Abstract

This paper studies the use of cement fly ash to stabilize the graded gravel and the use of aeolian sand instead of fine aggregates in the design of mixture composition. Firstly, the effect of different cement-fly ash ratios on the aeolian sand bases was investigated, and then the synergistic effects of osmotic crystalline surface protectant (OCSP) and different cement-fly ash ratios on the mechanical properties and water-blocking properties of aeolian sand were analyzed. The results indicated that the optimal water content and maximum dry density of the mixture are increased and the unconfined compressive strength of the 7 d and 28 d both is downward by fly ash. The unconfined compressive strength of the aeolian sand base treated by OCSP was significantly improved, and the enhancement effect was more significant with the increase of cement content. The water absorption rate of each group of specimens increased rapidly during the first 10 hours of immersion., However, the water absorption rate of the specimen treated with OCSP was almost zero in the whole water absorption process after 10 hours.

1. Introduction

At present, China is one of the most decertified countries in the world with the largest desertification area, and serious damage from aeolian sand. In China, it will play a positive role in controlling sand damage and providing land for cultivation if aeolian sand resources can be used to build roads. In addition, aeolian sand resources can also replace natural river sand for pavement construction and relieve the pressure of natural river sand caused by insufficient resources. In recent years, the use of aeolian sand to fill the base of roads in desert areas has become increasingly popular.

Scholars have conducted extensive research on the engineering characteristics of aeolian sand. They agree that Aeolians and have many special engineering characteristics, such as poor gradation, high water permeability, and difficulty in compaction [1-5]. They also discovered that the compaction behavior of aeolian sand differs from that of other clays. Specifically, aeolian sand forms a “double hump” shape after compaction, indicating that it can achieve proper compaction when it's at an air-dried state and optimal moisture content states [6-11]. Aeolian sand cannot be used directly in road bases, and as a result, numerous researchers have conducted extensive research to improve its engineering properties for road construction purposes. According to Fan et al. [12], mixing rolled aeolian sand with round gravel soil can improve the foundation coefficient and porosity. Additionally, many scholars have used various cementitious materials and curing agents to stabilize the aeolian sand and achieved good results. For instance, Banhdadi and Rahman [13] investigated the effect of different ratios of kiln dust cement on the performance of aeolian sand bases and identified the optimal ratio. However, most of the existing research has been limited to indoor experiments and lacks studies on aeolian sand bases in natural environments. This is particularly important given the unique environmental factors of desert areas, such as high wind speeds and large temperature variations between day and night, which can exacerbate water loss and lead to the degradation of the road performance of the base. Therefore, effective measures should be taken when using aeolian sand in such environments, considering the influence of environmental factors. Recent studies have suggested that coating the surface of cement-based materials with an osmotic crystalline surface protectant (OCSP) can block the interaction of internal and external moisture and enhance the durability of cement-based materials [14-16].

This research aimed to mitigate the negative impacts of environmental factors on aeolian sand bases by utilizing the crystalline seal effect of OCSP. In addition, the study investigated the use of cement fly ash to stabilize graded gravel and replaced fine aggregates with aeolian sand in the mixture composition. The effect of varying cement-fly ash ratios on the mechanical and water-blocking properties of aeolian sand bases was analyzed. Furthermore, the study explored the synergistic effects of OCSP and different cement-fly ash ratios on the properties of aeolian sand. These findings provide important theoretical support for the wider adoption and utilization of aeolian sand in desert areas.

2. Materials and methods

2.1. Fine aggregate (Aeolian sand)

The aeolian sand employed in the current study was from the Mu Us Desert, this area’s aeolian sand was composed primarily of light minerals such as quartz and feldspar, with smaller amounts of hornblende, epidote, and garnet. At the same time, the natural dry density, natural water content, and mud content of sand in this area were generally 1.53-1.64 g cm-3, 1.3 %-3.2 %, 5.0 %-10.0 %, respectively [5-10]. The results of the aeolian sand screening are shown in Table 1, and the sieving results indicate that the main particle size distribution was between 0.075 and 0.3 mm, it can be obtained by calculating the results in Table 1 that the non-uniformity coefficient (Cu), curvature coefficient (Cc), and fineness modulus (Mx) of this area were 2.13, 2.13 and 5.73, respectively. According to the standard “Soil Engineering Classification Standard” GB/T50145-2007, aeolian sand in this area is poorly graded sand and belongs to fine sand.

