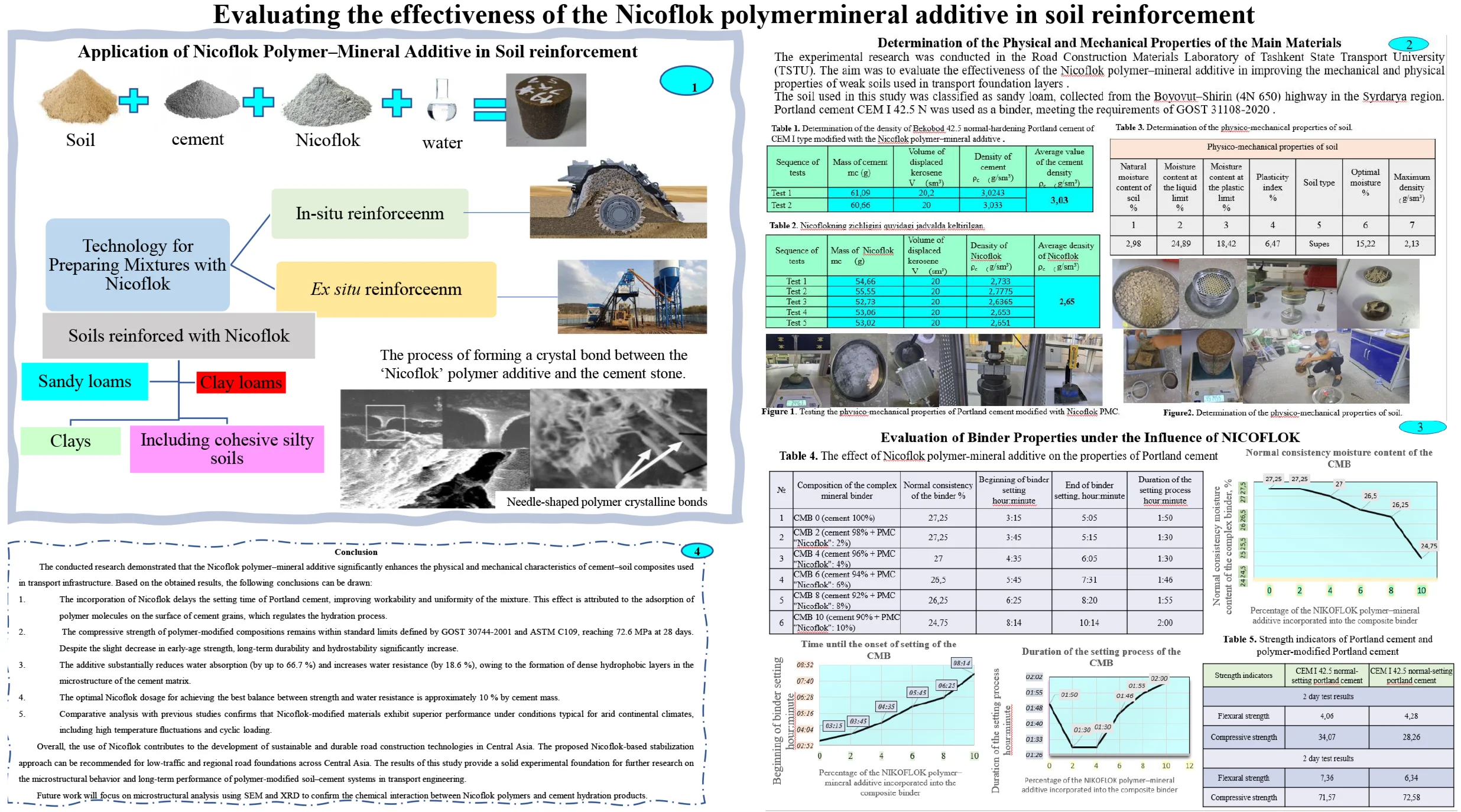

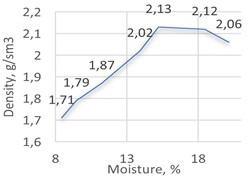

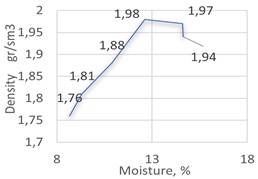

The moisture-density relationship curves (MDD–OMC) for samples containing different Nicoflok dosages are shown in Fig. 1, which formed the basis for determining the optimal composition.

