Abstract

To enhance the performance of cement concrete pavements in saline soil areas, this study investigated the damage patterns of flexural and compressive strengths in pavement concrete internally cured with super absorbent polymer (SAP) under sulfate-dry-wet erosion cycles. The deterioration of chloride ion penetration resistance under different numbers of environmental erosion cycles was then examined. Furthermore, the characteristics of hydration products were analyzed based on infrared spectroscopy (FTIR) test, revealing the mechanism by which internal curing influences the performance of pavement concrete under environmental actions. The results indicate that after 90 cycles of sulfate-dry-wet erosion, the internal curing group exhibits higher flexural and compressive strengths than the control group, with maximum increases of 29.6 % and 12.8 %, respectively, while the chloride migration coefficient is reduced by 19.46 %. At the same SAP content, the specimens subjected to natural curing exhibits superior effectiveness compared to those with sealed curing using an anti-cracking coating. The incorporation of SAP is found to provide buffer space for the expansion of erosive products, thereby mitigating the extent of concrete damage during the middle and late stages of sulfate erosion.

Highlights

- The flexural and compressive strengths of SAP pavement concrete under sulfate-dry-wet erosion cycles were analyzed.

- The chloride penetration resistance SAP pavement concrete under different times of erosion cycles was researched.

- The influence mechanism of internal curing technology on pavement concrete performance under environmental action was revealed.

- The performance of SAP concrete cured by natural curing was better than that curing by anti-cracking agent.

1. Introduction

For cement concrete pavements located in saline soil areas of China, sulfate ions from the soil often migrate from the subgrade into the pavement through diffusion or capillary action. This leads to the formation of expansive products, and the erosion is accelerated under wet-dry cycles, resulting in durability issues such as spalling, disintegration, and cracking. Conventional curing methods often difficult to adequately saturate concrete interiors with water, leading to early-age cracking and incomplete hydration due to combined water evaporation and hydration water consumption the forming period, which accelerates pavement durability deterioration of pavements in saline soil regions.

As one of the internal curing materials for concrete, SAP can pre-absorb water during mixing and subsequently release it gradually when the environment humidity decreases, promoting further cement hydration and hardening. This process mitigates microcrack initiation and reduces inherent material defects [1]. Scholars generally concur that incorporating SAP can enhance the hydration degree of cement concrete, thereby improving its mechanical strength [2, 3]. However, the efficacy of SAP internal curing depends on multiple factors including SAP particle size, dosage, internal curing water content and water-to-binder ratio [4, 5]. Research indicates that the selection of SAP with appropriate particle size and content can promote internal hydration reactions in concrete, thereby optimizing its microstructure and enhancing its impermeability [6]. Furthermore, SAP refines the pore structure of concrete by reducing the volume of macropores and capillary pores, while significantly increasing the proportion of transition pores and gel pores. This modification enhances the material's capacity for “air-entraining frost resistance” [7]. However, the performance of SAP internally cured concrete under sulfate-dry-wet erosion environment has not yet been investigated, hindering its widespread application in pavement engineering in saline soil regions.

Thus, the degradation patterns of flexural strength, compressive strength and chloride penetration resistance in pavement concrete under sulfate-dry-wet erosion cycles were researched in this study. The influence mechanism of SAP on concrete durability was analyzed and elucidated through FTIR test.

2. Materials and methodology

2.1. Materials

Sodium polyacrylate-based SAP sourced from Shandong Huadi Co., Ltd was employed as the internal curing agent, which with a particle size of 100 mesh (150 μm). The absorption ratio in cement paste reached 24.8 at 30 minutes, after which it stabilized.

P.O 42.5 Ordinary Portland cement from Hailuo Cement Co., Ltd. was used, exhibiting a density of 3.15 g/cm3, a specific surface area of 358 m2/kg and a blaine fineness of 3900 cm2/g. The flexural strengths measured at day 3 s and day 28 were 5.6 MPa and 7.2 MPa, respectively.

