Abstract

The article presents original research results on the substantiation of the forward motion parameters of a freight train with a fixed maximum mass of the train and the main traction and operational characteristics of the energy efficiency of O’z-EL type AC freight electric locomotives on a real flat section of the railway. Energy-optimal control modes for the movement of the aforementioned freight train by electric locomotives of the O’z-EL series have been developed using the original computer hardware and software complex KORTES, and their traction and energy characteristics are presented in the form of numerical values and graphs with an error of no more than five percent compared to the practical data of the Kokand locomotive depot of the Uzbek Railway. The above results will be further used by the authors to evaluate the effectiveness of various options for energy-optimal control modes for the power equipment of the Oʼz-EL series electric locomotives when implementing freight transportation on sections of the Uzbekistan railway industry of varying complexity under real operating conditions.

Highlights

- The results of the study are recommended to specialists and engineering and technical workers of the locomotive complex, whose professional activities are related to the organization and implementation of railway freight transportation on sections of railways with a flat type of track profile.

- An original methodology for performing traction calculations implemented, based on the KORTES computer hardware and software complex and the principle of using the maximum power of the traction properties of the "Oʼz-EL" electric locomotive under study.

- An optimal trajectory for a freight train with a fixed axle load on the wheelset was providing approximately 4.33 percent savings in the amount of electrical energy consumed by the "Oʼz-EL" electric locomotive per trip, compared to similar trajectories movement of the Kokand locomotive depot.

1. Introduction

At present, finding ways and means to reduce energy consumption for train traction and reducing the prices and cost price of electric energy for the acquisition and efficient use of traction electrified railway transport still remains a pressing issue. Here the determining link is not only and not so much ensuring the carrying capacity and throughput of railways track with the minimum reduced total and specific costs of funds, how much improvement of the system of modern software information and computer technologies, which, first of all, are directly related to the creation and modeling of energy-optimal modes of driving trains with using electric traction railway vehicles.

The introduction is presented in a relatively brief manner and does not sufficiently demonstrate the standard academic logical structure (usually organized into 4-5 progressive levels). A more comprehensive discussion of the background, related literature, research gap, and study objectives would improve its clarity and scientific depth.

Russian authors propose increasing the service life of traction electric motors of vehicles by increasing the strength of their anchor bandages by improving their design [1, 2] or by using modern methods of technical diagnostics [3] in the repair production of locomotives.

The research of Russian scientists from the Tashkent Institute of Railway Engineers is devoted to the issues of the dynamics of electrical and mechanical units of traction electric motors of diesel locomotives [4] and electric machines for cotton-growing equipment [5], as well as statistical analysis of the reliability of anchors of traction electric motors of diesel locomotives [6].

The authors [7, 8] conduct research on the force loading of windings and pole terminals of traction electric machines, where they study the nature of their oscillations and propose a method for calculating the strength of terminals and pole windings, taking into account the justification of the stress values in the material of the specified pole windings.

In order to eliminate scientific “gaps” made by the authors in the analyzed sources of literature, taking into account their research objectives, the staff of the Tashkent State Transport University, together with foreign scientists, began to conduct joint research [9-12 and many others], aimed at studying the issues of modeling energy-optimal control modes for traction rolling stock, which are based on traction calculations for various types and series of locomotives.

In the study [9], the authors substantiate the kinematic parameters of the movement of a freight train of fixed mass with a constant number of axles, implemented by electric locomotives of the 3VL80S series on railway sections of varying complexity. Research [10-12] is devoted to some issues of substantiating the efficiency of use and optimization of transportation work of locomotives on virtual sections of railways.

The above is the reference point (prerequisite) on the basis of which the authors formulate the purpose of the study, outlined in the second section of this theoretical work.

2. Objects and methods of research

As a result of modernization of the JSC Uzbekistan Railways by increasing the general length of railway sections receiving electricity from power plants and by replenishing the operating fleet of locomotives with new generation electric locomotives, which include the “Oʼz-EL” and “Oʼz-ELR” electric locomotives, the average annual growth in the total volume of freight traffic is approximately 2.9 percent. Moreover, about 6.1 percent of the average annual growth in rail freight transportation is accounted for by electric traction locomotives, while at the same time, there is a decrease in freight turnover by diesel traction locomotives by 3026 million ton-km gross or, on average, by 13.72 percent per year.