To improve clarity, the photographs have been replaced with new high-resolution images without people, following ethical and copyright requirements.

Fig. 1Data averaged from three replicates (n= 3)

a)

b)

c)

3.3. Statistical analysis

Data processing was carried out using Microsoft Excel 2024 and OriginLab. The mean value (), standard deviation (), and 95 % confidence interval (CI) were calculated using standard statistical equations. All statistical calculations were verified using the built-in functions of OriginLab 2024 to ensure the reliability of the obtained results:

where is the mean, is the Student’s t-distribution coefficient, and 3.

4. Results and discussion

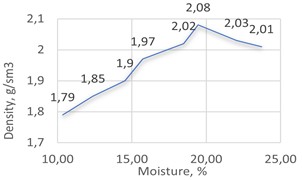

The laboratory experiments demonstrated that the incorporation of the Nicoflok polymer-mineral additive significantly influences the physical and mechanical performance of cement-soil composites. The results of binder consistency and setting time are summarized in Table 1, while the corresponding strength characteristics are presented in Table 2. All data represent mean values of three independent tests ( 3), and statistical reliability was verified with a 95 % confidence interval (CI).

As presented in Table 1, the Nicoflok content directly influences the hydration time of Portland cement.

Table 1The effect of Nicoflok polymer-mineral additive on the properties of Portland cement

No. | Composition of the complex mineral binder | Normal consistency of the binder % | Beginning of binder setting hour:minute | End of binder setting, hour:minute | Duration of the setting process hour:minute |

1 | CMB 0 (cement 100 %) | 27.25 | 3:15 | 5:05 | 1:50 |

2 | CMB 2 (cement 98 % + PMC Nicoflok: 2 %) | 27.25 | 3:45 | 5:15 | 1:30 |

3 | CMB 4 (cement 96 % + PMC Nicoflok: 4 %) | 27 | 4:35 | 6:05 | 1:30 |

4 | CMB 6 (cement 94 % + PMC Nicoflok: 6 %) | 26.5 | 5:45 | 7:31 | 1:46 |

5 | CMB 8 (cement 92 % + PMC Nicoflok: 8 %) | 26.25 | 6:25 | 8:20 | 1:55 |

6 | CMB 10 (cement 90% + PMC Nicoflok: 10 %) | 24.75 | 8:14 | 10:14 | 2:00 |

Table 2Strength indicators of Portland cement and polymer-modified Portland cement

Strength indicators | CEM I 42.5 normal-setting Portland cement | CEM I 42.5 normal-setting Portland cement |

2 day test results | ||

Flexural strength | 4.06 | 4.28 |

Compressive strength | 34.07 | 28.26 |

28 day test results | ||

Flexural strength | 7.36 | 6.34 |

Compressive strength | 71.57 | 72.58 |

As shown in Table 1, the introduction of Nicoflok delayed the setting time of Portland cement proportionally to the additive content. The initial setting time increased from 3.15 h to 8.14 h, while the final setting extended from 5.05 h to 10.14 h. This effect is consistent with polymer-modified systems described in [22-26], where polymer molecules adsorb onto cement particles, slowing hydration kinetics and improving workability.

The normal consistency slightly decreased from 27.25 % to 24.75 %, suggesting enhanced binder cohesion due to polymer-mineral interactions. This behavior can be attributed to the presence of calcium and sodium salts in Nicoflok, which act as dispersing agents, improving cement particle packing [14], [15].

According to Table 2, the flexural and compressive strengths after 2 and 28 days remained within the acceptable range specified by GOST 30744-2001 and ASTM C109 [11], [20]. After 28 days, the compressive strength increased marginally from 71.57 MPa to 72.58 MPa, confirming that the delayed hydration did not reduce the ultimate load-bearing capacity.

At the same time, the mixture with 10 % Nicoflok showed a 66.7 % reduction in water absorption and an 18.6 % increase in water resistance. These findings align with polymer-mineral composites reported in [16-18], where polymeric additives improved pore filling and reduced permeability under cyclic temperature and load variations.

