Abstract

The article presents the methodology for conducting field tests of lime-soil cushions to examine the technology of their construction, gain strength, their operation under rigid stamps, and the characteristics of stress-strain state development. The results of field studies showed that the lime-soil mixture can be used as a structural material in the preparation of bases on loess- loess soils in the conditions of the Republic of Tajikistan. Field tests showed that the lime-soil mixture achieved a dry density of 1.53-1.56 t/m3, while the deformation modulus increased by 5-10 times compared to natural loess soils.

1. Introduction

In recent years, due to the high rates of industrial, civil, agricultural, and water management construction, intensive development of territories composed of loess loess soils of varying thickness has been carried out. Ensuring the reliability and stability of the buildings and structures being constructed in such complex engineering-geological conditions is a very complex task. The complexity of this problem is further aggravated by the region's high seismicity, when additional subsidence deformations (seismic subsidence) can manifest during earthquakes [2-8].

In addition, intensive development of adyr territories is currently underway, characterized by dissected relief and a large thickness of loess soils. Solving this problem requires considering a complex of engineering measures that ensure the elimination of the sedimentary properties of loess soils on one side and the seismic stability of slopes on the other. At the same time, an important condition is that during construction, it is necessary to make the best possible use of the existing terrain relief from the point of view of the architectural layout of the territory.

Currently, specialists have developed effective methods for preparing bases, as well as work is being carried out to further improve them on shrinking soils, including in conditions of complex relief and high seismicity. However, despite the successes achieved, the problem of building buildings and structures in such conditions remains relevant and requires further comprehensive research.

The results of laboratory studies of lime-soil mixtures indicate the effectiveness of their use as artificial foundations for various buildings and structures constructed on loess- loess soils. It should be noted that in this direction, the features of working compacted cushions made of local loess soils for high-rise buildings have been sufficiently studied. Studying this issue has important practical significance and will allow for the rational design of lime-soil cushions in the future, as well as determining the area of their application, therefore, the main goal of the field experimental experiments was to study the operation of lime-soil cushions under natural conditions.

2. Materials and methods

Experimental studies were conducted under field conditions at the 7 km experimental site of the Dushanbe-Vakhdat highway, where loess- loess soils are widespread, as well as at two field plots located in the territory of the “Kyzyl Kala” farm in the Jaloliddin Balkh district.

Geomorphologically, the area is adjacent to the III right-bank terrace of the Kafirnigan River. The terrain is uneven, with artificial excavations 4-5 m deep.

Quaternary age alluvial deposits, represented by loess-like macroporous loams and sandy loams, yellow-brown in color, of medium density, from slightly moist to moist, participate in the geological structure of the described area. Loess-like soils are covered in places by loose soil with a thickness of up to 1 m. The exposed thickness of loess-like soils is 46.5 m, with a total thickness of more than 100 m. Loess-like soils are lined with gravel deposits. Groundwater was not exposed by a well drilled to a depth of 46.5 m. Taking into account the data of previously conducted surveys, groundwater lies at a depth of more than 50 m.

Individual soil horizons are characterized by low values of the total deformation modulus, approximately 3-5 MPa. The research data allow for the characterization of soils from highly compressible to weakly compressible. Strongly and moderately compressible soils predominate. The internal friction angle is 27° and the clutch is 0.0033-0.0083 MPa; the average values are 29-28°, 0.0050-0.0066 MPa, respectively.

The physical properties of the soil of the experimental site are presented in Table. 1.

These properties of the soil of the experimental site relate to the research conducted by the “TajikGIINTIZ” institute in Dushanbe. To clarify the characteristics of the soil in the experimental plot, a depth of 4.5 m was dug, samples were taken every meter, and appropriate laboratory studies were conducted according to the standard methodology.

