Abstract

The study evaluates the efficiency of a natural diatomite-based sorbent, Diamiks Aqua, for removing petroleum hydrocarbons and suspended solids from railway wastewater. Laboratory tests using a vertical filtration column (0.5 m/h, 30 min contact time) demonstrated up to 98.9 % removal of suspended solids and 99.0 % of petroleum products. A three-layer filtration strip, integrated into railway embankments, provides a reagent-free and energy-efficient treatment process. The proposed design ensures reliable protection of water bodies from diffuse hydrocarbon runoff and contributes to the environmental sustainability of railway transport enterprises.

1. Introduction

Surface water pollution caused by petroleum products from railway facilities remains a serious environmental challenge. The main sources of contamination include fuel spills, leakage during refueling, and the absence of preventive collection systems [1-3]. Hydrocarbon pollution from snowmelt and rainwater runoff at railway yards leads to the accumulation of oil residues and suspended solids in nearby soils and water bodies, reducing their ecological quality [4-6].

While centralized treatment systems for industrial wastewater are well studied, the purification of diffuse surface runoff from transport enterprises is still insufficiently addressed. During long cold periods, hydrocarbons accumulate in the ballast and soil layers, later entering the environment during spring meltwater flow [5, 7]. Studies have shown that the composition of this runoff is highly variable and difficult to treat by conventional filtration or coagulation methods [8, 9].

Recent research on natural mineral sorbents, including diatomite-based materials, demonstrates their potential for deep purification of hydrocarbon-contaminated wastewater without chemical reagents [6], [10], [15]. Their porous structure, large specific surface area, and catalytic properties make them efficient for both adsorption and oxidation processes. However, practical applications integrated into railway infrastructure are still limited.

Therefore, the objective of this study is to evaluate the efficiency of natural diatomite sorbent Diamiks Aqua for treating railway runoff and to develop a scalable three-layer filtration strip that can be embedded into the railway embankment to ensure reagent-free purification and long-term environmental protection.

2. Methods and materials

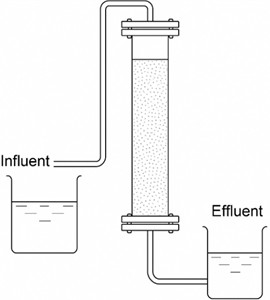

Laboratory experiments were conducted to evaluate the filtration performance of the diatomite-based sorbent Diamiks Aqua under controlled conditions. Tests were performed in a vertical acrylic column (height 1.0 m, diameter 0.1 m) operating in downward flow mode. The filter bed consisted of Diamiks Aqua granules (0.8-2 mm) pre-washed with distilled water to remove fine particles and ensure uniform packing [4], [8], [11].

Simulated meltwater represented typical contamination of railway runoff, containing 138 mg/dm3 of suspended solids and 3.9 mg/dm3 of petroleum hydrocarbons. The influent was supplied at a filtration rate of 0.5 m/h with a contact time of 30 minutes. Each experiment was repeated three times to confirm reproducibility; measurement uncertainty did not exceed ±3 %.

Pollutant concentrations were determined by gravimetric analysis and infrared spectrophotometry. The purification efficiency (%) was calculated by:

where and are the influent and effluent concentrations of pollutants (mg/dm3), and represents the removal efficiency in percentage (%).

Hydraulic permeability was evaluated according to Darcy’s law:

where is the flow rate (m3/s), is the cross-sectional area of the filter (m2), is the hydraulic head difference (m), is the filter bed height (m), and is the filtration coefficient (m/s).

All tests were carried out at 20±2 °C, pH = 7.2±0.1. The obtained data provided the basis for subsequent efficiency evaluation and design of the filtration system [10], [12].

Figure 1 illustrates the laboratory setup used for the vertical column filtration tests. The influent tank supplied simulated wastewater to the column through a controlled pump and flow meter. The effluent was collected in a separate vessel for subsequent quality assessment.

All measurements were carried out under constant temperature (20±2 °C) and pH = 7.2 ± 0.1.

Fig. 1Schematic diagram of the vertical filtration column setup

The objective of this study is to experimentally evaluate the purification efficiency of the natural diatomite sorbent Diamiks Aqua and to develop a scalable filtration design for railway runoff treatment.

3. Results and discussion

Conventional filter materials, including sand-gravel, opoka-based, and carbon sorbents, are still used in local treatment systems. However, they provide limited removal of fine suspended solids and petroleum hydrocarbons and require frequent regeneration or replacement [6], [7]. Quartz sand, with its smooth surface and low porosity, retains only large particles, quickly clogs, and consumes large volumes of backwash water. Carbon filters, though possessing a high surface area, lose efficiency due to rapid pore fouling by hydrocarbons and organic matter [10], [12]. Opoka-based filters have greater strength but limited pore accessibility and a short service life [13].