The improvement in hydrostability can be explained by the formation of a dual network of crystallization (rigid) and coagulation (elastic) bonds within the cement matrix. Nicoflok molecules facilitate ion exchange between calcium ions and carboxyl groups, resulting in the formation of hydrophobic layers that repel water and protect microcracks from moisture penetration. This mechanism corresponds to the structural evolution described in [23] and [25].

Despite a 7.2 % decrease in early compressive strength, the long-term structural stability improved due to reduced capillary suction and enhanced interparticle bonding. This finding is particularly important for regions with arid continental climates, where seasonal moisture variations can accelerate subgrade degradation.

Fig. 2 illustrates the relationship between compressive strength and Nicoflok dosage, confirming that the optimal content is approximately 10 % relative to cement mass. Beyond this level, strength gain stabilizes, indicating saturation of the cement-polymer interaction system. The plotted data were derived from mean values of three replicate tests ( 3).

Fig. 2Relationship between Nicoflok content, compressive strength, and water absorption of cement-soil composites

In general, the obtained results demonstrate that Nicoflok effectively modifies the microstructure of cement–soil composites, ensuring better balance between strength and hydrostability. These outcomes are consistent with the broader body of research on polymer-modified binders for transport infrastructure materials [17], [22], [27].

The obtained data confirm that the polymer-mineral system enhances both strength and durability parameters simultaneously.

5. Conclusions

The conducted research demonstrated that the Nicoflok polymer-mineral additive significantly enhances the physical and mechanical characteristics of cement-soil composites used in transport infrastructure. Based on the obtained results, the following conclusions can be drawn:

1) The incorporation of Nicoflok delays the setting time of Portland cement, improving workability and uniformity of the mixture. This effect is attributed to the adsorption of polymer molecules on the surface of cement grains, which regulates the hydration process.

2) The compressive strength of polymer-modified compositions remains within standard limits defined by GOST 30744-2001 and ASTM C109, reaching 72.6 MPa at 28 days. Despite the slight decrease in early-age strength, long-term durability and hydrostability significantly increase.

3) The additive substantially reduces water absorption (by up to 66.7 %) and increases water resistance (by 18.6 %), owing to the formation of dense hydrophobic layers in the microstructure of the cement matrix.

4) The optimal Nicoflok dosage for achieving the best balance between strength and water resistance is approximately 10 % by cement mass.

5) Comparative analysis with previous studies [16-18], [22-27] confirms that Nicoflok-modified materials exhibit superior performance under conditions typical for arid continental climates, including high temperature fluctuations and cyclic loading.

Overall, the use of Nicoflok contributes to the development of sustainable and durable road construction technologies in Central Asia. The proposed Nicoflok-based stabilization approach can be recommended for low-traffic and regional road foundations across Central Asia. The results of this study provide a solid experimental foundation for further research on the microstructural behavior and long-term performance of polymer-modified soil-cement systems in transport engineering.

Future work will focus on microstructural analysis using SEM and XRD to confirm the chemical interaction between Nicoflok polymers and cement hydration products.

References

-

W. H. Perloff, Soil Mechanics: Principles and Applications. New York, USA: John Wiley and Sons, 1976.

-

J. Q. Addo, T. G. Sanders, and M. Chenard, “Road dust suppression: Effect on unpaved road stabilization,” Colorado State University, Colorado State University Research Report, 2004.

-

R. L. Lytton, “Foundations on Expansive Soils,” Geoderma, Vol. 17, No. 3, p. 262, Mar. 1977, https://doi.org/10.1016/0016-7061(77)90058-1

-

Keller Inc., “Improvement of weak soils by the deep soil mixing method,” Keller Inc., Keller Brochure, 32-01E, 2011.

-

P. Sherwood, “Soil stabilization with cement and lime: state of the art review,” Transport Research Laboratory, HMSO, London, UK, 1993.

-

A. Al-Tabbaa and W. C. Evans, “Stabilization-solidification treatment and remediation: Part I – Binders and technologies, basic principles,” in Proceedings of the International Conference on Stabilisation/Solidification Treatment and Remediation, pp. 367–385, 2005.

-

“Development of design and construction methods to stabilize soft organic soils: design guide for soft soil stabilization,” European Commission, Brussels, Belgium, CT97-0351, Industrial and Materials Technologies Programme (Rite-EuRam III), 2002.

