Abstract

The article examines how to enhance the load bearing capacity and tensile strength of the concrete structures by dispersing reinforcement using a hybrid mixture of steel and basalt fibers. This experiment used locally available coarse and fine aggregates of the Namangan area, steel and basalt fibers which were manufactured in Uzbekistan. Experimentally Residual tensile strength Residual tensile strength was tested on prismatic specimens 150×150×600 mm. The findings revealed that plain concrete failed brittlely with sudden disbanding whilst fiber-reinforced concrete failed progressively as a consequence of bridging effect of the fibers that supported the integrity of the specimen. It was found out that with an addition of content of steel fibers there was a progressive increase in residual tensile strength with the best performance being recorded at 3 % steel fibers and 0.2 % basalt fibers. The results substantiate the assumption that the joint use of steel and basalt fibers considerably increases the resistance to crack propagation, strength and ductile properties of concrete.

1. Introduction

Already after the end of the previous century and the start of the twentieth century, several research works have been actively conducted in Uzbekistan and in most of the foreign countries to enhance the quality indicators of heavy and lightweight concrete in the manufacturing of construction and building materials [1, 2]. The primary objective of the researches is to enhance the strength of the concrete, the most common material in the world and to decrease its deformability and, consequently, economic efficiency [3]. Concrete is known to be a composite material [4]. Strength and long-term reinforcement of concrete can be enhanced through a number of ways. One of them is to make it stronger by incorporating fibers of different materials into concrete and in some situations, dispersion reinforcement can be used; there are a possibility of saving steel reinforcement [5]. The manufacturing of products of dispersed reinforced concrete consisting of mixtures of basalt and steel fibers is a new trend. The peculiarities of the research in this field are the fact that Uzbekistan possesses enough reserves of raw materials in basalt and steel fibers, their low prices, and the simplicity of technology to receive basalt and steel fibers [6].

Russian and Ukrainian scientists discovered that with basalt fiber content of up to 800 kg/m3 strength of basalt fiber concrete increases and with cement content of more than 500 kg/m3, tensile strength of fiber concrete decreases [7]. Due to research works of S.A. Osadchenko, S.F. Kanaev and others, the physical and mechanical characteristics of the fiber concrete manufactured on the basis of different fibers were investigated. Besides, the economic efficiency of the dispersed reinforcement, its influence on the deformability and the durability was researched [8]. Given the research that the author conducted, the strength of the fiber concrete rose by 40-45 % and the deformability of the material fell dramatically [9, 10]. The aspects of technology of combined fiber concrete prepared on the basis of different fibers, and the analysis of the effects of steel fibers and basalt ones on its formation were mirrored in the works by numerous researchers [11]. The correlation of tensile strength and deformation of basalt fibers-reinforced concrete and steel-reinforced concrete is provided [12-14].

Despite the fact that in some countries during the twentieth century dispersed reinforcement of concrete with combined basalt and steel fibers was employed, it was not widely used due to a number of reasons. This is mainly because the properties of fiber concrete have not yet been explored completely, and conversely, it can be said that there are no sufficient raw materials locally available in making fiber concrete and thus is not economically viable. Taking into account the fact that basalt and steel fiber are already in sufficient amounts in Uzbekistan, it becomes obvious that one of the significant tasks is the detailed study of physical and mechanical properties of basalt and steel fiber fiber concrete.

Furthermore, the contemporary civil engineering constructions are being exposed to dynamic, cyclic, and seismic loads, which also play an important role in determining the cracking behavior, strain energy capacity, and long-term durability. Tensile performance is extremely vital in concrete's capability to withstand vibration stresses, impacts, and seismic forces. It is said that hybrid reinforcement with steel and basalt fiber is one of the most promising strategies towards the provision of better post-cracking behavior, better ductility, and better resistance to dynamic and fatigue loading. Thus, the tensile properties of reinforced concrete with mixed steel and basalt fibers should be studied to further the material design approaches aimed at vibration resistance, seismic safety, and the general safety of the structures. That is why the research is very topical to the applications of vibroengineering and fits the scientific scope of the current research.

2. Method

When we consider theoretical and experimental research on the stress-strain diagram of concrete, it is obvious that the application of the diagram modulates the strength, the deformability, and the long-term durability of reinforced concrete. It is worth mentioning that techniques of obtaining reinforced concrete by the complete stress-strain diagram have not yet been completely standardized and were applied in a limited number of studies. Nevertheless, the deformation diagram allows to fully evaluate the stress-strain condition at each stage even in their service life. It comes in especially handy when trying to state the association amid strain and pressure in indeterminate (statical) systems and in pressurized structural features. Special trials were done to establish the residual tensile strength of fiber-reinforced concrete that was combined and dispersely reinforced with a combination of basalt and steel fibers to use in flexural. To reinforce the concrete with the combined basalt and steel fibers in a dispersed mode, the quantity of fibers was measured on a high-precision model scale named SF-400.