Table 1Indicators of the physical condition of the soil of the experimental site at the 7 km of the Dushanbe-Vakhdat highway

No | Sampling depth, m | Density of soil particles, t/m3 | Soil density t/m3 | Dry density soil t/m3 | Natural humidity | Porosity coefficient | Number plasticity | Water saturation coefficient |

1 | 1 | 2.67 | 1.52 | 1.29 | 0.18 | 0.910 | 0.07 | 0.53 |

2 | 2 | 2.67 | 1.76 | 1.45 | 0.20 | 0.820 | 0.06 | 0.68 |

3 | 3 | 2.68 | 1.81 | 1.46 | 0.23 | 0.866 | 0.07 | 0.71 |

4 | 4 | 2.68 | 1.85 | 1.46 | 0.26 | 0.752 | 0.06 | 0.95 |

5 | 5 | 2.68 | 1.95 | 1.54 | 0.27 | 0.786 | 0.06 | 0.98 |

6 | 6 | 2.68 | 1.98 | 1.57 | 0.26 | 0.740 | 0.06 | 0.99 |

7 | 7 | 2.69 | 2.04 | 1.62 | 0.26 | 0.682 | 0.07 | 1.08 |

8 | 8 | 2.69 | 2.08 | 1.68 | 0.23 | 0.654 | 0.07 | 1.0 |

9 | 9 | 2.69 | 2.04 | 1.62 | 0.26 | 0.665 | 0.08 | 1.0 |

3. Results and discussion

The research results showed that the soils are mainly represented by loams and sandy loams. The upper 3.0 m soil layer is considered sedimentary and is characterized by a small bulk density of dry soil (1.30-1.47 g/cm3) and a low moisture content of 7-9 %. The density of the soil is 1.35-1.50 g/cm3, and the particle density fluctuates within the range of 2.66-2.68 g/cm3.

According to research data, groundwater up to a depth of 18.0 meters has not been excavated. The construction site is composed of sandy loam soils, the explored thickness of which is 18.0 m.

In terms of shrinkage, the soils belong to the II-type. The thickness of the sedimentary layer is 10-12 m. The amount of settlement from the soil’s own weight when soaked to the specified thickness is 18 cm, and under a load of 0.2 MPa – 45 cm.

To more thoroughly study the engineering-geological conditions of the experimental areas, a pit with a cross-section of 2 m2 and a depth of 10 m was drilled. During the drilling process, monoliths were selected from various depths and the corresponding physical and mechanical properties of the soils were determined.

It should be noted that the soils of the experimental plot No. 1 before the start of the tests were transferred to the 1st type of soil condition by surface wetting through a pit.

The physical and mechanical properties of the soils of experimental plots No. 1.2 are presented in Table 2 and 3.

Experimental studies were conducted at an experimental site located at the 7th km of the Dushanbe-Vahdat highway to develop the technology for installing lime-soil cushions, determine their strength parameters, and determine the influence of climatic factors on the stability of the above-mentioned cushions.

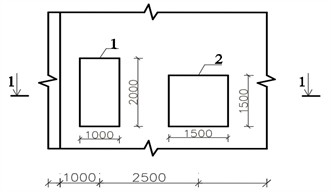

For this purpose, models of lime–soil cushions measuring 2.0×1.0 m were removed from the experimental plot; 1.5×1.5 m and thickness, respectively, 1.0 and 1.3 m. (Fig. 1).

The No. 1 cushion was intended for determining strength parameters, while the No. 2 cushion was intended for studying water resistance and frost resistance.

The cushions were installed by layered compaction using a 35 kg hand roller. The thickness of the layer during filling was taken as 8-10 cm, and the number of passes on one track was taken as 10. The thickness of the deposited layers, as well as the number of passes, are selected depending on the characteristics of the compacting mechanism of the hand roller. The adopted technology for constructing a pillow made it possible to achieve a dry soil density of 1.53-1.56 t/m3.

The mixture required for the construction of a lime-soil cushion was prepared in a SO-26B mortar mixer as follows: the natural moisture content of the soil selected near the experimental site was prepared in portions and poured into the mortar mixer. After loosening the soil, ground quicklime was added as a powder and mixed with water until a uniformly moistened mass was obtained. The amount of lime soil and water required to prepare the mixture was determined by calculation.

