Abstract

This paper presents the results of a study on airborne dust pollution in the Kamchik Railway Tunnel caused by train movements. Field measurements were carried out to determine the concentrations of suspended particulate matter (PM10, PM2.5, PM1), as well as air temperature, pressure, and humidity in different sections of the tunnel – near the portals and in its central part. It was established that during train passages, the level of dust concentration increases by 6-10 times compared to background values, exceeding sanitary and hygienic standards. The main sources of dust generation were identified as frictional interactions between wheels and rails, braking processes, and the transportation of bulk materials. To reduce dust concentrations, engineering solutions are proposed, including the implementation of automatic water-based dust suppression systems, enhanced tunnel ventilation, and the use of hydrophobic surface coatings. The obtained results can be used to optimize ventilation modes and improve the operational safety of the Kamchik Railway Tunnel.

Highlights

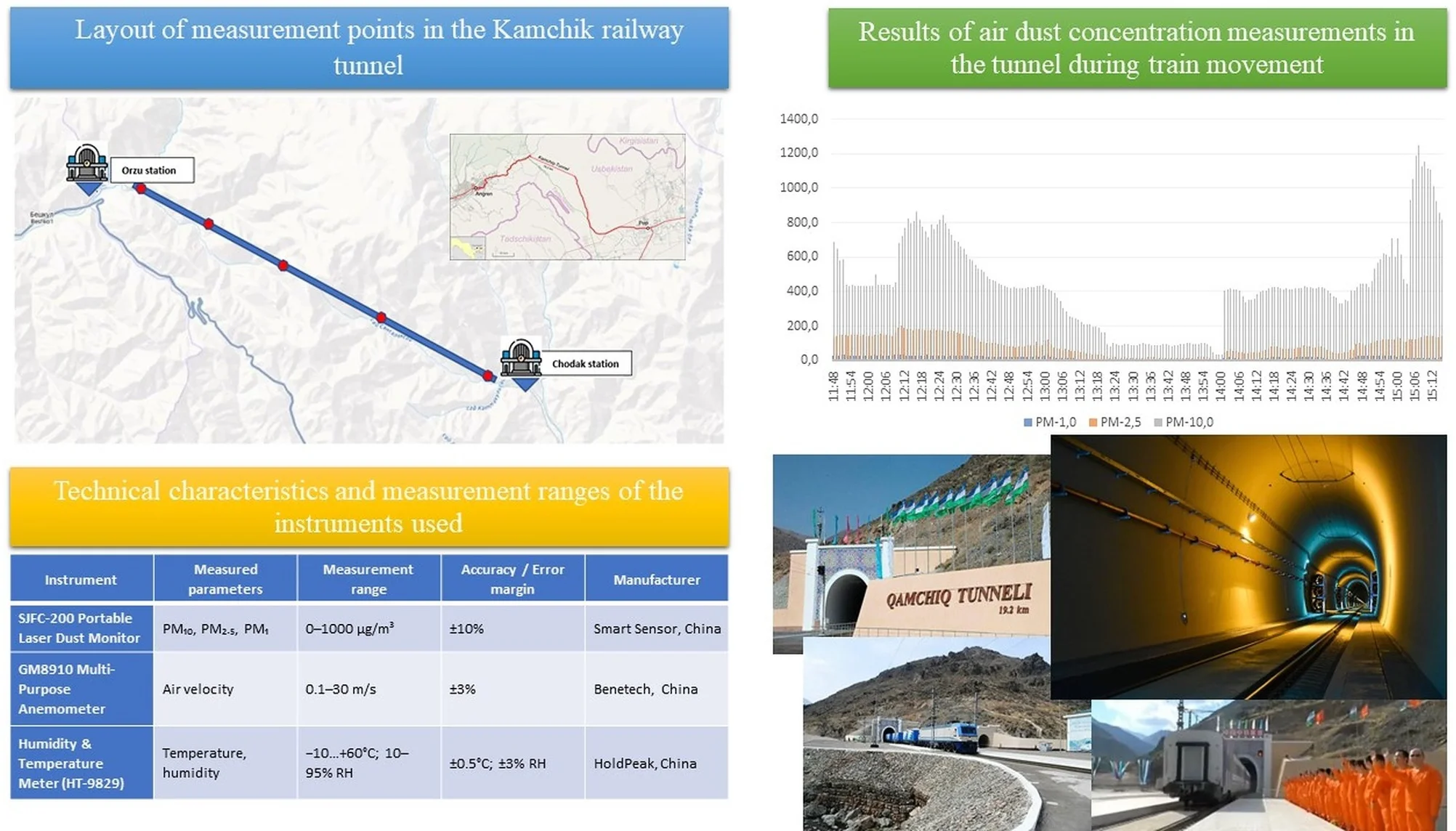

- Layout of measurement points in the Kamchik railway tunnel.

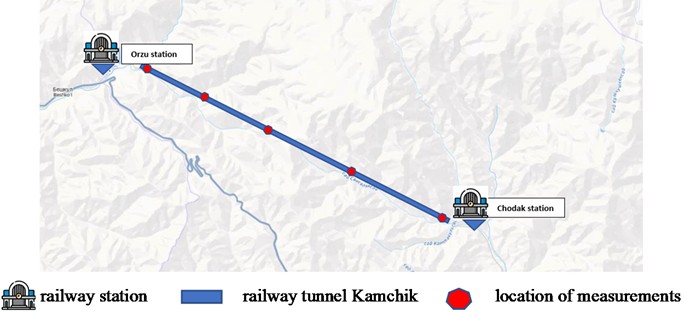

- Technical characteristics and measurement ranges of the instruments used.

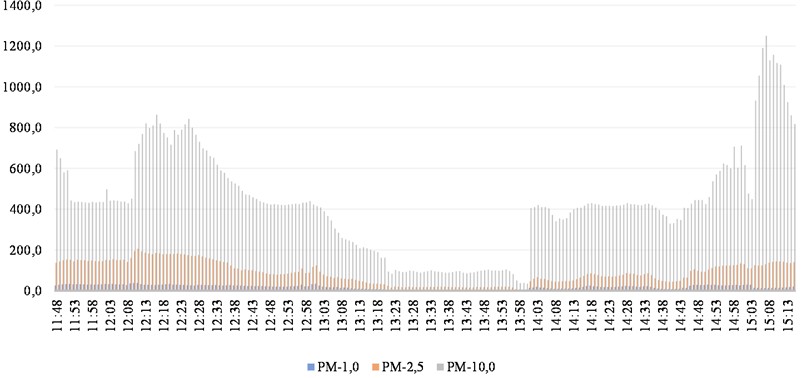

- Results of air dust concentration measurements in the tunnel during train movement.

1. Introduction

The Angren-Pap Tunnel, the largest railway tunnel in Central Asia, is a strategic infrastructure facility ensuring reliable year-round connectivity between the central regions of Uzbekistan and the Fergana Valley. This 19.2 km-long structure, comprising two parallel tunnels, solves one of the most critical transport challenges of the region. However, intensive freight operation of the tunnel has revealed a serious issue – increased dust pollution of the air environment within the tunnel space. The primary sources of dust are soil particles, wear products of brake pads, contact networks, and track elements. The piston effect generated by train movements not only complicates the operation of the ventilation system but also promotes the continuous resuspension of settled dust, forming a stable aerosol. This leads to a deterioration in operational conditions, elevated health risks for personnel, and increased frequency of equipment maintenance.

2. Literature review

The issue of dust suppression in transport tunnels has been widely studied in scientific literature. Olander et al. conducted a detailed chemical analysis and determined that the main components of railway dust are iron (from rail and wheel wear), carbon (from braking systems), and silicon (from ballast and transported materials), confirming the complex nature of dust formation in tunnels.