Table 1Basic size and style requirements

Size of the mesh / mm | < 0.075 | 0.075 | 0.15 | 0.3 | 0.6 | 1.18 | 2.36 | 4.75 |

Pass rate / % | 0.11 | 11.2 | 90.7 | 94.3 | 93.7 | 95 | 99.63 | 99.98 |

2.2. Coarse aggregate (crushed stone)

The test coarse aggregate was used from the Sun Mountain region of Ningxia, and the particle sizes of this coarse aggregate were 2.36-4.75 mm, 4.75-9.5 mm, and 9.5-26.5 mm. The results of its basic engineering performance testing are presented in Table 2.

Table 2Results of basic engineering performance tests

Performance indexes | Particle size / mm | ||

2.36-4.75 | 4.75-9.5 | 9.5-26.5 | |

Crushing value / (%) | 19.2 | 17.8 | 20 |

Elongated particle / (%) | 14.2 | 13.5 | 12 |

Water absorption / (%) | 0.78 | 0.38 | 0.22 |

Performance density / (g/cm3) | 2.64 | 2.71 | 0.22 |

2.3. Cementitious material

The cement employed in the current study was P.I 42.5 (from Jidong Cement Co., Ltd). The physical and chemical composition of the cement were shown in Table 3. And the fly ash employed was Class III fly ash (from Zhongyu Thermal Power Plant of Zhongyang Iron and Steel, Shanxi Province). The basic engineering performance tests of the fly ash were shown in Table 4.

Table 3Physical and chemical composition of cement

Loss on ignition / % | Specific surface area / (m2kg-1) | Setting time / min | Compressive strength / MPa | Bending strength / MPa | |||

3.89 | 364 | Initial setting | Final setting | 3d | 28d | 3d | 28d |

202 | 259 | 30.4 | 50.4 | 6.4 | 7.5 | ||

Table 4Basic engineering performance of fly ash

SiO2 | Al2O3 | Fe2O3 | MgO | Loss on ignition / % | The passing rate of 0.3 mm sieve / % | The passing rate of 0.075 mm sieve / % |

47.3 | 28.99 | 18.74 | 3.01 | 3.51 | 99.4 | 84.5 |

2.4. Osmotic crystalline surface protectant

The surface protective agent selected in this test was a commercially available osmotic crystalline surface protective agent, whose basic properties are shown in Table 5.

Table 5Basic properties of osmotic crystalline surface protective agent

Density / (g/cm3) | Viscosity / s | Surface tension / (Mn/m) | Infiltration height / mm |

1.10 | 11.7 | 25.0 | 30 |

3. Experimental design

In this study, aeolian sand was used to replace fine aggregates below 0.3 mm in size, with a continuous grading test conducted using a cement-fly ash to crushed stone ratio of 17:83. The composite grading of the mixture is shown in Table 6.

Table 6Grading table of inorganic binder synthesis

P / mm | 31.5 | 26.5 | 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.075 |

The upper limit of grading / % | 100 | 100 | 86 | 79 | 72 | 62 | 45 | 31 | 22 | 15 | 5 |

Median of gradation / % | 100 | 95 | 78 | 70.5 | 63 | 52 | 35 | 23.5 | 16.5 | 11 | 3.5 |

The lower limit of grading / % | 100 | 90 | 70 | 62 | 54 | 42 | 25 | 16 | 11 | 7 | 2 |

Synthetic gradation / % | 100 | 100 | 85.5 | 73.6 | 67.0 | 53.8 | 33.4 | 17.1 | 14.5 | 14.4 | 2.1 |

