Abstract

The thermal condition of power transformers is a critical factor influencing insulation aging and overall operational reliability, especially under varying load and environmental conditions. Accurate forecasting of transformer temperature enables preventive maintenance and supports the development of intelligent monitoring systems within smart grid environments. In this study, an Adaptive Neuro-Fuzzy Inference System (ANFIS) model is developed to predict transformer temperature based on ambient temperature and load factor. The proposed ANFIS model is trained and validated using experimental field data and its performance is benchmarked against a classical linear regression model. The comparative evaluation demonstrates that the ANFIS model provides superior accuracy, achieving RMSE = 0.89 °C, MAE = 0.75 °C, and 0.987, whereas the regression model yields RMSE = 1.95 °C, MAE = 1.63 °C, and 0.871. These results indicate that ANFIS effectively captures nonlinear thermal dynamics that cannot be represented by linear approximation methods. The study highlights the suitability of the proposed approach for real-time transformer thermal monitoring and its potential integration into smart grid-based predictive maintenance and asset health management frameworks.

Highlights

- An adaptive neuro-fuzzy inference system (ANFIS) is proposed for accurate prediction of the thermal state of oil-filled power transformers under real operating conditions.

- The developed model effectively captures nonlinear thermal dynamics using only ambient temperature and load factor as input variables.

- Comparative analysis demonstrates that the ANFIS model significantly outperforms classical linear regression, achieving RMSE = 0.89 °C, MAE = 0.75 °C, and R² = 0.987.

- High prediction accuracy is obtained even with a limited real-world dataset, confirming the data efficiency and robustness of the proposed approach.

- The proposed ANFIS-based framework is suitable for real-time thermal monitoring, predictive maintenance, and integration into smart grid asset management systems.

1. Introduction

Power transformers are essential components of electrical power transmission and distribution networks, and their long-term operational reliability is largely determined by their thermal condition. Excessive temperature accelerates insulation degradation, leading to a reduction in transformer lifespan and an increased likelihood of unexpected failures. According to the Arrhenius thermal aging law, even a slight rise in operating temperature significantly reduces insulation service life, emphasizing the importance of accurate thermal monitoring and forecasting in transformer asset management [1-5]. The temperature of a transformer is mainly influenced by ambient environmental conditions and load variations. However, the relationship between these factors and internal thermal response is inherently nonlinear and dynamic, especially under fluctuating load profiles or sudden environmental changes. Traditional analytical and regression-based models often assume simplified linear behavior, which limits their applicability in real operating conditions and weakens real-time predictive performance [5-7]. In recent years, computational intelligence methods have been increasingly applied in transformer monitoring systems to address nonlinear parameter interactions. Among these methods, the Adaptive Neuro-Fuzzy Inference System (ANFIS) is particularly notable due to its hybrid structure combining fuzzy inference with neural network learning capabilities. ANFIS does not require an explicit physical model and can adapt to operational data, making it suitable for real-time condition evaluation and predictive maintenance.

Although various ANN and statistical modeling approaches have been applied to transformer thermal analysis, existing studies often require large datasets or complex training procedures. There is still a need for a compact, interpretable, and accurate model capable of operating in real-time with limited measurement input.

The purpose of this study is to develop and evaluate an ANFIS-based model for predicting transformer temperature using ambient temperature and load factor measurements obtained in real operating conditions. The performance of the proposed model is compared with a classical linear regression model to demonstrate its advantages in capturing nonlinear thermal dynamics.

The novelty of this research lies in:

1) Demonstrating that reliable thermal prediction can be achieved using a small real-world dataset by employing an adaptive neuro-fuzzy inference structure.

2) Integrating the model output framework for potential deployment in smart grid monitoring systems and predictive maintenance platforms.

3) Showing that ANFIS significantly improves prediction accuracy compared to conventional regression, particularly under varying load conditions.

Thus, the results presented in this study contribute to the development of intelligent transformer health assessment solutions and support the transition toward smart, self-diagnostic power infrastructure.

