Abstract

In this paper, a detailed analysis was carried out of the methods that have been developed by various countries and organizations to calculate the losses of oil and petroleum products from tanks caused by natural factors. In the course of the study, legislative and regulatory documents regulating emissions into the atmosphere in various countries of the world were considered. Both positive and negative sides of the methods under consideration were identified, and based on the results obtained, a new and more improved method of automatic accounting of hydrocarbon vapors from tanks was proposed, the effectiveness and operability of the proposed method was proved. The study also formulated recommendations for future research in this direction, which may be useful for further improvement of methods for automatic calculation of losses of oil and petroleum products in various conditions.

Highlights

- Enterprises are interested in reducing losses from evaporation in order not to incur economic losses, in turn, the state is dealing with this problem from the environmental side, where regulation is already taking place at the legislative level. In this case, enterprises are placed in a framework in which they are forced to control emissions at a certain level.

- Summing up the results of the analysis, it can be concluded that the existence of methods for accounting for losses of oil and petroleum products from the tank as a result of evaporation / emissions into the atmosphere is conditioned by domestic legislation and international agreements.

- At the moment, there is no single unified methodology on which the enterprises of the oil refining complex, environmentalists and the state could rely.

- To further improve the methodology, it is necessary to solve the following tasks: 1. To refine the existing mathematical model obtained in the previous paper; 2. Conduct tests using the Ansys software package and compare it with laboratory tests on the installation; 3. Compare the data obtained with the existing methods for accounting for the evaporation of oil and petroleum products from tanks.

1. Introduction

Since the middle of the XX century, with the growth of oil production, the number of oil depots and oil storage facilities for transshipment and storage of oil and petroleum products began to grow, and, as a result, the losses of hydrocarbons associated with their storage in the tank, pumping increased/pumping and transshipment. There was a need for a theoretical description of the processes leading to hydrocarbon losses, as well as subsequent calculations and the development of tools and methods to reduce hydrocarbon losses.

