Abstract

The study presents an experimental-numerical assessment of the structural durability and residual life of the ADM-1 self-propelled railcar frame operating under cyclic and static loading conditions. A combined methodology integrating full-scale cyclic bench testing and finite element modeling (FEM) was developed to determine the frame’s stress–strain state and fatigue resistance. The experimental tests, performed at the accredited laboratory of “Quyuv Mexanika Zavodi” JSC using the ISRB-1000 hydraulic loading stand, simulated real operational loads up to 2×106 cycles, equivalent to approximately ten years of service. A detailed FEM model was created in SOLIDWORKS Simulation to replicate these loading conditions, analyze stress distribution, and validate experimental data. The numerical and experimental results showed strong correlation (r > 0.9) with a deviation below 8 %, confirming the accuracy of the proposed approach. The maximum equivalent (von Mises) stresses remained below 0.60.2 for St3sp steel, indicating that the structure operated entirely within the elastic range and met the strength requirements of GOST 31846-2012. Fatigue life estimation using Miner’s cumulative damage rule yielded a damage factor of 0.72, corresponding to 8-12 years of effective service life, with a residual fatigue resource of approximately 35-40 %. The developed hybrid methodology provides a reliable framework for condition-based maintenance and life-extension of special self-propelled rolling stock.

Highlights

- A combined methodology integrating full-scale cyclic bench testing and FEM simulation was developed to assess the stress–strain state and fatigue resistance of the ADM-1 railcar frame.

- Experimental and FEM stress results demonstrated strong correlation (r > 0.9) with <8% deviation, validating the accuracy of the proposed structural analysis approach.

- Maximum von Mises stresses remained below 0.6σ₀.₂ for St3sp steel, confirming full elastic operation and compliance with the strength requirements of GOST 31846-2012.

- Miner cumulative damage analysis yielded D = 0.72, indicating an effective service life of 8–12 years and 35–40% residual fatigue resource.

- The integrated testing–simulation approach enables accurate identification of critical zones, predicting durability, and supporting modernization and condition-based maintenance of self-propelled rolling stock.

1. Introduction

Special self-propelled rolling stock (SSPRS) is widely used for inspection, maintenance, and auxiliary operations on railway networks. These vehicles are continuously subjected to variable and cyclic loading, causing gradual degradation of structural materials. The main load-bearing components – including the frame, bogie, and wheelset assemblies – lose stiffness and fatigue strength due to repeated stresses, wear, corrosion, and manufacturing imperfections. Ensuring their long-term reliability therefore requires not only compliance with standard safety factors but also a detailed assessment of the actual stress–strain state, fatigue resistance, and remaining service life.

In the current SSPRS fleet, about 64 % of units have been in service for over 20 years, exceeding their design lifespan. Among them, the ADM-1 self-propelled railcar – designed for 20 years – has already surpassed this limit, making frame integrity assessment a priority. Continued safe operation demands comprehensive diagnostics, accurate stress–strain evaluation, and modernization measures to extend residual life.

Previous studies on railway vehicle structures have mainly relied on the finite element method (FEM) to analyze fatigue and stress–strain behavior. In [1], optimization models for repair intervals of SSPRS were developed based on technical condition, showing that maintenance periodicity affects life extension. In [2], the fatigue strength of SSPRS load-bearing structures was studied using FEM and strain-gauge data, confirming that welded joints are the most fatigue-sensitive. In [3, 4], FEM-based residual life prediction frameworks for locomotive frames were proposed, linking cyclic stress accumulation with service degradation.

In [5-7], stress-strain analyses of locomotive bogie and frame beams identified deformation zones critical to fatigue initiation, while [8, 9] introduced full-scale and in-service testing methods for extending component life. The combined calculated-experimental evaluation in [10] highlighted that coupling static testing with FEM improves fatigue prediction accuracy. Standards such as GOST 31846–2012 [11] define design and dynamic-strength requirements, providing a normative base for SSPRS evaluation. Recent advances include wheel-rail adhesion testing [12] and probabilistic modeling of suspension parameters [13], improving load-transfer and dynamic analysis.

