Abstract

This study investigates the stress-strain state of the KZF-07 rail fastenings under high-speed train movement using the finite element method (FEM). The modeling showed that the stresses in the key components of the fastenings (sleeper, baseplate, clamp, screws, and dowels) do not exceed the allowable values, confirming their reliability. Increasing the stiffness of the rail pads reduces longitudinal stresses, improving the service life of the rails, while the metal components have nearly unlimited service life. It is recommended to optimize the design of the rail pads and investigate the material stability against aging. The obtained results contribute to improving the safety and durability of the railway track under high-speed conditions.

1. Introduction

High-speed rail transport has become an integral part of global transport infrastructure, ensuring fast and efficient transportation of passengers and cargo over long distances. With the increase in train speeds, the requirements for the railway track, especially for its key components – rail fastenings, have grown [1-4]. These components play a crucial role in ensuring the reliability and safety of the track, and their reliability becomes particularly important when operating on high-speed railways [5].

Global research experience shows that fastenings are subjected to significant loads during high-speed movement, leading to complex stress-strain states [6, 7]. Modern studies, such as those conducted in Japan and Germany, demonstrate that high train speeds create unique conditions for the wear of rail fastenings [2, 5].

The relevance of this research is determined by the increasing demands for the safety and durability of railway track components as train speeds rise. Despite their importance, poorly maintained rail fastenings are often subject to wear and defects, which, at high speeds, can lead to critical consequences for operations [8, 9]. In conditions of limited maintenance for such railway sections, it is crucial to develop methods for predicting and assessing the stress-strain state of fastenings to prevent emergency situations and ensure safe movement.

The novelty of this research lies in the detailed FEM-based evaluation of the KZF-07 fastening system under high-speed dynamic loads, providing quantitative insights for improving pad stiffness and extending track service life.

Additionally, modern methods for analyzing and modeling the stress-strain state of fastening components require more in-depth research to identify the factors affecting their reliability under high-speed movement and to develop new solutions to enhance their operational characteristics [10, 11].

The subject of the research is the components of poorly maintained rail fastenings and their stress-strain state under high-speed and very high-speed train operations.

The goal of the research is to assess the stress-strain state of poorly maintained rail fastenings under high-speed and very high-speed conditions and to develop recommendations for improving them to enhance the reliability and safety of railway track operations.

To achieve the goal, the following tasks must be solved:

1) Review existing methods for analyzing the stress-strain state of rail fastenings and identify the characteristics of their behavior under high-speed movement.

2) Assess the impact of high-speed loads on poorly maintained fastening components and identify key factors contributing to their wear.

3) Develop methods for evaluating the residual life of poorly maintained fastenings based on dynamic loads during high-speed movement.

4) Develop recommendations for improving the design and materials of fastenings to increase their durability and reduce safety risks.

5) Evaluate the effectiveness of the proposed solutions and their impact on the operational characteristics of railway lines.

The results of this research will contribute to improving the operational characteristics of rail fastenings, ensuring safe movement, and providing recommendations for increasing the service life of railway track components.

2. Materials and methods

For the study of the stress-strain state of poorly maintained KZF-07 rail fastenings, the numerical modeling method using the finite element method (FEM) was chosen, as it allows for accurate simulation of the physical and mechanical processes occurring in complex structures like rail fastenings under dynamic loads from high-speed train movement [12, 13].

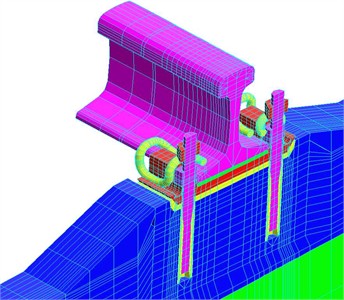

The research was conducted using ANSYS software, which is ideal for such tasks due to its ability to model complex stress and deformation mechanisms in various materials. All figures in this paper were obtained by the authors using ANSYS software. As part of the study, a finite element model of the track superstructure with KZF-07 rail fastenings was developed, taking into account all key components: the sleeper, baseplate, rail pads, screws, dowels, and clamps [12, 14]. The modeling was performed for an axial load of 35 tons per axle, typical for modern high-speed trains, to analyze the behavior of the components under extreme operating conditions.