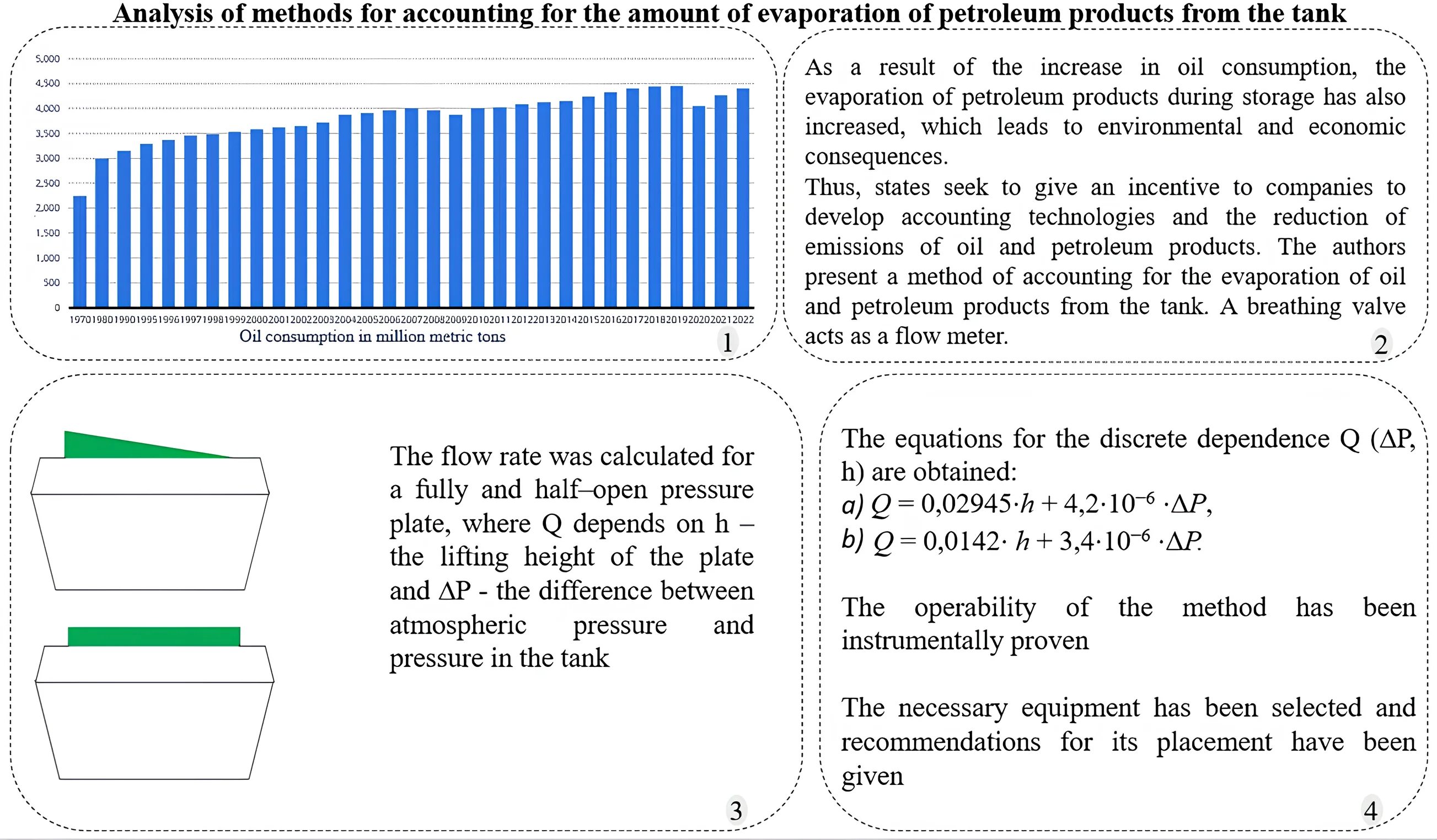

According to the statistical resource [1], energy consumption by the world community increased 1.5 times from 2000 to 2021 (from 400 EJ to 600 EJ), while, in recent years, the volume of oil and petroleum products amounted to approximately 30 %. At the same time, the volume of emissions increased in proportion to energy consumption, by 1.5 times (from 25 to 37 billion tons).

According to forecasts [1], the demand for electricity will increase, despite the fact that the share of oil and petroleum products will decrease, nevertheless, the volume of consumption will grow, which means that the problems associated with the loss of oil from tanks as a result of evaporation will be relevant in the near future.

The purpose of this work is to analyse the legislative framework and methods for accounting for hydrocarbon evaporation from the tank, to identify their advantages and disadvantages, which will further help in the development of their own methodology and methodology.

Evaporation from the tank has two problems: economic and environmental. An urgent problem of humanity is global climate change, one of the causes of which are greenhouse gases. Thus, methane, which is part of oil and petroleum products and is released during evaporation from storage tanks, is part of greenhouse gases.

Enterprises are interested in reducing losses from evaporation in order not to incur economic losses, in turn, the state is dealing with this problem from the environmental side, where regulation is already taking place at the legislative level. In this case, enterprises are placed in a framework in which they are forced to control emissions at a certain level.

2. Theoretical description

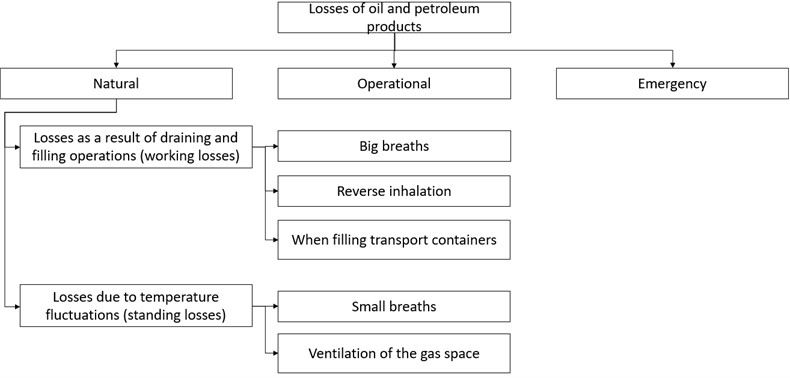

Conventionally, losses of oil and petroleum products are divided into three categories: natural, operational and emergency [2].

Natural losses (losses from evaporation), arise as a result of meteorological factors, due to the imperfection of existing means of reducing losses from evaporation or are a consequence of the physicochemical properties of petroleum products.

Operational losses are associated with imperfect technological operations (mixing /incomplete discharge from tanks/overflow) or are associated with the use of outdated equipment (leakage/filling/leaks/poor sealing of tanks and equipment). This type of loss, unlike natural losses, can be eliminated by maintaining the equipment in good condition.

Emergency losses occur as a result of the filling of oil or petroleum products from a pipeline or tank in emergency situations.

