Abstract

In the course of highway construction and use in loess area, subgrade settlement disease is common and has great destructiveness. The cone penetration test (CPT), especially the pore pressure cone penetration test, can provide three continuous readings along the exploration depth cone tip resistance, lateral friction resistance and excess pore water pressure. In this paper, CPT tests are carried out in the losses areas in Shanxi, China. Some data and curves are obtained by using CPT, which are quite different from those obtained by conventional drilling, reflecting the soil layer characteristics of the subgrade section, in order to provide a reference for similar projects. The results showed that CPT has a strong advantage in the analysis of the effect of compacted pile in the treatment of pile length and the improvement and reduction of indicators of different layers along the depth direction. However, the correlation between the static penetration and the compaction coefficient commonly used in the current norms still needs to be further studied to enhance the correlation analysis with detection parameters.

Highlights

- CPT tests are carried out on loess after compacted lime soil

- CPT has a strong advantage in the analysis of the effect of compacted pile

- Cement-soil compaction pile has obvious influence on the cone tip resistance

1. Introduction

Subgrade settlement disease is common and has great destructiveness in loess areas. The reasons of highway diseases in loess areas consist of loess property factors, natural environment factors, construction factors, investigation and design factors, etc. However, in terms of investigation and design, the reasons mainly lie in the property test measures of the loess subgrade and the parameter acquisition of settlement calculation.

The main reason for the influence of property testing measures is that field borehole sampling and laboratory test are commonly used in investigation and design [1]. Due to the poor quality of the borehole in the survey period, water-drilling and core tube sampling methods are commonly used in the exploration, which leads to unclear analysis of settlement and it cannot accurately judge the difference of diseases, such as excessive water content and uncompact [2, 3]. At present, the quality assessment technology cannot develop synchronously, and there is a lack of effective methods in the quality detection of highway subgrade [4]. The test index of cone penetration is a comprehensive reflection of the physical and mechanical properties of the subsoil. The cone penetration test (CPT), especially the pore pressure cone penetration test (CPTU), can provide three continuous indexes along the exploration depth, including cone tip resistance (), lateral friction resistance () and excess pore water pressure () [5]. Dhakal et al. [6] proposed a procedure to obtain CPT-based liquefaction that can be applied to gravel-sand-silt mixtures. Guan et al. [5] proposed a novel probabilistic method for characterizing spatial distribution of 3D soil liquefaction. Bol [1] developed a method to obtain the correlation of SPT-CPT depending on the soil behavior. Zhao et al. [7] proposed a data-driven, non-parametric, and directly method that can be applied to non-stationary CPT data without pre-stratification of subsurface soils.

In this paper, CPT tests are carried out on loess areas in Shanxi, China. Some data and curves are obtained by using CPT, which are quite different from those obtained by conventional drilling. It reflects the soil layer characteristics of the subgrade section. This method was first applied in loess areas, which has the advantages of obtaining reliable test data with fast test speed and low labor intensity. The results can provide a reference for similar projects.

2. Project overview

This project is located in the Dayu Town. The geomorphic unit is the piedmont inclined plain area, and the ground elevation is 998.30-1010.66 m. According to the results of drilling, excavation and laboratory geotechnical tests, the subsoil of the site can be divided into two layers from top to bottom according to geological time, namely the Upper Pleistocene (Q3pl) and the Middle Pleistocene (Q2pl).

A large-scale test of lime soil compacted piles has been carried out in the site, with the number of 600-2800 piles depending on the structure. Fig. 1 shows the construction site and the instrument of the piling machine. Lime soil compacted pile is used to treat the collapsibility of loess and improve the bearing capacity of foundation soil. The pile diameter is 400 mm and the triangular arrangement. In order to ensure the reliability of the experiment, the piles used in the experiment were randomly selected within the site, so that the characteristics of the soil layer near different compacted piles can be obtained.

Fig. 1Test site of lime soil compaction pile

The Cougar series crawler work module (120 kN-250 kN) was used in the field tests, which were designed to perform static penetration tests (CPT) and associated static propulsion penetration equipment. The equipment includes a wireless remote controller, 200 kN penetration equipment with the latest design technology, rotary support rod frame, hydraulic pushing and pulling fixture and other accessories. All units feature a flatbed and a folded steel chassis that provides very low ground pressure, ensuring perfect conditions for all types of terrain.

The Cougar series crawler static contact probe is equipped with an electric cone probe using a strain gauge measuring element to measure cone tip resistance () and sidewall friction (), as shown in Fig. 2. In addition, a piezoelectric sensor was used to measure the (excess) pore water pressure () and an acceleration sensor was used to measure the dip angle in both the and directions.