By contrast, the Diamiks Aqua diatomite sorbent exhibits high mechanical durability, porosity, and sorption capacity, achieving 2000–2500 g/m³ of solids retention with minimal abrasion (≤ 0.04 %) (Table 1). Its heterogeneous pore structure and catalytic surface enable stable long-term operation without chemical reagents. Laboratory tests confirmed removal efficiencies of 98.9 % for suspended solids and 99.0 % for petroleum hydrocarbons, meeting discharge standards for fishery water bodies (Table 2) [12-14], [16].

Fig. 2Structure and morphology of Diamiks Aqua granules (schematic representation)

Table 1Comparative properties of filter media

Filter material | Sand-gravel filter | Carbon filter | Opoka-based filter | Diamiks aqua |

Mechanical strength: | ||||

Abrasion, % | ≤ 0.09 | 4-5 | 0.04-0.06 | ≤ 0.04 |

Crushing, % | ≤ 2.8 | 0.5-1 | 0.08-0.10 | ≤ 0.06 |

Comment | – | – | – | High strength of Diamiks Aqua |

Filtration efficiency (by contaminant-holding capacity for solids and suspended matter), g/m³ | 750-1400 | 750-2500 | 1800-2000 | 2000-2500 |

Comment | – | – | – | Diamiks Aqua provides the maximum contaminant-holding capacity |

Table 2Results of melt wastewater treatment using a column filled with Diamiks Aqua filter-sorbent material

Water quality parameter | Suspended solids, mg/dm³ | Petroleum products, mg/dm³ |

Initial melt wastewater | 138 | 3.9 |

After treatment with Diamiks Aqua diatomite | 1.4 | 0.04 |

Discharge requirements for fisheries water bodies (Russia) | 2 | 0.05 |

The superior performance of Diamiks Aqua is explained by its aluminosilicate structure that combines adsorption, ion exchange, and catalytic oxidation. During filtration, Fe2+ and Mn2+ ions oxidize to insoluble hydroxides according to:

These precipitates form active sites on the diatomite surface, enhancing the catalytic effect and ensuring long-term stability [13], [16].

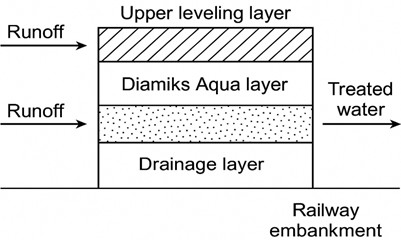

A three-layer filtration strip (Fig. 3) was developed for railway embankments to treat runoff in a passive, gravity-driven mode. The structure includes:

1) A lower drainage layer (gravel 2-10 mm, 150 mm).

2) A main filtration layer (Diamiks Aqua, 0.8-2 mm, 500 mm).

3) A top regulating layer with coarse gravel and vegetation to stabilize flow and prevent erosion [16], [17].

Fig. 3Schematic diagram of the three-layer filtration strip integrated into the railway embankment

This configuration ensures sequential removal of solids, hydrocarbons, and heavy metals without external power or reagents.

Field simulations show that treating 9,340.7 m3 of runoff per year prevents the release of ~18.7 kg of petroleum products and ~672.5 kg of suspended matter, avoiding environmental damage estimated at over 75 million RUB during the system’s lifetime [18], [19].

The technology provides high efficiency, long service life, and low maintenance – combining mechanical filtration and catalytic purification in one system.

Although filtration rate decreases at low temperatures (< 5 °C), this can be compensated by increasing the contact time or surface area. The system performs best for diffuse, low-flow runoff, while highly concentrated effluents may require pretreatment [17], [19]. Overall, the proposed design supports the sustainable and environmentally safe operation of railway transport enterprises.

4. Conclusions

The conducted studies confirmed the high efficiency of the natural diatomite-based sorbent Diamiks Aqua for the purification of railway wastewater containing petroleum hydrocarbons and suspended solids [12-14]. The developed three-layer filtration strip ensures stable operation and a long service life, combining mechanical filtration, sorption, and catalytic oxidation processes within a single structure [15].

Laboratory tests demonstrated 98.9 % removal of suspended solids and 99.0 % of petroleum products, exceeding environmental discharge standards for fishery water bodies [13], [14]. The system effectively replaces conventional filter media such as quartz sand and carbon sorbents, significantly reducing maintenance frequency and energy consumption [17].

Filtration performance slightly decreases below +5 °C due to increased water viscosity but can be restored by extending contact time, ensuring applicability under various climatic conditions [18].

The proposed eco-friendly, reagent-free, and energy-efficient filtration system provides reliable long-term protection of water bodies from hydrocarbon pollution and supports the sustainable operation of railway infrastructure [18], [19]. Comparative evaluation confirmed its superior performance over traditional sand, carbon, and opoka filters, making it suitable for large-scale implementation in railway drainage systems [19].

References

-

“Technical report on engineering and hydrometeorological surveys (Explanatory Note): Antipinsky refinery-2 start-up complex. Development of inland railway transport,” Development of Inland Railway Transport, UralGIPROTRANS, Yekaterinburg, 2012.