Recent studies demonstrate growing attention to the quality of air in railway tunnels and the influence of the microclimate on transport safety. Lee et al. (2023) analyzed the dynamics of PM2.5 and PM₁₀ particle distribution in Korean metro tunnels and showed that the geometry of portals and the shape of locomotives play a key role in dust concentration patterns [1]. Zhao et al. proposed a CFD model to predict the dispersion of dust particles at different train speeds, confirming the high efficiency of combined ventilation systems [2].

Nakamura et al. (2024) investigated the effectiveness of adaptive water-based dust suppression systems using ultrasonic nozzles and found that fine aerosol sprays (up to 50 µm) can reduce dust concentration by more than 70 % [3]. These findings highlight the need for an integrated approach combining airflow modeling, ventilation optimization, and modern dust control technologies.

Abramov V. V., using CFD modeling, demonstrated that PM10 and PM2.5 particles can be carried over long distances by air currents with minimal sedimentation, emphasizing the insufficiency of passive methods and the necessity for active intervention in dust formation processes [4, 11].

The study by Kim J. Y. showed the importance of proper ventilation design. The authors concluded that appropriately spaced transverse ventilation is the most effective for uniform particle removal, although it is characterized by high energy consumption [5].

In his monograph, Ivanov S. P. noted that for freight tunnels, standard ventilation systems often fail to handle peak dust loads, particularly under energy-saving conditions [6]. The author emphasized the need for localized dust suppression systems in areas with the highest dust generation.

A promising approach is the use of water mist systems. Wang H. investigated the efficiency of fine water sprays for suppressing coal dust and proved that small aerosol droplets (50-200 µm) are highly effective in coagulating and precipitating dust particles [7]. Ryzhkov A.D. demonstrated that the addition of surfactants to water reduces surface tension and significantly improves the wetting of hydrophobic particles – a principle that can be applied to dust originating from brake pad wear [8].

The technical feasibility of such an approach is confirmed by the patent of Petrov A. V., describing a nozzle-based system installed in the portal zone and activated by a train-approach sensor [9].

Abdullaev R. Ya. established a relationship between agrologistical processes and the environmental aspects of railway operations, showing how dust pollution in tunnel and near-portal zones affects the quality of transport and the preservation of agricultural cargoes [10].

Gustafsson et al. studied the friction and wear characteristics of railway brake block materials and identified key components of emitted particles formed during braking [12]. Olander et al. analyzed airborne particles in a railway tunnel, showing that dust consists mainly of metallic and mineral compounds produced by wheel-rail and brake interactions [13].

Shihnazarov et al. compared the technical and economic performance of wire and chain track systems used for strengthening loads in open railway traffic. Their findings underline the importance of selecting optimal structural and operational parameters to ensure stability and safety under dynamic load conditions – an approach that aligns with the present study’s focus on improving the operational environment and safety of railway tunnels [14].

The analysis reveals a lack of research focused on the comprehensive application of pre-spray dust suppression systems at tunnel portals specifically for railway freight transport. Therefore, the proposed solution – installation of a high-pressure water-spray system at the tunnel portal – represents a relevant and promising direction for further scientific investigation.

3. Methods

The study aimed to determine the parameters of the microclimate, aerodynamic characteristics of airflows, and the content of coal dust in various zones of the Kamchik railway tunnel. To achieve this, methods of instrumental monitoring, airflow modeling, and comparative analysis of the obtained data with industrial safety standards were used.

The research was conducted during 2023-2024 and included three main stages:

Preparatory stage – involved collecting baseline data on the geometric parameters of the tunnel, characteristics of locomotives and train compositions, as well as studying the existing ventilation system.

Experimental stage – included direct measurements of temperature, humidity, pressure, air velocity, and dust concentration at three control points: the entrance portal (at the entrance zone (300 m), near the entrance (4800 m), the middle section(at the tunnel midpoint (9600 m), and the exit portal(near the exit (12,900 m), and at the exit section (18,600 m) of the tunnel. A schematic diagram of the control point locations along the tunnel is presented in Fig. 1 to visualize the experimental setup.