Fig. 1Layout of the experimental site: 1 – lime–soil cushion (1.0 m); 2 – lime-soil cushion (1.3 m); 3 – loess soil layer

Table 2Physical and mechanical properties of the soil of the experimental site №3

No | Sampling depth | Soil particle density, / m3 | Soil density, / m3 | Dry soil density, / m3 | Natural humidity, / % | Natural porosity, % | Porosity coefficient, | Plasticity number, | Internal friction angle, | kPa clutchc | Internal friction angle, | Flowability indicator |

1 | 2.0 | 2.67 | 1.41 | 1.30 | 7.8 | 51.31 | 1.053 | 6.5 | 30о | 7.5 | 30 | < 0 |

2 | 4.0 | 2.67 | 1.35 | 1.24 | 8.9 | 53.55 | 1.153 | 3.7 | 30о | – | 29 | < 0 |

3 | 6.0 | 2.68 | 1.40 | 1.33 | 4.8 | 50.37 | 1.015 | 7.5 | 28о | – | 30 | < 0 |

4 | 8.0 | 2.67 | 1.37 | 1.29 | 5.6 | 51.68 | 1.069 | 6.2 | 30о | – | 30 | < 0 |

5 | 10.0 | 2.67 | 1.49 | 1.41 | 5.5 | 47.19 | 0.893 | 5.0 | 30о | – | 30 | 0 |

The amount of filled mixture was selected taking into account ensuring homogeneous compaction. For this, the pillow was divided by height into several parts and the required amount of mixture was determined for each part.

After installing the pillow, samples were taken from the body to determine the density of the dry mixture.

Around the No. 2 pillow, a rolling was carried out to investigate the influence of multiple water saturation and drying cycles on the mixture stability.

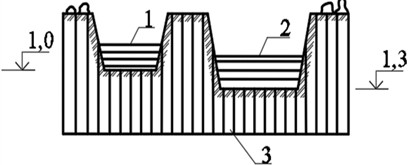

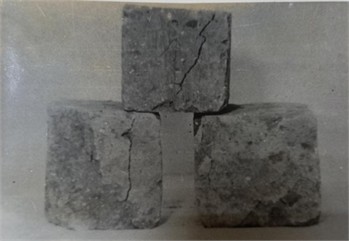

To study the strength gain of the lime–soil cushion (pillow No. 1), cube-shaped samples measuring 10×10×10 cm were selected from its body and tested for uniaxial compression (Figs. 2, 3).

Table 3Physical and mechanical properties of the soils of experimental site №3

No | Sampling depth | Soil particle density, / m3 | Soil density, / m3 | Dry soil density, / m3 | Natural humidity, / % | Porosity coefficient, | Plasticity number, | kPa clutchc | Internal friction angle, | Flowability indicator, |

1 | 1.5 | 2.67 | 1.34 | 1.28 | 53.93 | 1.17 | 6.7 | 30 | < 0 | |

2 | 3.5 | 2.68 | 1.33 | 1.34 | 52.61 | 1.11 | 8.0 | 7.1 | 29 | < 0 |

3 | 5.5 | 2.67 | 1.38 | 1.38 | 47.19 | 0.893 | 6.4 | 30 | < 0 | |

4 | 7.0 | 2.68 | 1.43 | 1.42 | 46.50 | 0.864 | 5.6 | 2.3 | 30 | 0.86 |

5 | 8.0 | 2.67 | 1.56 | 1.46 | 44.73 | 0.837 | 5.2 | 30 | 0.95 | |

6 | 10 | 2.68 | 1.69 | 1.52 | 41.56 | 0.79 | 4.7 | 30 | 1 |

Field tests were carried out under natural climatic conditions. During the test period, the average air temperature ranged from 18-26 °C, and relative humidity varied between 45-60 %. Each load stage was monitored for 2 hours until conditional stabilization (0.01 mm). During soaking tests, a constant water level of 0.2-0.3 m was maintained above the surface, and the degree of saturation of foundation soils ranged between 0.80-0.95. These details ensure reproducibility and allow more accurate interpretation of the mechanical behavior of the lime-soil cushions.

The main objective of the experimental studies conducted in the experimental plots of the “Kyzyl Kala” deposit was to study the operation of lime-soil cushions under hard stamp bases and to identify the developmental features of deformations occurring in their bodies.

Fig. 2Increase in the strength of the lime-soil mixture based on the test results of samples selected from the body of the lime-soil cushion 1-at optimal moisture content of the samples; 2-the same, water-saturated samples

Fig. 3Destruction of cube-shaped samples during one-axis compression tests

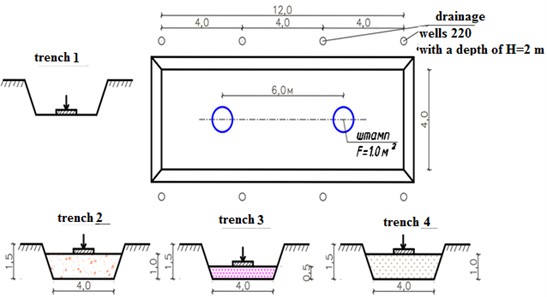

To conduct the tests, 3 trenches were constructed in the 1st section, and in the second section, one pit measuring 4×12 m in plan and 1.5 m deep was constructed (Fig. 4).