3. Test result of cone tip resistance of lime soil compacting pile

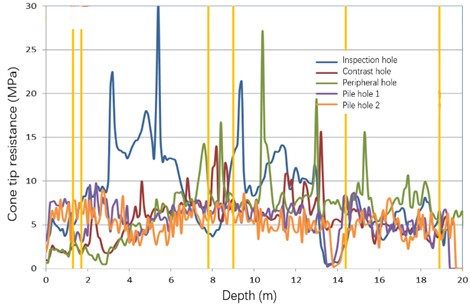

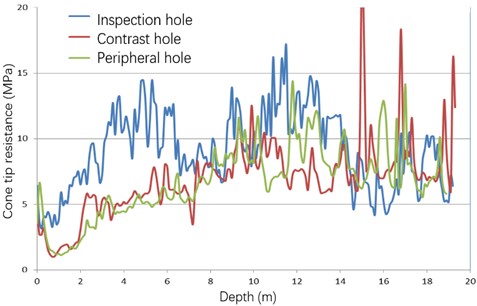

Fig. 3 shows the test results of two different locations of the test site, named site A and Site B, respectively. The analysis of resistance parameters of cone tip of compacting pile shows that:

(1) The cement-soil compacted pile has a significant effect on the resistance of the cone tips between piles, and the mechanical index of the soil between piles is improved effectively within a certain depth range. For site A, the improvement depth range is 0-6.5 m and 8.6-13 m. For site B, the improvement depth range is 14.2 m. In the range of compact-pile, the improved range of soil mechanics index between piles is 0.1-11.5, with an average value of 1.685. Considering that the bearing capacity and compression modulus in the code are directly proportional to the cone tip resistance, the bearing capacity and compressibility are generally increased in proportion after compaction.

Fig. 2Jaguar series crawler static contact probe

Fig. 3Test result of cone tip resistance of lime soil compacting pile

a) Site A

b) Site B

(2) The average values of the test holes in the two sites are 9.36 MPa and 9.74 MPa, respectively. According to the relationship between the foundation soil and the cone tip resistance for building foundation testing, the bearing capacity of the two sites is 523 kPa and 543 kPa, respectively, which both meet the requirement. The compaction coefficient was used to analyze the effect of the lime soil compaction pile. Static penetration could not obtain this parameter, but similar ratios of the cone tip resistance before and after compaction were obtained, which were 1.8 and 1.56 in the two sites, respectively.

(3) Site A shows that although the lime soil compacted pile can effectively improve the cone tip resistance of soil between piles within a certain depth range, it can seriously weaken the cone tip resistance of soil between piles within a certain range, which is not proposed in previous literature. The reason may be that there is a thick layer of silty clay under the soil weakening depth between piles. It is estimated that the underlying silty clay is a hard shell for the upper silty soil in the compaction process of the lime soil, and the impact process is easy to cause the “liquefaction” or “softening” of the upper silty soil. There is no hard silty clay shell in site B, and the compaction effect of this site is better than that of site A.

(4) Although the cement-soil compaction pile effectively improves the quality and compressibility of foundation soil, the strength of the cement-soil pile meets the standard requirements, but the quality is quite different from that of ordinary piles. Firstly, the uniformity of the cement-soil pile is poor, and the strength of the whole pile fluctuates; secondly, the mechanical index of the cement-soil pile is generally lower than that of the soil between piles. This may be related to the fact that the test time is only 3 days.

4. Test result of side wall resistance of lime soil compacting pile

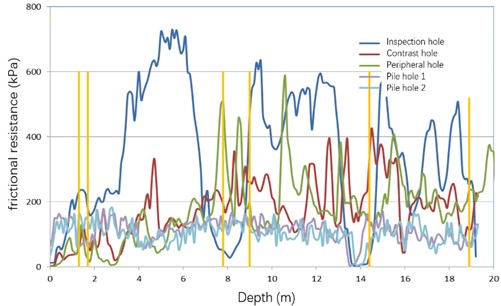

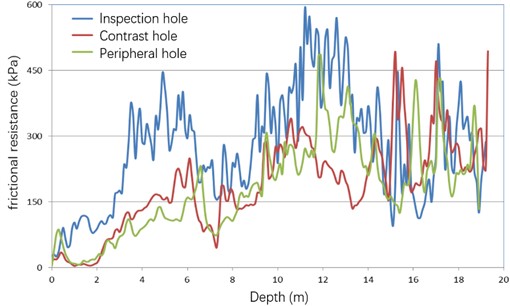

The sidewall resistance parameters of compacted pile are analyzed, as shown in the Fig. 4.

Fig. 4Test result of side wall resistance of lime soil compacting pile

a) Site A

b) Site B

The results show that:

(1) The cement-soil compaction pile has a significant effect on the lateral resistance of soil between piles, and can effectively improve the mechanical index of soil between piles within a certain depth range. For site A, the improvement depth range is 0-6.5 m and 8.6-13 m. For site B, the improvement depth range is 14.2 m. In the range of lime soil compaction piles, the improvement range of the soil mechanics index between piles is 0.1-27.5, with an average value of 2.589. The effect of lateral compaction is the main ability of lime soil compaction pile.

