Abstract

This study investigates the influence of thermally activated sparingly soluble additives – phosphogypsum, limestone, and fly ash – on the rheological behavior and strength characteristics of Portland cement. Additives were incorporated in amounts of 1-5 % into clinkers from the Kuvasoy and Bekabad plants and evaluated for workability, water-cement ratio, and compressive strength. The results demonstrate that thermal activation (200-400 °C) enhances the surface reactivity of additives, promoting accelerated hydration of calcium silicates and improved microstructural densification. Compressive strength reached 534×105 Pa at 28 days for mixtures containing 5 % limestone activated at 200 °C. These improvements are particularly relevant for vibration-resistant transport structures – such as bridge decks, pavements, and railways – where enhanced flowability and durability are essential. The research also supports sustainable cement production through the valorization of industrial by-products like phosphogypsum and fly ash.

1. Introduction

Cement-based composites play a crucial role in modern transport infrastructure, including bridge decks, pavements, and railway foundations, where materials are continuously subjected to vibration-induced and cyclic loads. Under such service conditions, ordinary Portland cement often exhibits limitations in rheological stability, workability retention, and early strength development, which may compromise long-term durability of transport structures [1-3]. Therefore, improving the fresh-state flow behavior and hydration kinetics of cement systems is essential for ensuring both structural integrity and energy-efficient construction.

Recent studies have shown that the incorporation of mineral additives and supplementary cementitious materials (SCMs) can effectively modify hydration mechanisms and microstructural evolution of Portland cement matrices [4-6]. Among these, sparingly soluble substances such as phosphogypsum, limestone, barium sulfate, and fly ash have attracted significant attention due to their dual effect: they can enhance workability through controlled release of ionic species and contribute to the formation of stable hydration products such as ettringite and calcium silicate hydrates (C-S-H) [7-9]. Furthermore, these additives support sustainable material utilization by valorizing industrial by-products from the chemical and energy sectors.

In particular, thermal activation of such additives increases their surface acidity and reactivity, which accelerates the hydration of aluminate and silicate phases in cement [10-12]. However, the optimal activation conditions, dosage ratios, and their combined impact on both rheological and strength characteristics – especially in the context of vibration-resistant transport concretes – remain insufficiently explored.

The present study investigates the effect of thermally activated sparingly soluble additives (phosphogypsum and limestone, activated at 400 °C and 200 °C, respectively, and Angren coal fly ash) on the rheological behavior, hydration, and compressive strength of Portland cement. Additives were incorporated at low dosages (1–5 wt%) into industrial clinkers from the Kuvasoy and Bekabad plants.

The novelty of this work lies in the integrated assessment of thermal activation, hydration kinetics, and rheological improvement in relation to the performance requirements of vibration-resistant transport structures. The findings contribute to the development of durable, sustainable, and vibration-tolerant cement composites applicable in road, bridge, and railway engineering.

2. Materials and methods

2.1. Materials

Portland cement clinkers were obtained from the Kuvasoy and Bekabad cement plants (Uzbekistan). The clinkers served as the base material for all mixes. The following sparingly soluble additives were used:

1) Phosphogypsum.

2) Limestone.

3) Barium sulfate

4) Coal fly ash from the Angren thermal power plant.

Phosphogypsum and limestone were thermally activated at 400 °C and 200 °C, respectively, in a laboratory furnace for 2 h to enhance surface acidity and reactivity, following the approach reported in [11]. The additives were introduced into cement in amounts at 1-5 wt% of binder mass.

2.2. Sample preparation

Cement pastes and mortars were prepared at a constant temperature of 20±2 °C using a laboratory planetary mixer.

The water-to-cement ratio (w/c) was adjusted to achieve a target cone spread of 110-115 mm, in accordance with GOST 310.4-81 and ISO 679:2009 standards.

Each composition was labeled according to the type and activation temperature of the additive:

1) K.K – control sample without additives.

2) L200 – cement with 5 % limestone activated at 200 °C.

3) PG400 – cement with 3 % phosphogypsum activated at 400 °C.