2. Materials and methods

This study aims to assess the thermal state of oil-filled power transformers and to develop a predictive model for transformer temperature variations under operational load conditions. The research utilizes historical measurement data obtained from periodic diagnostics and continuous monitoring systems. The dataset includes transformer load factor, ambient temperature, oil temperature, and other relevant insulation condition indicators [10-13]. Prior to modeling, the raw data were subjected to preprocessing steps, including noise filtering, normalization, and statistical smoothing, in order to improve data consistency and minimize measurement uncertainty [7-10].

To model the nonlinear and partially uncertain relationship between the influencing factors and the resulting temperature response, the Adaptive Neuro-Fuzzy Inference System (ANFIS) was employed. ANFIS integrates the learning capability of artificial neural networks with the rule-based interpretability of fuzzy logic inference. This hybrid nature enables the model to capture complex nonlinear dynamics while maintaining a logically transparent structure [8-9].

Transformer thermal behavior is influenced by multiple interacting variables, many of which exhibit nonlinear dependencies and uncertain fluctuations. Traditional neural networks, while powerful in approximation, generally lack interpretability and depend heavily on large training datasets. On the other hand, classical fuzzy inference systems provide transparency but do not possess intrinsic learning mechanisms and therefore require expert-defined membership functions and rule sets.

ANFIS provides a suitable compromise between these two approaches. Its advantages are summarized in Table 1.

Table 1Comparative evaluation of neural networks, fuzzy logic, and ANFIS for transformer temperature prediction

Criterion | Neural networks | Fuzzy logic system | ANFIS (selected approach) |

Nonlinear system modeling | High | Moderate | High |

Interpretability of model structure | Low | High | High |

Ability to learn from data | High | None | High |

Handling uncertainty and imprecision | Moderate | High | High |

Given these considerations, ANFIS was selected as the optimal modeling approach to describe the transformer thermal processes where uncertainties, measurement errors, and nonlinear effects are significant.

The ANFIS model was implemented using the MATLAB Fuzzy Logic Toolbox. The available dataset was randomly divided into training (70 %) and testing (30 %) subsets to ensure robust performance evaluation. The hybrid learning algorithm, combining least-squares estimation and backpropagation, was used to optimize membership functions and rule parameters. The model input variables included transformer load factor and ambient temperature, while the output variable represented the predicted oil temperature.

Model performance was evaluated using standard error metrics, including the Mean Squared Error (MSE) and Coefficient of Determination (R²), to quantify both accuracy and predictive reliability.

The ANFIS model includes a Sugeno-type fuzzy logic system and artificial neural networks. Its structure consists of 5 layers [1-6]:

– 1st layer. Fuzzification.

Each input parameter (e.g., , ) is decomposed into fuzzy sets. The Gaussian (normal) membership function is used:

where: – center (center of the MF), – dispersion (degree of distribution).

– 2nd layer. Rule activity level.

Each rule is expressed by the power of activity: .

– 3rd layer. Normalization

Relative value of activity forces:

– 4th layer. Output function.

The output function of each rule based on the Sugeno model: .

Final output in normalized form: .

– 5th layer. Aggregation.

The final model output is determined as follows:

According to their ambient temperature, load factor, ANFIS model was generated successfully to predict the transformer temperature. Looking at Table 2, a 15-hour data set is used in this study.

The data for model training were brought to the interval [0;1] based on the following normalization formula:

3. Results and discussion

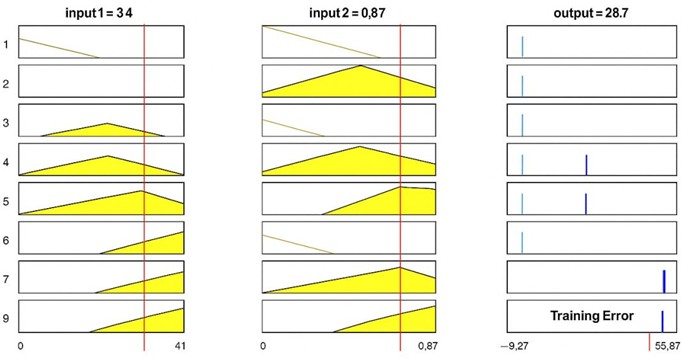

The ANFIS model was successfully developed using MATLAB to predict transformer temperature based on ambient temperature and load factor. The fuzzy rules and membership functions generated by the model were visualized in Fig. 1, showing the structure and interaction of the fuzzy sets for the input variables. This visualization confirms that the model captures the underlying nonlinear relationships between the inputs and the output.