Coarse aggregate with a nominal maximum size of 20 mm was used, consisting of granite. It was graded into two fractions of 5-10 mm and 10-20 mm, which were blended at a mass ratio of 3:7. Fine aggregate was selected as river sand, classified as Zone II medium sand, with a fineness modulus of 2.80.

A standard-grade polycarboxylate high performance water reducer (HPWR-Q8011) from Shaanxi Qinfen Co., Ltd.was utilized, which is a light yellow liquid with a water reduction rate of 26 %. Tap water from the municipal supply in Foshan was used as mixing water.

To mitigate drying shrinkage induced by internal moisture evaporation and thereby investigate the performance development of internally cured cement concrete under sealed conditions, a subset of test specimens in this study was subjected to sealed curing using a proprietary anti-cracking agent. The anti-cracking agent used was a pale yellow and odorless liquid, exhibiting a plastic shrinkage ratio of 50 % at 12 hours (as required by the standard to be ≤ 60 %) and a shrinkage ratio of 50 % at 28 days (as required by the standard to be ≤ 70 %).

2.2. Mix proportion

The compressive strength grade of pavement concrete was C30, with SAP contents of 0.125 %, 0.150 %, and 0.175 %. The mix proportions are presented in Table 1. Two curing methods were employed: natural curing at 20±2 °C and 80±5 % RH, and sealed curing, which involved the additional application of an anti-cracking agent under the same environmental conditions. SAP-0.150 % denotes the pavement concrete test group with a SAP content of 0.150 % by mass of cement; ACA-0.150 % represents the test group coated with a high performance anti-cracking agent and containing 0.150 % SAP.

Table 1Mix proportions of C30 pavement concrete/(kg/m3)

NO. | Internal curing water | SAP | The basic composition of the pavement concrete | |||||

Cement | Water | Sand | 5-10 mm coarse aggregate | 10-20 mm coarse aggregate | Water-reducer | |||

Control group | – | – | 360 | 144 | 756 | 349 | 814 | 4.32 |

SAP-0.125 % | 11.16 | 0.45 | ||||||

SAP-0.150 % | 13.39 | 0.54 | ||||||

SAP-0.175 % | 15.62 | 0.63 | ||||||

ACA-0.150 % | 13.39 | 0.54 | ||||||

2.3. Simulation scheme of sulfate-dry-wet erosion environment

The fully automatic concrete sulfate-dry-wet cycle testing machine from Tianjin Sansi Test Instrument Manufacturing Co., Ltd. was used to simulate the erosion environment. The concentration of sodium sulfate used in the test was 5 %. Each cycle lasted 24 hours, with the specific procedure as follows: (a) After drying, specimens were immersed in the sodium sulfate solution for 15 hours at a solution temperature of 25~30 °C; (b) Air-dried for 1 hour; (c) Oven-dried for 6 hours at a temperature of (80±5) °C; air-dried for 1 hour; cooled for 1 hour. The macroscopic and microscopic properties of the specimens were tested and analyzed after every 30 cycles. There are four time points in total: 0, 30, 60, and 90 cycles. The specimen dimension was 100 mm×100 mm×400 mm.

2.4. Mechanical and durability test methods

In accordance with the “Testing Methods of Cement and Concrete for Highway Engineering” [8], tests for flexural strength and compressive strength were conducted on cement concrete specimens that had reached the 28 d curing age and designated testing intervals.

Based on the “Standard for test methods of long-term performance and durability of ordinary concrete” [9], the chloride ion penetration resistance of concrete at various testing intervals was evaluated, and the evaluation index was the chloride migration coefficient ().

2.5. FTIR

The evolution laws of functional groups of cement concrete under erosion environment were investigated via FTIR Spectrometer. Based on the changes in the vibration peaks of functional groups obtained from testing, the microstructural performance state of cement concrete could be evaluated.