4) FA500 – cement with fly ash activated at 450-500 °C.

2.3. Rheological tests

The rheological behavior was characterized by cone spread measurements for both pastes and mortars using a standard flow table test. Plasticity was quantified by the spread diameter and expressed as the ratio of cone spread to sample height. The water demand corresponding to a target spread was recorded for each composition.

This method provides a reliable estimate of yield stress and consistency for comparative analysis of mineral additives [4], [5].

2.4. Mechanical tests

The flexural and compressive strengths of hardened specimens were determined after 3 days and 28 days of curing under standard humidity (95±5 %) and temperature (20±2 °C), following GOST 310.4-81 procedures.

Compressive strength was measured using a hydraulic press (loading rate = 0.5 MPa/s).

The results were averaged over three parallel tests for each mix to ensure reproducibility.

2.5. Physicochemical characterization

To elucidate the hydration and activation mechanisms, the following analytical techniques were employed:

1) X-ray diffraction (XRD) – phase composition and crystalline structure (Cu Kα radiation, 10–60°).

2) Infrared (IR) spectroscopy — identification of sulfate, silicate, and hydroxyl vibrations (400-4000 cm⁻¹).

3) Differential thermal analysis (DTA/TG) – thermal effects during activation of fly ash (up to 700 °C, heating rate 10 °C/min).

These methods follow established protocols described in [7], [8], [11].

For activated fly ash, mass loss and phase transformations were analyzed to determine the optimal calcination temperature range (450-500 °C), as recommended in [12].

2.6. Data analysis

The experimental data were processed using OriginPro 2023 for regression analysis and graphical visualization.

Each test result was checked for consistency; the standard deviation did not exceed ± 5 % for strength data and ± 2 % for flow measurements.

3. Results and discussion

3.1. Rheological behavior and plasticizing effect

The incorporation of sparingly soluble additives significantly influenced the workability of Portland cement pastes and mortars [15], [16].

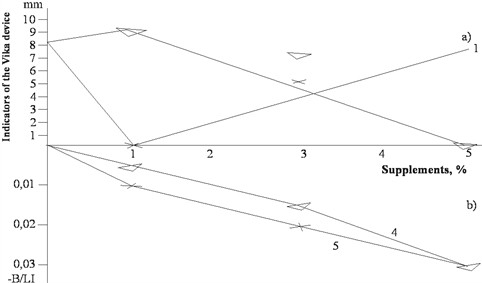

As shown in Fig. 1, the optimum plasticizing effect was achieved when 1 % phosphogypsum and 5 % limestone were added to the cement mixture.

Fig. 1Effect of sparingly soluble additives on the spreadability of cement pastes (1-3) and mortars (4-5): 1, 3 – phosphogypsum; 4 – limestone (200 °C); 5 – phosphogypsum (400 °C). K.K – control cement samples

These compositions exhibited a wider cone spread at an equivalent water-to-cement ratio, indicating improved flowability.

The improvement in rheology can be attributed to two factors:

1) Partial dissolution of the additives, which releases Ca2⁺ and SO42⁻ ions that promote dispersion of cement grains.

2) Surface activation caused by heat treatment, which enhances interaction with the silicate phase [4], [8].

The results correspond well with previously reported data on limestone-filled cements with optimized particle size distributions [2].

Such rheological stability is particularly beneficial for transport concretes (bridge decks, pavements, railway slabs), where uniform workability is essential for vibration-resistant placement and compaction under cyclic loading.

3.2. Water-to-cement ratio and hydration activity

The water demand decreased from 0.40 (control) to 0.37 for the mixture containing 5 % limestone activated at 200 °C, while maintaining equal plasticity (Table 1).

Table 1Strength characteristics of portland cements activated with thermally treated limestone

Limestone | Water-to-cement ratio (W/C (-)) | Cone spread, (mm) | Duration (days) | ||||

Flexural strength (MPa) | Compressive strength (MPa) | ||||||

Content, (%) | Temperature, (°C) | 3 | 28 | 3 | 28 | ||

– | – | 0.40 | 110 | 38 | 62 | 248 | 462 |

5 | 100 | 0.38 | 114 | 42 | 61 | 286 | 502 |

5 | 200 | 0.37 | 114 | 47 | 74 | 300 | 534 |

This reduction in water demand indicates a packing density improvement and the formation of a denser particle skeleton, in agreement with [3].