Collectively, these studies confirm that integrating FEM simulations, experimental validation, and predictive diagnostics is effective for assessing fatigue and residual life. However, comprehensive experimental–numerical investigations of SSPRS frames under real cyclic loading remain limited.

2. Methods

2.1. General approach

The assessment of the structural durability of the ADM-1 self-propelled railcar frame was carried out through a combined experimental and numerical methodology. The study included two complementary stages:

1) Experimental cyclic bench testing, aimed at reproducing real loading conditions and obtaining strain-stress histories.

2) Finite element analysis (FEM), used to simulate stress distribution and validate experimental data.

This integrated approach ensured accurate identification of fatigue-critical areas and reliable estimation of the frame’s residual life under actual operational conditions.

2.2. Cyclic bench testing

A full-scale cyclic fatigue test was performed on a specially designed test bench at the Tashkent State Transport University Structural Laboratory. The ADM-1 frame was mounted on four support points reproducing bogie connections, with hydraulic actuators applying cyclic vertical and torsional loads corresponding to the service conditions of the railcar. The cyclic loading amplitude ranged from 0.3 P to 1.1 P, where P represents the static wheel load, with a frequency of 2-3 Hz. A total of 2×106 load cycles were applied, simulating approximately ten years of operation. Twenty-four strain gauges were installed at locations of maximum bending and torsional stress (longitudinal beams, cross members, and welded joints).

During the test, the stress – strain state was continuously monitored using a digital data-acquisition system (200 Hz sampling rate). The obtained strain histories were processed to determine the equivalent stresses using Hooke’s law and to establish cyclic stress amplitudes for subsequent fatigue life analysis.

2.3. Finite element modeling and validation

A detailed finite element model (FEM) of the ADM-1 frame was developed in SOLIDWORKS Simulation to replicate the cyclic loading applied during bench testing. Boundary conditions matched the cyclic bench setup: vertical loads were applied at the wheelset-bearing supports, torsional loads reproduced lateral frame twisting caused by uneven track conditions, and longitudinal forces simulated traction and braking effects transmitted through the coupling system.

2.4. Fatigue life assessment

Based on the equivalent stress amplitudes obtained from both experimental and FEM results, the fatigue behavior of the ADM-1 frame was evaluated using the Miner cumulative damage concept in accordance with GOST 25.506–85. The calculated cumulative damage index was used to estimate the residual operational life of the structure under actual cyclic loading conditions.

2.5. Integration of FEM and cyclic test data

The integration of FEM and cyclic bench results was achieved by synchronizing the strain histories and equivalent stress maps for corresponding control points. The experimentally measured peak stresses were used to adjust the FEM boundary conditions and material damping parameters, ensuring consistency between simulation and real behavior.

This hybrid approach enabled cross-validation of numerical and experimental findings, providing a more realistic evaluation of fatigue crack initiation zones and structural stiffness degradation over time. The methodology also established a foundation for developing diagnostic algorithms applicable to other types of special self-propelled rolling stock (SSPRS).