In this paper, natural losses will be considered in detail. Natural losses, according to API [3], in turn, are divided into two groups (“working” and “standing”), and, according to Russian sources [4, 5] into 5 groups:

1. Losses from “big breaths” – arise as a result of filling the tank, which leads to saturation of the gas space (GS) with oil or petroleum product vapors and their subsequent displacement.

2. Losses from “small breaths” – are the result of an increase and decrease in pressure in the GS tank due to daily temperature fluctuations.

3. Losses from “reverse inhalation” – arise as a result of the saturation of the vapor-air mixture in the GS tank after pumping oil or petroleum products.

4. Losses from the “ventilation” of the GS – losses from leakage of the GS.

5. Losses during filling of transport containers – arise as a result of leakage of systems involved in draining and filling operations.

All of the above groups can be summarized in the following scheme to simplify perception (Fig. 1).

Fig. 1Types of hydrocarbon losses from the tank as a result of evaporation

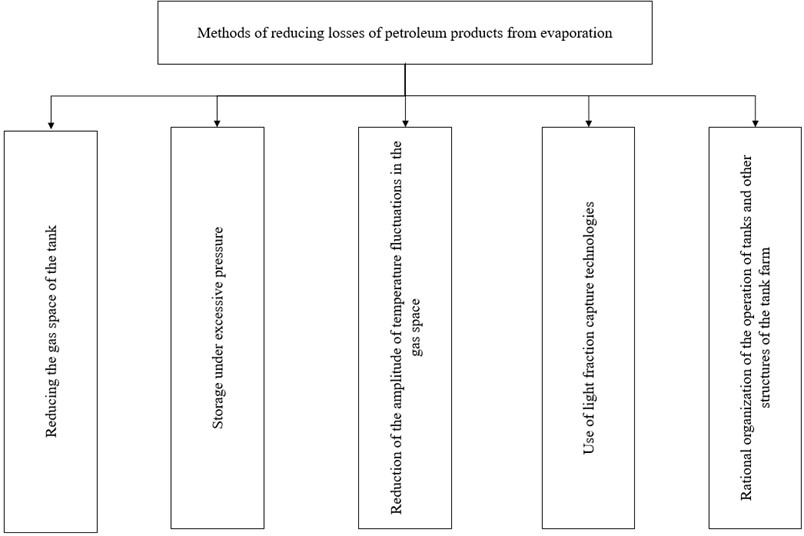

The development of methods to reduce the loss of oil and petroleum products during storage has been carried out since the 60s of the XX century. There are several types of loss reduction, which are selected depending on various factors: from the purpose of the oil product, storage conditions and terms, to the meteorological conditions of the storage area. The methodology of choosing the most appropriate means of reducing oil product losses as a result of evaporation is considered in [6].

According to general classifications, the main methods for reducing losses of petroleum products from evaporation are five groups presented (Fig. 2). Thus, according to the calculations of a number of authors, it was found that “a tank with a floating roof and a pontoon are most effective when the annual turnover coefficient of the tank is more than 12” [7].

Fig. 2Methods for reducing losses of petroleum products from evaporation

3. Analysis of accounting methods

In order to evaluate the effectiveness of methods to reduce the loss of oil and petroleum products from evaporation, as well as to keep the most accurate records of stored hydrocarbons and assess the impact of the oil sector on the environment, many scientists from different countries have developed and continue to develop methods for calculating the loss of hydrocarbons from tanks as a result of evaporation.

Scientists F. F. Abuzova, N. I. Belokon, V. B. Galeev, N. N. Konstantinov, A. A. Korshak, R. E. Levitin, V. I. Chernikin made the main contribution to the development of this direction, namely, to the development of a theoretical framework that allows describing the process of evaporation of hydrocarbons, as well as the development of methods for their accounting, V. F. Novoselov, S. A. Korshak, J. R. Beckman and others, as well as organizations of the American Petroleum Institute API, the Ministry of Energy of the Russian Federation, the Federal State Budgetary Educational Institution UGNTU and others [3, 8, 9].

The comparative analysis carried out in articles [10-14] demonstrates that despite the fact that all methods, both Russian and foreign, interpret the process of evaporation of hydrocarbons from a tank with a stationary roof in the same way, there are slight differences in the approaches in the initial data, their quantity, degree and detail of study.

Compared with foreign methods, Russian methods are overloaded with input data, contain a large number of formulas, not all of which are easily applicable in production conditions. In Germany, in turn, a technique is used where only three formulas are used, where most of the data is proposed to be taken from one table [8]. If for Germany, as for European countries, this algorithm is possible, then for Russia this approach of determining the initial data is not applicable, since this territory is long and passes through several climatic zones.

