Abstract

This article focuses on the mathematical modeling of counter-rail transportation processes, examining the parameters of forces acting on vehicles transported on railway platforms. It aims to improve the mathematical model of fastening conditions in counter-rail transportation, considering various factors, and to develop a device for securing vehicles to railway platforms. The shear strength of the fastening device must not be less than the calculated shear forces. By determining the values of individual forces acting on each fastening device, the correct number of fastening points can be established. In addition to the continuous forces acting on the load, centrifugal force during curves and turns is also considered when calculating the fastening devices. The total forces experienced by the fastening devices due to the combined effects of “shear” and “holding” forces on the load placed on the platform are determined. Considering that the longitudinal displacement and transverse vibration of vehicles depend on their design, surface characteristics, speed, radius of curvature, and coefficient of friction, the values of individual forces acting on each of the fasteners were calculated.

Highlights

- Using this method, taking into account the strength limit of the fastening device, it is possible to choose the material based on the distance of displacement of the load, the total number of fastening devices, the number of wires, the diameter of the wire, and the degree of stiffness.

- It has been established that an increase in fastening means leads to a decrease in the displacement distance of the load.

- In this case, when the number of fasteners is 2, the displacement distance is 30 mm, when there are 3, the displacement distance is 20 mm, and when there are 4, the displacement distance is about 15 mm.

- The resulting formula allows for a more accurate, safe and reliable choice of technology for securing a vehicle to a platform during counter-trailer transportation.

1. Introduction

Research is being conducted worldwide to implement various tasks in the transportation sector. These include applying new technologies to ensure cooperation between different modes of transport, identifying potentially promising future routes, planning cargo transportation on both local and international routes, developing transportation based on service capabilities, effectively utilizing existing station capacities, and designing cargo area complexes and new terminals suitable for the logistics services market. In this context, research on the use of piggyback transportation in railway systems is considered a priority as the best solution to existing problems in road and rail transport. Currently, measures are being taken in our country to develop the transport sector, particularly to further enhance the capabilities of railway transport in the field of freight transportation within multimodal systems. One of the urgent tasks is to organize environmentally friendly and timely “door-to-door” cargo delivery without reloading, losses, or damage. There are numerous problems awaiting solutions in this field. Specifically, to ensure traffic safety, it is necessary to develop technical specifications for these transportation methods and establish fastening regulations in accordance with local standards.

2. Analysis literature and methodology

The primary requirements for cargo transportation involve verifying stability criteria to ensure the safe arrival of goods at their destination. Shippers must select an effective securing method and conduct the transportation while considering all factors that may affect the cargo’s delivery to its destination. The research work of several scientists on this subject has been examined [1-3].

Drawings depicting the placement and securing of vehicles in open traffic formations, as well as proposals for determining the stresses on the fastening components resulting from their displacement and vibration, were examined in scientific research [4-6].

A number of studies have been conducted to determine the movement of trains on railway curves and their displacement under the influence of external winds. Many researchers have researched this topic [7-10].

3. Main content

When determining the displacement of road trains in the transverse and longitudinal directions, the wagon-fastening-load system is used, and the location of forces in the -dimensional space must be taken into account.