Fig. 1Fine and coarse aggregates used in the experimental research work. Photo taken by Bakhtiyor Maksud Ugli at the Namangan State Technical University Laboratory, March 2025

In putting up the samples, fineness aggregate of density 1025 kg/m3, 0-6 mm particle size, and 3.1 percent moisture content were obtained in Namangan quarry of the Turakurgan district of Namangan region. Coarse aggregate was made of granite broken stone that had a density of 815 kg/m3, and a particle size of 5-24 mm. Fig. 1 indicates the appearance of the fine and coarse aggregates used to the cube specimens.

Fig. 2. These tests were done using steel fibers that are made by the ProCab Uzbekistan-UK joint venture in the region of Tashkent in Uzbekistan and basalt fiber products manufactured by the production plant in the area of Egizbuloq MFY, Forish district, Jizzakh region. Table 1 shows the properties of the fibers.

Fig. 2Appearance of a) Basalt, b) steel fibers. Photo taken by Bakhtiyor Maksud Ugli at the Namangan State Technical University Laboratory, March 2025

a)

b)

Table 1Key indicators of fiber in combination

Fiber type | Density kg/m3 | Modulus of elasticity, GPa | Tensile strength, MPa | Diameter, mm | Length, mm |

Basalt | 2650 | 90 | 30 | 0.17 | 30 |

Steel fibers | 7850 | 200 | 250 | 1.2 | 10, 20, 30 |

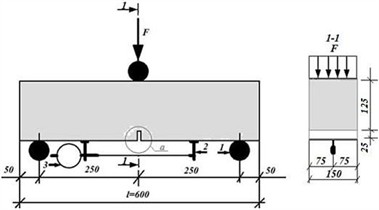

Among the primary goals, which were developed in the study, was the residual tensile strength of fiber-reinforced concrete, which was to be established via experimental examination, in compliance with the provisions of GOST 59535-2021. To this end, concrete prism specimens of 150×150×600 mm size were made in three series. Fig. 4 gives a schematic drawing of the prismatic beam specimen. Fig. 3 shows the specimens. In the process of pouring in the concrete mixtures in the specially prepared moulds, specific focus was directed in following the normal preparation procedures and in the compaction of the concrete mixture in the specimens.

Fig. 3Concrete prism specimens with added combination of steel and basalt fibers. Photo taken by Bakhtiyor Maksud Ugli at the Namangan State Technical University Laboratory, April 2025

After being cured under standard conditions, the prepared specimens were removed from the molds, labeled, and placed in a standard curing chamber where they were stored for 28 days. The prism specimens prepared for testing are shown in Fig. 3. The specimens were positioned at the center of the lower plate of the testing machine, as shown in Fig. 5. During the test, the external load was continuously increased at a rate of 0.3-0.5 MPa/s.

The failure and fracture behavior of the mixed steel-basalt fiber-reinforced concrete specimen was clearly different to plain concrete specimen. The brittle mode of failure was predominant in the case of ordinary concrete that has no fiber. The specimens began to fail immediately large cracks occurred during loading and fractured into discrete pieces, with no further load-carrying ability. Such sudden crack is characteristic of traditional concrete, which has no mechanisms to hold or close emerging cracks. In contrast, specimens of concrete that was reinforced by a mixed dispersed aggregate of steel and basalt fibers exhibited much more ductile and gradual failure process. The fiber-reinforced beams could be mainly intact even after reaching, and exceeding, the peak load. Rarely oriented fibers placed into the concrete matrix served as internal ties that basically filled cracks and stopped a sudden disintegration. The separated parts were bound together by the deformed fibers which substantially enhanced the post-cracking integrity of the specimens and retarded catastrophic failure.

Fig. 4Test scheme of the sample. Photo taken by Bakhtiyor Maksud Ugli at the Namangan State Technical University Laboratory, April 2025

Fig. 5Test scheme of the sample. Photo taken by Bakhtiyor Maksud Ugli at the Namangan State Technical University Laboratory, April 2025

Fig. 6General view of the sample after the test: a) ordinary concrete and b) fiber concrete. Photo taken by Bakhtiyor Maksud Ugli at the Namangan State Technical University Laboratory, April 2025

a)

b)

3. Results and discussion

In order to determine this behavior quantitatively, residual tensile strength tests were conducted to prismatic beam specimens- 150×150×600 mm. The relative outcome between plain and fiber-reinforced specimens showed greatly the beneficial input of fibers. As shown in Fig. 6(a) plain specimen broke sharply into two separate parts as its ultimate load bearing capacity was reached. In contrast, Fig. 6(b) indicates that at the reinforced specimens, which had the combined steel and basalt fibers, there was no full splitting even as applied force exceeded the critical capacity of the control sample. This underscores the high-toughness and crack-stifling properties the hybrid fiber system has brought.