Table 2Data obtained as a result of experimental studies

Time, hour | Ambient temp, °C | Load factor | Transformer temp, °C |

8-00 | 24 | 0.6 | 56.2 |

9-00 | 25 | 0.7 | 58.1 |

10-00 | 28 | 0.68 | 60.3 |

11-00 | 31 | 0.7 | 62.1 |

12-00 | 33 | 0.83 | 65 |

13-00 | 36 | 0.85 | 67.2 |

14-00 | 40 | 0.86 | 70.3 |

15-00 | 41 | 0.87 | 70 |

16-00 | 38 | 0.84 | 68.5 |

17-00 | 34 | 0.67 | 63.2 |

18-00 | 29 | 0.7 | 64.3 |

19-00 | 26 | 0.65 | 59.1 |

20-00 | 24 | 0.61 | 58.1 |

21-00 | 23 | 0.69 | 56.3 |

22-00 | 22 | 0.62 | 55.2 |

Fig. 1Fuzzy rule visualizer showing the activity and mapping of fuzzy sets for each input variable

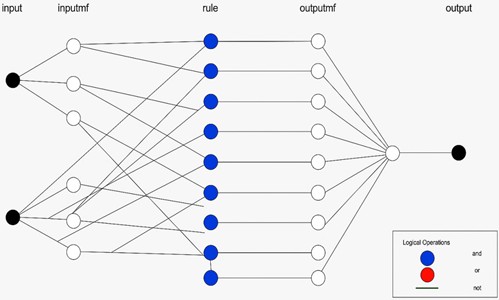

The detailed architecture of the neuro-fuzzy inference system is illustrated in Fig. 2. The diagram highlights the five-layer ANFIS structure – fuzzification, rule activity, normalization, rule-based output, and aggregation – demonstrating how the input parameters are transformed into the predicted transformer temperature. This structural representation provides transparency into the inference process and justifies the use of ANFIS over purely statistical models for handling nonlinear and uncertain data.

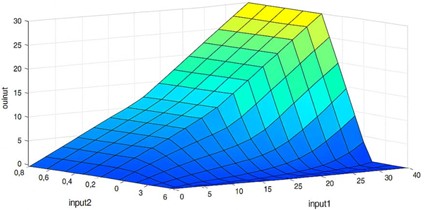

The resulting fuzzy inference surface is presented in Fig. 3, illustrating how the transformer temperature varies with changes in ambient temperature and load factor. The surface clearly indicates the nonlinear dependency between the variables, with steeper gradients at higher load factors and elevated ambient temperatures. This confirms that simple linear regression models would not be able to accurately capture such behavior, particularly during periods of rapid load changes or temperature fluctuations.

Quantitative evaluation of the ANFIS model demonstrated high predictive accuracy. The model achieved a Root Mean Square Error (RMSE) of 0.89 °C, Mean Absolute Error (MAE) of 0.75 °C, and a coefficient of determination () of 0.987. By comparison, a classical linear regression model applied to the same dataset produced RMSE = 1.95 °C, MAE = 1.63 °C, and 0.871. These results confirm that the ANFIS model more effectively captures the nonlinear dynamics of transformer thermal behavior.

Fig. 2Neuro-fuzzy inference structure for predicting transformer temperature, showing the five-layer processing of inputs to outputs

Fig. 3Fuzzy inference surface showing the predicted transformer temperature as a function of ambient temperature and load factor

The improved accuracy of ANFIS is attributed to its hybrid structure, which combines adaptive learning with fuzzy reasoning, allowing the model to adjust membership functions and rule outputs automatically based on real operational data. This adaptability makes the ANFIS approach particularly suitable for real-time monitoring and integration into smart grid systems, where accurate prediction of transformer temperature is essential for preventive maintenance and system reliability.

Overall, the results demonstrate that the ANFIS-based model provides a robust and reliable approach for transformer thermal prediction, outperforming classical regression methods, and offering significant potential for deployment in intelligent energy management frameworks.