Considering the high strength and deformation properties of the lime-soil mixture, the thickness of the cushions was taken as 0.5 and 1.0 m. The construction of the cushions was carried out by deposition of a 25 cm thick layer of lime-soil mixture with optimal moisture content, followed by compaction with a 6.0 t roller to a dry mixture density of 1.6 t/m3.

Studies of the operation of natural and artificial bases with an upper compacted layer made of lime-soil mixtures were conducted using round rigid stamps with an area of 10000 cm3 ( = 112 cm) according to the standard methodology. Stamp loading and deformation measurements were performed in accordance with GOST 20276-2012 and GOST 30416-2012, which correspond to the principles of ISO 22476-2.

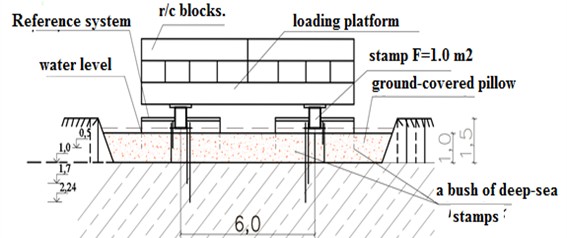

During the experiments, 2 stamps were simultaneously loaded through a metal platform with reinforced concrete blocks (Fig. 5). The stamps were placed at a distance of at least 5 from each other. Stamp displacements were measured at 4 points.

Fig. 4Trench diagrams during testing

Fig. 5Diagram of conducting stamp tests

To measure the layered deformations of the foundation soils in experiments 5 and 6, helical depth marks were used, which were set at intervals of 0.5; 1.0; 1.7; 2.24 m. The movement of stamps and base soils was recorded by Maximov's deflection gauges installed on a rigid benchmark system.

The loading of the stamps was carried out in stages of 50 kPa, with each stage holding until the conditional stabilization of the precipitate, which we accepted as equal to 0.01 mm for 2 hours of observations.

In the 1st section, lime-soil cushions were laid with a thickness of 0.5 and 1.0 m (Fig. 4). Before loading the stamps, the soil was soaked to a value of 0.8. In addition, during the testing process, a constant water level of 0.2-0.3 m was maintained in the reservoir to determine the possibility of water penetration into the body of the pillow and the change in its strength and deformation characteristics.

In the II section /pit 4/, cushions were laid with a thickness of 1.0 m. Initially, the stamps were loaded to maximum load, and then the soil was soaked. The water level in this pit was also maintained constantly.

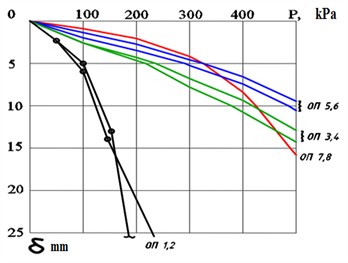

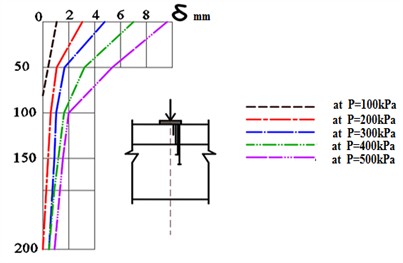

Based on the results of static tests, a graph of the dependence of stamp settlement on pressure was constructed, as well as diagrams of the development of layered movements of soils at the depth of the stamp base (Figs. 6, 7). Based on these dependencies, the design resistances of the artificial foundation soils and the depth of the active zone were determined.

Fig. 6Dependence of stamp settlement on pressure P

Fig. 7Development of soil sediments at depth (pit 3)

To clarify the engineering significance of the obtained results, a comparative quantitative analysis was performed. The uniaxial compressive strength of the lime–soil mixture increased by approximately 25-35 % compared to untreated loess soils. The deformation modulus of the treated material exceeded the natural soil values by 5-10 times. In stamp tests, the settlement under equivalent loads decreased by 20-30 %. These quantitative improvements demonstrate the efficiency of lime-soil cushions in reducing compressibility and increasing load-bearing capacity of foundations in loess terrains.