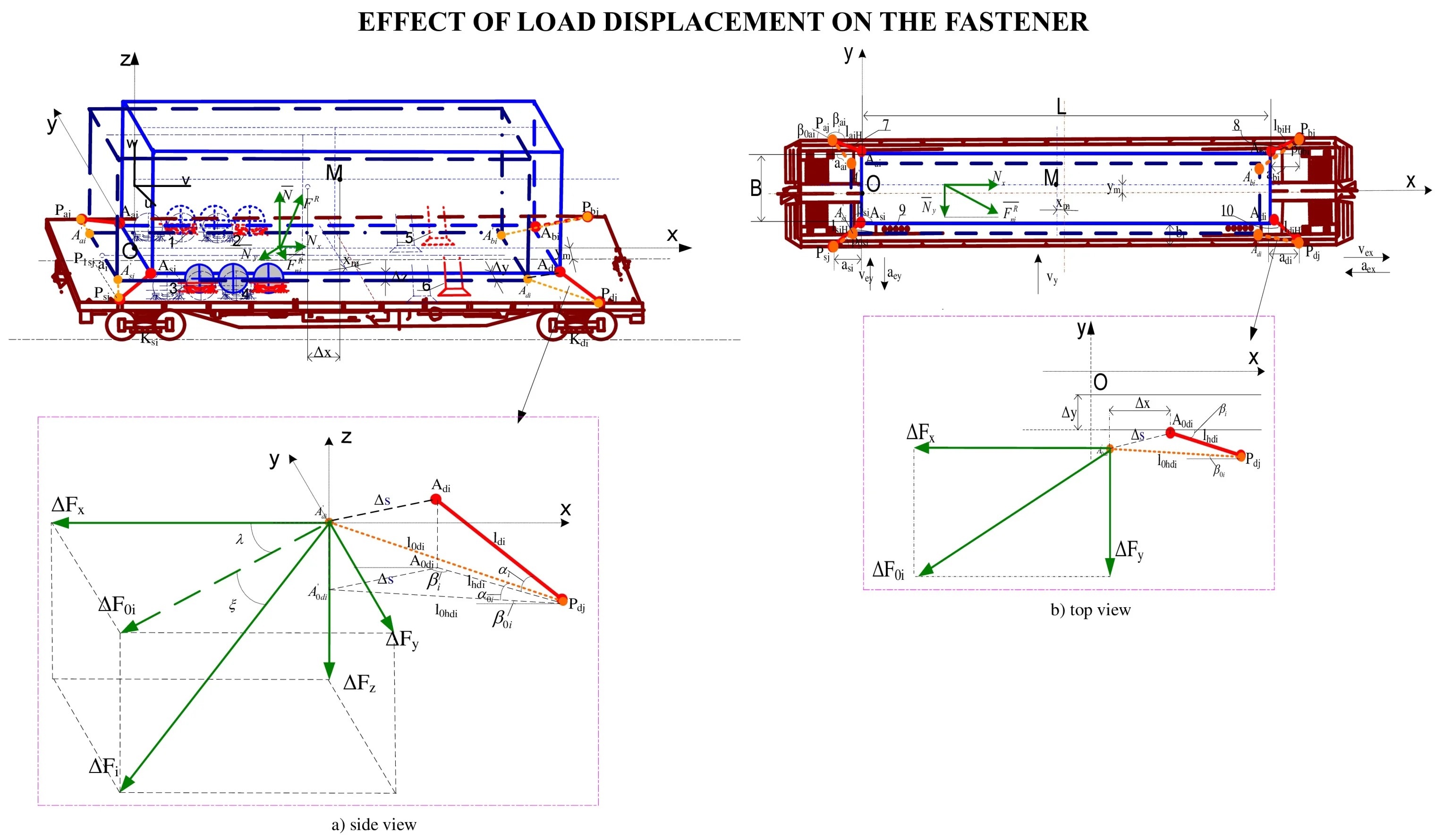

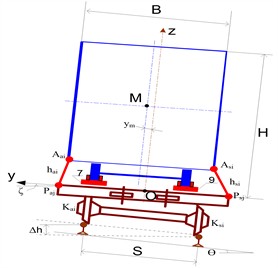

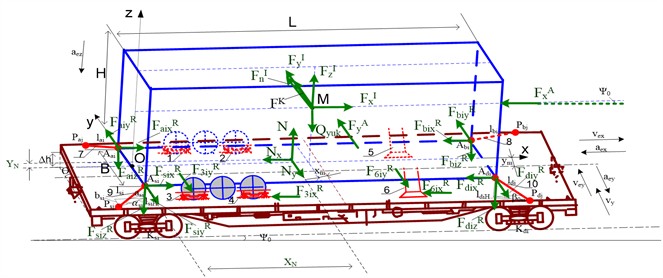

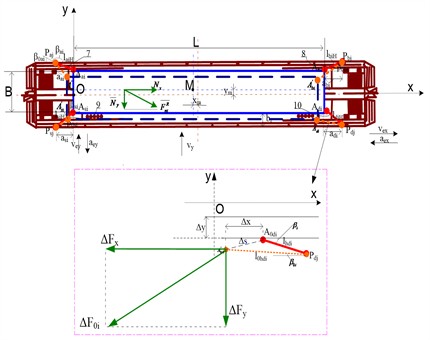

Fig. 1Scheme of placing and securing a semi-trailer on a universal four-axle platform (model 13-9961)