Fig. 1Layout of measurement points in the Kamchik railway tunnel

Analytical stage – consisted of processing and interpreting the collected data, constructing graphs of parameter variations, and identifying distribution patterns.

To measure temperature and humidity, Humidity and Temperature Meters were used; for air velocity, Multi-Purpose Anemometer GM8910; and for determining suspended particulate concentrations (PM10 and PM2.5), a portable laser dust monitor SJFC-200 was employed. The measurement errors and ranges of the instruments used to record PM10 and PM2.5 parameters were determined according to the manufacturers’ specifications (Table 1).

Table 1Technical characteristics and measurement ranges of the instruments used

Instrument | Measured parameters | Measurement range | Accuracy / error margin | Manufacturer |

SJFC-200 portable laser dust monitor | PM10, PM2.5, PM1 | 0-1000 µg/m3 | ±10 % | Smart Sensor, China |

GM8910 multi-purpose anemometer | Air velocity | 0.1-30 m/s | ±3 % | Benetech, China |

Humidity and temperature meter (HT-9829) | Temperature, humidity | −10…+60 °C; 10-95 % RH | ±0.5 °C; ±3 % RH | HoldPeak, China |

The listed parameters correspond to the certified specifications of the instruments used in the field measurements.

The measurement procedure provided for real-time data recording under different operational conditions of the tunnel – both during train movement and in its absence. During field measurements in the Kamchik railway tunnel, the air dustiness parameters were analyzed before the train entered, during its passage, and after its exit. Measurements were carried out using portable aerosol analyzers that recorded concentrations of suspended particles (PM10, PM2.5, and PM1), airflow velocity, and dust retention time.

Before the train entered the tunnel, the average particle concentration was PM10: 28.4-400 μg/m3, PM2.5: 4.2-30 μg/m3, with an air velocity of 0.5-1.0 m/s. As the train began to move, a sharp increase in concentration was recorded: PM10 rose to 450-800 μg/m3, PM2.5 to 70-130 μg/m3, and PM1 to 10-23 μg/m3, while the airflow velocity increased to 6-8 m/s under the influence of the piston effect (see Fig. 1).

Fig. 2Results of air dust concentration measurements in the tunnel during train movement

After the passage of a train, a gradual decrease in dust concentration was observed. Within 5-7 minutes, the particle levels dropped by 40-50 %, and a complete return to background values occurred on average after 15-20 minutes, depending on the ventilation intensity and the direction of natural airflow. However, due to the considerable length of the tunnel, in its central section, suspended dust particles remained in the air for an extended period. This indicates insufficient efficiency of natural ventilation and highlights the necessity for additional ventilation units or dust collection systems.

Special attention was given to the analysis of dust load depending on the type of transported cargo. During the transportation of bulk materials (coal, cement, ore), PM10 concentrations reached 950-1100 µg/m3, which is 30-40 % higher than during the passage of container or passenger trains. At the same time, dust particles persisted in the air for up to 30 minutes after the train’s passage.

4. Results and discussion

After the passage of a train, a gradual decrease in dust particle concentration was observed. Within 5-7 minutes, the concentration values decreased by 40-50 %, while a complete restoration to background levels occurred on average within 15-20 minutes, depending on the intensity of ventilation and the direction of natural airflow. However, due to the considerable length of the tunnel, the central section exhibited prolonged retention of suspended dust particles, indicating insufficient natural ventilation efficiency and the need for additional ventilation devices or localized dust collection systems.

Particular attention was paid to analyzing dust load depending on the type of transported cargo. During the transportation of bulk materials (coal, cement, ore), the PM10 concentration reached 950-1100 µg/m3, exceeding the levels recorded for container or passenger trains by 30-40 %. Moreover, in these cases, dust particles remained suspended in the air for up to 30 minutes after train passage.

The obtained results confirm the necessity of local dust suppression systems and enhanced ventilation when operating heavy and dust-generating trains to maintain the required microclimatic conditions within the tunnel.