Speaking about the American methodology [3], it is the most optimal of all presented and the most applicable in practice. The only disadvantages of this technique are that the coefficients used in the methodology were calculated for American climatic zones, as well as all calculations are not made in the SI system, which makes it difficult to use it everywhere.

One common disadvantage of all methods is that they cannot be universal, that is, they can be applied in different countries, to different types of tank, and sometimes even to different types of losses (applicable only to losses from small or only from large “breaths”). Also, many techniques involve taking samples and obtaining the necessary values in the laboratory for further calculations, which prevents this process from being automated.

A review of programs and documentation related to environmental protection shows that the world community in this regard has a common goal – to reduce anthropogenic impact. Thus, the most significant documents in relation to the protection of the atmosphere are:

– Vienna Convention for the Protection of the Ozone Layer (1985).

– United Nations Framework Convention on Climate Change (1992).

– Kyoto Protocol to the United Nations Framework Convention on Climate Change (1997).

– Paris Agreement (2016).

All of the above agreements regulate the level of greenhouse gas emissions by countries and enterprises in order to stabilize and further reduce the anthropogenic impact on the environment. Today, countries are striving for a carbon-free economy or zero emissions (Net Zero Emissions). Not only the states, but also many large international and domestic oil and gas companies (BP, Total, Shell, Equinor, ENI, Repsol, Gazprom, etc.) have begun to set targets to reduce emissions, including to zero [15].

The situation in Russia is somewhat different from the global one, since at this stage climate change still has a low priority, both for business and for the population, which hinders the development of decarbonisation of the oil and gas sector in comparison with the best world practices.

The legislation of the Russian Federation in the field of climate issues is in the initial stage, and decarbonisation, at this stage, is not a priority of important tasks. The creation of a legislative and regulatory framework in the Russian Federation has only recently begun. So, on June 23, 2021, Federal Law No. 296-FL was adopted and approved, which spelled out the basic concepts and goals for accounting and limiting greenhouse gas emissions. Another key step of the Russian Federation towards carbon neutrality is Federal Law No. 34-FL, the purpose of which is to conduct an experiment in the Sakhalin Region and other subjects of the Russian Federation included in the list – to achieve carbon neutrality by 2025.

Regarding the oil and gas sector, the main regulatory parameter for limiting emissions is reducing the burning of associated petroleum gas and regulating methane emissions. However, Russia's leading oil and gas companies, following the example of foreign companies, have begun to develop and implement regulatory documents and technologies to reduce and account for greenhouse gas emissions [15].

As noted above, for Western countries, as for the countries of the center, environmental protection is one of the priorities. All developed Western countries are part of the IEA, where you can get acquainted with the roadmap describing their strategy to achieve zero emissions by 2050 [16].

In Europe, Germany has been and remains one of the most active countries in environmental protection. The basis of German environmental legislation is formed by the Federal Law on Protection against Emissions from 1974, which was based on the “Clean Air Act”, developed in the USA in 1970. Within the framework of the presented work, technical manuals and documentation on keeping the air clean are more interesting. In this paper, the legislative and regulatory act VDI 3479 was considered [8].

In turn, in the United States, the first and main environmental law was the “Clean Air Act”, which regulated emissions from stationary and mobile sources. A little later, the Environmental Protection Agency (EPA) was formed. The most significant regulatory documents for the work are the methods developed by the American Petroleum Institute (API), which were presented in EPA AP42 as methods for accounting for oil and petroleum products vapors from tanks with a pontoon API MPMS 19-1 and API MPMS 19-2 [3].

Summing up the results of the analysis, it can be concluded that the existence of methods for accounting for losses of oil and petroleum products from the tank as a result of evaporation / emissions into the atmosphere is conditioned by domestic legislation and international agreements. Thus, the methods used in Germany and the USA are part of the legislative and regulatory part of their countries and contain officially recognized calculation methods [14]. The situation in Russia is different. There are various methods for determining emissions used by environmentalists in assessing the impact of harmful substances on the surrounding atmosphere, as well as methods proposed by scientists at different times, which are overloaded with an excessive amount of data, and most importantly do not have the status of official regulatory documents. At the moment, there is no single unified methodology on which the enterprises of the oil refining complex, environmentalists and the state could rely.