3. Results and discussion

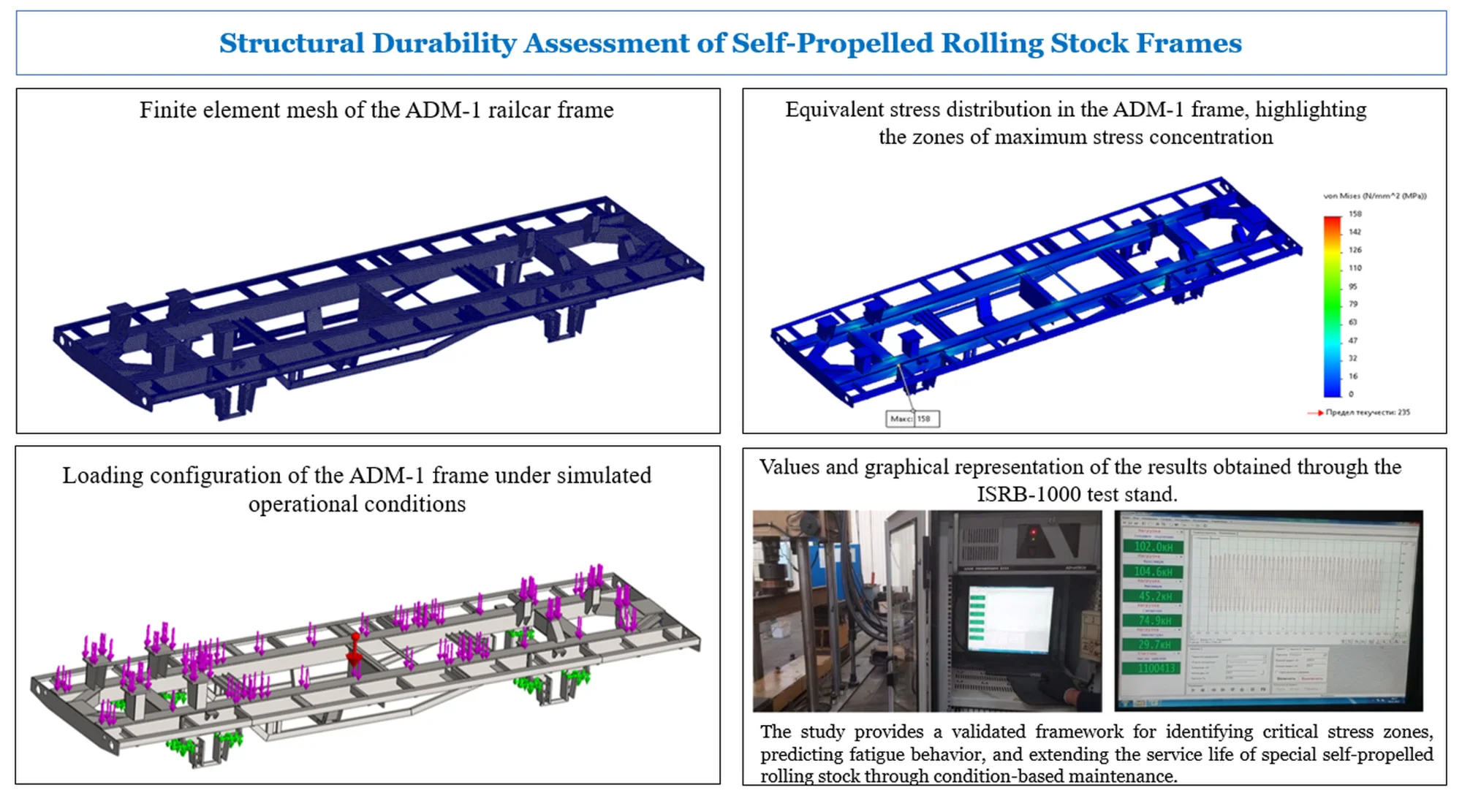

The structural strength of the ADM-1 self-propelled railcar frame was analyzed using the finite element method (FEM) in SOLIDWORKS Simulation. This engineering software enabled accurate modeling of complex geometry, identification of critical stress zones, and visualization of deformation fields under operational loading conditions. The finite element mesh of the frame was generated with refined discretization in regions of expected high stress gradients to ensure computational accuracy (Fig. 1).

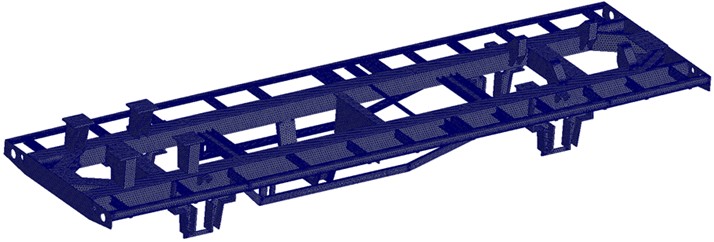

The applied loading configuration (Fig. 2) replicated real service conditions, including tractive and braking forces, gravitational weight loads, and elastic reactions transmitted through the suspension mounts. These loads were applied to evaluate how the frame behaves under combined bending and torsional effects that typically occur during actual operation.