For the mathematical analysis, statistical data processing methods were used, including the calculation of mean values, variances, and correlation coefficients between temperature, airflow velocity, and suspended particle concentrations. The comparison with safety standards was based on the regulations of the Republic of Uzbekistan, SNiP 2.05.03-84, and international railway tunnel safety standards.

The ventilation regime was calculated using mass balance equations, taking into account the tunnel’s geometric parameters, cross-sectional area, and aerodynamic resistance. The research methodology also included an assessment of sanitary and hygienic working conditions for maintenance personnel, as well as an analysis of the existing microclimate monitoring systems. Surveys of duty personnel were conducted, and instances of exceeding permissible dust concentrations were recorded to evaluate the effectiveness of the mitigation measures [1–2].

The average air temperature in the tunnel ranged from +8…+10 °C near the portals to +22 °C in the central sections. In winter, the temperature difference between the external air and tunnel air reached 20-25 °C, which promoted natural airflow and active ventilation through the portals. In summer, the situation reversed: warm air masses entered the tunnel, increasing humidity and reducing the efficiency of natural ventilation. Thus, the seasonal circulation pattern is a key factor determining the microclimate and operational safety of train movements.

The average relative humidity ranged between 43-64 %, reaching maximum values in the central 5 km section. During peak periods, PM10 concentrations reached 300-400 µg/m3, which is 3-4 times higher than the sanitary limit. After a train’s passage, dust concentrations gradually returned to background levels within 15-18 minutes under natural ventilation, and within 3-8 minutes when mechanical ventilation was activated.

Aerodynamic calculations demonstrated that train motion generates a strong piston effect, increasing the air velocity in the tunnel up to 12-15 m/s. This contributes to the partial removal of exhaust gases; however, counterflow movements may cause stagnant zones, especially in the tunnel’s central part [7]. During periods of high traffic (2-3 trains per hour), periodic accumulation of CO₂ and water vapor was observed, indicating the need for real-time ventilation control.

The optimal air exchange was achieved at a total airflow rate of 75-85 m3/s. Reducing this rate to 50 m3/s resulted in relative humidity exceeding 90 %, leading to moisture condensation and reduced visibility.

Based on the obtained data, a set of engineering measures was proposed to improve the tunnel’s microclimate, including:

– Installation of a combined automatic ventilation system.

– Placement of humidity and CO concentration sensors along the tunnel.

– Implementation of fine water mist spraying systems in portal zones to suppress dust.

– Application of hydrophobic and anti-corrosion coatings on tunnel lining surfaces.

The highest levels of air pollution were recorded during winter, when low ambient temperatures coincided with high traffic intensity of diesel locomotives. In contrast, during summer, the strengthened ventilation caused by temperature inversion significantly reduced pollutant concentrations. These results confirm the necessity of adaptive ventilation control systems, taking into account seasonal factors and train flow intensity.

Overall, the conducted research provided a comprehensive assessment of microclimatic parameters and aerodynamic processes within the Kamchik Railway Tunnel. It was established that dust pollution is non-stationary and directly depends on train traffic intensity, type of transported cargo, track condition, and ventilation efficiency. Concentrations of PM10 and PM2.5 during freight train movements exceeded permissible limits by 6-10 times, posing potential risks to maintenance personnel and tunnel systems.

The main sources of dust formation were identified as frictional interactions between wheelsets and rails, braking system operations, and open bulk cargo transport. Settling dust reduces the efficiency of signaling, ventilation, and lighting systems, while also degrading visibility inside the tunnel. The accumulation of fine particles further increases health risks for workers and decreases equipment reliability.

5. Conclusions

The conducted research made it possible to identify the patterns of air dust concentration variation in the Kamchik railway tunnel during train movement and to determine the key directions for improving the efficiency of ventilation and dust suppression systems.

To ensure safe operating conditions and maintain standard microclimatic parameters, the implementation of a comprehensive set of engineering and technical measures is recommended:

1) Implementation of automated water-based dust suppression systems installed in the portal zones of the tunnel. The spraying of fine water mist at the moment a train enters the tunnel promotes the aggregation and deposition of dust particles, preventing their dispersion throughout the tunnel airspace.

