Abstract

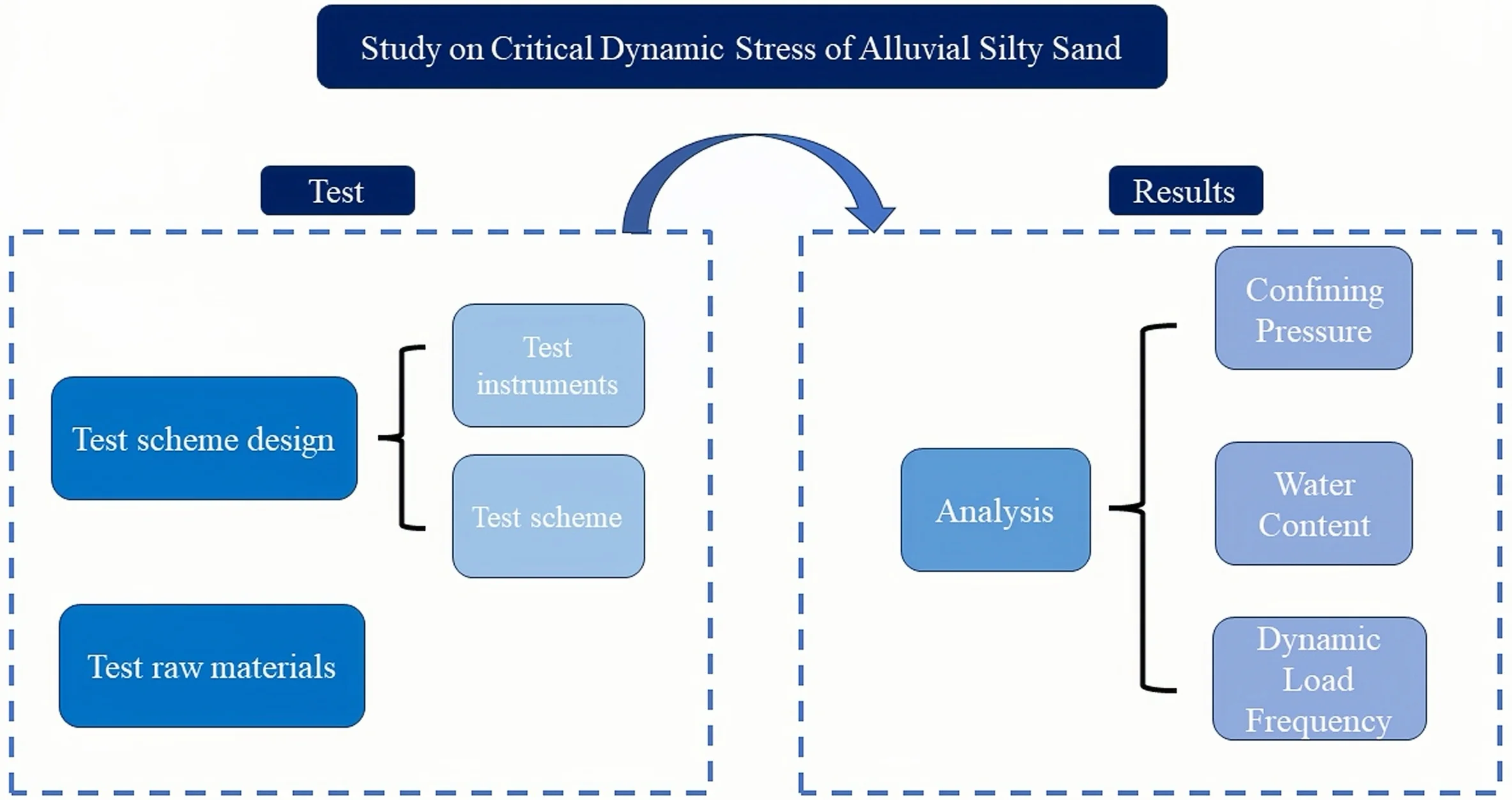

With the development of engineering construction, alluvial silty sand is widely used in highway construction, and its mechanical properties are becoming more and more important. In this paper, the pluvial silty sand in practical engineering is taken as the research object, and its physical properties are obtained through basic test. The critical dynamic stress of pluvial silty sand under different confining pressure, water content and dynamic load frequency is studied by indoor dynamic triaxial test. The results show that the critical dynamic stress of alluvial silty sand is affected by confining pressure and water content, and the frequency of dynamic load has little effect on it. The critical dynamic stress of alluvial silty sand is proportional to the confining pressure. When the water content of the soil sample is the best water content, the critical dynamic stress of the alluvial silty sand is the largest; the dynamic load frequency has little effect on the critical dynamic stress. Through the study of the critical dynamic stress of alluvial silt, it provides some reference for its engineering application and theoretical research.

1. Introduction

In recent years, with the rapid development of highway construction, alluvial silt has been widely used in roadbed filling in highway construction due to its abundant reserves and low price [1]. The study of the characteristics of alluvial silt has become a major focus of highway construction. Chang et al. [2] studied the variation of stress-strain relationship curve, static strength, elastic modulus and shear strength parameters of silt soil under different freeze-thaw cycles, freezing temperature and confining pressure. Zhang Hongbo et al. [3] conducted a series of cyclic loading triaxial tests considering different initial densities, different initial confining pressures and different dynamic stress levels. Zhu Hui et al. [4] studied the application of cement lime improved soil in the treatment of silty sand roadbed. Zhang Xiangdong et al. [5-6] carried out a lot of research on the dynamic characteristics of aeolian soil in western Liaoning. The results show that with the increase of confining pressure and consolidation ratio of aeolian soil, the dynamic strength, maximum elastic modulus and dynamic shear modulus of aeolian soil gradually increase, and the damping ratio decreases with the increase of confining pressure and consolidation ratio.