3. Results and discussion

3.1. Flexural strength and compressive strength

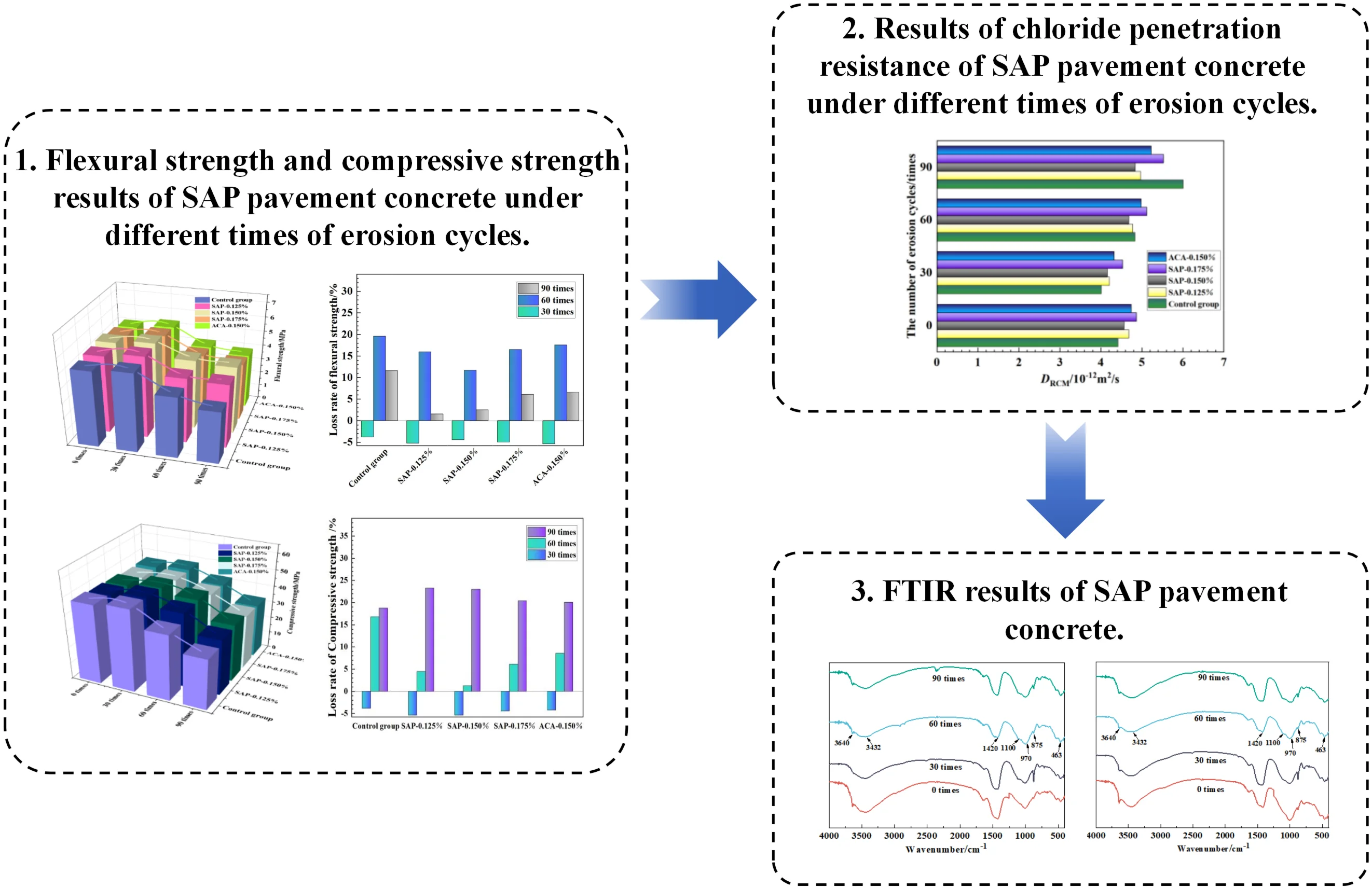

The flexural strength and its loss rate of specimens subjected to 0~90 erosion cycles were measured and calculated, with the results shown in Fig. 1.