These results are consistent with international studies conducted in China, Iran, and Italy, where lime stabilization has demonstrated similar reductions in compressibility and improvements in seismic performance.

4. Conclusions

1) The conducted model-experimental studies allow us to study the qualitative picture of the nature of the work of limestone-soil cushions in the loess soil massif.

2) Field tests of lime-soil cushions showed that they can be used as a structural material as an artificial base on type I loess soils.

3) Quantitative data on the load-bearing capacity and deformability of cushions made of lime-soil mixtures can only be obtained based on extensive field tests.

4) The deformability indicators of lime-soil mixtures exceed the same indicators of soils by 5-10 times, which allows them to be classified as structural materials. For practical application, the recommended parameters of lime-soil mixtures are: optimal moisture 12-15 %, lime content 8-10 %, and achieved dry density 1.53-1.60 t/m3.

References

-

G. U. Babushkin and L. K. Ginzburg, “Strengthening of foundations on collapsible soils by means of jacked piles,” Soil Mechanics and Foundation Engineering, Vol. 21, No. 1, pp. 14–20, Jan. 1984, https://doi.org/10.1007/bf01715511

-

I. I. Krieger, A. D. Kozhevnikov, and S. I. Lavrusova, “Seismic settlements,” in Engineering-Geological Basis of Seismic Microregionization, 1975, pp. 76–85.

-

L. V. Lavrusevich, “Study of seismic settlements of loess soils,” TSU named after V. I. Lenin, Dushanbe, 1979.

-

A. A. Musaelyan, “Engineering-geological and seismic microdistricting of the City of Dushanbe,” in Soil Mechanics, Dushanbe: Donish, 1966, pp. 65–77.

-

A. A. Musaelyan, “Some results of studying the deformation of compacted loess soils under dynamic loads in the laboratory,” in Hydrogeology and Engineering Geology of the Arid Zone of the USSR, 1969, pp. 97–105.

-

A. A. Mualyan, “Results of preliminary studies of clay soils under dynamic loads,” in Soil Mechanics, Dushanbe: Donish Publishing House, 1966, pp. 23–25.

-

H. Z. Rasulov, Seismic Resistance of Loess Foundations of Buildings and Structures. Tashkent: Uzbekistan, 1977.

-

E. N. Skvaletskiy, “Loess rocks of the Garauta Plateau and their structural properties,” in Engineering Surveys for Water Management Construction in Tajikistan, Dushanbe: Irfon, 1969, pp. 12–80.

-

V. I. Krutov, Bases and Foundations on Sedimentary Soils. Kyiv; Moscow: Budivelnik, 1982.

-

I. M. Litvinov, Strengthening and Compaction of Sedimentary Soils in Housing and Civil Construction. Kyiv: Budivelnik, 1977.

-

N. M. Hasanov and M. A. Sulaymonova, “Experimental study of limestone-soil cushions in laboratory conditions,” Bulletin, TNU – Dushanbe: TNU, Series of Geological and Technical Sciences, No. 2, pp. 147–154, 2023.

-

M. A. Sulaymonova and D. K. Khudoykulov, “Chemical analysis of the components of soil-lime compositions,” Polytechnic Bulletin of TTU Named After Academician M.S. Osimi, Vol. 4, No. 44, pp. 77–80, 2018.

-

A. Adilkhodjaev, I. Kadyrov, B. Kudratov, D. Azimov, and U. Abdullayev, “Effect of binary microfiller on structure formation of cement stone,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030033, Jan. 2025, https://doi.org/10.1063/5.0267410

-

N.M. Mukhammadiev and G. Malikov, “Use of basalt fiber in concrete mixture for manufacture of prefabricated concrete and reinforced concrete structures,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030043, Jan. 2025, https://doi.org/10.1063/5.0266812

-

V. Tsoy, D. Abdullaeva, and N.M. Mukhammadiyev, “Influence of silica-containing additives on structure formation of composite cement binder for non-autoclaved aerated concrete,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060019, Jan. 2024, https://doi.org/10.1063/5.0197488