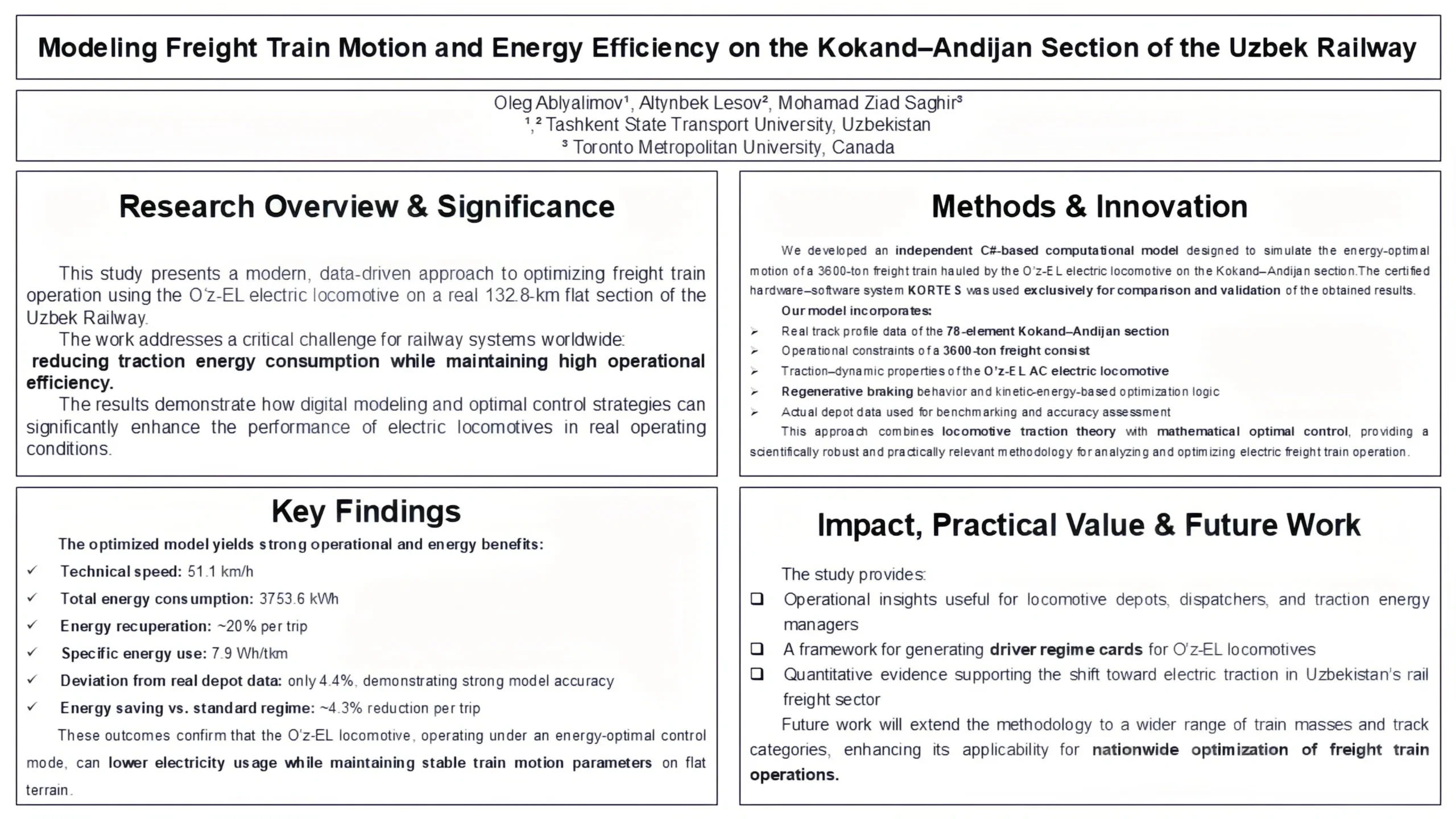

This is confirmed by the diagram in Fig. 1, which characterizes the changing dynamics of the general volume of cargo turnover in millions of gross ton-kilometers, including that carried out by mainline (train) diesel and electric traction locomotives.

Fig. 1Freight traffic work volumes diagram

A comparative analysis of energy savings in train traction based on the reporting data of the locomotive complex enterprises of the Uzbekistan Railway shows that in recent years the volume of cargo transported by electric traction locomotives of various types, types, structures and contents has gradually increased and currently accounts for approximately 79.5 percent of the general volume of freight rail transport.