Furthermore, thermally activated phosphogypsum acted as a controlled sulfate source, regulating aluminate hydration and contributing to the formation of ettringite during early stages.

This behavior corresponds to the mechanism of sulfate activation reported by Chen et al. [11].

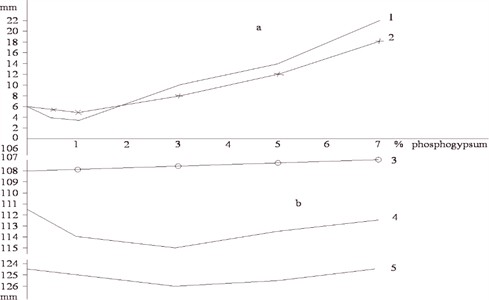

The visual difference in spread and surface texture between the control and modified samples is illustrated in Fig. 2.

Fig. 2Influence of phosphogypsum on cement pastes and mortars (Bekabad cement): 1 – natural phosphogypsum; 2 – phosphogypsum activated at 400 °C; 3-5 – mortars with natural phosphogypsum (w/c = 0.34, 0.36, 0.38)

3.3. Strength development and hydration kinetics

Mechanical testing revealed that the compressive strength of the composite containing 5 % limestone activated at 200 °C reached 534×105 Pa after 28 days, representing a ~15 % increase compared to the control.

Flexural strength also improved by 20-25 %.

Infrared (IR) spectroscopy confirmed the acceleration of silicate hydration, evidenced by the transformation of Si-O-Si stretching vibrations near 880 cm-1 and by the increased intensity of hydroxyl peaks around 3640 cm-1.

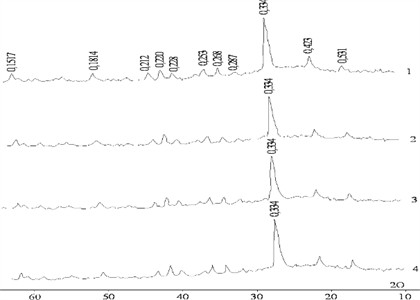

X-ray diffraction (XRD) analysis showed stronger ettringite reflections (1125-1150 cm-1) and a decreased intensity of gypsum bands near 650 cm-1, indicating the consumption of free sulfates [14].

These results demonstrate that thermal activation enhances surface acidity and ion exchange capacity, which accelerates the formation of C-S-H and ettringite phases [7], [11].

Similar improvements in early hydration kinetics have been observed for nano-SiO2 and high-surface-area fillers [4], [6].

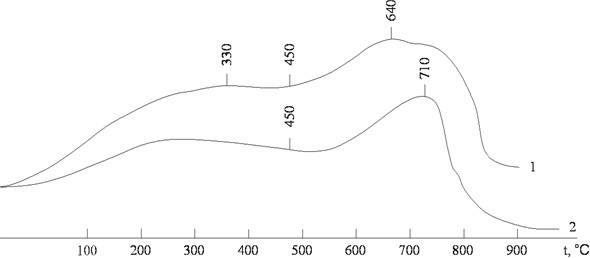

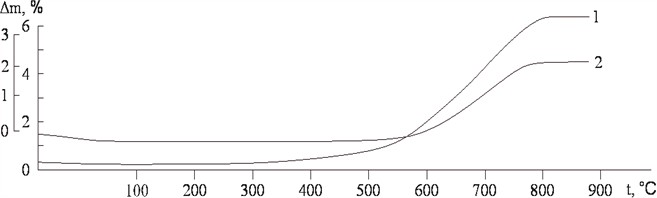

3.4. Activation of fly ash and phase transformations

Fly ash from the Angren coal deposit was analyzed as a potential aluminosilicate activator.

