Abstract

This paper examines how the type of fiber and the amount of fiber in concrete impacts the mechanical characteristics of fiber-reinforced concrete (FRC) by both experimental testing and statistical modelling. Basalt, polypropylene, and steel fiber reinforced concrete specimen were cast at different percent ratios (0, 0.1, 0.2 and 0.3) and subjected to laboratory conditions to measure compressive strength. At every dose and fiber type, three specimens were tested, and average values of the strengths were computed. OriginPro was used to fit the data in polynomial regression models (second degree) to quantify the connections between the parameters of this fiber and compressive strength. The most important statistical indicators provided in the assessment of the model accuracy were coefficients of determination (), adjusted , -statistics, -values, and residual analysis. The results revealed that the models were all characterized by high predictive accuracies ( 0.72, 0.93) and found to be significant using ANOVA ( 0.0001). Results validated that the type of fiber along with the dosage were critical in the effectiveness of strength with optimal amount enhancing performance and loads beyond or below those levels decreasing the matrix bonding. The produced models offer a predictive predicting model that would be helpful in FRC mixture optimization. The study presents significant information in the field of structural engineering where a newly established structure will be needed to have superior durability, dependability, and load capacity.

1. Introduction

Fiber-reinforced concretes (FRC) scientific studies have emerged as an important source of innovation in the last few years. The research has mainly involved improving mechanical properties-compressive strength, tensile strength, flexural strength, crack resistance, and availability in the long run-by adding polypropylene, basalt, and steel fibers, and their hybrid composites, to the concrete mass [1], [2]. These fibers are micro-reinforcements that seal cracks and slow their propagation, hence improving the structural integrity of concrete. During the study, Almohammed and Thakur [3] utilized artificial intelligence methods such as artificial neural networks, random forests, and decision trees to accurately predict the compressive strength of a concrete reinforced with basalt and polypropylene fibers. Their results showed that AI-based approaches can sufficiently embrace the multifaceted nonlinear connections among fiber parameters and mechanical performance. Similarly, Wang et al. [4] examined the workability and mechanical enhancement of the polypropylene fiber-reinforced rubber concrete and ranked it as one of the future-generation materials in the field of construction.

In the International Journal of Concrete Structures and Materials, the authors studied how polypropylene fiber length affected the mechanical and thermal characteristics of ultra-mild semi-lightweight aggregate concrete and found that the most desirable results could be obtained with the introduction of an optimal length of fiber. Long-term durability of the self-compacting concretes (Chen et al.) with micro- and macro-polypropylene fibers was also discussed, where the author stated that the mix with the addition of 1 percent of fibers showed the best resistance to freezing, sulfate, and acid attacks [5]. Najaf [6] investigated the functional impact of macro-synthetic polypropylene fibers (Forta and Barchip) on mechanical behaviors, where 1.5 % hybrid fiber composites elevated the compressive strength up to 32 % and flexural strength up to 85 %. Gong et al. [7] indicated synergetic gains in efficient compounding between polypropylene fibers and nano-silica in enhancing the strength and freeze-thaw property of recycled brick aggregate concrete. According to research conducted by the Scielo Brasil [8] research team, the addition of both polypropylene fibers and steel fibers in ultra-high-performance fiber-reinforced concrete really improved strength, cracking, and ductility.

Taken together, the studies conducted during this time have justified the validity of new fiber mixtures and methodological procedures in the technology of FRC, and the combination of experimental work with the statistical treatment of data and the artificial intelligence model as the way to increase the accuracy and confidence of research findings has had an additional positive effect [9], [10]. Determination of the level of significance of factors that affect the mechanical properties of FRC through the analysis of variance (ANOVA) is one of the most topical studies in modern concrete technology [11]. This is because the strength, reliability, and durability of FRC will be determined to a large extent by the strength and durability of the fibers used and their dosage and geometry (length and diameter, etc.) within the mixture. Hence, it is considerably important scientifically and practically to determine which of the factors influences the mechanical performance to a great extent [12].

In recent years, within transport infrastructure, particularly in railway slabs, bridges, road pavements, and industrial floor systems, the fatigue resistance, stability under resonance conditions, and energy absorption capacity of concrete structures under dynamic and vibrational loads have become increasingly important [13]. From this perspective, an in-depth study of the mechanical properties of fiber-reinforced concrete (FRC) is essential not only for evaluating its behavior under static loading but also for assessing its performance under vibrational effects. Steel, basalt, and polypropylene fibers effectively limit microcracking and shrinkage in the internal structure of concrete, enhance its energy absorption (damping) ability, and improve its resistance to cyclic loading. Therefore, the findings of this study have practical significance for improving the strength, vibration resistance, and long-term reliability of concrete elements used in vibration engineering and transport infrastructures.