Fig. 1Results of flexural strength and loss rate under 0~90 erosion cycles

a) Flexural strength

b) Loss rate of flexural strength

As shown in Fig. 1(a), the flexural strengths of SAP-0.125 % and SAP-0.150 % groups consistently higher than those of control group during all stages. After 30 cycles, flexural strength of all test groups shows initial enhancement, followed by a consistent declining trend in subsequent cycles. For SAP-0.175 %, although its flexural strength is lower than that of the control group at 0 and 30 cycles, it exceeded the latter during the 60~90 cycle period. As for ACA-0.150 %, its flexural strength within 0~60 cycles was lower than that of the control group, but after 90 cycles, its strength surpassed the latter.

The analysis indicates that as the number of cycles increases, the advantage of internal curing with SAP becomes progressively more evident in the SAP-0.175 % and ACA-0.150 % experimental groups. Meanwhile, as shown in Fig. 1(b), the control group exhibited the highest rate of flexural strength loss during the final 30 cycles. After 90 cycles, the flexural strengths of the SAP-0.125 %, SAP-0.150 %, SAP-0.175 %, and ACA-0.150 % groups are 1.23, 1.30, 1.11, and 1.05 times that of the control group, respectively, demonstrating that internal curing with SAP mitigates the degradation of flexural performance in pavement concrete under sulfate-wet-dry environment. Among these, the SAP-0.150 % group showed the most pronounced curing effect, followed by SAP-0.125 %. During concrete mixing, SAP absorbs water. When the internal humidity of concrete decreases, the SAP gel gradually releases its stored moisture, sufficiently moistening the internal materials. This process enhances cement hydration, suppresses the initiation of microcracks within the structure, and improves the bonding between cement paste and aggregate. Consequently, the flexural strength of pavement concrete is improved.

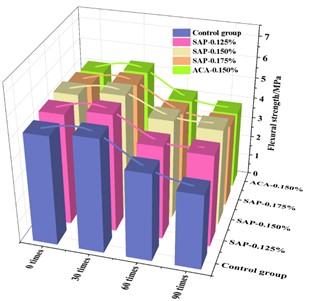

The compressive strength results and corresponding loss rates are presented (Fig. 2).

Fig. 2Results of compressive strength and loss rate under 0~90 erosion cycles

a) Compressive strength

b) Loss rate of compressive strength

As shown in Fig.2.a), the compressive strengths of SAP-0.125 %, SAP-0.150 %, SAP-0.175 % and ACA-0.150 % are all lower than that of the control group before the test, with reductions ranging from 2 % to 7 %. During the initial erosion stage (0~30 cycles), the strength of all groups increased. However, in the middle to late stages of erosion (30~90 cycles), the strength of each group shows a declining trend. Combined with Fig. 2(b), control group exhibits the highest compressive strength loss rate, indicating the most pronounced decline in erosion resistance. After 90 cycles, the strengths of SAP-0.125 %, SAP-0.150 %, SAP-0.175 %, and ACA-0.150 % increased by 5.8 %, 8.0 %, 3.8 %, and 2.5 %, respectively, compared to the control group. It can be concluded that under natural curing conditions, concrete with a 0.150 % SAP content demonstrates relatively optimal erosion resistance.

The specimen mass increased during the initial stage of erosion, which is attributed to the filling effect of reaction products formed during sulfate-dry-wet cycling. These products densified the concrete matrix, thereby enhancing the compressive strength. In the middle-to-late erosion stages, the decline in strength likely resulted from continued expansion of erosion products, causing microstructural damage. The residual pores after SAP water release provide buffer space for expansive products. The pores remaining after water release from SAP can provide buffer space for expansive products. At a 0.125 % dosage, the number of SAP is lower than at 0.150 %, resulting in fewer pores after water release and thus less buffer space compared to the latter. At the high dosage of 0.175 %, on one hand, the compressive strength of the specimen is significantly affected before testing; on the other hand, during the erosion process, more pores in the concrete become filled with erosion products, leading to more severe expansion damage. In contrast, a 0.150 % SAP dosage achieves a better balance between buffer space and the amount of expansive products.