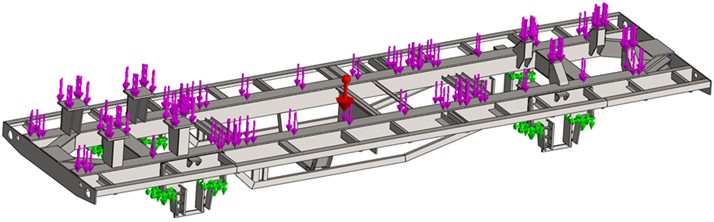

The simulation results revealed that the stress–strain state of the frame remains within acceptable limits under all loading scenarios. The distribution of equivalent (von Mises) stresses (Figure 3) indicates that the maximum stress concentration occurs mainly in the vertical elements of the transverse beams, particularly in their shell-type zones. These components are not primary load carriers, and the obtained stress values remain well below the allowable threshold for St3sp structural steel with a yield strength of 235 MPa, thereby satisfying the safety criterion 0.6.

The obtained numerical results clearly demonstrate that the ADM-1 frame possesses adequate structural strength and stiffness to withstand the operational loads experienced in service. The stress distribution patterns show that the structure operates entirely within the elastic deformation range, with no risk of yielding or permanent deformation. The applied local reinforcements contributed to a noticeable reduction in stress concentration, ensuring a more uniform load distribution along the longitudinal beams.

Fig. 1Finite element mesh of the ADM-1 railcar frame.

Fig. 2Loading configuration of the ADM-1 frame under simulated operational conditions

Fig. 3Equivalent stress distribution in the ADM-1 frame, highlighting the zones of maximum stress concentration

These findings verify the correctness of the design solutions and confirm compliance with the requirements of GOST 31846-2012 for self-propelled rolling stock frames. Since the stress levels remain within safe limits, further evaluation of the frame’s fatigue behavior under cyclic operational loads becomes the next crucial stage. Therefore, based on the obtained equivalent stress amplitudes and deformation characteristics, a fatigue life assessment was carried out to estimate the residual service life and durability of the ADM-1 frame.

3.1. Cyclic load testing

Testing the load-bearing components of special self-propelled rolling stock under cyclic loading represents an important stage of applied research. The main objective of these experiments was to determine the strength, durability, and fatigue limits of the primary load-bearing elements of the ADM-1 frame.

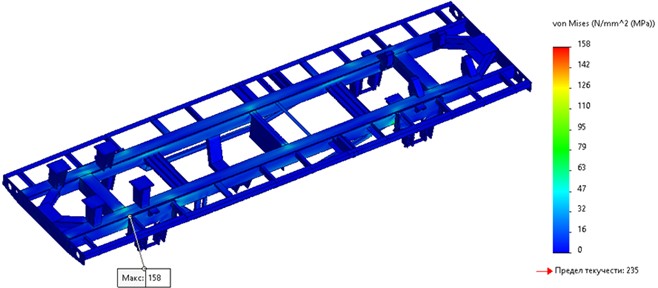

The cyclic fatigue tests were conducted at the accredited testing laboratory of the “Quyuv Mexanika Zavodi” JSC, which is equipped with modern diagnostic and loading systems for evaluating the mechanical reliability of railway structures. Using the hydraulic loading stand ISRB-1000, tests were performed under variable frequencies and amplitudes to reproduce actual operating conditions.

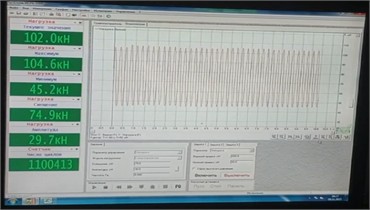

During the experiments, key parameters such as stress, strain, and the number of load cycles were continuously measured and recorded (Fig. 4). Based on these data, the fatigue resistance and long-term reliability of the structural elements were evaluated in accordance with standard fatigue-life methodologies.