-

I. Mukhamataliyev, N. Mukhammadiev, F. Ruzmetov, A. Khudoyorov, and S. Uzakov, “Performance properties of fiber-reinforced concrete particle-fiber-reinforced fox polfiber M12 BASF companies,” in 6th International Scientific Conference Construction Mechanics, Hydraulics and Water Resources Engineering (CONMECHYDRO 2024), Vol. 3286, p. 020003, Jan. 2025, https://doi.org/10.1063/5.0281474

-

A. Ilyasov, A. Adilkhodjaev, I. Makhamataliev, and A. Allamuratov, “Optimization of the composition of fiber foam concrete with polypropylene fiber Fox Polfiber M12 produced by basf company,” in E3S Web of Conferences, Vol. 452, p. 06011, Nov. 2023, https://doi.org/10.1051/e3sconf/202345206011

-

K. J. Osinubi and A. O. Eberemu, “Effect of hydrated lime on the plasticity of lateritic soils,” Journal of Materials in Civil Engineering, Vol. 21, No. 8, pp. 362–370, 2009.

-

S. Shaumarov, K. Karakulov, S. Kandakhorov, Z. Okilov, and J. Yusupov, “Composition of aerated concrete using local raw materials,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030047, Jan. 2025, https://doi.org/10.1063/5.0268040

-

U. Turgunbaev, N. Rakhimova, and T. Eshmanov, “Thermokinetic monitoring of concrete using chemical additives,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060027, Jan. 2024, https://doi.org/10.1063/5.0197423

-

U. Turgunbayev and D. Sharipova, “About properties of polymer cement glue (PCA) with use of acetone-formaldehyde resin (AFR),” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 060035, Jan. 2025, https://doi.org/10.1063/5.0267599

-

M. Khemissa and A. Mahamedi, “Cement and lime mixture stabilization of expansive clay for use in road pavement layers,” Engineering Geology, Vol. 168, pp. 96–102, 2014.

-

A. Arifjanov, R. Pirmatov, U. Vakhidova, A. Khaydarov, S. Arifjanov, and K. Ruziyev, “Efficient use of reservoirs in Uzbekistan,” in BIO Web of Conferences, Vol. 141, p. 03022, Nov. 2024, https://doi.org/10.1051/bioconf/202414103022

-

U. J. Turgunbayev, D. T. Sharipova, and E. I. Tykhtaboev, “The influence of technological factors on the properties of non-autoclaved aerated concrete,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 050025, Jan. 2024, https://doi.org/10.1063/5.0197541

-

J. Wu, H. Yu, and X. Shi, “Effectiveness of products in managing metallic corrosion induced by cyclic deicer exposure: laboratory study using multielectrode array sensors, electrochemical impedance, and laser profilometer,” Journal of Materials in Civil Engineering, Vol. 28, No. 5, May 2016, https://doi.org/10.1061/(asce)mt.1943-5533.0001449

-

S. Tekin and L. Fernández, “Effect of lime stabilization on the geotechnical properties of expansive soils,” Engineering Geology, Vol. 267, p. 105495, 2020.

-

V. Soy, “Investigation of effect of silica-containing additives on structure of composite binders,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030039, Jan. 2025, https://doi.org/10.1063/5.0267635

-

B. C. Diniz et al., “Lime stabilization of tropical soil for resilient pavements: mechanical, microscopic, and mineralogical characteristics,” Materials, Vol. 17, No. 19, p. 4720, Sep. 2024, https://doi.org/10.3390/ma17194720

-

C. Raupov and G. Malikov, “Creep in expanded clay concrete at different levels of stress under compression and tension,” in E3S Web of Conferences, Vol. 365, p. 02008, Jan. 2023, https://doi.org/10.1051/e3sconf/202336502008

-

S. Salikhanov and F. Zokirov, “Studying possibilities of joint operation of main beam and protective layer constructions,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030029, Jan. 2025, https://doi.org/10.1063/5.0266815

-

C. Raupov and G. Malikov, “Comparison of microcrack formation boundaries determined by complex of physical methods with long-term strength of expanded clay concrete under different types of stress state,” in E3S Web of Conferences, Vol. 365, p. 02023, Jan. 2023, https://doi.org/10.1051/e3sconf/202336502023

-

N. B. Shaumarov, “Strength and deformation of materials and structures under the influence of seismic loads,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 050043, Jan. 2024, https://doi.org/10.1063/5.0197366