The differential thermal analysis (DTA/TG) (Fig. 3-5) revealed that optimal activation occurs between 450-500 °C, where exothermic oxidation of carbon residues leads to the removal of amorphous coatings and formation of reactive silica phases.

Fig. 3DTA/TG curves of fly ash: 1 – raw; 2 – calcined at 460 °C

Fig. 4Mass loss (TG) of fly ash: 1 – raw; 2 – calcined at 460 °C

After heat treatment at ~460 °C, XRD patterns displayed a decrease in carbon-related peaks (0.334 nm → 0.333 nm) and the appearance of mullite-type reflections, indicating enhanced reactivity.

IR spectra also showed stronger –OH vibration bands (3640-3700 cm-1), consistent with surface hydroxylation [12].

Activated fly ash promoted hydration of both silicate and aluminate components, stabilized ettringite, and improved the microstructure of hardened cement pastes, similar to observations in [9].

This mechanism supports the sustainable reuse of coal combustion residues in cement composites for transport infrastructure applications [13], [14].

Fig. 5DTA/TG curves of fly ash: 1 – raw; 2 – 460 °C; 3 – 600 °C; 4 – 700 °C

3.5. Implications for transport and vibration-resistant structures

The experimental findings confirm that thermally activated phosphogypsum, limestone, and fly ash additives can substantially improve rheological stability, hydration rate, and mechanical performance of Portland cement [12], [13], [17].

For transport structures exposed to repeated vibration and dynamic loading – such as road pavements, bridge slabs, and rail bases – these modifications offer three key advantages:

Better workability at lower w/c ratios enables uniform compaction and reduced air entrapment under vibration.

Faster hydration ensures earlier strength gain, minimizing downtime for construction operations.

Denser microstructure enhances long-term durability, reducing crack propagation caused by cyclic stresses.

Therefore, thermally activated sparingly soluble additives provide a cost-effective and eco-efficient route to producing vibration-tolerant transport concretes, aligning with the sustainability goals highlighted in [12].

4. Conclusions

This study examined the effect of thermally activated sparingly soluble additives – phosphogypsum, limestone, and fly ash – on the rheological, hydration, and strength properties of Portland cement composites intended for vibration-resistant transport structures.

The following key conclusions can be drawn:

Thermal activation of phosphogypsum (400 °C) and limestone (200 °C) increases surface acidity and reactivity, resulting in accelerated hydration and improved workability.

The optimal combination of 1 % phosphogypsum and 5 % limestone yielded the highest flowability and a 15 % increase in compressive strength compared to the control sample (534×105 Pa at 28 days).

Fly ash activated at 450-500 °C enhanced the formation of ettringite and C-S-H, contributing to microstructural densification and sustainability through industrial waste utilization.

The improved rheology and hydration kinetics particularly for bridge decks, pavements, and railway concretes, where vibration and cyclic loading demand high cohesion and early strength.

The obtained results align with international findings on thermally activated binders [11] and sustainable transport composites [12].

Overall, the proposed approach demonstrates a cost-effective, eco-efficient pathway toward the production of vibration-tolerant and resource-saving cement composites for transport infrastructure.

References

-

S. Jiang et al., “Rheological properties of cementitious composites with nano/fiber fillers,” Construction and Building Materials, Vol. 158, pp. 786–800, Jan. 2018, https://doi.org/10.1016/j.conbuildmat.2017.10.072

-

Y. Knop and A. Peled, “Packing density modeling of blended cement with limestone having different particle sizes,” Construction and Building Materials, Vol. 102, pp. 44–50, Jan. 2016, https://doi.org/10.1016/j.conbuildmat.2015.09.063

-

Y. Qian and S. Kawashima, “Use of creep recovery protocol to measure static yield stress and structural rebuilding of fresh cement pastes,” Cement and Concrete Research, Vol. 90, pp. 73–79, Dec. 2016, https://doi.org/10.1016/j.cemconres.2016.09.005