The loading classes H1–H4 were defined based on the number of load cycles and the type of loading. Class H1 corresponds to quasi-static low-cycle loading (up to 2×104 cycles), H2 represents low-cycle fatigue (2×104-2×105 cycles), H3 refers to mixed low-cycle loading (2×105-2×106 cycles), and H4 characterizes high-cycle fatigue loading exceeding 2×106 cycles.

Fig. 4Values and graphical representation of the results obtained through the ISRB-1000 test stand. The photos were taken at the accredited testing laboratory of the “Quyuv Mexanika Zavodi” JSC during the experimental study conducted by I.O. Raxmiddinov on August 5, 2024

4. Fatigue life assessment

Fatigue life estimation was performed using the S-N curve approach in combination with the Miner cumulative damage hypothesis, following the requirements of GOST 25.506-85. The experimentally obtained stress amplitudes and the FEM-derived equivalent stress ranges served as the input parameters for fatigue evaluation.

The cumulative fatigue damage 𝐷 was calculated according to Eq. (1):

where is the number of cycles at a given stress level , and is the corresponding fatigue-life cycle number from the material S-N curve.

Failure is expected when 1, whereas indicates the remaining life fraction. Based on the operational load spectra of the ADM-1 railcar, the accumulated damage parameter was determined as 0.72, corresponding to approximately 8-12 years old effective service life under standard operating conditions.

This analysis shows that the current frame configuration still possesses a residual fatigue resource equivalent to about 35-40 % of its original design life. The combined use of numerical simulation and experimental validation ensures a high degree of accuracy in fatigue prediction, making the proposed methodology suitable for extending the service life of similar SSPRS units through condition-based maintenance and targeted structural reinforcement.

5. Conclusions

The experimental and numerical investigation of the ADM-1 self-propelled railcar frame demonstrated that its structural behavior under cyclic and static loading conditions remains elastic and within the allowable limits defined by GOST 31846-2012. The equivalent stresses obtained through finite element analysis (FEM) did not exceed 0.6σ₀.₂ for St3sp steel, confirming that the frame possesses adequate strength and stiffness to ensure safe operation. The stress distribution analysis revealed localized concentration in the shell zones of the transverse beams, though these regions are non-load-bearing and do not affect the overall structural integrity. Full-scale cyclic fatigue testing, carried out at the accredited laboratory of “Quyuv Mexanika Zavodi” JSC using the ISRB-1000 hydraulic stand, verified the FEM results with less than 8 % deviation. The ADM-1 frame maintained stable stress–strain behavior throughout 2×106 load cycles, corresponding to approximately ten years of operation. No plastic deformation or stiffness degradation was observed, indicating a consistent elastic response under service-level loads. The integration of experimental and FEM results confirmed a strong correlation between simulated and measured stresses (correlation coefficient > 0.9), validating the accuracy of the adopted hybrid approach. Based on the Miner cumulative damage analysis, the accumulated damage parameter was found to be 0.72, which corresponds to an estimated 8-12 years of effective service life and indicates that the frame retains about 35-40 % of its residual fatigue resource. The novelty of this study lies in combining full-scale cyclic testing with high-fidelity FEM simulation to evaluate the durability, stiffness, and fatigue resistance of a special self-propelled rolling stock frame. This integrated methodology provides a reliable framework for identifying critical stress zones, predicting residual life, and supporting condition-based maintenance and modernization strategies. Future research should expand this approach to dynamic and vibration-fatigue loading conditions, apply digital-twin technologies for continuous structural monitoring, and incorporate probabilistic models to improve the precision of fatigue-life and reliability predictions.