a) Side view

b) Top view

c) Rear view

In Fig. 1 – the weight of a road train or semi-trailer, loaded or empty, N; – number of drawers; , , – height, length and width of the semi-trailer, m; , , , – length of the drawer, m; , , , – height of the projection of the fastening tool on the transverse axis, m; , , , – the length of the projection of the fastener on the longitudinal axis, m; , , , – the length of the projection of the fastening tool on the transverse axis, m; , , , – angle between the fastening tool and the platform plane, °; , , , – angle between the projection of the fixture and the plane of the platform on the -axis, o; – difference in height between outer and inner rails, , m; – distance between rail axles, m; – angle describing the height of the outer rail relative to the inner rail, , o; – the angle at which the loaded wagon frame tilts when the platform moves along the longitudinal -axis, °; – the angle at which the loaded wagon frame tilts when the platform moves in the transverse -axis is taken into account, °; – slope angle, °; – radius of curvature trajectory, m; – speed of the wagon, m/s; , , , – towbar mounting points on the platform; – acceleration of the wagon, m/s2; , , , – vehicle towbar mounting points; – wind speed that opposes movement in the longitudinal direction, m/s; – wind speed that opposes movement from the side, m/s.

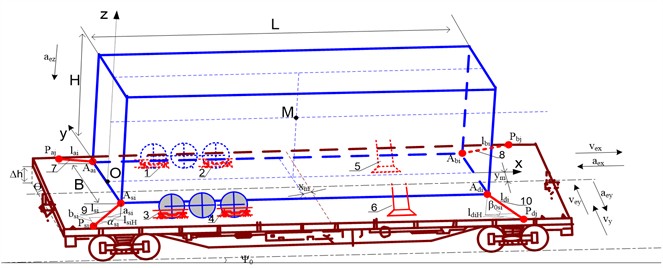

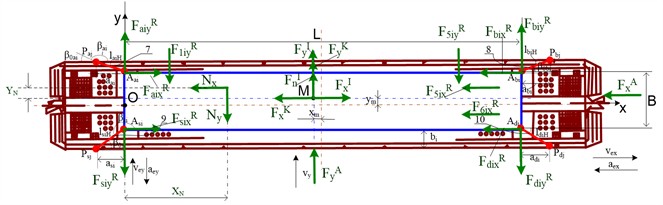

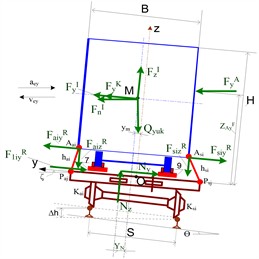

Fig. 2Diagram of forces acting on a platform and semi-trailer moving on a curve and slope

a) Side view

b) Top view

c) Rear view

The law of dynamics of physics:

where, – active forces (, , ), N.

, , is projection of the weight of the load on the coordinate axes, N:

is bond reactivity (elasticity) strength of the additional fastening means (pull), N:

is Coriolis inertial force, N:

where, – tangential or relative velocity, m/s; – relative angular velocity, m/s.

Projections of force vectors on coordinate axes:

where, , , – relative inertia force projections on coordinate axes, N; – projections of the weight of the load on the coordinate axes, N; – projection of the Coriolis inertial force on the axes, N; ; ; , , – active forces and their projections on the axes, N; , , , – reactive forces and their projections on the axes, N; ; .

To develop a mathematical model for securing vehicles to a railway platform during counter-trailer transportation, it is necessary to consider the displacement of the cargo during movement in difficult conditions.

4. Result and their discussion

To ensure safety requirements under the influence of transverse vibration and longitudinal shear forces during load movement, especially on curves and slopes, the projections of force vectors on the coordinate axes were analyzed and the resultant forces were determined.

The force of tension in displacement from the acting forces is given by:

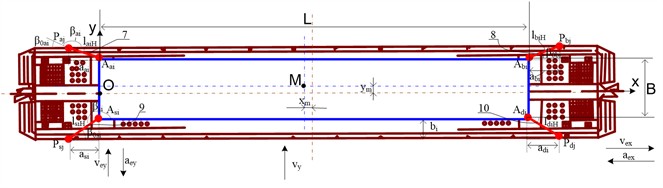

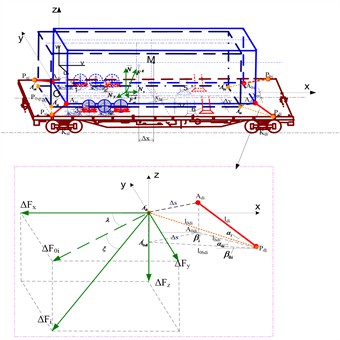

Fig. 3Effect of load displacement on the fastener: Pj – mounting points for the platform’s fastening tool (drawbar); Ai – vehicle mounting points; li, ai, bi, hi – fastener lengths, m; Δx, Δy, Δz – vehicle displacement, m; αi – angle between the fastening tool and the platform plane, °; α0i – angle between the position of the fastening tool after displacement and the plane of the platform, o; β0i – acute angle between the projection of the fixture on the platform plane and the longitudinal x-axis, °; λ – in the horizontal plane ΔFi power projection and Ox angle between the axes, °; ε – ΔFi and the angle between its projection on the horizontal plane, °

a) Side view

b) Top view

Load displacement in the direction of the impact force:

where, – equivalent stiffness of flexible wire restraints and elastic means of the semi-trailer in the direction of the impact force.