Table 7Test scheme

Number | Cement: Fly ash | OCSP |

Cff-1 | 1:3 | 0 |

Cff-2 | 1: 4 | 0 |

Cff-3 | 1: 5 | 0 |

Cfo-1 | 1: 3 | 1 |

Cfo-2 | 1: 4 | 1 |

Cfo-3 | 1: 5 | 1 |

Compaction tests were carried out based on the “Test Regulations for Highway Engineering Inorganic Binder Stabilized Materials” (JTJ57-2009), with five different moisture contents used for each mixing ratio. Wet and dry densities of the stabilized materials were calculated for each test. Based on the results of the compaction test, the amount of various materials in each group was determined, and 13 cylindrical test pieces of size 150 mm × 150 mm were formed by static pressure with a press. After molding, the specimens were left standing for 24±2 h for demolding. The surface of the demolded specimens was cleaned with a cleaning agent to remove oil, and then OCSP was applied three times to the surface of each specimen in a wet state, with an interval of four hours between each application. The treated specimens were then sealed in plastic bags and moved to a standard curing room for curing. Once the specimens reached the desired age, unconfined compressive strength and water absorption tests were conducted after saturating the specimens in water for 24 hours. The specimens were dried to a constant weight before performing the water absorption test. The specific test plan is presented in Table 7.

4. Results and discussion

4.1. Compaction test results and analysis

Table 8 shows the compacting test results of each group, as can be seen from Table 8, the optimal water content and maximum dry density of the mixture gradually increase as the amount of fly ash increases in the cement-fly ash stable system. The reason is that fly ash has the engineering characteristics of a large specific surface area, large water requirement, and low density, as well as the ball effect of fly ash in the mixture. which improves the surface characteristics of aeolian sand to a certain extent and reduces the influence of aeolian sand on the mixture.

Table 8Compaction test results of each group

Cement: Fly ash | Optimal water content / % | Maximum dry density / (g/cm3) | Cement: Fly ash / (g/cm3) |

1: 3 | 6.30 | 1.76 | 1: 3 |

1: 4 | 6.90 | 1.81 | 1: 4 |

1: 5 | 7.30 | 1.82 | 1: 5 |

4.2. Unconfined compressive strength test results and analysis

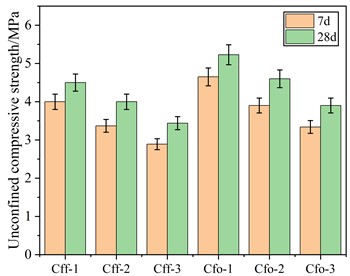

Fig. 1 shows the unconfined compressive strength test results of each group at 7 and 28 days. According to Fig. 1, the unconfined compressive strength of 7 d and 28 d tends to decrease with increasing fly ash content. As compared with the Cff-1 group, the unconfined compressive strength of the Cff-2 group and the Cff-3 group at 7d decreased by 15.75 % and 27.75 %, respectively. The unconfined compressive strength of the Cff-2 group and Cff-3 group at 28 d decreased by 12.5 % and 23.56 %, respectively. As compared with the Cfo-1 group, the unconfined compressive strength of the Cfo-2 group and Cfo-3 group at 7 d decreased by 16.13 % and 28.17 %, respectively, and the compressive strength decreased by 13.73 % and 19.61 %, respectively, at 28 days.

In addition, the unconfined compressive strength of the OCSP treatment groups was higher than that of the reference groups, as the unconfined compressive strength of each group treated with OCSP increased by 16.25 %, 15.73 %, and 15.57 % at 7 days, respectively, and the unconfined compressive strength increased by 16.22 %, 15.00 %, and 13.37 %, at 28 days. However, cement is also one of the main reasons affecting the mechanical properties of specimens. As the cement content increases, the effect of OCSP on the mechanical properties of specimens becomes more prominent. This is due to the fact that OCSP penetrates the surface pores of the specimen through capillary action and primarily reacts with the Ca2+ and Al3+ ions in the matrix to form crystals, which reinforce the specimen. With an increase in the amount of cement, more reactants become available for the crystallization reaction, resulting in the formation of a greater number of crystals [17-20].