The soil structure will change under load. With the change of dynamic stress, load cycle and vibration times, the deformation degree and strength of soil structure change differently. The effective parameter reflecting the structure and strength of soil is the critical dynamic stress, which can be obtained by dynamic triaxial test, elastic-plastic numerical analysis or stability theory analysis. Hu Guoxing [7] studied the deformation characteristics of aeolian sand fillers and obtained an empirical formula for the critical dynamic stress of aeolian sand fillers considering the dynamic stress amplitude, moisture content and confining pressure. Based on the results of test and model analysis, Xu et al. [8] proposed an empirical formula for critical dynamic stress of coarse-grained soil considering the influence of confining pressure and water content. Yang Zhihao et al. [9] carried out a series of large-scale dynamic triaxial tests under different stress levels to establish a critical dynamic stress calculation model for plastic creep state considering confining pressure and fine particle content parameters, and analyzed the influence of fine particle content and confining pressure on dynamic strength.In general, although there are many studies on the engineering application of pluvial silty sand, there are few studies on the dynamic characteristics, and the actual traffic load is mainly dynamic load. In order to better study the dynamic characteristics of pluvial silty sand, this paper studies the deformation characteristics of pluvial silty sand by considering different confining pressure, water content and dynamic load frequency through GDS dynamic triaxial apparatus. The corresponding critical dynamic stress is found, and the response mechanism of confining pressure, water content and dynamic load frequency to the deformation characteristics of pluvial silty sand is explored, which provides a certain reference for the engineering application and theoretical research of pluvial silty sand.

2. Test raw materials

The test soil is taken from the alluvial silty sand in a high-speed area. The non-uniformity coefficient is 7.43 and the curvature coefficient 2.42 calculated by the particle test, indicating that the alluvial silty sand is a well-graded soil sample. The plastic limit = 21.4 %, the liquid limit = 29.6 %, and the plasticity index = 8.2. According to the compaction test, the maximum dry density of the soil sample is 1.975 g/cm3, and the optimum moisture content is 8.0 %.