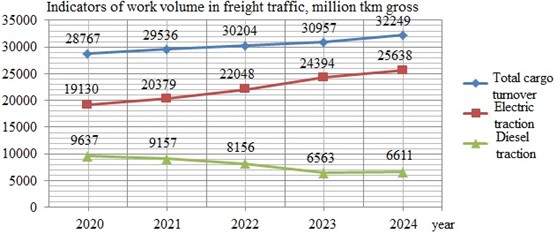

Fig. 2 shows a diagram of changes in the total energy consumption for train traction by JSC Uzbekistan Railways for 2020-2024, including for each regional railway junction of the Uzbekistan Railways, in particular.

From the analysis of the numerical values of the given diagram it is evident that the expense of electricity by electric traction locomotives increases by an average of eight percent, and the highest growth is twenty-six percent and occurs at the regional railway junction (RRJ) “Kokand”.

Fig. 2The shares of electricity consumption by mainline electric locomotives in freight traffic at regional railway hubs of the Uzbek Railways

The purpose of this research is to definition in quantitative terms and analysis the parameters of the forward motion of cargo trains and the parameters of the main indicators of energy efficiency of mainline cargo electric locomotives, based on material, technical and technological conditions of the operational activity of a real plain area of the railway track.

To achieve the stated research goal, the authors use original methodology and research techniques based on the laws of the theory of locomotive traction [13] and on the methods of the mathematical theory of optimal control of objects [14], as well as the C# (C Sharp) programming language with the development of an application layout in the Microsoft Visual Studio 12.0 programming environment [15], and besides that the object and subject of the study.

Here, the object of research is taken as is the cargo electric locomotive of the alternating current series “Oʼz-EL”, a freight train and a straightened track profile of the Kokand - Andijan area of the Uzbek Railway track.

The subject of the research is the parameters of the forward motion of a cargo train with a maximum masses of compositions 3600 t and energy efficiency indicators for the use of the specified Oʼz-EL electric locomotives, the parameters of which represent the quantitative consumption of electrical energy as a result of the implementation of rail freight transportation on the studied section of the Uzbekistan railway.

The specified electric locomotive was developed on the basis of the basic electric locomotive model HXD3C [16] by the Dalian Locomotive and Carriage Building Company (People’s Republic of China) jointly with the Japanese company Toshiba. Electric locomotives of this model are designed for hauling freight and passenger trains and have received high marks due to their high technical characteristics and high operational stability.

Such electric locomotives can be operated in the “normal” mode at ambient temperatures from –30 ℃ to + 50 ℃ in the shade and maximum air humidity not exceeding 90 percent, and their distinctive feature is the electrical transmission of alternating-direct-alternating current with contactless regulation of the speed of traction electric motors and power.

The electric locomotive is equipped with the KLUB-U safety system, which ensures the reception of signals in the automatic locomotive signaling mode (ALSN), has a digital radio channel and a satellite navigation system, and is also equipped with an on-board computer from Siemens and, together with the driver's cabin, has a modern design. This electric locomotive has two identical bogies that are interchangeable. Each bogie contains three wheel-motor units and consists of a frame, a traction device, two spring suspension stages, and primary and secondary braking systems.

The wheel-motor unit features a frame-mounted traction electric motor suspension with a single-sided gear engagement of the traction gearbox. To facilitate removal of the wheel center from the wheelset axle, a special channel is provided to supply oil to the wheelset axle hub area through the wheel center.

At present, the introduction of the “Oʼz-EL” series electric locomotives into the practice of operation of railway sections, including Uzbek ones, receiving electricity supply from electric power stationselectrified sections has yielded a significant economic effect, in particular, the labor intensity of the work has been reduced by twenty-five percent with a decline in the consumption of electrical energy for each trip, on average, by ten percent due to the use of regenerative braking mode [9, 17].

The 132.8-kilometer section of the Kokand-Andijan railway contains seventy-eight elements. The specified “plain” section represents the 1st type of track profile, since here the share of track profile elements with light elements, characterized by areas with a slope of 0 ‰ and slopes from +3.0 ‰ to –3.0 ‰, is 68.9 percent the entire length of the area being studied (investigated) [18].

The above is fully consistent with the classification structure of the railway track profile [19], which is presented in Table 1.