For comparative analysis, a multiple linear regression (MLR) model was developed to predict the transformer oil temperature () based on two influencing parameters – the ambient temperature () and the load factor (). The general form of the regression model is expressed as: , where: – predicted transformer temperature (°C), – ambient temperature (°C), – load factor, , , – regression coefficients estimated using the least squares method.

Using the dataset presented in Table 2, the optimal regression coefficients were obtained as: 1.325, 12.47, 22.18.

Thus, the final regression equation used in this study is: .

The regression model was implemented in MATLAB using the fitlm() function, and its statistical parameters are summarized in Table 3.

The results show that both predictor variables – ambient temperature and load factor – have a positive correlation with transformer temperature, confirming that temperature increases with both higher load and ambient conditions. However, the linear model’s limited flexibility causes it to underestimate temperature at high load and temperature combinations, as shown in Fig. 4.

Table 3Statistical evaluation of the linear regression model

Parameter | Value | Description |

RMSE | 1.95 °C | Root mean square error |

MAE | 1.63 °C | Mean absolute error |

R² | 0.871 | Coefficient of determination |

F-statistic | 58.21 | Significance of regression |

p-value | < 0.001 | Model significance |

Although the regression model provides a reasonable first-order approximation of thermal behavior, it assumes a strictly linear dependency, which does not accurately represent the nonlinear thermal interactions occurring inside the transformer. This limitation motivates the use of the ANFIS model, which adaptively captures such nonlinearities and dynamic relationships between parameters.

The comparative analysis (Fig. 4) clearly demonstrates that ANFIS yields smaller prediction errors (RMSE = 0.89 °C vs. 1.95 °C for regression) and achieves a higher coefficient of determination (0.987 vs. 0.871). Therefore, the ANFIS model can be considered a more robust and accurate approach for real-time transformer thermal state estimation.

Fig. 4Comparison of measured transformer temperature with ANFIS and linear regression predictions

Fig. 4 compares the predicted temperatures from the ANFIS and linear regression models against the measured values. The linear regression model underestimates or overestimates temperature during periods of rapid load change or high ambient temperatures, highlighting its limitations in capturing nonlinear thermal dynamics.

The comparative analysis clearly demonstrates the superiority of ANFIS in capturing complex nonlinear relationships between transformer operating parameters and temperature. While linear regression provides a rough approximation, it fails to accurately model variations under extreme or rapidly changing operating conditions.

The ANFIS model’s ability to adapt membership functions and rule outputs based on real data allows it to predict transformer temperature with high precision even using a relatively small dataset. This makes ANFIS particularly suitable for real-time monitoring, predictive maintenance, and integration into smart grid management systems.

Overall, the results confirm that ANFIS not only improves prediction accuracy but also provides a flexible and interpretable framework for transformer thermal monitoring, whereas linear regression is limited to linear trends and less reliable in dynamic operating scenarios.

4. Conclusions

In this study, an Adaptive Neuro-Fuzzy Inference System (ANFIS) model was developed to predict the temperature of oil-filled power transformers based on ambient temperature and load factor. The model was trained and validated using experimental data collected over a 15-hour period, and its performance was compared with a classical linear regression approach.

The results demonstrate that the ANFIS model accurately captures the nonlinear relationship between transformer operating conditions and temperature, outperforming the linear regression model in both prediction accuracy and robustness under fluctuating load and environmental conditions. Specifically, the ANFIS model achieved RMSE = 0.89 °C, MAE = 0.75 °C, and 0.987, whereas the linear regression model yielded RMSE = 1.95 °C, MAE = 1.63 °C, and 0.871. These findings confirm that ANFIS provides a reliable and interpretable framework for transformer thermal monitoring.

Furthermore, the study highlights the potential application of the ANFIS model in real-time monitoring, predictive maintenance, and smart grid integration. By accurately forecasting transformer temperature, the model can support preventive interventions, optimize cooling strategies, and enhance the operational reliability of power systems.