3. Test scheme design

3.1. Test instruments

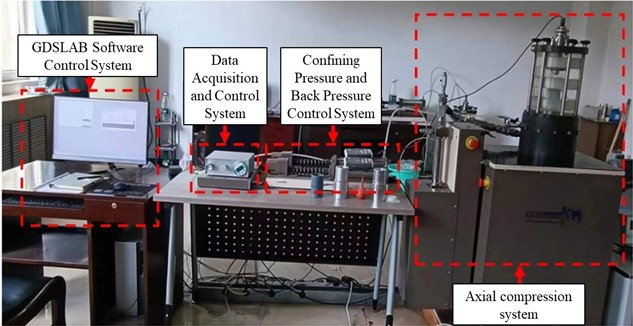

The GDS dynamic triaxial test equipment used in this test is shown in Fig. 1. The GDS dynamic triaxial tester can apply a maximum dynamic axial load of ±10 kN, the frequency range is 0-5 Hz, and the accuracy is 0.1 % of the range. The maximum deformation of the sample is 100 mm, the displacement resolution is 0.208 mm, and the accuracy is 0.07 % of the interval. It can simulate sine wave, oblique wave and other waveforms, and can test soil dynamic indexes such as dynamic strength.

Fig. 1GDS dynamic triaxial equipment

3.2. Test scheme

This test mainly analyzes its influence on the critical dynamic stress from three aspects: confining pressure, moisture content and dynamic load frequency. The tests were carried out under confining pressure of 30 kPa, 50 kPa, 80 kPa, moisture content of 6 %, 8 %, 10 %, and dynamic load frequency of 1 Hz, 3 Hz, 5 Hz. The specific process is as follows: the test with alluvial silty sand soil is sieved and dried, the amount of soil and water in each sample is calculated in turn, and the sample is prepared after sealing the soil for one day and night. The specimen was 50×100 (mm) in size and compacted into five layers. Each layer was scraped to avoid delamination. During the test, the loading waveform is set to sine wave, and the consolidation ratio of 1.5 is selected as the test condition. The loading failure mode is strain-controlled, and the indoor dynamic triaxial instrument is used to load the waveform of vehicle load.

4. Test results and analysis

The critical dynamic stress of soil is related to many factors, such as soil structure, compaction degree, water content, particle gradation, frequency and size of dynamic load. The pluvial silt sand used in this test was tested under different confining pressure, water content and dynamic load frequency under compaction degree of 96 %. According to the results of indoor dynamic triaxial test, the following analysis was presented.

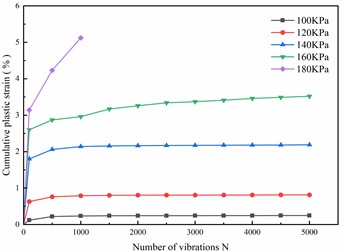

4.1. Critical dynamic stress under different confining pressure

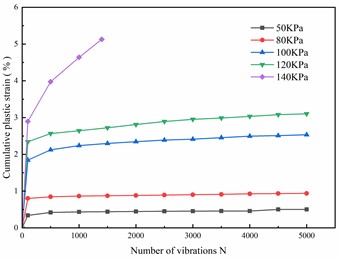

The test results under dynamic loads with confining pressure of 30 kPa, water content of 8 % and 1 Hz is shown in Fig. 2. When the confining pressure is 30 kPa, the dynamic stress amplitude is 100 kPa, 120 kPa and 140 kPa, respectively. When the number of vibrations is low, the plastic deformation of critical dynamic stress increases gradually with the increase of vibration times, and the expansion base increases gradually. Then, with the increase of vibration times, the cumulative plastic strain growth rate gradually approaches zero, which is mainly related to the process of compaction of soil samples during the test. When the set vibration tends to end, the cumulative plastic strain does not exceed 3 %, indicating that the sample can still maintain a good state under this dynamic stress amplitude. When the dynamic stress amplitude is 160 kPa, the cumulative plastic strain increases faster than the previous three groups, but when the applied vibration reaches a certain degree, the growth rate slows down. Similarly, when the vibration tends to end, the cumulative plastic strain reaches about 3 %, and the growth rate is small. This shows that under the condition of sufficient time, the cumulative plastic strain of the soil sample will reach the failure limit when the number of actions is large enough. When the dynamic stress amplitude is 180 kPa, the sample structure reaches the failure limit about 1200 times under the dynamic load, and the soil sample structure is destroyed. Therefore, it is considered that the critical dynamic stress of the alluvial silty sand in this state is about 180 kPa.