Table 1Classification of railway sections according to the degree of difficulty of their route profile

No. | Path profile characteristic | |||

Category | Percentage of light elements, % | Type | Calculated rise, ‰ | |

1 | 2 | 3 | 4 | 5 |

1. | Flat | More than 60 | First | 4.0-7.0 |

2. | Hilly | 60 (less) – 40 (more) | Second | 5.0-9.0 |

3. | Hilly-mountainous | 40 (less) – 30 (more) | Third | 7.0-10.0 |

4. | Mountainous | Less than 30 | Fourth | 9.0-12.0 and more |

On this section there are ten intermediate separate points, including six stations – Art. Furkat, st. Altyaryk, st. Margilan, st. Akhunbabaeva, st. Kuva and st. Asaka, four sidings – rzd. Kakir, rzd. Mehnatabad, rzd. Akbarabad and rzd. Akhtachi, as well as two junction stations – Kokand and Andijan-1. Speed limits for freight trains on the highway. Kakir, st. Furkat and Art. Kuva is 60 km/h, and according to Art. Kokand, st. Altyaryk, st. Margilan, st. Akhunbabaeva, st. Asaka and Art. Andijan-1 – 40 km/h. The maximum speed motion (driving) limit for a cargo train on the area of railway in question is 60 km/h.

3. Results and their discussion

The stated objective of the study was achieved by conducting a traction-energy calculation for the studied freight electric locomotive “O'z-EL” of alternating current on the existing flat area of Kokand-Andijan of Uzbek railway track using of the computer software package KORTES, which was based on the nominal position of the еlectric locomotive driver controller in combination with the idle and braking modes.

The computer software package KORTES, developed by VNIIZhT [20, 21], allows for calculations of the consumption diesel fuel and losses of electrical energy, as well as the parameters of the traction power supply system with an assessment of energy consumption for various modes of operation and train schedules.

The specified hardware and software complex KORTES provide the ability to model and process data in real time and contains three main functional modules - input data, calculation and optimization, and a module that provides graphical and tabular display of results.

The initial data for the specified calculations are [18, 19]: track profile; maximum permissible speed on the section (, km/h); wagon type; wagon tare mass (, t); wagon rated length (, m); number of wagon axles (, units); wagon carrying capacity (, t); wagon loading factor (); length of receiving and dispatching tracks (, m); type of electric locomotive; estimated tractive force of the electric locomotive (, kN); estimated speed of the electric locomotive (, km/h); estimated mass of the electric locomotive (, t); estimated length of the electric locomotive (, m).

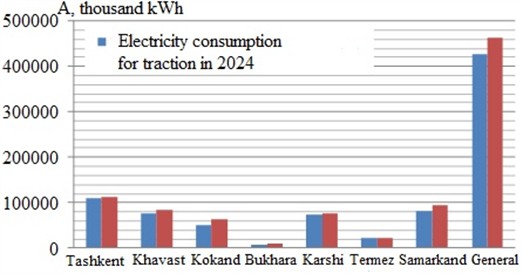

The results of energy, traction-operational and traction calculations on Kokand-Andijan section for the freight electric locomotive “Oʼz-EL”, obtained by the KORTES computer software package, are shown, respectively, in Table 2, Table 3 and Fig. 3.

Table 2Traction and energy calculation data on the flat section Kokand – Andijan for the freight electric locomotive of the alternating current series “O’z-EL”

Block section | Length, km | Travel time, min | Energy consumption | |

kWh | kVAh | |||

Kokand-Kakir | 11.0 | 14.5 | 867.9 | 986.2 |

Kakir-Furkat | 15.0 | 15.8 | 113.7 | 422.3 |

Furkat-Altyaryk | 26.0 | 30.1 | 636.8 | 776.9 |

Altyaryk-Margilan | 18.0 | 20.4 | 942.7 | 1072.9 |

Margilan-Akhun | 4.0 | 5.5 | 142.9 | 166.9 |

Akhun-Kuva | 27.0 | 30.6 | 359.0 | 860.9 |

Kuwa-Asaka | 15.0 | 17.3 | 276.1 | 345.7 |

Asaka-Akhtachi | 7.0 | 9.6 | 54.8 | 66.8 |

Akhtachi-Andijan | 9.0 | 11.2 | 359.6 | 428.9 |

Kokand-Andijan | 132.0 | 155.0 | 3753.6 | 5127.7 |

Note | ||||

Railway company | “O’zbekiston Temir Yo’llari” | |||

Section | Kokand-Andijan | |||

Track type | Continuous welded | |||

Train | Freight, weight 3600 t, locomotive O'z-El | |||

Energy consumption | 3753.6 kWh; recuperation 751.3 kWh; (20%) | |||

Specific consumption | active 7.9 Wh/tkm; full 10.8 VAh/tkm | |||

Technical speed | 51.1 km/h | |||

Max. train current | 317 A per km 83.83 | |||

Table 3Indicators of the “O’z-EL” series AC freight electric locomotives on the Kokand-Andijan area of Uzbek Railway track