4. The method being developed

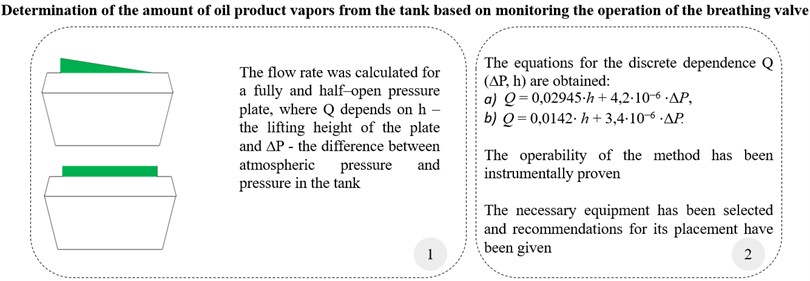

As noted earlier, one of the priority tasks of this study is to improve the existing methods of automatic accounting for the evaporation of hydrocarbons from the tank. In a previously performed work [17], where the authors obtained 2 equations using the ANSYS software package describing the relationship between the flow rate of the gas-air mixture exiting through the breathing valve as a result of evaporation, pressure and the degree of opening of the pressure plate where is the overpressure, is the opening height of the pressure plate. In the course of the work, two variations of opening the pressure plate by half and completely were considered, which is demonstrated in (Fig. 3), where the main conclusions obtained during the work are also recorded [17].

Fig. 3The main stages and results of the work done earlier

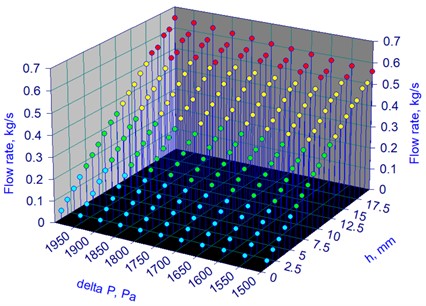

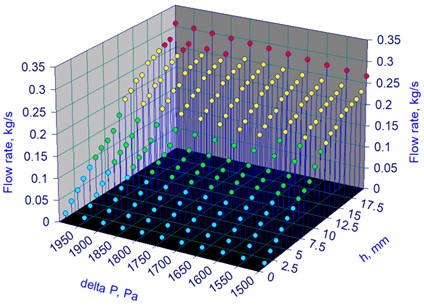

So, during a series of experiments with changing the position of the pressure plate and the overpressure inside the tank, a dependence of the form was obtained, which is presented graphically for easier perception (Fig. 4), which as a result of the analysis was described by the equations for a fully open pressure plate and half (Fig. 3).

A methodology was also proposed for accounting for losses resulting from the release of the gas-air mixture through the breathing valve; it was instrumentally proved that this method is workable by conducting an experiment.

To implement the proposed technique, it is necessary to install an overpressure sensor, a concentration sensor and an accelerometer, the brands of equipment and their location are considered in [17] and the main idea is as follows. When the overpressure in the tank reaches the lower limit of the operating range of the breathing valve, namely, at the moment of opening the pressure plate, the recording of sensor readings begins every second: concentration, position of the plate and overpressure.

So, with the help of these data, we will be able to calculate the losses from the evaporation of light fractions of hydrocarbon through the breathing valve:

where – the total mass flow rate of the gas-air mixture through the breathing valve, kg/s; – the mass flow rate of the gas-air mixture in the -th second, calculated by the formula , kg/s.

Where the mass of LFH is calculated by the formula:

where – the mass of the gas-air mixture in the -th second, kg; – 1 second, s; – the concentration of light fraction of hydrocarbons in the -th second coming out of the breathing valve, measured using an optical gas analyzer, %.

Accordingly, the total losses for the entire period of opening the pressure cap will be calculated according to the formula:

Fig. 4The graphical representation of the distribution of the dependence Q∆P,h is obtained

a) Fully open

b) Half open

5. Conclusions

Therefore, in Russia there is a need to improve the methods for accounting for the evaporation of oil and petroleum products from the tank and to create a state document regulating the use of a unified methodology for accounting for losses from evaporation, as in Western countries.

Thus one can observe the main results obtained during the execution of the work [17]. In the first paragraph, a model of a breathing valve is demonstrated, with the help of which experiments were carried out. In the second paragraph, the course of the experiment is described directly, and its results in the form of graphs are presented in paragraph three (for a fully open pressure plate and half). The final fourth paragraph demonstrates the main results of the work.

To further improve the methodology, it is necessary to solve the following tasks:

1) To refine the existing mathematical model obtained in [17].