Fig. 2The εp-N curve when confining pressure is 30 kPa

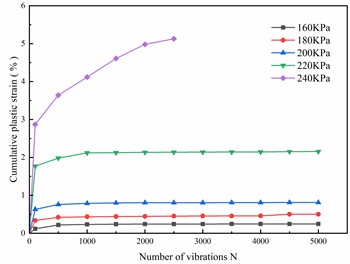

Figs. 3 and 4 show the test results under dynamic loads with confining pressure of 50 kPa and 80 kPa, water content of 8 % and 1 Hz, and the analysis process is similar to Fig. 2. According to Fig. 2, when the confining pressure is 50 kPa, the critical dynamic stress of the alluvial silty sand is about 240 kPa. Under the confining pressure, when the dynamic stress amplitude is 160 kPa, 180 kPa, 200 kPa and 220 kPa, the plastic deformation of the soil sample does not reach the failure criterion specified in the test. Therefore, it can be concluded that when the confining pressure is 50 kPa, the critical dynamic stress of the alluvial silty sand is about 240 kPa.

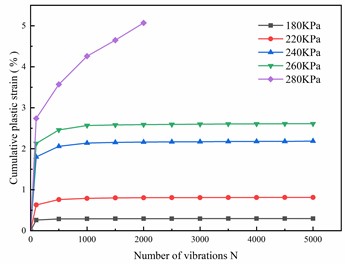

As shown in Fig. 4, when the confining pressure is 80 kPa, the critical dynamic stress of the alluvial silty sand is about 280 kPa. When the dynamic stress amplitude is 180 kPa, 220 kPa, 240 kPa and 260 kPa, the cumulative plastic deformation is within the safe range, and no structural damage occurs.

Fig. 3The εp-N curve when confining pressure is 50 kPa

Fig. 4The εp-N curve when confining pressure is 80 kPa

According to the above analysis, the critical dynamic stress of the alluvial silty sand is proportional to the confining pressure. The greater the confining pressure, the higher the compactness of the soil, the closer the contact between the soil particles, and the greater the friction between the soil particles. Therefore, greater dynamic stress is needed to overcome the frictional resistance between soil particles and cause damage to the soil.

4.2. Critical dynamic stress of soil samples under different water content

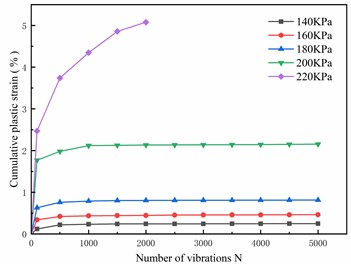

Taking the dynamic triaxial test results under the confining pressure of 50 kPa and the dynamic load of 1 Hz as an example, when the water content is 6 %, 8 % and 10 % respectively, the curves are shown in Figs. 5, 6 and 7. As shown in Figs. 5 and 6, when the water content is 6 % and 8 %, when the dynamic stress amplitude is below 200 kPa, the soil sample tends to be stable in a short time, and the growth rate tends to be zero. After the cyclic loading is applied, the plastic strain of the soil sample does not exceed 2.2 %. When the water content is 6 %, the cumulative plastic strain of the soil sample reaches 5 % within the specified time under the dynamic stress amplitude of 220 kPa, and it fails after about 2000 cycles. When the water content is 8 %, when the dynamic stress amplitude is 220 kPa, the soil sample does not fail within the number of vibrations, but the plastic deformation continues to grow, indicating that when the water content is 6 %, the critical dynamic stress of the alluvial silty sand is about 220 kPa. When the water content of the soil sample is 8 %, the critical dynamic stress is 240 kPa.