Traction calculation option | Speed motion and travel driving time of the train | Electrical energy consumption | ||||

Technical speed h, km/h | Total min | Divergence , min | Total | Specific | Deviation | |

Per trip , kWh | Specifical , Wh/tkm gross | Specific , % Wh/tkm gross | ||||

1 | 2 | 3 | 4 | 5 | 6 | 7 |

According to LOD* [16] | 50.3 | 158.4 | – | 3923.6 | 8.21-8.26 | – |

According to the KORTES program | 51.4 | 155.0 | 3.4 | 3753.6 | 7.85-7.90 | 4.33-4.55 |

A comparative analysis of the data in Table 2 and Table 3 shows that the recovery of electrical energy back into the contact network for the energy-optimal mode of operation of a freight train is about 20 percent of the total consumption for train traction per trip, moreover, the technical speed of movement and the total travel time of the train on the studied section of the railway are approximately at the same level and amount to 2.14-2.19 percent, and the specific consumption of electrical energy, according to the Kokand locomotive depot, exceeds the recommended one by an average of 4.57 percent.

Analysis of the data in Table 3 confirms sufficient validation (on average, 4.43 percent), that is, a fairly high correspondence between the obtained data on the energy-optimal mode of operation of a freight train and the actual (experimental) data of the Kokand locomotive depot of JSC Uzbekistan Railways.

Fig. 3Fragment of traction calculation on the flat section Kokand-Andijan for the AC electric locomotive of the “O’z-EL” series

4. Conclusions

An analysis of the results of the conducted research showed that the set research objective was successfully achieved and the following conclusions were formulated.

1) An original methodology for performing traction calculations has been implemented, based on the KORTES computer hardware and software complex and the principle of using the maximum power of the traction properties of the “Oʼz-EL” electric locomotive under study, taking into account the kinetic energy of the train’s movement.

2) An optimal trajectory for a freight train with a fixed axle load on the wheelset was obtained depending on the path traveled on a real, flat section of the Uzbek railway, providing approximately 4.33 percent savings in the amount of electrical energy consumed by the “Oʼz-EL” electric locomotive per trip, compared to similar trajectories movement of the Kokand locomotive depot.

3) The obtained numerical values of the parameters characterizing the forward motion of a freight train and the traction and energy qualities (properties) of an “Oʼz-EL” type freight electric locomotive for the existing conditions of organizing railway freight transportation on the Kokand-Andijan section of the Uzbek railway, have fairly good convergence with the results of previously conducted studies [9, 11, 12, 19], including taking into account indirect results [22, 23] on diesel engines and practical data from the Kokand locomotive depot of JSC Uzbekistan Temir Yollari, the error of which does not exceed the permissible five percent barrier.

4) Although the research methodology has been confirmed by a relatively high level of validation, nevertheless, from the point of view of optimal vehicle traffic management, additional constraint assessments will provide reliable and valuable information that predicts and predicting the formation of energy-optimal operating modes for locomotives of electric traction, taking into account the traction-energy and operational efficiency of their use in freight traffic conditions.

5) Taking into account the established restrictions on the weight standards of freight trains and the length of receiving and departure tracks, these studies need to be continued for a wider range of freight train masses taking into account the development of regime cards for driving freight trains using “Oʼz-EL” electric locomotives on the flat Kokand-Andijan section of the Uzbek Railway.

6) The results of the study are recommended to specialists and engineering and technical workers of the locomotive complex, whose professional activities are related to the organization and implementation of railway freight transportation on sections of railways with a flat type of track profile.

References

-

G. V. Strokov, “Improving the design of anchor bands for traction electric motors of locomotives,” Moscow, 1999.

-

V. I. Kiselev and G. V. Strokov, “Methods of calculating anchor bands of traction electric motors of transport electric machines for strength,” Moscow, TSNIITEI MPS. No. 6134 railway 97, 1997.

-

A. P. Semenov, “Development of a model for managing the life cycle of locomotives using modern methods of technical diagnostics,” News of the Trans-Siberian Railway, Vol. 3, No. 43, pp. 58–65, 2020.