2) Optimization of the ventilation regime by increasing the air exchange rate during periods of intensive freight traffic. At an airflow velocity of no less than 6-8 m/s, effective removal of polluted air is achieved, while maintaining relative humidity below 90 %, thereby preventing condensation and the formation of secondary dust.

3) Application of environmentally safe chemical additives (based on magnesium and calcium salts) to create a thin film on the track surface, reducing dust formation during train movement.

4) Regular maintenance of ventilation systems, including duct cleaning, wall washing, and wet cleaning of the tunnel, as well as continuous monitoring of harmful substances using automatic gas analyzers and dust meters.

5) The comprehensive implementation of these proposed measures – a combination of fine water mist dust suppression systems and adaptive ventilation control – will significantly reduce the concentration of suspended particles in the tunnel atmosphere, extend the service life of engineering structures, and ensure a high level of operational safety for train movements in the Kamchik railway tunnel.

References

-

J. H. Lee, D. S. Kim, and S. W. Choi, “Numerical analysis of particulate matter distribution in subway and railway tunnels under varying ventilation conditions,” Tunnelling and Underground Space Technology, Vol. 135, p. 105057, 2023.

-

Y. Zhao, X. Zhang, and Q. Li, “CFD simulation of air and dust flow behavior in long railway tunnels with high-speed trains,” Building and Environment, Vol. 223, p. 109486, 2022.

-

T. Nakamura, K. Ito, and H. Fujii, “Application of adaptive mist-spraying systems for dust reduction in underground transport tunnels,” Journal of Cleaner Production, Vol. 442, p. 140928, 2024.

-

V. V. Abramov and S. P. Ivanov, “Influence of piston effect on the distribution of aerosol particles in long railway tunnels,” (in Russian), Transport: Science, Technology, Management, No. 5, pp. 45–51, 2019.

-

J. Y. Kim and K. Y. Kim, “Effects of vent shaft location on the ventilation performance in a subway tunnel,” Journal of Wind Engineering and Industrial Aerodynamics, Vol. 95, No. 9-11, pp. 1025–1045, 2007.

-

S. P. Ivanov, Ventilation of Transport Tunnels. (in Russian), Moscow: Izdatel’stvo MGTU im. N. E. Baumana, 2018.

-

H. Wang, D. Wang, and C. Wang, “Experimental study on the suppression of coal dust explosion by water mist,” Journal of Hazardous Materials, Vol. 320, 2016.

-

A. D. Ryzhkov, “Effectiveness of wetting agents for dust suppression in mine workings,” Industrial Safety, Vol. 3, pp. 78–84, 2021.

-

A. V. Petrov, “Dust suppression installation in railway tunnels,” Russian Patent RU 123456, 2019.

-

R. Abdullayev and S. Abduvakhitov, “Fundamental and Applied Scientific Research in the Development of Agriculture in the Far East,” in BIO Web of Conferences, Vol. 173, p. 04009, 2024.

-

World Health Organization, “Air quality guidelines for particulate matter (PM2.5 and PM10): Global update 2021,” WHO, Geneva, 2021.

-

M. Gustafsson, L. Olander, and P. Jönsson, “Friction and wear behavior of railway brake block materials,” Wear, Vol. 394–395, pp. 240–247, 2018.

-

L. Olander, P. Jönsson, and M. Gustafsson, “Characterization of airborne particles in a railway tunnel,” Journal of Aerosol Science, Vol. 144, p. 105518, 2020.

-

J. A. Shihnazarov, D. S. Boboev, E. S. Shermatov, and R. S. Bozorov, “Comparison of technical and economic performance of wire and chain tracks used in strengthening loads in open traffic,” in The Third International Scientific Conference Construction Mechanics, Hydraulics and Water Resources Engineering (CONMECHYDRO 2021 AS), Vol. 2612, p. 060024, Jan. 2023, https://doi.org/10.1063/5.0130838

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.