Besides, it is considered that in the case of ACA-0.150 %, the sealing and water-retaining effect of the sealed anti-cracking agent impedes the adequate release of internal curing water stored in SAP during the early stage. Consequently, the early-stage pore size of ACA-0.150 % group is significantly larger than that of SAP-0.150 %.

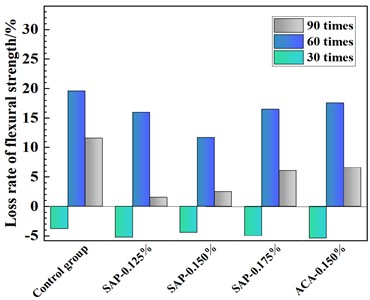

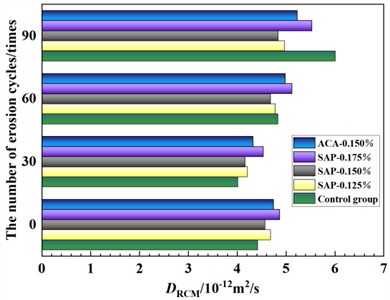

3.2. Chloride penetration resistance

As shown in Fig. 3, control group exhibited the optimal resistance to chloride ion penetration at 30 cycles. During 60~90 cycles, the initially decreased and then increased with rising SAP content. The values for SAP-0.125 % and SAP-0.150 % were both lower than those of the control group at 60 cycles. After 90 cycles, the chloride migration coefficient of the control group was the highest among all groups, indicating a significant deterioration in its chloride penetration resistance after erosion. The chloride migration coefficients of SAP-0.125 %, SAP-0.150 %, and SAP-0.175 % were 82.70 %, 80.53 %, and 92.01 % of that of the control group, respectively, with SAP-0.150 % showing the most pronounced improvement.

Fig. 3Results of DRCM under 0~90 erosion cycles

In the middle to late stages of cycling, the chloride penetration resistance of internally cured concrete gradually became more advantageous. This is attributed, on one hand, to the mitigation of expansion damage from products by the residual pores after SAP water release, and on the other hand, to the adsorption of salt solution by SAP, which hinders further penetration of chloride ions. However, higher SAP content does not invariably yield better results.

Regarding the influence of curing conditions on the chloride penetration resistance of concrete, it can be observed from Fig. 3. that the DRCM values of ACA-0.150 % were consistently higher than those of SAP-0.150 %, indicating that natural curing provides superior resistance to chloride ion penetration compared to sealed curing.

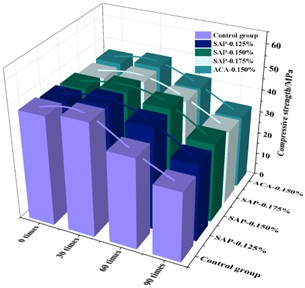

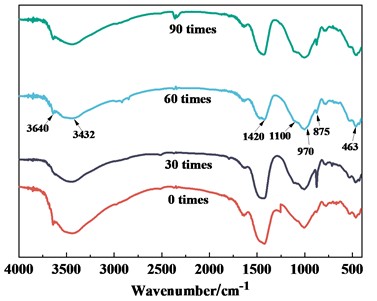

3.3. FTIR

FTIR analysis was performed on the control group and tSAP-0.150 % (superior performance in macroscopic tests) at different erosion stages, the spectra are shown in Fig. 4.

As shown in Fig. 4(a), the CH absorption peak (around 3640 cm-1) of the control group decreases significantly after 30 cycles compared to the initial state (0 cycles), and subsequently this peak nearly disappears, which is attributed to the consumption of CH during sulfate attack. Meanwhile, the [C-O] peak at 875 cm-1 intensifies (indicating an increase in calcium carbonate), with a more pronounced enhancement observed in the control group. After 90 cycles, comparison of the results between control group and SAP-0.150 %, it can be found that the [SO4] absorption peak (representing AFt, thenardite, etc.) at 1100 cm-1 is larger in the control group than in the internal curing group. This indicates that the internal curing technology using SAP could suppress the increase of harmful products such as AFt, alleviate the expansion stress caused by their swelling, reduce the durability damage from sulfate attack, and thereby improve the macroscopic performance of SAP internal curing pavement concrete.