-

A. D. Glushchenko and V. I. Yushko, Dynamics of Traction Electric Motors of Diesel Locomotives. Tashkent: Fan, 1990.

-

A. Glushchenko, M. Tashpoltaev, and O. Ablyalimov, “Methods of evaluating cotton harvesting machines,” Khlopok, Vol. 69, No. 4, pp. 25–28, 1990.

-

G. V. Gladilov, V. I. Romanov, and R. Mukhin, “On the reliability of the anchors of traction electric motors of locomotives,” in Issues of Improving the Reliability of Traction Engines of Locomotives, 2007, pp. 62–65.

-

H. H. Tulchinskaya, “Method of calculating voltages in wires and terminals of pole windings of traction electric motors of locomotives,” Proceedings of TashIIT, No. 166, pp. 22–30, 2002.

-

A. D. Glushchenko and H. H. Tulchinskaya, “Substantiation of the parameters of the structures of high-strength terminals for magnetic systems of electric motors of diesel locomotives,” Proceedings of TashIIT, No. 146, pp. 6–12, 1998.

-

B. Gayratov and D. Insapov, “On the kinematic parameters of the movement of a freight train on various sections of railways,” in 6th International Scientific Conference Construction Mechanics, Hydraulics and Water Resources Engineering (CONMECHYDRO 2024), Vol. 3286, p. 060007, Jan. 2025, https://doi.org/10.1063/5.0279777

-

O. Ablyalimov, “Optimization of transport operation of diesel locomotives,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 060002, Jan. 2025, https://doi.org/10.1063/5.0266946

-

O. Ablyalimov, “Efficiency of locomotives of electric tractions on hilly section of railway,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 060004, Jan. 2025, https://doi.org/10.1063/5.0266948

-

O. Ablyalimov, “Towards substantiation of optimal train traffic control modes on various sections of railway,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 060030, Jan. 2025, https://doi.org/10.1063/5.0266949

-

S. I. Osipov, S. S. Osipov, and V. P. Feoktistov, Theory of Electric Traction. Moscow: Route, 2006.

-

V. G. Boltyansky, Mathematical Methods of Optimal Control. Ripol Classic, 2013.

-

A. T. Lesov and V. O. Ivashchenko, “Energy optimization of train movement modes in the language of C # program,” Proceedings of Petersburg Transport University, Vol. 2021, No. 4, pp. 480–490, Dec. 2021, https://doi.org/10.20295/1815-588x-2021-4-480-490

-

“On the powerful electric locomotive with alternating current drive type SKE 1: training materials for preparation,” Uzbekistan State Railway, Tashkent, 2013.

-

A. B. Vasil’Ev, A. G. Kotenko, and V. V. Prokof’Eva, “Development of the algorithm of the train dispatchers decision-making support when organising train traffic,” (in Russian), Volga Region Transport Bulletin, No. 1, pp. 52–56, 2014.

-

O. Ablyalimov, S. Petrochenko, and N. Kodirov, “Analyzing the movement of a freight train at stops on flat sections of the railway,” in Lecture Notes in Networks and Systems, Cham: Springer International Publishing, 2022, pp. 165–171, https://doi.org/10.1007/978-3-031-11051-1_16

-

O. Ablyalimov, “Towards the development of regime cards for driving trains using of locomotives of diesel tractions,” in E3S Web of Conferences, Vol. 621, p. 03006, Mar. 2025, https://doi.org/10.1051/e3sconf/202562103006

-

S. M. Ovcharenko, I. S. Ring, and S. S. Ovcharenko, “Study of temperature conditions of diesel locomotive cooling systems during operation,” Transsib News, Vol. 2 No. 50, pp. 116–123, 2022.

-

P. A. Kozlov, O. V. Osokin, and V. S. Kolokolnikov, “Study of railway station and landfill development projects using simulation modeling,” Railway transport, No. 6, pp. 12–16, 2018.

-

M. D. Garipov, R. Y. Sakulin, and D. R. Rezvanov, “Characteristics of a two-stroke spark-ignition engine when running on diesel fuel,” Vestnik UGATU, Vol. 21, No. 2(76), pp. 30–41, 2017.

-

R. M. Bashirov, F. R. Safin, and R. Z. Magafurov, “Improving the method of regulating diesel fuel equipment,” Vestnik AGAU, Vol. 6, No. 152, pp. 158–163, 2017.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.