4.3. Water absorption test results and analysis

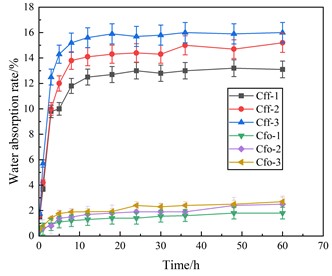

The water absorption test results for each group at 28 days are shown in Fig. 2. On the whole that the water absorption rate of each group increased rapidly before 10 h and tended to remain stable after 10 h. After 10 h, the water absorption rate of Cff-1, Cff-2, Cff-3, Cfo-1, Cfo-2, and Cfo-3 were stable at 13.1 %, 15.2 %, 16.0 %, 1.8 %, 2.2 %, and 2.5 %, respectively. Compared with Cff-groups, the water absorption of Cfo-1, Cfo-2, and Cfo-3 groups after OCSP treatment decreased by 86.25 %, 85.53 %, and 84.38 %, respectively. This indicates that OCSP treatment is beneficial to improve the density of the specimen surface. In addition, with the increase of cement dosage in the cement-fly ash stabilization system, the water absorption rate of specimens decreases.

This is because the osmotic crystallization of OCSP enhances the density of the surface layer and prevents water from entering the sample. At the same time, compared with fly ash, cement hydrates earlier and is more conducive to crystallization reaction [18-20].

Fig. 1Unconfined compressive strength test results

Fig. 2Water absorption test results in 28 d

5. Conclusions

1) In this study, aeolian sand was used as a replacement for fine aggregates in road base stabilization with different cement-fly ash ratios. Compaction tests showed that increasing the fly ash content increased the optimum water content and maximum dry density.

2) The unconfined compressive strength of 7 d and 28 d decreased with the increase of fly ash content. Moreover, the unconfined compressive strength of aeolian sand base was significantly improved after OCSP treatment, and the improvement effect of OCSP was obvious with the increase of cement content.

3) The water absorption rate increased rapidly before 10 hours and stabilized after 10 hours, with different stabilization systems showing varying rates. However, OCSP treatment significantly reduced water absorption.

4) The research results of this paper provide a theoretical basis support for the popularization and application of aeolian sand in the road base, which has important significance for further improving the quality of highway construction in desert areas.

References

-

Y. Yuan, X. Wang, and X. Zhou, “Experimental research on compaction characteristics of aeolian sand,” Frontiers of Architecture and Civil Engineering in China, Vol. 2, No. 4, pp. 359–365, Dec. 2008, https://doi.org/10.1007/s11709-008-0053-3

-

T. Cheng, “Vibro-crushed stone pile is used to treat aeolian sand wet soft foundation (in Chinese),” (in Chinese), Journal of Highway and Transportation Research and Development (Applied technology edition), Vol. 7, pp. 63–66, 2011.

-

X. L. Yan, R. Q. Ma, Y. F. Zhang, J. L. Zhu, and J. Shi, “Engineering classification of aeolian sand in Yulin Area,” Highway, Vol. 66, No. 3, pp. 54–60, 2021.

-

F. L. Wang, H. Feng, and Z. T. Liu, “Application of aeolian sand on National Highway 242 from Ganqimaodu to Linhe Highway (in Chinese),” (in Chinese), Journal of Highway and Transportation Research and Development (Applied technology edition), Vol. 14, No. 3, pp. 14–15, 2018.

-

Y. Zhao, “The application of use aeolian sand treating wet-soft subgrade base research,” Chang’an University, 2021.

-

M. L. Zheng, Q. Q. Wang, W. Chen, Y. Gao, S. Zhang, and L. L. Zhu, “Materials characteristics and shear strength of aeolian sand in different areas,” China Science Paper, Vol. 16, No. 4, pp. 415–421, 2021.