It was possible to divide the fiber-reinforced beams loading process into four typical stages. Stage 1 was the first elastic stage. At this stage, the steel fibers were completely engaged in the matrix and no cracks were seen. The material acted like an elastic solid with the equivalent distribution of stress. The micro-cracking began in Stage 2. Cracks started appearing as local stresses, which were more than the tensile limit of the matrix, in small cracks of 0.1-0.2 mm. This phase marked the change of elastic behavior to elastoplastic one. Stage 3 was the stage of progressive crack propagation and widening when the process of fiber pull-out became more evident. The fibers started to resist the crack opening by redistribution of stresses across the crack surfaces. The last stage, stage 4, was the ultimate state that is associated with the fact that the effectiveness of fibers in bridging and relaying stresses was also highly lowered. This is where the cracks grew very fast with continued loading until they were at the neutral axis and heading towards eventual failure. The results of the experiments conducted based on these tests give scientifically significant results with direct practical applicability to structural applications. The data analysis that follows and is graphically depicted in Fig. 7-9, shows clearly the benefits of dispersed reinforcement using steel and basalt fibers. In addition, the comparative post-test results also prove that plain concrete beams are susceptible to unexpected brittle fracture whereas the hybrid fiber-reinforced concrete specimens are more ductile, have controlled cracking and greater residual load-bearing capacity.

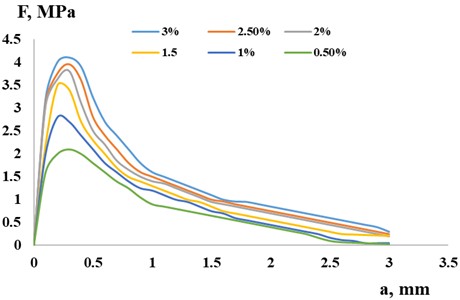

Fig. 7Tested strength properties of a prism reinforced with dispersed fibers of 0.5 %, 1.0 %, 1.5 %, 2.0 %, 2.5 %, 3.0 % in steel with a length of 10 mm and 0.2 % in basalt with a length of 30 mm

Using the analysis of experimental tests, it was established that the higher the dosage of steel fibers in the concrete mixture dispersively reinforced with a mix of 10 mm steel and 30 mm basalt fibers, the greater the residual tensile strength of the prism beams that was obtained in the experimental tests: 4.12 MPa.

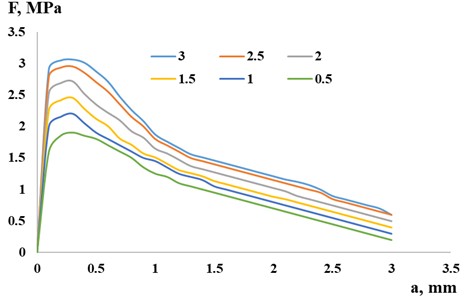

Fig. 8Tested strength properties of a prism reinforced with dispersed fibers of 0.5 %, 1.0 %, 1.5 %, 2.0 %, 2.5 %, 3.0 % in steel with a length of 10 mm and 0.2 % in basalt with a length of 30 mm

Experimental testing showed that on a concrete mix reinforced with a hybrid type of dispersion of 10 mm steel and 30 mm basalt fibers the remaining tensile capacity of the prismatic beams demonstrated progressive improvement with an increase in steel fiber content, and in laboratory tests ultimately reached a strength level of 3.12 MPa.

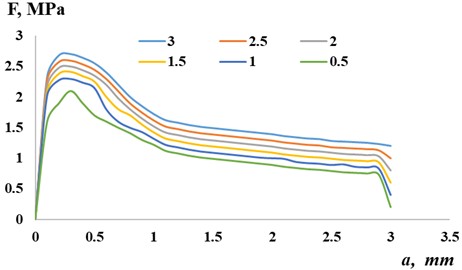

Fig. 9Tested strength properties of a prism reinforced with dispersed fibers of 0.5 %, 1.0 %, 1.5 %, 2.0 %, 2.5 %, 3.0 % in steel with a length of 10 mm and 0.2 % in basalt with a length of 30 mm

Experimental testing indicated that the tensile strength in residue of prism beams also rose with dosage of steel fibers with 2.71 MPa being the maximum tensile strength in the concrete where steel fibers are dispersively reinforced by 10 mm steel and 30 mm basalt fibers.

4. Conclusions

It was established through the extensive examination of the current literature in the field of fiber-reinforced concrete and examination of the experimental data obtained in the course of the given research project that the valuable insights could be made concerning the tensile and flexural behavior of the prismatic concrete beam specimens reinforced with steel and basalt fibers. The core findings are the following:

1) Basalt and steel fibers when added into the concrete result in an apparent enhancement of the flexural strength of the concrete.

