Abstract

Composite curved panels are widely used in civil aircraft, yet they are susceptible to hidden damage such as delamination due to low-velocity impacts, making effective detection essential. Most existing guided wavefield damage imaging methods rely on Fourier transform-based wavenumber analysis, which processes signals globally and often overlooks local damage features. Moreover, current techniques are primarily developed for flat plates, with limited application to curved panels. To overcome these limitations, this paper proposes a TKEO-wavefield imaging algorithm for detecting hidden delamination in composite curved panels. The approach is based on the principle that delamination induces local wavefield singularities in the spatial domain. By leveraging the Teager-Kaiser Energy Operator (TKEO) to amplify these singularities, a damage image is constructed from the fused TKEO-wavefield energy. Experimental results confirm that the algorithm accurately images hidden delamination, offering a novel solution for damage detection in aerospace composite curved structures.

1. Introduction

Advanced composite materials are widely used in aerospace applications owing to their superior mechanical properties [1]. During long-term service, composite structures are susceptible to hidden damage when subjected to external impact. Undetected damage may compromise structural integrity, and failure to identify and repair it in a timely manner can lead to catastrophic accidents [2]. While composite structures exhibit diverse geometries, current damage detection research has predominantly focused on simple flat plates, with relatively limited attention given on curved panels. Notably, composite curved panels are extensively used in launch vehicles and aircraft (e.g., fuselage skins, wing spars, and ribs). The complex and variable external loads encountered during flight directly affect the stability and safety of these structures, underscoring the importance of targeted damage detection [3]. Among various structural damage detection methods – such as static non-destructive testing (NDT) [4] and vibration-based techniques [5], guided wave-based approaches are particularly promising due to their broad coverage and high sensitivity to minor defects [6-8]. Conventional methods often employ piezoelectric sensor arrays for excitation and reception, combined with ellipse- or probability-based imaging algorithms for damage identification. However, limited sensor density often impedes precise imaging of hidden damage. Emerging tools such as Scanning Laser Doppler Vibrometers (SLDV) overcome this limitation by enabling non-contact, full-field wavefield measurements with high spatial resolution. While simple wavefield energy mapping provides preliminary damage localization, it often struggles to detect subtle defects. Techniques such as frequency-wavenumber filtering [9] can enhance damage-related singularities, yet these have been primarily developed for flat plates. Consequently, wavefield imaging for curved structures remains underexplored. Existing Fourier-based wavenumber analysis methods process signals globally, which tends to obscure local damage features and limit sensitivity to incipient hidden damage.

In this work, we leverage the ability of the Teager-Kaiser energy operator (TKEO) to amplify signal singularities for spatial wavefield analysis. A TKEO-based wavefield damage imaging algorithm is developed and applied to visualize hidden delamination in composite curved panels.

2. TKEO-wavefield imaging algorithm

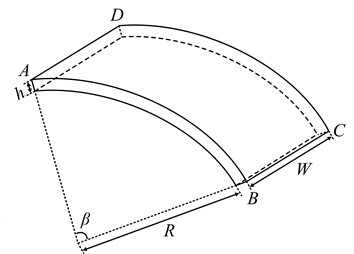

This study investigates a cylindrical curved panel as illustrated in Fig. 1. The geometric parameters include the inner radius , panel thickness , arc angle , arc length , and the length of the straight edge . The analyzed wavefield signal corresponds to the out-of-plane velocity field on the panel surface, denoted as . The wavefield data are provided in discrete form as , where 1, 2, ..., and 1, 2, ..., are the spatial indices along the - and -directions, respectively, and 1, 2, ..., is the discrete time index.

Fig. 1Schematic diagram of the curved panel

a) Three-dimensional diagram

b) Planar diagram

The TKEO was initially proposed for estimating the energy of a one-dimensional discrete signal . It is defined as a nonlinear operator given by [10]:

where represents the value of the signal at point . The operator was later extended to two-dimensional (2D) discrete signals , with the 2D form expressed as [11]:

In this work, is applied to the discrete wavefield to enhance local singularities associated with structural damage:

where denotes the resulting TKEO-wavefield.

The temporal evolution of the wavefield energy is characterized by the wavefield energy time distribution function, defined as:

A time window is selected for subsequent analysis, where the starting frame satisfies the condition . The TKEO-wavefield images within the time window are synthesized into a single energy map by computing their accumulated energy:

Damage can be directly visualized from this TKEO-wavefield energy map.