2. Method

In the present study, the experimental data was studied, and a mathematical model was created by means of the OriginPro program. Initially, OriginPro is a secure and strong platform of analysis applicable to scientists and scholars in the scientific community. It is defined by its graphic interface that can be easily handled by diverse users and a powerful set of graph visualization capacities, as well as very accurate functions of statistical analysis. Software allows a fast and accurate estimation of regression model, both linear and polynomial (th order) one. Essential statistical indicators also needed on the model like the necessary coefficients, standard errors, - statistics, -statistic and the coefficient of determination () are automatically measured in originPro. Additionally, the software has effective graphical visualization options of the model such as drawing of trend lines and confidence intervals to ensure effective presentation of data that is clear. Polynomial regression was chosen to evaluate the influence of fiber volume fraction and length on the mechanical properties of the polymer composites due to the fact that observed relations were nonlinear.

3. Results and discussion

According to experimental findings, it was observed that as the fiber content was increased beyond 0.3 %, reduction in compression strength increase. To better measure this behavior and be able to write it in mathematical form, a second degree polynomial regression model was constructed:

where: – the compressive strength of concrete (MPa), – the percentage of fiber (%).

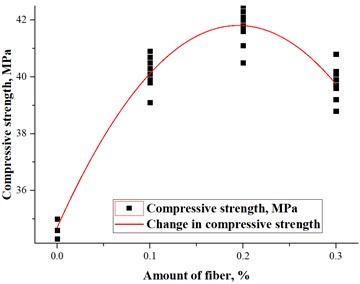

Coefficients: Intercept = 34.716, 72.92, –187.12

The “intercept” is the starting value in a regression equation, that is, the value of when there is no effect of any independent variable (). Model accuracy: 0.93053 – the model represents the results with 93.1 % accuracy. 0.9253 – the corrected coefficient is high.

The importance of fiber content for the compressive strength of concrete is shown in Fig. 1.

Fig. 1The importance of the amount of basalt fibers for the compressive strength of concrete

The theoretical evaluation of the influence of the content of polypropylene fibers on the concrete reinforced with fibers was conducted. The model had 30 data points altogether in the polynomial regression analysis. The model had 27-degrees of freedom. In particular, the model was estimated separately on three parameters (Intercept, B1, and B2), hence with the total degrees of freedom value (29), the residual degrees of freedom were resourced to the number of degrees of freedom (3) estimated minus the total degrees of freedom (29), which returned a value of 27 residual degrees of freedom. Residual Sum of Squares (RSS) was obtained as 19.00303. In a case where this value is very large, the reliability of the model is deemed to be low but in this case, this value was quite small meaning that the model was quite reliable.

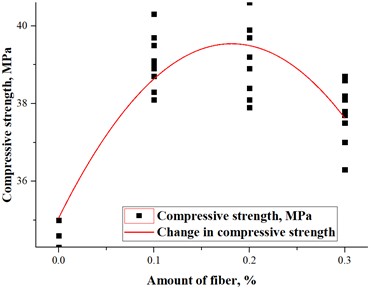

Fig. 2Importance of polypropylene fiber content for compressive strength of concrete

The model had a coefficient of determination () value of 0.72188 which is a good outcome. It implies that the model can highly comprehensively describe the principal variables affecting compressive strength. Fig. 2 shows how fiber content has affected the compressive strength of polypropylene fiber-reinforced concrete.

Nevertheless, the coefficient of determination, after adjustment (Adjusted ) with the minimum and maximum values of 0.68 and 0.72, was equal to 0.70128. This measure considers the element of artificial increase in that may arise when extra predictors are added to the model so it gives a better measure of the exact explanatory capacity of the model. The value of 0.70128 can also be discussed as very good and proves once again the statistical reliability of the model. Second degree polynomial regression model was created to elucidate the outcome of the effect of the polypropylene fibers on concrete compressive strength:

In this case, is a compressive strength and and , the independent variables that will affect it. The coefficient is positive since hence when it increases with , the compressive strength will increase with . Nevertheless, the coefficient of is negative meaning that a rise in will lead to a decrease in the compressive strength.