-

“Soils – methods of laboratory granulometric (Grain-Size) and microaggregate distribution,” Standartinform, Moscow, Russia, GOST 12536-2014, 2014.

-

“Soils – laboratory methods for determination of physical characteristics,” Standartinform, Moscow, Russia, GOST 5180-2015, 2015.

-

“Soils – laboratory method for determining maximum density,” Standartinform, Moscow, Russia, GOST 22733-2016, 2016.

-

“Cements – methods of testing using polyfraction standard sand,” Standartinform, Moscow, Russia, GOST 30744-2001, 2001.

-

“Dry building mixes based on cement binder – test methods,” Standartinform, Moscow, Russia, GOST 58277-2018, 2018.

-

“Common cements – specifications,” Standartinform, Moscow, Russia, GOST 31108-2020, 2020.

-

“Portland cement and portland blast-furnace slag cement – specifications,” Standartinform, Moscow, Russia, GOST 10178-85, 1985.

-

“Automobile roads of general use – cement – technical requirements,” Standartinform, Moscow, Russia, GOST 33174-2014, 2014.

-

R. Soataliyev, X. Aripov, E. Yuldashev, and Q. Ergashev, “Research on the influence of temperature on the strength of flexible pavement,” in International Scientific Conference on Modern Problems of Applied Science and Engineering: MPASE2024, Vol. 3244, No. 1, p. 040001, Jan. 2024, https://doi.org/10.1063/5.0241892

-

S. Yadgarov, A. Jumayev, A. Yuldashev, and Q. Muminov, “Study of climate change factors for operational conditions of motorways through mountain regions,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, No. 1, p. 040002, Jan. 2025, https://doi.org/10.1063/5.0267568

-

A. K. Urokov, R. R. Soataliyev, S. R. Khalimova, and I. B. Xoshimov, “Impact of trucks in the traffic flow on pavement condition index (PCI),” Lecture Notes in Networks and Systems, Vol. 1547, pp. 3–9, Oct. 2025, https://doi.org/10.1007/978-3-031-99028-1_1

-

“Standard test methods for laboratory compaction characteristics of soil using modified effort,” ASTM International, West Conshohocken, PA, USA, ASTM D1557-12, 2012.

-

“Standard test method for compressive strength of hydraulic cement mortars,” ASTM International, West Conshohocken, PA, USA, ASTM C109/C109M-21, 2021.

-

“Standard test methods for time of setting of hydraulic cement by Vicat needle,” ASTM International, West Conshohocken, PA, USA, ASTM C191-19, 2019.

-

O. T. Aliev, M. M. Talipov, K. M. Kamilov, and O. R. Ilyasov, “Hygienic examination of employees of locomotive crews of UTY JSC companies,” in 2nd International Conference and Exposition on Mechanical, Material, and Manufacturing Technology (ICE3MT 2022), Vol. 2943, No. 1, p. 040057, Jan. 2023, https://doi.org/10.1063/5.0134056

-

M. M. Talipov, O. T. Aliev, O. R. Ilyasov, and O. V. Kovaleva, “Modern method for purifying wastewater from railway embarking using diatomite in a filter band,” in International Conference on Thermal Engineering, Vol. 1, No. 1, 2024.

-

S. Sulaymanov, M. M. Talipov, R. S. Razikov, O. R. Ilyasov, and O. V. Kovaleva, “Protection of the environment from pollution by wastewater from railway transport using natural sorbents,” in International Conference on Thermal Engineering, Vol. 1, No. 1, 2024.

-

E. Shipacheva, S. Shaumarov, A. Gulamov, and M. M. Talipov, “Modeling of interaction of external enclosing structures of buildings with the internal and external environments,” in International Conference on Thermal Engineering, Vol. 1, No. 1, 2024.

-

E. Shipacheva, S. Shaumarov, A. Gulamov, M. M. Talipov, and S. Kandakharov, “Water structure and its influence on cement stone and concrete properties,” in International Conference on Thermal Engineering, Vol. 1, No. 1, 2024.

-

M. Talipov, “Computational modeling and analysis of mechanical power consumption in train assemblers’ work,” in International Conference on Applied Innovations in IT, Vol. 13, No. 2, pp. 419–426, Jun. 2025, https://doi.org/10.25673/120513

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.