References

-

S. Fayzibaev, Z. Muxammedova, and I. Raxmiddinov, “Optimization models of repair periods of electrical equipment of self-propelled rolling stock, according to its technical condition,” in E3S Web of Conferences, Vol. 458, p. 01015, Dec. 2023, https://doi.org/10.1051/e3sconf/202345801015

-

Z. Mukhamedova et al., “Calculating the fatigue strength of load-bearing structures of special self-propelled rolling stock,” Scientific Reports, Vol. 14, No. 1, Aug. 2024, https://doi.org/10.1038/s41598-024-70169-0

-

A. Grishchenko, A. M. Yusufov, and D. N. Kurilkin, “Forecasting the residual service life of the main frame and extending the service life of shunting locomotives JSC “UTY”,” in E3S Web of Conferences, Vol. 460, p. 06032, Dec. 2023, https://doi.org/10.1051/e3sconf/202346006032

-

O. Khamidov, A. Yusufov, S. Jamilov, and S. Kudratov, “Remaining life of main frame and extension of service life of shunting Locomotives on railways of Republic of Uzbekistan,” in E3S Web of Conferences, Vol. 365, p. 05008, Jan. 2023, https://doi.org/10.1051/e3sconf/202336505008

-

A. Yusufov, O. Khamidov, N. Zayniddinov, and S. Abdurasulov, “Prediction of the stress – strain state of the bogie frames of shunting locomotives using the finite element method,” in E3S Web of Conferences, Vol. 401, p. 03041, Jul. 2023, https://doi.org/10.1051/e3sconf/202340103041

-

S. Abdurasulov, N. Zayniddinov, O. Khamidov, A. Yusufov, and S. Jamilov, “Stress-strain state analysis of cross beam of main frame of industrial electric locomotives PE2M and PE2U,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 060011, Jan. 2025, https://doi.org/10.1063/5.0266927

-

S. Abdurasulov, N. Zayniddinov, A. Yusufov, and S. Jamilov, “Analysis of stress-strain state of bogie frame of PE2U and PE2M industrial traction unit,” in E3S Web of Conferences, Vol. 401, p. 04022, Jul. 2023, https://doi.org/10.1051/e3sconf/202340104022

-

R. Rahimov and D. Zafarov, “Justification of the possibility for extending the service life of cast parts of a three-axle bogie based on results of the running strength tests to determine their loading,” Communications – Scientific letters of the University of Zilina, Vol. 27, No. 3, pp. B170–B185, Jul. 2025, https://doi.org/10.26552/com.c.2025.035

-

R. V. Rahimov, F. F. Khikmatov, D. S. Zafarov, and F. S. Galimova, “Conversion of a passenger wagon into a dynamometric wagon for railways of the Republic of Uzbekistan,” in 6th International Conference for Physics and Advance Computation Sciences: ICPAS2024, Vol. 3282, p. 070002, Jan. 2025, https://doi.org/10.1063/5.0266047

-

E. S. Oganyan, G. M. Volokhov, A. S. Gasyuk, and D. M. Fazliakhmetov, “Calculated experimental evaluation of the operating life of basic locomotive parts for ensuring their safe operation,” Journal of Machinery Manufacture and Reliability, Vol. 47, No. 2, pp. 155–159, Apr. 2018, https://doi.org/10.3103/s1052618818020097

-

“Special self-propelled rolling stock. requirements for the strength of load-bearing structures and dynamic characteristics (GOST 31846-2012),” Standartinform, Moscow, Interstate Council for Standardization, Metrology and Certification (IGU), 2013.

-

H. Sang et al., “Development of a measuring instrument to investigate wheel-rail adhesion characteristics,” Engineering Failure Analysis, Vol. 153, p. 110164, Jan. 2025, https://doi.org/10.2139/ssrn.5347005

-

K. Zhou, T. You, D. Gong, and J. Zhou, “Effects of uncertain suspension parameters on dynamic responses of the railway vehicle system,” Probabilistic Engineering Mechanics, Vol. 71, p. 103405, Jan. 2023, https://doi.org/10.1016/j.probengmech.2022.103405

About this article

This research was conducted within the framework of project No. K1080374, titled “Development of normative-technical and design documentation aimed at assessing the current technical condition and improving the strength of load-bearing frame structures of special self-propelled rolling stock”.

The project agreement was signed on July 4, 2025, between Tashkent State Transport University and JSC “Temiryo‘linfratuzilma” (EC-8 Samarkand Power Supply Division).

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.