2) Conduct tests using the Ansys software package and compare it with laboratory tests on the installation.

3) Compare the data obtained with the existing methods for accounting for the evaporation of oil and petroleum products from tanks.

The laboratory installation will be a reduced model of the tank, namely: a 160-liter barrel (tank), a breathing valve (SMDK-50), a temperature sensor, a pressure sensor, a concentration measurement sensor (gas analyser), an accelerometer to measure the movements of the pressure cap of the breathing valve and a scale to register accurate mass losses from the tank.

In the event of “standing losses” or imitation of “working losses” (discharge of petroleum products from the installation), evaporation losses will occur, which will be recorded using the above proposed devices. When the threshold pressure is reached, for example, with “standing losses”, the breathing valve will work, that is, the pressure cap will rise to relieve excess pressure inside the tank. At this moment, with the help of the accelerometer, the degree of opening of the pressure plate will be recorded every second. At the same time, the values of excess pressure and the concentration of the escaping vapor-air mass will be recorded. The data obtained will allow us to calculate the consumption in the future, and then the mass of the evaporated oil product. The resulting value can be compared with the reference losses that will be obtained as a result of registering the mass of the “tank” before and after the “breaths”.

Next, it will be necessary to conduct experiments without a breathing valve, but with the presence of ventilation holes through which losses will occur as a result of ventilation of the gas space.

References

-

“Statista: INDUSTRIES and MARKETS Energy industry worldwide.”. https://www.statista.com/

-

A. A. Korshak, Modern means of reducing gasoline losses from evaporation. Ufa: Designpoligrafservice, 2001.

-

“API MPMS – Manual of Petroleum Measurement Standards Chapter 19.4 Evaporative Loss Reference Information and Speciation Methodology – Third Edition,” 2017.

-

F. F. Abuzova et al., Combating Losses of Oil and Petroleum Products during Their Transportation and Storage. Moscow: Nedra, 1981.

-

A. A. Korshak, G. E. Korobkov, and E. M. Muftakhov, Oil Depots and Gas Stations: Studies. Ufa: Designpoligrafservice, 2006, p. 416.

-

A. A. Korshak and N. V. Morozova, “Methodological foundations of the choice of technical means of reducing oil (gasoline) losses from evaporation,” 2013.

-

A. A. Korshak, 50 Questions and Answers about How to Reduce Gasoline Vapor Emissions from Tanks into the Atmosphere. Ufa: Designpoligrafservice, 2008, p. 87.

-

“VDI 3479,” Emissionsminderung, Raffinierieferne Mineralöltanklager, 2010.

-

“GD 153-39-019-97, 1997: Methodological guidelines for determining technological losses of oil at the enterprises of oil companies of the Russian Federation,” 1997.

-

E. I. Zorya and O. V. Loshchenkova, “Evaluation of publicly available technologies and methods for determining losses of petroleum products from evaporation from a storage tank,” in Oil and Gas Chemistry, 2019.

-

A. Elizaryev et al., “Influence of seasonal changes in climatic conditions on losses at oil tanks filling (on example of the Republic of Bashkortostan),” in E3S Web of Conferences, No. 175, p. 12021, 2020.

-

A. F. Maksimenko and S. S. Lopovok, “Comparative analysis of methods of accounting for losses of oil and petroleum products in tanks from evaporation,” Oil, Gas and Business, Vol. 5, pp. 56–59, 2015.

-

Mednikova and M. I., “Comparative analysis of methods for calculating oil loss from evaporation of the XXI century,” in LII Student International Scientific and Practical Conference, Vol. 4, No. 51, 2017.

-

R. E. Levitin, “Foreign and Russian experience in determining oil vapor emissions from vertical steel tanks,” Tyumen, 2015.

-

T. Mitrova and I. Gaida, “Decarbonization of the oil and gas industry: international experience and priorities of Russia,” Energy Center of the Moscow School of Management SKOLKOVO, 2021.

-

“International Energy Agency. Net Zero by 2050 A Roadmap for the Global Energy Sector,” 2021.

-

S. Glushkov and A. Valeev, “Determination of the amount of oil product vapours from the tank based on monitoring the operation of the breathing valve,” Liquid and Gaseous Energy Resources, Vol. 2, No. 1, pp. 44–50, Jun. 2022, https://doi.org/10.21595/lger.2022.22745

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Semyon Glushkov is a postgraduate student. Anvar Valeev is a scientific supervisor.

The authors declare that they have no conflict of interest.