Using the FEM, the Mises stress distributions were assessed for various fastening components under different operational scenarios, such as rail clamp pressure with a force of 1.2 tons and the standard tightening of screws. Special attention was given to the behavior of elements like the rail pad and dowel, which may experience aging and wear during operation [15-19].

3. Results and discussion

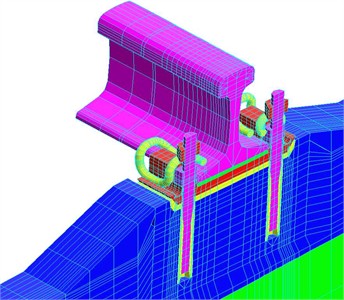

The results of the numerical modeling of the stress distribution in the components of KZF-07 rail fastenings showed that the main elements (sleeper, clamp, dowel, screws) do not exceed critical stress values under a load of 35 tons per axle. Figs. 1 and 2 show, respectively: the finite element model of the track superstructure and a fragment of the axisymmetric three-dimensional model with the KZF-07 rail fastening. No overstressing was observed in the sleeper, clamp, dowel, or screws.

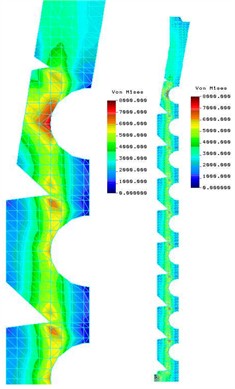

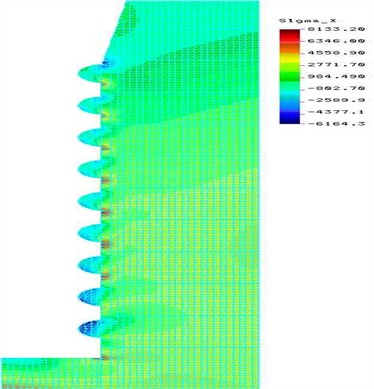

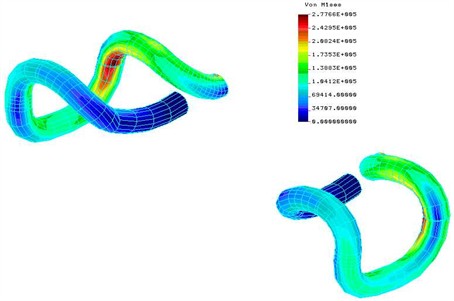

Fig. 3 illustrates the distribution of von Mises stresses in the dowel under a clamping force of 1.2 tons, showing that the stress levels remain within the permissible limits. The stress distribution in the sleeper under standard screw tightening is shown in Fig. 4, while Fig. 5 presents the stress distribution in the clamp. The distribution of equivalent von Mises stresses in the concrete sleeper resulting from screw tightening is presented in Fig. 6.

Fig. 1Finite element model of the railway superstructure with KZF-7 rail fastening system

Fig. 2Fragment of the axisymmetric three-dimensional finite element model of the railway superstructure with RZF-7 rail fastening system

Fig. 3Von Mises stress distribution in the dowel under a clamping force of 1.2 tons applied by the rail clip

Fig. 4Stress distribution in the sleeper under standard screw tightening

Fig. 5Von Mises stress distribution in the rail clip under standard screw tightening

Fig. 6Equivalent von Mises stresses in the concrete sleeper caused by screw tightening

For further assessment of the service life of the KZF-07 fastening system components, a computational evaluation was carried out and is presented in Table 1. The table includes the maximum stress values for each component and the estimated tonnage service life, allowing an evaluation of the durability and reliability of the fastening elements. The results show that all metal components – such as the baseplate, screws, and rail clips – exhibit a sufficiently high service life, comparable to that of the rails.