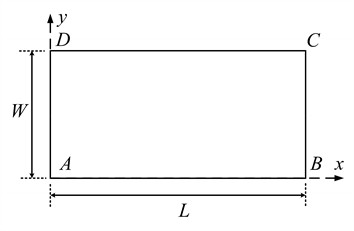

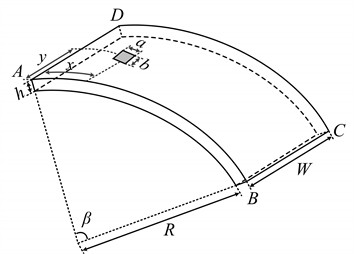

3. CFRP curved panel specimen

The CFRP curved panel with delamination used in the experiment is illustrated in Fig. 2. Its geometry is defined by of 210 mm, of 390 mm, and of 64.5°. The panel consists of 12 plies of carbon fiber in a [0°/90°]3s stacking sequence, with a nominal ply thickness of 0.13 mm. A delamination is created during lay-up by placing a Teflon film at the predefined interface. The damage is characterized by an in-plane center at (110 mm, 105 mm) and planar dimensions of 30 mm by 30 mm.

Fig. 2Schematic diagram and photograph of the CFRP curved panel with delamination

a) Schematic diagram

b) Photograph

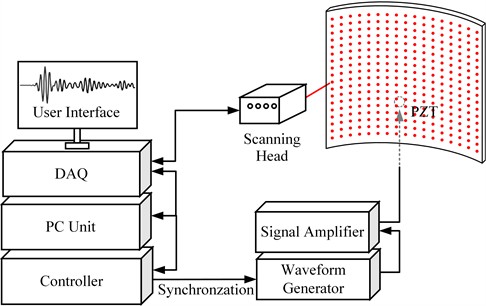

4. Wavefield measurement

A PZT sensor with a diameter of 10 mm is used to excite guided waves, while a SLDV serves as the sensing device. The excitation signal is a 5-cycle Hann-windowed sine pulse with a central frequency of 50 kHz.

Fig. 3Wavefield measurement system

As illustrated in Fig. 3, the wavefield measurement system comprises four key components: a waveform generator, a signal amplifier, the PZT sensor, and the SLDV. The measurement procedure is outlined as follows: The PZT sensor is bonded to the geometric center on the back side of the curved panel. The specimen is then positioned on the measurement platform. During PZT excitation, the SLDV scans the panel surface to capture the out-of-plane velocity signals at all measurement points.

5. Experimental results

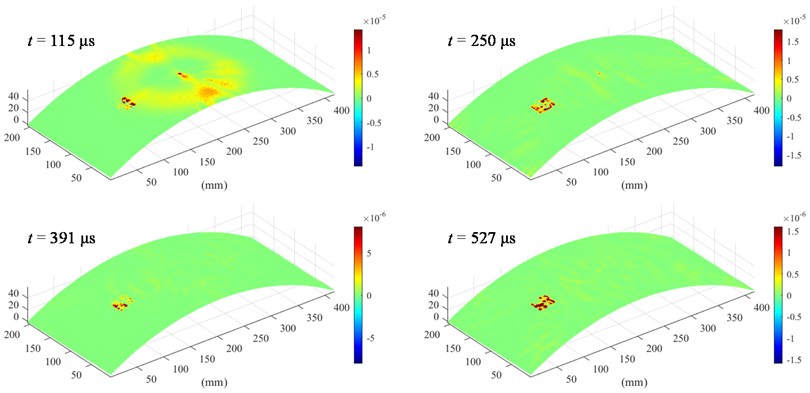

The propagation of guided waves in the CFRP curved panel over time is illustrated in the wavefield images shown in Fig. 4. To improve damage identification, these wavefields are processed using the TKEO, with the results presented in Fig. 5.