-

M. L. Zheng, H. Y. Jing, W. Chen, L. L. Zhu, S. Zhang, and Y. Gao, “Experimental study on basic characteristics and pozzolanic activity of natural aeolian sand,” Bulletin of the Chinese Ceramic Society, Vol. 40, No. 1, pp. 163–171, 2021, https://doi.org/10.16552/j.cnki.issn1001-1625.2021.01.015

-

H. Xia, J. Zhang, J. Cai, H. Pan, and X. She, “Study on the bearing capacity and engineering performance of Aeolian sand,” Advances in Materials Science and Engineering, Vol. 2020, pp. 1–11, Apr. 2020, https://doi.org/10.1155/2020/3426280

-

C. N. Jin, “Comparative analysis of windy accumulated sands by heavy-typed compaction and surface vibration compression method of desert areas in China,” Materials Science Forum, Vol. 987, pp. 3–9, Apr. 2020, https://doi.org/10.4028/www.scientific.net/msf.987.3

-

Y. Q. Yuan, X. C. Wang, and H. J. Shao, “Study on impact compaction of Aeolian sand subgrade and its effect evaluation,” Advanced Materials Research, Vol. 378-379, pp. 370–373, Oct. 2011, https://doi.org/10.4028/www.scientific.net/amr.378-379.370

-

S. X. Hu, “Research into physical improvement of Aeolian sand as filling material in Yulin section of Baotou-Xi’an railway,” Railway Standard Design, No. 7, pp. 18–22, 2012, https://doi.org/10.13238/j.issn.1004-2954.2012.07.010

-

Y. Fan and Y. Z. Wang, “Experimental study of improvement technology of subgrade fill consisting of poorly graded fine sand,” Rock and Soil Mechanics, Vol. 24, No. 6, pp. 965–968, 2003, https://doi.org/10.16285/j.rsm.2003.06.021

-

Z. A. Baghdadi and M. A. Rahman, “The potential of cement kiln dust for the stabilization of dune sand in highway construction,” Building and Environment, Vol. 25, No. 4, pp. 285–289, Jan. 1990, https://doi.org/10.1016/0360-1323(90)90001-8

-

Z. W. Jiang and J. H. Tang, “Application of cement-based permeable crystalline waterproof material in dam (in Chinese),” (in Chinese), New Building Materials, No. 8, pp. 21–22, 2001.

-

H. Liu, S. H. Yin, T. F. Li, Z. Y. Wen, H. O. Shi, and J. M. Liu, “Experimental research of cementitious capillary crystalline waterproofing material applied tom Etro engineering concrete,” Concrete, No. 4, pp. 40–42, 2007.

-

B. G. Chen, G. Q. Ni, and G. Y. Li, “Composition and function of cementitious capillary crystalline waterproof coating,” New Building Materials, No. 5, pp. 65–67, 2008.

-

K. L. Wang, T. Z. Hu, and S. J. Xu, “Influence of permeated crystalline waterproof materials on impermeability of concrete,” Advanced Materials Research, Vol. 446-449, pp. 954–960, Jan. 2012, https://doi.org/10.4028/www.scientific.net/amr.446-449.954

-

M. Y. Wang, C. Z. Li, and Z. S. Niu, “Effects of osmotic crystalline surface protectant on the waterproof and anti-corrosion properties of concrete,” Materials Reports, 2020.

-

J. J. Chu, C. L. Shen, and X. G. Zhang, “New type rigid waterproof materials and its application,” New Building Materials, Vol. 43, No. 7, pp. 60–64, 2016.

-

C. Y. Shen et al., “Influence of capillary crystalline waterproofing on the resistance of concrete to chloride ion penetration,” New Building Materials, Vol. 42, No. 11, pp. 81–83, 2015.

About this article

The research was supported by the Transportation Science and Technology Project in Shaanxi Province (No. 21-50K).

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.