Table 1Tonnage service life assessment of KZF-07 fastening system components

Element name | Maximum stress (kg/cm²) | % of allowable stress | Service life (million tons gross) |

Concrete Tie with KZF-07 Fastening | Concrete compression 90-270 | 22.5-65 | 2 billion tons |

Pad | 1445 | 55 | unlimited |

Underpad | 42 | 21 | > 1 billion tons |

Rail Pad | 110 | 40 | > 1 billion tons |

Screw-Bolt (High Strength) | 3000 | 20 | > 1 billion tons |

Washer | unlimited | ||

Plastic Anchor | 17-34 | 50 | > 1 billion tons |

Stopper Clamp | unlimited | ||

OP-105 Terminal | 8000-12000 | 70.5 | 1 billion tons |

The obtained results confirm the high reliability and durability of the KZF-07 fastening elements. They also show that most components, including pads and metal elements, have a service life comparable to that of the rail. According to calculations, fastening elements such as screws and terminals have a significant service life (over 1 billion tons gross), which meets modern standards for high-speed railway tracks.

Particular attention should be given to rail and tie pads, which may undergo material aging, leading to a reduction in their service life to 25 years. However, increasing the stiffness of rail pads from 40-60 t/cm to 150-200 t/cm can significantly reduce longitudinal stresses on the base of the rail, thereby extending the rail’s service life by 20 %.

A comparison with the results of other authors, such as the works of Benedict and Novak (2016), confirms the correctness of the chosen methodology and the comparability of results. In particular, their research shows similar results on the durability of metal components of fastenings and emphasizes the importance of developing pads with improved characteristics to extend the track’s service life.

Furthermore, for sections with curves having a radius of less than 600 meters, it is recommended to use intermediate rail fastenings, which will minimize maintenance costs and meet the requirements of low-maintenance continuous welded track.

4. Conclusions

The study of the stress-strain state of the KZF-07 rail fastening elements under high-speed train movement conditions revealed key relationships between loads and deformations of the components. The assessment of stress distribution in the tie, pad, anchor, terminal, and screws showed that the stress levels do not exceed the allowable values under an axial load of 35 t/axle, confirming the high reliability and durability of the elements in operation.

The main scientific results include the following conclusions:

1) The stresses are proportional to the axial load, with maximum values observed in the pad and terminals.

2) Increasing the stiffness of rail pads (from 40-60 t/cm to 150-200 t/cm) reduces longitudinal stresses on the rail base by 20 %, which contributes to an increased rail service life.

3) The service life of the KZF-07 fastening elements is comparable to that of the rail. The metal components have an almost unlimited service life, while the pads are limited to 25 years due to material aging.

The conducted research confirms that the KZF-07 fastening elements can effectively function under high-speed conditions, with the greatest impact on rail longevity being the changes in pad stiffness, which reduce stresses and improve operational characteristics.

Recommendations for further research:

1) Optimization of pad stiffness to reduce loads on rails and increase their service life.

2) Study of the resistance of plastic pads to aging in order to extend service life.

3) Modeling of dynamic loads for accurate durability assessment of elements in real conditions.

4) Use of intermediate KZF-07 fastenings on sections with a curve radius of less than 600 meters to ensure reliability and minimize costs.

Further studies should focus on improving material characteristics, increasing durability, and reducing operational costs to ensure the safety and reliability of the railway track.

References

-

N. I. Karpushchenko and N. I. Antonov, Improvement of Rail Fastenings: Monograph. (in Russian), Novosibirsk, Russia: SGUPS Publishing House, 2003.

-

R. Smith and A. Kapoor, “Advancements in rail fastening systems for high-speed railways,” Journal of Railway Engineering, Vol. 34, No. 2, pp. 123–136, 2020.