Using Eq. (7), the equivalent stiffness of the fastener can be expressed as:

For the strength of the semi-trailer fastening:

where, – permissible tension value when fastening, N.

Shift value:

where, , , – longitudinal, transverse and vertical displacement of the load, m.

The resulting formula allows for a more accurate, safe and reliable choice of technology for securing a vehicle to a platform during counter-trailer transportation. Taking into account the forces of displacement and retention of the load acting on the load, the force acting on the fastening device during the displacement of the load under complex conditions was determined. In addition, using this method, taking into account the strength limit of the fastening device, it is possible to choose the material based on the distance of displacement of the load, the total number of fastening devices (tractors), the number of wires, the diameter of the wire, and the degree of stiffness. It has been established that an increase in fastening means leads to a decrease in the displacement distance of the load. In this case, when the number of fasteners is 2, the displacement distance is 30 mm, when there are 3, the displacement distance is 20 mm, and when there are 4, the displacement distance is about 15 mm.

5. Conclusions

Based on the above, the following conclusions can be drawn:

1) The mathematical model for securing semi-trailers to various platforms in counter-trailer transportation has been improved, taking into account the railway layout and profile, based on the assessment of cargo displacement during movement.

2) Through mathematical modeling of the forces acting on the towbars securing vehicles loaded onto the railway platform, the optimal values of their geometric parameters have been scientifically substantiated.

3) A method for securing vehicles to the railway platform was developed, taking into account traffic safety requirements when organizing counter-rail transportation.

References

-

J. J. Andersen, “Environmental and economic impacts of contrailer transportation compared to traditional road transport,” Journal of Transport Geography, Vol. 76, pp. 45–56, 2019.

-

G. Zhang, T. Wang, H. Wang, S. Wu, and Z. Shao, “Stability analysis of a vehicle-cargo securing system for autonomous trucks based on 6-SPS-type parallel mechanisms,” Machines, Vol. 11, No. 7, p. 745, Jul. 2023, https://doi.org/10.3390/machines11070745

-

R. Guseynov, “Technical and technological parameters of railway stations for loading and unloading municipal solid waste transported using contrailer technology,” Bulletin of the Rostov State University of Railway Transport, Vol. 4, pp. 72–83, 2023.

-

A. A. Gordienko and K. T. Turanov, “Some problems of the theoretical premise of the dynamics of rolling a wagon along the slope of a sorting slide,” Bulletin of Transport Information, Vol. 3, pp. 29–36, 2015.

-

D. V. Kuz’Min, “The concept of passenger transportation safety,” Transport Economics and Logistics, Vol. 1, pp. 12–18, 2023.

-

Z. Mukhamedova et al., “Mathematical modeling of fastening conditions in piggyback transport: ensuring safety and stability across different transport modes,” Discover Applied Sciences, Vol. 7, No. 6, Jun. 2025, https://doi.org/10.1007/s42452-025-07188-7

-

M. Rasulov, M. Masharipov, S. Sattorov, and R. Bozorov, “Study of specific aspects of calculating the throughput of freight trains on two-track railway sections with mixed traffiс,” in E3S Web of Conferences, Vol. 458, p. 03015, Dec. 2023, https://doi.org/10.1051/e3sconf/202345803015

-

D. Zhang, S.-M. Wang, Y.-Y. Tang, Y.-Q. Ni, J.-W. Guo, and Q.-Y. Peng, “A novel method for evaluating load restraint assemblies to ensure the safety of railway freight transportation,” Scientific Reports, Vol. 14, No. 1, p. 4612, Feb. 2024, https://doi.org/10.1038/s41598-024-54772-9

-

G. I. Gadzhimetov, “Estimation of the maximum forces acting on the side bearings of freight car bogies,” Bulletin of the Petersburg University of Railway Engineering, Vol. 19, No. 2, pp. 249–258, 2022.

-

Y. Wang and Z. Liu, “Improving simulations of sulfate aerosols during winter haze over central and eastern China,” Atmospheric Environment, Vol. 70, pp. 30–42, 2013.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.