-

A. Adilkhodjaev, I. Kadyrov, B. Kudratov, D. Azimov, B. Xasanov, and I. Umarov, “On the structure of cement stone with fillers from metallurgical waste,” in E3S Web of Conferences, Vol. 410, p. 01020, Aug. 2023, https://doi.org/10.1051/e3sconf/202341001020

-

A. Adilkhodzhaev, I. Kadirov, B. Kudratov, B. Khasanov, M. Radjabov, and V. Kondrashenko, “Some aspects of the processes of obtaining and application of mineral powders as fillers for cement systems,” in E3S Web of Conferences, Vol. 410, p. 01021, Aug. 2023, https://doi.org/10.1051/e3sconf/202341001021

-

A. Adilkhodjaev, I. Kadyrov, and M. Rasulmukhamedov, “Research of porosity of a cement stone with a zeolite containing filler and a superplastic stificator,” in E3S Web of Conferences, Vol. 264, p. 02007, Jun. 2021, https://doi.org/10.1051/e3sconf/202126402007

-

A. I. Adylkhodzhaev, M. I. Muminovich, K. I. Abdullaevich, S. S. Sanatovich, and R. F. Sharifboevich, “To the question of the influence of the intensity of active centers on the surface of mineral fillers on the properties of fine-grained concrete,” International Journal of Innovative Technology and Exploring Engineering, Vol. 8, No. 9S2, pp. 219–222, Aug. 2019, https://doi.org/10.35940/ijitee.i1044.0789s219

-

A. I. Adilkhodzhaev, I. A. Kadirov, D. T. Azimov, and B. S. Kudratov, “Thermodynamic analysis of mineral powder grinding processes,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 060003, Jan. 2024, https://doi.org/10.1063/5.0197549

-

L. Khamidov, S. Makhkamov, M. Turapov, S. Kholmirzaev, S. Suyunov, and B. Kudratov, “Visualization of macroseismic parameters during examination of epicentral zones of strong earthquakes,” in E3S Web of Conferences, Vol. 264, p. 02039, Jun. 2021, https://doi.org/10.1051/e3sconf/202126402039

-

V. Tsoy, F. Karimova, N.M. Mukhammadiyev, and J. Turgayev, “Parameters of the oscillatory process of the sleeper base in the area of the rail joint when using elastic spacers,” in E3S Web of Conferences, Vol. 401, p. 05078, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105078

-

R. Narov, “Development of intensive technology for constructing low-rise building walls from ash-cement mix,” in E3S Web of Conferences, Vol. 452, p. 06020, Nov. 2023, https://doi.org/10.1051/e3sconf/202345206020

-

S. Vladimir and V. Bekkulov, “Investigation of physical and mechanical properties of non-autoclaved aerated concrete from prescription and technological factors,” in E3S Web of Conferences, Vol. 401, p. 03006, Jul. 2023, https://doi.org/10.1051/e3sconf/202340103006

-

S. Shaumarov, S. Kandakhorov, A. Babaev, and B. Kodirov, “Modeling development of optimal composition of non-autoclaved aerated concrete based on industrial waste,” in E3S Web of Conferences, Vol. 401, p. 03011, Jul. 2023, https://doi.org/10.1051/e3sconf/202340103011

-

V. I. Kondrashchenko, N. A. Telyatnikova, A. I. Adylkhodzhaev, and E. V. Kondrashchenko, “Concrete macrostructure modelling – as a method of increasing the quality of transport facilities construction,” in IEEE International Conference Quality Management, Transport and Information Security, Information Technologies, pp. 106–112, Sep. 2018, https://doi.org/10.1109/itmqis.2018.8525013

-

S. S. Salixanov, F. Z. Zokirov, Y. T. Xakimova, and G. B. Ismailova, “The effect of increasing loads on foundations of operating bridges,” in E3S Web of Conferences, Vol. 401, p. 01080, Jul. 2023, https://doi.org/10.1051/e3sconf/202340101080

-

S. Hussain, M. Fahim, F. A. Khan, and S. Zaman, “Experimental evaluation of lime column as a ground improvement method in soft soils,” SN Applied Sciences, Vol. 3, No. 10, Sep. 2021, https://doi.org/10.1007/s42452-021-04781-4

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.