Fig. 5The εp-N curve when the water content 6 %

Fig. 6The εp-N curve when the water content 8 %

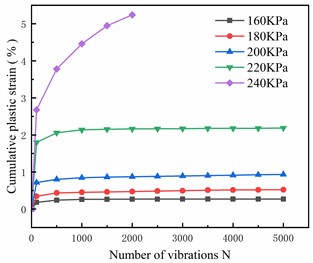

Similarly, as shown in Fig. 7, when the soil moisture content is 10 % and the applied dynamic stress amplitude is below 100 kPa, the curve can remain stable and the plastic deformation growth rate tends to 0. After the cyclic loading is applied, the cumulative plastic strain does not exceed 2.4 %. When the dynamic stress amplitude is 120 kPa, the cumulative plastic strain of the soil sample reaches 3.12 % after about 5000 cycles. When the dynamic stress amplitude is 140 kPa, the cumulative plastic strain of the soil sample reaches 5 %, and it fails after about 2000 cycles. It shows that when the water content is 10 %, the critical dynamic stress of the alluvial silty sand is about 140 kPa.

Therefore, when the other conditions are the same, the critical dynamic stresses of the pluvial silty sand at the water content of 6 %, 8 % and 10 % are 220 kPa, 240 kPa and 140 kPa, respectively. This indicates that the critical dynamic stress of the alluvial silty sand is the highest when it is close to the optimum moisture content.

Fig. 7The εp-N curve when the water content 10 %

4.3. Critical dynamic stress under different dynamic load frequency

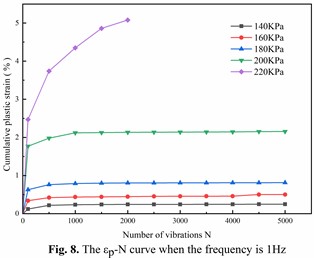

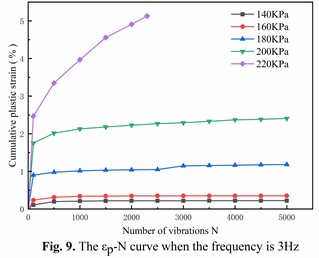

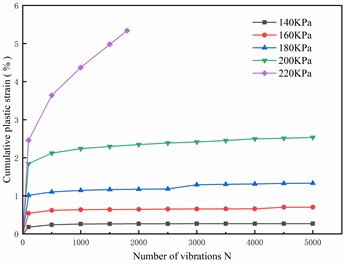

Under the action of 1 Hz, 3 Hz and 5 Hz dynamic loads, the critical dynamic stress of alluvial silty sand under confining pressure of 50 kPa and water content of 8 % was studied. The results are shown in Figs. 8, 9 and 10. When the dynamic stress amplitude is 220 kPa, the plastic strain of the soil sample reaches 5 %. When the dynamic load cycle is about 1700 times, the soil sample fails. For the dynamic stress amplitude of 140 kPa, 160 kPa, 180 kPa and 200 kPa, there is no damage, and the plastic deformation tends to be stable and does not increase. The cumulative plastic strain does not exceed 2.5% after the end of the number of load vibrations. When the dynamic load cycle is about 1700 times, it can be concluded that the critical dynamic stress of the alluvial silt sand under the dynamic load of 1 Hz, 3 Hz and 5 Hz is about 220 kPa. That is, under the condition that other conditions remain unchanged, the critical dynamic stress of the alluvial silt sand is the same under the dynamic load of 1 Hz, 3 Hz and 5 Hz frequencies. Therefore, it can be concluded that the critical dynamic stress is not affected by the dynamic load frequency.