-

U. Ergashev and N. Begmatov, “Ensuring safety of track-laying works while long-welded rails replacement,” Discover Applied Sciences, Vol. 7, No. 5, p. 470, May 2025, https://doi.org/10.1007/s42452-025-07049-3

-

K. Lesov, A. O. ’Ralov, M. Kenjaliyev, N. Begmatov, and U.B. Ergashev, “Calculation of slope stability against erosion deformations,” in E3S Web of Conferences, Vol. 583, p. 01006, Oct. 2024, https://doi.org/10.1051/e3sconf/202458301006

-

K. Yamada and T. Tanaka, “Durability and maintenance-free rail fastening systems in Japan: innovations and applications,” Proceedings of the Japan Society of Civil Engineers, Vol. 56, No. 4, pp. 45–58, 2019.

-

D. Mcneil and P. Johnson, “Elasticity and resilience in rail track components: a North American perspective,” Journal of Transportation Engineering, Vol. 47, No. 5, pp. 212–224, 2021.

-

“Innovative Practices in Rail Infrastructure Maintenance,” Canadian National Railway (CN), Internal Technical Report, 2020.

-

“Rules for Acceptance and Operation of Concrete Ties,” (in Russian), JSC “NC Kazakhstan Temir Zholy” Astana, Kazakhstan, 2014.

-

“Pre-stressed Concrete Ties for Railways with a Gauge of 1520 mm with KPP-5 Fastening,” (in Russian), ST 36135-1910-TOO-14-2013, 2013.

-

V. K. Fink and S. A. Kosenko, “Intermediate rail fastening KPP-5 in Kazakhstan,” (in Russian), Science and Progress of Transport. Bulletin of Dnepropetrovsk National University of Railway Transport, pp. 79–81, 2008.

-

N. Begmatov, U. Ergashev, K. Lesov, and S. Shayakhmetov, “Bearing capacity of the subgrade for high-speed train traffic,” in E3S Web of Conferences, Vol. 531, p. 02006, Jun. 2024, https://doi.org/10.1051/e3sconf/202453102006

-

“Basic FEA System User Guide for Unix, Windows NT, and Windows 95,” Structural Research and Analysis Corporation, Los Angeles, CA, Part 1, 1996.

-

C. M., “Basic FEA System User Guide,” Structural Research and Analysis Corporation, Los Angeles, CA, Part 1., 1995.

-

V. S. Lysyuk, V. N. Sazonov, and L. V. Bashkatova, Strong and Reliable Railway Track. (in Russian), Moscow, Russia: Akademkniga, 2003.

-

S. B. Shayakhmetov and B. E. Yerzhan, “Study of the stress-strain state of rail fastening elements with Skl 14 type elastic terminals on concrete ties,” (in Russian), Almaty, 2024.

-

A. M. Zhangabylova, I. S. Bondar, M. Ya. Kvashnin, A. M. Ablyazova, and A. D. Konysbay, “Analysis of the performance of intermediate rail fastenings under operational load,” (in Russian), KazATK Bulletin, Vol. 133, No. 4, 2024, https://doi.org/10.52167/1609-1817

-

K. Lesov, A. Abdujabarov, M. Kenjaliyev, and O. Mirzakhidova, “Techno-economic evaluation of geotextile application as a separation layer and its contribution,” in E3S Web of Conferences, Vol. 583, p. 01008, Oct. 2024, https://doi.org/10.1051/e3sconf/202458301008

-

U. Shermukhamedov, M. Sobirova, N. Azamov, and S. Ibrokhimova, “Analysis of technical and operational condition of urban reinforced concrete bridge structures,” in E3S Web of Conferences, Vol. 365, p. 02015, Jan. 2023, https://doi.org/10.1051/e3sconf/202336502015

-

A. Z. Khasanov, U. Z. Shermukhamedov, and A. R. Abdullayev, “The method for determining the designed resistance of soils with considering the theory of soil strength proposed by the authors,” in Smart Geotechnics for Smart Societies, London: CRC Press, 2023, pp. 464–467, https://doi.org/10.1201/9781003299127-54

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.