Fig. 4FTIR spectra of the control group and SAP-0.150 % under different cycles

a) Control group

b) SAP-0.150 %

4. Conclusions

The mechanical properties of the pavement concrete exhibited an initial increase (0~30 cycles) followed by a subsequent decrease (30~90 cycles) with the increasing number of sulfate-wet-dry cycles. After 90 cycles, the mechanical properties of internal curing groups are superior to those of the control group.

As the dosage of SAP increases, the chloride ion penetration resistance of concrete first improves and then declines. After 90 cycles, the for SAP-0.150 % is only 80.53 % of that of the control group. Under identical SAP content, natural curing demonstrates superior effectiveness compared to sealed curing with anti-cracking agent coating.

After 90 cycles, the control group exhibits a larger [SO4] absorption peak at 1100 cm-1 compared to the internal curing groups, indicating that SAP could effectively inhibit the formation of harmful products such as AFt and reduce durability damage to concrete caused by sulfate erosion.

References

-

A. Shen et al., “Review on cement concrete internally cured by SAP,” (in Chinese), Journal of Traffic and Transportation Engineering, Vol. 21, No. 4, pp. 1–31, 2021, https://doi.org/10.19818/j.cnki.1671-1637.2021.04.001

-

L. Senff, R. C. E. Modolo, G. Ascensão, D. Hotza, V. M. Ferreira, and J. A. Labrincha, “Development of mortars containing superabsorbent polymer,” Construction and Building Materials, Vol. 95, pp. 575–584, Oct. 2015, https://doi.org/10.1016/j.conbuildmat.2015.07.173

-

O. M. Jensen and P. Lura, “Techniques and materials for internal water curing of concrete,” Materials and Structures, Vol. 39, No. 9, pp. 817–825, Jul. 2006, https://doi.org/10.1617/s11527-006-9136-6

-

A. J. Klemm and K. S. Sikora, “The effect of Superabsorbent Polymers (SAP) on microstructure and mechanical properties of fly ash cementitious mortars,” Construction and Building Materials, Vol. 49, pp. 134–143, Dec. 2013, https://doi.org/10.1016/j.conbuildmat.2013.07.039

-

V. Mechtcherine et al., “Effect of internal curing by using superabsorbent polymers (SAP) on autogenous shrinkage and other properties of a high-performance fine-grained concrete: results of a RILEM round-robin test,” Materials and Structures, Vol. 47, No. 3, pp. 541–562, Jun. 2013, https://doi.org/10.1617/s11527-013-0078-5

-

Z. Yin et al., “Research on impermeability and mechanism of SAP internal curing pavement concrete,” (in Chinese), Highway Engineering, Vol. 49, No. 2, pp. 131–137, 2024, https://doi.org/10.19782/j.cnki.1674-0610.2024.02.019.(in

-

X. Qin et al., “Salt frost resistance and fatigue characteristics of self-curing pavement concrete,” (in Chinese), Bulletin of the Chinese Ceramic Society, Vol. 40, No. 8, pp. 2784–2793, 2021, https://doi.org/10.16552/j.cnki.issn1001-1625.20210517.007

-

“Testing methods of cement and concrete for highway engineering,” JTG 3420-2020, 2020.

-

“Standard for test methods of long-term performance and durability of ordinary concrete,” GB/T 50082-2009, 2009.

About this article

This study was financially supported by the Natural Science Foundation of Guangdong Province (grant No. 2024A1515030113), Teaching Quality and Reform Project for Undergraduate Institutions of Guangdong Province (grant No. 2025ZDZX4057) and 2025 Key Areas Program Serving the Hundreds, Thousands and Tens of Thousands Project for Regular Universities of Guangdong Province (grant No. 57).

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.