Fig. 8The εp-N curve when frequency is 1 Hz

Fig. 9The εp-N curve when frequency is 3 Hz

The frequency of different dynamic loads has little effect on the plastic deformation of the sample, and the critical dynamic stress has no obvious change. The reason is that the particles in the sample are not rearranged, but vibrate at the original position, so that the strain of the soil can be better released, and the plastic deformation and cumulative strain are reduced. Therefore, the effect of different dynamic load frequencies on the critical dynamic stress is not obvious.

Fig. 10The εp-N curve when frequency is 5 Hz

5. Conclusions

1) The critical dynamic stress of alluvial silty sand is proportional to the confining pressure. When the confining pressure is 30 kPa, 50 kPa and 80 kPa, the critical dynamic stress of the alluvial silty sand is 180 kPa, 240 kPa and 280 kPa. The reason is that the greater the confining pressure, the higher the compactness of the soil, the closer the contact between the soil particles, the greater the friction between the soil particles.

2) When the water content of the soil sample is the best water content, the critical dynamic stress of the alluvial silty sand is the largest. When the water content is 6 %, 8 % and 10 %, the critical dynamic stress of the alluvial silty sand is 220 kPa, 240 kPa and 140 kPa. The reason is that when the water content is the best, the cohesion between the particles increases, and the shear strength of the soil increases, so that the critical dynamic stress increases.

3) Under the condition that other conditions remain unchanged, the critical dynamic stress of the alluvial silt sand is the same under the dynamic load of 1 Hz, 3 Hz and 5 Hz frequencies. Therefore, it can be concluded that the critical dynamic stress is not affected by the dynamic load frequency.

References

-

Y. C. Cai et al., “Study of dynamic response of silty sand subgrade loaded by airplane,” Rock and Soil Mechanics, Vol. 33, No. 9, pp. 2863–2868, 2012.

-

D. Chang, J. K. Liu, and X. Li, “Experimental study on yielding and strength properies of silty sand under freezing-thawing cycles,” Chinese Journal of Rock Mechanics and Engineering, Vol. 34, No. 8, pp. 1721–1728, 2015.

-

H. B. Zhang, M. S. Huang, and G. X. Song, “Experimental study on cumulative deformation of silty sand roadbed under repeated loading,” Journal of Highway and Transportation Research and Development, Vol. 26, No. 9, pp. 6–12, 2009.

-

H. Zhu, M. F. Du, and E. J. Yuan, “Application on silt subgrade treatment by cement-lime improved soil,” Architecture Technology, Vol. 45, No. 7, pp. 608–611, 2014.

-

X. D. Zhang, S. Y. Feng, and C. J. Wuang, “Experimental study of dynamic characteristics for aeolian soil in west liaoning province,” Journal of Experimental Mechanics, Vol. 27, No. 2, pp. 165–170, 2012.

-

X. D. Zhang, S. Y. Feng, and J. J. Zhang, “Experimental study on dynamic shear modulus and damping ratio of aeolian soil in west LiaoNing province,” Mechanics in Engineering, Vol. 33, No. 1, pp. 48–52, Feb. 2011, https://doi.org/10.6052/1000-0879-lxysj2010-239

-

G. X. Hu, “Critical dynamic stress of wind-blown sand filler under cyclic load,” Railway Engineering, Vol. 63, No. 8, pp. 113–118, 2023.

-

F. Xu et al., “Study on critical dynamic stress of coarse-grained soil based on large-scale dynamic triaxial test and neural network,” Journal of the China Railway Society, Vol. 45, No. 5, pp. 119–127, 2023.

-

Z. H. Yang et al., “Study on critical dynamic stress and dynamic strength properties of fouled graded macadam in heavy haul railway subgrade bed,” Journal of the China Railway Society, Vol. 44, No. 7, pp. 145–153, 2022.

About this article

The research in this paper is supported by Key R & D Projects of Shaanxi Province (2018GY-155).

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.