Using these data, the value of F-statistic was obtained as 35.04015 and -value was obtained as 3.14152×10-8 (i.e., less than 0.0000000314). The p-value that is extremely small gives a very strong indication that the model is significant. That is, the null hypothesis (model with no predictors) is denied, and the model can be discussed as theoretically reputable in general.

The model residuals analysis generated a balanced distribution of the model residuals that are near to normal distribution. When the model is well-specified, it is expected that the residuals be randomly positioned with no systemic pattern. In this sense, the validity of the model could also be confirmed by the residual plot. When the residuals are between –1 and +1 that means the predictions of the model are near the actual values.

In the same manner, the regression analysis of two independent variables was used to assess the importance of the fibers in the reinforced concrete that was composed of steel fibers. According to this hypothetical regression analysis, a mathematical model of predicting compressive strength of steel fiber-reinforced concrete was created:

The importance of fiber content for the compressive strength of concrete based on steel fibers is shown in Fig. 3.

Fig. 3Importance of steel fiber content for compressive strength of concrete

The analysis of variance (ANOVA) of the model shows that the model sum of squares was 273.40096 and the mean square 136.70048 with F-statistic as 157.84978 and the -value 3.73071×10-7. This -value is so small, which implies that on a general note, the model is statistically significant. The error sum of squares is 6.92813 with the mean square equaling 0.86602. All components total sum of squares was 280.32909.

The mathematical model proves to have very high accuracy since both independent variables were statistically significant. The residuals are negligible and the model, in general, is stable. The variable has a beneficial effect. is a degrading factor and both play a significantly great role in reducing compressive strength. Also, the and -statistic values endorse the model’s strength and reliability.

4. Conclusions

The originality of the present study is the combination of an experimental and statistical method that has been used to study the mechanical behavior of fiber-reinforced concrete (FRC) using various types and volume fractions of fibers. This research, in contrast to the past studies whose main aim was to either conduct one kind of fiber testing or employed empirical relationships via tests, is a combination of experimental compressive strength tests and more complexes of polynomial regression and ANOVA that was used to identify the best fiber content in basalt, polypropylene, and steel fibers. To provide a tool of quantitative strength performance prediction of FRC mixtures, this dual approach will make sure that not only the trends are identified but also that the trends are statistically proven to be significant.

Moreover, the experiment provides a comparative theoretical framework in assessing the efficacy of different fiber materials in the same mix and testing conditions. A structure of this kind allows developing predictive models that could be applied directly to improve fiber dosage in the structural design and mix formulation. Specifically, the study concludes that the compressive strength can decrease with an increase in fiber content above 0.3 percent fiber volume fraction- a significant discovery in the practical mix optimization in the engineering of constructions.

The form and quantity of fibers have a potent effect on the mechanical functionalities of concrete. Basalt, polypropylene fibers, and steel fibers were added, which increased compressive strength, but strength decreased once the optimum fiber volume fraction was surpassed.

All three types of fiber used to develop polynomial regressions indicated high degrees of predictive abilities, with the coefficients of determination () varying between 0.72 and 0.93, hence indicating the ability of the models to predict the behavior of compressive strengths and demonstrate a high degree of accuracy.

The statistical significance of the models was confirmed in all cases through analysis of variance (ANOVA) results that showed that p-values were very low (< 0.0001), and hence, it was always rejected that there was no substantial effect of the chosen factors on compressive strength.

The key decision is the optimum amount of fibers, which should not be too low or too high since too little and too much fiber volume can interfere with the bonds in the cementitious structure. By determining this optimum, better performance is achieved and negative consequences to the concrete structure’s integrity are avoided.

5. Conclusions

The results of the current research offer a great basis towards realizing the role of fiber type, geometry, and dosage on the mechanical competency of fiber reinforced concrete (FRC). Statistical modelling of the fiber parameters, using analysis of variance (ANOVA) and polynomial regression developed and transformed with different volume fraction percentages of basalt, polypropylene and steel fibres integration was found to be one of the efficient methods used to determine the strength relationship that was non-linear based on parameters of the fibres. However, there are several directions that the focus of the current work may be diversified further to meet new demands in the fields of materials science, structural engineering, and green building. Future studies must also take into account that more advanced statistical and computational modeling methods needed to be applied to the problem in order to increase the accuracy of predictions and describe complicated relationships between several parameters. Although the research was a concern about the second-degree polynomial regression, adding multivariate regression modus operandi, machine learning algorithms and data driven optimization models may offer superior predictive constructs. These models have the potential to incorporate more than just fiber type, length, and volume fraction and may accommodate even the water-cement ratio, aggregate gradation, curing, and exposure environment so that mix designs can be more accurately optimized to suit a particular application.