-

“SNiP 2.04.03-85 Sewerage: External Networks and Structures,” USSR State Construction Committee, Central Research and Production Center, Moscow, 1986.

-

M. I. Alekseev and A. M. Kurgaev, Organization of Drainage of Surface (Rain and Melt) Runoff from Urbanized Areas. Moscow; St. Petersburg: ASV Publishing; SPbGASU, 2000.

-

A. Gülay, K. Tatari, S. Musovic, R. V. Mateiu, H.-J. Albrechtsen, and B. F. Smets, “Internal porosity of mineral coating supports microbial activity in rapid sand filters for groundwater treatment,” Applied and Environmental Microbiology, Vol. 80, No. 22, pp. 7010–7020, Nov. 2014, https://doi.org/10.1128/aem.01959-14

-

V. L. Draginsky, “Methodological Recommendations for Ensuring Compliance with the Requirements of Sanitary Rules and Regulations SanPin 2.1.4.559-96,” Moscow, 2000.

-

Y. A. Ubaskina, I. V. Arsentyev, E. G. Fetyukhina, Y. A. Korosteleva, and T. V. Adaev, “Study of the mineralogical composition of diatomite for its safe extraction and use in industry,” Bulletin of the Belgorod State Technological University Named after V. G. Shukhov, No. 1, pp. 128–135, 2016.

-

Y. A. Ubaskina and Y. A. Korosteleva, “Adsorption of cations and anions of organic compounds on the surface of diatomite,” Bulletin of the Belgorod State Technological University Named after V. G. Shukhov, No. 10, pp. 172–178, 2016.

-

S. M. Salmin, Coagulation of Impurities of Natural Waters Using Coarse-Grained Contact Loading. Penza, 2015.

-

A. S. Kopylov, V. M. Lavygin, and V. F. Ochkov, Water Treatment in the Energy Sector. Moscow: MPEI Publishing, 2003.

-

O. R. Ilyasov, “Bioprotection of water sources in agricultural catchment areas from pollution by wastewater from poultry farms,” Ural State Agricultural Academy, Ekaterinburg, 2004.

-

O. R. Ilyasov, S. N. Koshelev, V. S. Khomyakova, and O. A. Sherstyuchenko, “Improvement of biotechnology for treating wastewater from livestock and poultry enterprises,” Glavnyj Zootekhnik, No. 9, pp. 13–19, 2020.

-

M. M. Talipov, O. T. Aliev, O. R. Ilyasov, and O. V. Kovaleva, “Modern method for purifying wastewater from railway embarking using diatomite in a filter band,” in ICTEA: International Conference on Thermal Engineering, 2024.

-

S. Sulaymanov, M. M. Talipov, R. S. Razikov, O. R. Ilyasov, and O. V. Kovaleva, “Protection of the environment from pollution by wastewater from railway transport using natural sorbents,” in ICTEA: International Conference on Thermal Engineering, 2024.

-

M. Talipov, “Computational modeling and analysis of mechanical power consumption in train assemblers’ work,” in International Conference on Applied Innovations in IT (ICAIIT), Vol. 13, No. 2, pp. 419–426, Jun. 2025, https://doi.org/10.25673/120513

-

O. T. Aliev, M. M. Talipov, K. M. Kamilov, and O. R. Ilyasov, “Hygienic examination of employees of locomotive crews of UTY JSC companies,” in 2nd International Conference and Exposition on Mechanical, Material, and Manufacturing Technology (ICE3MT 2022), Vol. 2943, No. 1, p. 040057, Jan. 2023, https://doi.org/10.1063/5.0134056

-

E. Shipacheva, S. Shaumarov, A. Gulamov, and M. M. Talipov, “Modeling of interaction of external enclosing structures of buildings with the internal and external environments,” in ICTEA: International Conference on Thermal Engineering, 2024.

-

E. Shipacheva, S. Shaumarov, A. Gulamov, M. M. Talipov, and S. Kandakharov, “Water structure and its influence on cement stone and concrete properties,” in ICTEA: International Conference on Thermal Engineering, 2024.

-

D. Radjibaev, G. Khromova, and U. Israilov, “Algorithm for the numerical studies on the model of contact temperature fields arising in a reinforcing steel plate welded to a modernized locomotive frame,” in 4th International Scientific Forum on Computer and Energy Sciences (WFCES II 2022), Vol. 2948, No. 1, p. 020023, Jan. 2023, https://doi.org/10.1063/5.0166220

-

S. Amirov, M. Yakubov, and U. Israilov, “Analysis and assessment of the insulation resource from the windings of a traction asynchronous electric motor of electric rolling stock,” in The 3rd International Scientific Conference Construction Mechanics, Hydraulics and Water Resources Engineering (CONMECHYDRO 2021 AS), Vol. 2612, p. 050036, Jan. 2023, https://doi.org/10.1063/5.0113022

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.