2) When concrete was reinforced with 0.2 % basalt fibers (30 mm length) and steel fibers of 10 mm length, the tensile strength increased by 31 % at 0.5 % steel fiber dosage, 62 % at 1 %, 112 % at 1.5 %, 130 % at 2 %, 143 % at 2.5 %, and reached a maximum increase of 156 % at 3 % steel fibers.

3) When basalt fiber (30 mm length) concrete reinforced with 20 mm steel fibers was used, tensile strength increased by 18, 37, 56, 79, 84 and 93 percent at 1/2, 1.0, 1.5, 2.0, and 2.5 percent respectively as compared to plain reinforcement.

4) It was established that 10 mm, 20 mm and 30 mm were optimum steel fiber lengths that did not reduce tensile performance relative to plain concrete whereas 30 mm was the optimum basalt fiber length.

5) The best tensile strength residual (among the tested combinations) was achieved in those cases when specimens were reinforced with 10 mm steel fibers and 30 mm basalt fibers.

6) The plain concrete specimens failed suddenly and completely under load whereas the fiber-reinforced beams failed gradually with flexural cracking and this shows that they are structurally sound.

7) The load deflection response and cracking patterns established that the hybrid fiber reinforcement enhanced greatly the ductility of concrete over plain concrete.

References

-

M. U. Bakhtiyorjon and S. Razzakov, “Experimental investigation of steel fiber dispersed reinforced concrete beams,” in EPJ Web of Conferences, Vol. 318, p. 01010, Feb. 2025, https://doi.org/10.1051/epjconf/202531801010

-

A. Martazaev and S. Khakimov, “Dispersed reinforcement with basalt fibers and strength of fiber-reinforced concrete beams,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030011, Jan. 2025, https://doi.org/10.1063/5.0266797

-

R. Mavlonov and S. Razzakov, “Numerical modeling of combined reinforcement concrete beam,” in E3S Web of Conferences, Vol. 401, p. 03007, Jul. 2023, https://doi.org/10.1051/e3sconf/202340103007

-

R. Hameed, A. Turatsinze, F. Duprat, and A. Sellier, “Metallic fiber reinforced concrete: Effect of fiber aspect ratio on the flexural properties,” ARPN Journal of Engineering and Applied Sciences, Vol. 4, No. 5, 2009.

-

A. M. Baby and P. R. Reshmi, “Improving the flexural performance of concrete beams using 2D steel fibres,” International Research Journal of Engineering and Technology (IRJET), Vol. 4, No. 4, pp. 2395–56, 2017.

-

A. Jodeiri and R. Quitalig, “Effect of steel fibre on flexural capacity of reinforced concrete beam,” Civil Engineering Research Journal, Vol. 2, pp. 100–107, 2012.

-

V. Gadgihalli, Meena, Sindu, and R. P. Dinakar, “Analysis of properties of concrete using steel fibers as fiber reinforcement admixture,” International Journal of Research – GRANTHAALAYAH, Vol. 5, No. 4RASM, pp. 59–62, Apr. 2017, https://doi.org/10.29121/granthaalayah.v5.i4rasm.2017.3370

-

P. Shweta and R. Kavilkar, “Study of flexural strength in steel fibre reinforced concrete,” International Journal of Recent Development in Engineering and Technology (IJRDET), Vol. 2, No. 5, 2014.

-

A. Ghaffar, A. S. Chavhan, and D. R. S. Tatwawadi, “Steel fibre reinforced concrete,” International Journal of Engineering Trends and Technology, Vol. 9, No. 15, pp. 791–797, Mar. 2014, https://doi.org/10.14445/22315381/ijett-v9p349

-

S. Razzakov and A. Martazaev, “Mechanical properties of concrete reinforced with basalt fibers,” in E3S Web of Conferences, Vol. 401, p. 05003, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105003

-

R. Mavlonov, S. Razzakov, and S. Numanova, “Stress-strain state of combined steel-FRP reinforced concrete beams,” in E3S Web of Conferences, Vol. 452, p. 06022, Nov. 2023, https://doi.org/10.1051/e3sconf/202345206022

-

A. Martazaev, M. Orzimatova, and M. Xamdamova, “Determination of optimum quantity of silica fume for high-performance concrete,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030012, Jan. 2025, https://doi.org/10.1063/5.0266799

-

A. M. Alani and M. Aboutalebi, “Mechanical properties of fibre reinforced concrete: A comparative experimental study,” International Journal of Civil Engineering, Vol. 7, No. 9, 2013.

-

F. Altun, T. Haktanir, and K. Ari, “Effects of steel fiber addition on mechanical properties of concrete and RC beams,” Construction and Building Materials, Vol. 21, No. 3, pp. 654–661, Mar. 2007, https://doi.org/10.1016/j.conbuildmat.2005.12.006

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.