Overall, this research demonstrates the novelty and practical value of combining neuro-fuzzy learning with transformer temperature prediction. The proposed ANFIS-based approach provides a flexible, high-accuracy, and data-efficient solution for intelligent energy system management, representing a significant improvement over conventional linear modeling techniques.

References

-

E. T. Mharakurwa and D. W. Gicheru, “Transformer hot spot temperature estimation through adaptive neuro fuzzy inference system approach,” Heliyon, Vol. 10, No. 4, p. e26338, Feb. 2024, https://doi.org/10.1016/j.heliyon.2024.e26338

-

M. Hosseinkhanloo, N. T. Kalantari, V. Behjat, and S. N. Ravadanegh, “Utilizing machine learning for transformer relative aging rate prediction based on aging parameters,” Array, Vol. 27, p. 100433, Sep. 2025, https://doi.org/10.1016/j.array.2025.100433

-

D. L. Alvarez, S. R. Rivera, and E. E. Mombello, “Transformer thermal capacity estimation and prediction using dynamic rating monitoring,” IEEE Transactions on Power Delivery, Vol. 34, No. 4, pp. 1695–1705, Aug. 2019, https://doi.org/10.1109/tpwrd.2019.2918243

-

R. A. Prasojo, K. Diwyacitta, Suwarno, and H. Gumilang, “Transformer paper expected life estimation using anfis based on oil characteristics and dissolved gases (Case Study: Indonesian Transformers),” Energies, Vol. 10, No. 8, p. 1135, Aug. 2017, https://doi.org/10.3390/en10081135

-

B. A. Thango and P. N. Bokoro, “A technique for transformer remnant cellulose life cycle prediction using adaptive neuro-fuzzy inference system,” Processes, Vol. 11, No. 2, p. 440, Feb. 2023, https://doi.org/10.3390/pr11020440

-

J. Feng, Z. Feng, G. Jiang, G. Zhang, W. Jin, and H. Zhu, “A prediction method for the average winding temperature of a transformer based on the fully connected neural network,” Applied Sciences, Vol. 14, No. 15, p. 6841, Aug. 2024, https://doi.org/10.3390/app14156841

-

Y. Zhou et al., “Using adaptive neuro-fuzzy inference system for predicting thermal conductivity of silica – MWCNT-alumina/water hybrid nanofluid,” Materials Today Communications, Vol. 37, p. 107612, Dec. 2023, https://doi.org/10.1016/j.mtcomm.2023.107612

-

E. I. Amoiralis, M. A. Tsili, and A. G. Kladas, “Transformer design and optimization: a literature survey,” IEEE Transactions on Power Delivery, Vol. 24, No. 4, pp. 1999–2024, Oct. 2009, https://doi.org/10.1109/tpwrd.2009.2028763

-

W. H. Tang and Q. H. Wu, “Condition monitoring and assessment of power transformers using computational intelligence,” in Power Systems, London: Springer London, 2011, pp. 74–89, https://doi.org/10.1007/978-0-85729-052-6

-

D. P. Rommel, D. Di Maio, and T. Tinga, “Transformer hot spot temperature prediction based on basic operator information,” International Journal of Electrical Power and Energy Systems, Vol. 124, p. 106340, Jan. 2021, https://doi.org/10.1016/j.ijepes.2020.106340

-

D. T. Yusupov, A. B. Muminov, A. B. Sa’Dullayev, A. E. Norboev, and O. E. Babaev, “Analysis of drying methods of oil-oiled power transformers,” in E3S Web of Conferences, Vol. 524, p. 01017, May 2024, https://doi.org/10.1051/e3sconf/202452401017

-

D. T. Yusupov, A. B. Muminov, A. I. Nosirov, U. T. Berdiev, and O. M. Kutbidinov, “Development of an algorithm of processes for cleaning power transformer oil in a circulatory way,” in 15th International Conference on Thermal Engineering: Theory and Applications, ICTEA 2024, 2024.

-

D. Yusupov, M. Muhammadyusuf, U. Berdiev, O. Kutbidinov, and D. Abdurakhimov, “Development of the algorithm of additional cooling process for oil power transformers with ONAN cooling system,” in ICTEA: International Conference on Thermal Engineering, Vol. 1, No. 1, Jun. 2024.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.