(2) Site A shows that although compacted piles can effectively improve the lateral resistance of soil between piles within a certain depth range, it can seriously weaken the lateral resistance of soil between piles within a certain range, which is not proposed in previous literature. The reason may be that there is a thick layer of silty clay under the soil weakening depth between piles. It is estimated that the underlying silty clay is a hard shell for the upper silty soil in the compaction process of the lime soil, and the impact process is easy to cause the “liquefaction” or “softening” of the upper silty soil. There is no hard silty clay shell in site B, and the compaction effect of this site is better than that of site A.

(3) Although the cement-soil compaction pile effectively improves the quality and compressibility of pile foundation soil, the strength of the cement-soil pile meets the standard requirements, but the quality is quite different from that of ordinary piles. Firstly, the uniformity of the cement-soil pile is poor, and the strength of the whole pile fluctuates; secondly, the mechanical index of the cement-soil pile is generally lower than that of the soil between piles. This may be related to the fact that the test time is only 7 days old.

In summary, the static-sounding parameters of the original stratum, the treated soil between piles and the pile body are analyzed in the test. It is easy to judge that the cone tip resistance and the side wall resistance of the soil between piles are improved to a large extent after the compaction treatment of the lime soil. It can be judged that the quality of the lime soil pile is good, but the improvement effect is worse than that of the pile foundation soil. The effect of lime soil compaction pile on silty soil is better than that of silty clay. It is suggested to select a reasonable bearing layer of lime soil pile after verifying soil properties when dealing with strata with interbedded silt and silt clay, and to place the bearing layer of lime soil pile under 1 m depth of silty clay.

5. Conclusions

In this paper, CPT test is used to analyze the compaction of lime soil compaction pile of a project in Taixin integrated Economic zone. The results show that:

1) The cement-soil compaction pile has obvious influence on the cone tip resistance and side wall resistance of the soil between piles, and can effectively improve the mechanical index of the soil between piles within a certain depth range.

2) For the underlying silty clay to the upper silty soil, the CPT test revealed that the compaction impact process could easily lead to the “liquefaction” or “softening” of the upper silty soil, resulting in local soft layer.

3) The compacted pile mainly produces lateral compaction on the soil between piles in the process of pore-forming, while the compacted pile hole produces almost no compaction or only weak compaction on the soil between piles.

4) Static penetration has a strong advantage in the analysis of the effect of compacted pile in the treatment of pile length and the improvement and reduction of indicators of different layers along the depth direction. However, the correlation between the static penetration and the compaction coefficient commonly used in the current norms still needs to be further studied to enhance the correlation analysis with detection parameters.

References

-

E. Bol, “A new approach to the correlation of SPT-CPT depending on the soil behavior type index,” Engineering Geology, Vol. 314, p. 106996, Mar. 2023, https://doi.org/10.1016/j.enggeo.2023.106996

-

M.-J. Lee, S.-J. Hong, Y.-M. Choi, and W. Lee, “Evaluation of deformation modulus of cemented sand using CPT and DMT,” Engineering Geology, Vol. 115, No. 1-2, pp. 28–35, Sep. 2010, https://doi.org/10.1016/j.enggeo.2010.06.016

-

Z. Guan, Y. Wang, and A. W. Stuedlein, “Efficient three-dimensional soil liquefaction potential and reconsolidation settlement assessment from limited CPTs considering spatial variability,” Soil Dynamics and Earthquake Engineering, Vol. 163, p. 107518, Dec. 2022, https://doi.org/10.1016/j.soildyn.2022.107518

-

Qingjie Qi, Shuai Huang, Jianzhong Liu, and Wengang Liu, “Tunnel surrounding rock stability prediction using improved KNN algorithm,” Journal of Vibroengineering, Vol. 22, No. 7, pp. 1674–1691, 2020.

-

Z. Guan and Y. Wang, “CPT-based probabilistic liquefaction assessment considering soil spatial variability, interpolation uncertainty and model uncertainty,” Computers and Geotechnics, Vol. 141, p. 104504, Jan. 2022, https://doi.org/10.1016/j.compgeo.2021.104504

-

R. Dhakal, M. Cubrinovski, and J. D. Bray, “Evaluating the applicability of conventional CPT-based liquefaction assessment procedures to reclaimed gravelly soils,” Soil Dynamics and Earthquake Engineering, Vol. 155, p. 107176, Apr. 2022, https://doi.org/10.1016/j.soildyn.2022.107176

-

T. Zhao, L. Xu, and Y. Wang, “Fast non-parametric simulation of 2D multi-layer cone penetration test (CPT) data without pre-stratification using Markov Chain Monte Carlo simulation,” Engineering Geology, Vol. 273, p. 105670, Aug. 2020, https://doi.org/10.1016/j.enggeo.2020.105670

About this article

Funding support (No. 20-JKKJ-32, No. 18-JKKJ-23) of Shanxi Transportation Holdings Group Co., LTD are appreciated.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.