A more detailed microstructural insight of fiber matrix interaction is actually going to help interpreting macroscopic mechanical outcomes. Scanning electron microscopy (SEM), X-ray computed tomography (XCT), and energy-dispersive X-ray spectroscopy (EDS) are some of the techniques that can divulge information on the orientation of fibers, dispersion and bonding to the cementitious matrix. The insights may then be matched to mechanical performance factors, enhancing the explanatory and predictive potential of regressions. It is also expected that the future research will look into the effects of various curing regimes and supplementary cementitious materials through the incorporation of fiber reinforcement by the following: by the use of silica fume, fly ash, and slag. These factors could then be statistically compared with counts of the significance of the particular variables relative to fiber parameters to allow more subtle approaches to be embraced in the process of optimization.

References

-

A. Martazaev and S. Khakimov, “Dispersed reinforcement with basalt fibers and strength of fiber-reinforced concrete beams,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030011, Jan. 2025, https://doi.org/10.1063/5.0266797

-

R. Mavlonov and S. Razzakov, “Numerical modeling of combined reinforcement concrete beam,” in E3S Web of Conferences, Vol. 401, p. 03007, Jul. 2023, https://doi.org/10.1051/e3sconf/202340103007

-

F. Almohammed and M. S. Thakur, “Forecasting compressive strength of concrete with basalt and polypropylene fiber by using ANN, RF and RT models,” Asian Journal of Civil Engineering, Vol. 25, No. 2, pp. 1671–1690, Aug. 2023, https://doi.org/10.1007/s42107-023-00870-4

-

Y. Wang et al., “Strength characteristics of polypropylene fiber-modified rubber foamed concrete,” Buildings, Vol. 15, No. 10, p. 1663, May 2025, https://doi.org/10.3390/buildings15101663

-

Y. Chen, M. S. Waheed, S. Iqbal, M. Rizwan, and S. Room, “Durability properties of macro-polypropylene fiber reinforced self-compacting concrete,” Materials, Vol. 17, No. 2, p. 284, Jan. 2024, https://doi.org/10.3390/ma17020284

-

E. Najaf and H. Abbasi, “Impact resistance and mechanical properties of fiber‐reinforced concrete using string and fibrillated polypropylene fibers in a hybrid form,” Structural Concrete, Vol. 24, No. 1, pp. 1282–1295, Aug. 2022, https://doi.org/10.1002/suco.202200019

-

S. Gong et al., “Effect of polypropylene fiber and nano-silica on the compressive strength and frost resistance of recycled brick aggregate concrete,” Nanotechnology Reviews, Vol. 12, No. 1, p. 20230, Dec. 2023, https://doi.org/10.1515/ntrev-2023-0174

-

K. Saravanan, R. Viswanathan, V. Sivakumar, and B. Thangavel, “Investigating the influence of polypropylene and steel fibers on the mechanical properties of UHPFRC,” Matéria (Rio de Janeiro), Vol. 29, No. 4, Jan. 2024, https://doi.org/10.1590/1517-7076-rmat-2024-0708

-

S. Razzakov and A. Martazaev, “Mechanical properties of concrete reinforced with basalt fibers,” in E3S Web of Conferences, Vol. 401, p. 05003, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105003

-

R. Mavlonov, S. Razzakov, and S. Numanova, “Stress-strain state of combined steel-FRP reinforced concrete beams,” in E3S Web of Conferences, Vol. 452, p. 06022, Nov. 2023, https://doi.org/10.1051/e3sconf/202345206022

-

E. S. George, R. Hari, and M. K. Madhavan, “Performance assessment of blended self-compacting concrete with ferrochrome slag as fine aggregate using functional ANOVA,” Journal of Building Engineering, Vol. 89, p. 109390, Jul. 2024, https://doi.org/10.1016/j.jobe.2024.109390

-

A. Martazaev, M. Orzimatova, and M. Xamdamova, “Determination of optimum quantity of silica fume for high-performance concrete,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030012, Jan. 2025, https://doi.org/10.1063/5.0266799

-

Y. Nouri, M. A. Ghanbari, and P. Fakharian, “An integrated optimization and ANOVA approach for reinforcing concrete beams with glass fiber polymer,” Decision Analytics Journal, Vol. 11, p. 100479, Jun. 2024, https://doi.org/10.1016/j.dajour.2024.100479

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.