-

L. Senff, D. Hotza, S. Lucas, V. M. Ferreira, and J. A. Labrincha, “Effect of nano-SiO2 and nano-TiO2 addition on the rheological behavior and the hardened properties of cement mortars,” Materials Science and Engineering: A, Vol. 532, pp. 354–361, Jan. 2012, https://doi.org/10.1016/j.msea.2011.10.102

-

M. A. Moeini, M. Hosseinpoor, and A. Yahia, “Effectiveness of the rheometric methods to evaluate the build-up of cementitious mortars used for 3D printing,” Construction and Building Materials, Vol. 257, p. 119551, Oct. 2020, https://doi.org/10.1016/j.conbuildmat.2020.119551

-

J. I. Tobón, O. Mendoza, O. J. Restrepo, M. V. Borrachero, and J. Payá, “Effect of different high surface area silicas on the rheology of cement paste,” Materiales de Construcción, Vol. 70, No. 340, p. e231, Nov. 2020, https://doi.org/10.3989/mc.2020.15719

-

N. Lutfullaeva et al., “Physico-chemical research of the processes of hydration of cements,” in E3S Web of Conferences, Vol. 497, p. 02034, Mar. 2024, https://doi.org/10.1051/e3sconf/202449702034

-

F. Lavergne, R. Belhadi, J. Carriat, and A. Ben Fraj, “Effect of nano-silica particles on the hydration, the rheology and the strength development of a blended cement paste,” Cement and Concrete Composites, Vol. 95, pp. 42–55, Jan. 2019, https://doi.org/10.1016/j.cemconcomp.2018.10.007

-

T. A. Atakuziev and N. R. Ruziev, Multicomponent Cements. Tashkent: Uzbek Academy Press, 2008.

-

S. H. Zuo, J. Xiao, Q. Zhang, and D. F. Wang, “Effect of nano-SiO₂ on rheological property of fresh cement pastes,” Bulletin of the Chinese Ceramic Society, Vol. 38, pp. 317–322, 2019.

-

X. Chen, C. Liu, and D. Zhang, “Thermal activation of phosphogypsum and its effect on the hydration and strength of cementitious systems,” Construction and Building Materials, Vol. 343, p. 128366, 2022.

-

T. Bualuang, P. Jitsangiam, and T. Tanchaisawat, “Sustainable flexible pavement base stabilization with pozzolanic materials incorporating sodium hydroxide and asphalt emulsion,” Transportation Engineering, Vol. 6, p. 100094, Dec. 2021, https://doi.org/10.1016/j.treng.2021.100094

-

M. Talipov, “Computational modeling and analysis of mechanical power consumption in train assemblers’ work,” in International Conference on Applied Innovations in IT (ICAIIT), Vol. 13, No. 2, pp. 419–426, Jun. 2025, https://doi.org/10.25673/120513

-

E. Shipacheva, S. Shaumarov, A. Gulamov, and M. Talipov, “Modeling of interaction of external enclosing structures of buildings with the internal and external environments,” in ICTEA: International Conference on Thermal Engineering, Jun. 2024.

-

E. Shipacheva, S. Shaumarov, A. Gulamov, M. Talipov, and S. Kandakharov, “Water structure and its influence on cement stone and concrete properties,” in ICTEA: International Conference on Thermal Engineering, Jun. 2024.

-

M. M. Talipov, O. T. Aliev, O. R. Ilyasov, and O. V. Kovaleva, “Modern method for purifying wastewater from railway embarking using diatomite in a filter band,” in ICTEA: International Conference on Thermal Engineering, 2024.

-

O. T. Aliev, M. M. Talipov, K. M. Kamilov, and O. R. Ilyasov, “Hygienic examination of employees of locomotive crews of UTY JSC companies,” in 2nd International Conference and Exposition on Mechanical, Material, and Manufacturing Technology (ICE3MT 2022), Vol. 2943, No. 1, p. 040057, Jan. 2023, https://doi.org/10.1063/5.0134056

About this article

The authors express their sincere gratitude to the organizers of the 74th International Conference on Vibroengineering – Resource-Efficient Technologies in Transport, to be held in Tashkent, Uzbekistan, on November 27-29, 2025, for providing the opportunity to present and discuss this research.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.