Fig. 4Wavefield images at different time frames

Fig. 5TKEO-wavefield images at different time frames

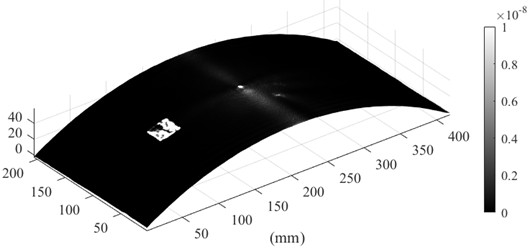

A comparison between Figs. 4 and 5 indicates that the TKEO-processed wavefields significantly enhance the singular components associated with structural damage. This enhancement effectively demonstrates the capability of the TKEO in highlighting damage-related features within the wavefield. Although the TKEO-wavefield images in Fig. 5 allow a preliminary estimation of the damage location, the developed TKEO-wavefield imaging algorithm is applied for accurate localization and visualization. As shown in Fig. 6, the algorithm successfully identifies the hidden delamination in the CFRP curved panel with improved clarity and precision, confirming its effectiveness. To evaluate localization accuracy, the delamination is represented by the coordinates of the peak point in the TKEO-wavefield energy map, specifically at 105 mm and 118 mm. This peak lies within the actual delamination region, confirming the high localization accuracy of the method.

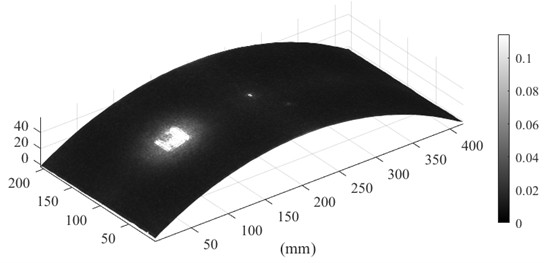

For comparison, delamination imaging in the CFRP curved panel was also performed using an established wavefield imaging technique – the adaptive wavenumber filtering method [12]. The resulting damage map is shown in Fig. 7. It can be seen that this method also locates the delamination with good accuracy. However, a comparison between Figs. 6 and 7 reveals that the proposed method achieves superior performance in delineating the exact size and shape of the delamination, as the result obtained by the adaptive wavenumber filtering method contains noticeable interference signals around the damaged area. Furthermore, the proposed method is more straightforward to implement, since the adaptive wavenumber filtering method requires careful selection of an optimal filter threshold.

Fig. 6TKEO-wavefield energy map

Fig. 7Damage map obtained by the adaptive wavenumber filtering method

6. Conclusions

This paper introduces a novel method for high-resolution imaging of delamination defects in composite curved panels. The proposed approach commences with the acquisition of full-wavefield measurements utilizing a PZT-SLDV system. This initial step is crucial as it captures subtle wavefield singularities, or localized anomalies, induced by the presence of internal delamination. Subsequently, the method strategically employs the TKEO, which is highly effective in amplifying these transient singularities directly in the spatial domain. Consequently, a damage imaging algorithm is constructed based on the enhanced TKEO-wavefield energy map. This process enables the successful and accurate visualization of the delamination’s precise location and extent. The efficacy and reliability of our proposed technique are conclusively validated through experimental results on a curved composite specimen.

References

-

W. Xiao et al., “Compressive failure analysis of composite honeycomb sandwich panels with impact damage and stepped-scarf repairs,” Thin-Walled Structures, Vol. 201, p. 112012, Aug. 2024, https://doi.org/10.1016/j.tws.2024.112012

-

W. Xiao et al., “Experimental and numerical studies on compressive failure behaviors of stepped-scarf repaired composite stiffened panels,” Engineering Failure Analysis, Vol. 163, p. 108458, Sep. 2024, https://doi.org/10.1016/j.engfailanal.2024.108458

-

G. Sha et al., “Enhanced wavefield singularity imaging of diverse defects in plate-type structures,” Mechanical Systems and Signal Processing, Vol. 234, p. 112798, Jul. 2025, https://doi.org/10.1016/j.ymssp.2025.112798

-

A. Zarei and S. Pilla, “Laser ultrasonics for nondestructive testing of composite materials and structures: A review,” Ultrasonics, Vol. 136, p. 107163, Jan. 2024, https://doi.org/10.1016/j.ultras.2023.107163

-

G. Sun, Y. Wang, Q. Luo, and Q. Li, “Vibration-based damage identification in composite plates using 3D-DIC and wavelet analysis,” Mechanical Systems and Signal Processing, Vol. 173, p. 108890, Jul. 2022, https://doi.org/10.1016/j.ymssp.2022.108890

-

G. Sha et al., “A two-step method for additional mass identification in beam structures by measurements of natural frequencies and guided waves,” Measurement, Vol. 186, p. 110049, Dec. 2021, https://doi.org/10.1016/j.measurement.2021.110049

-

G. Sha et al., “Global-local damage localization and imaging in beam structures using laser-measured natural frequencies and guided wavefields,” Measurement, Vol. 236, p. 115061, Aug. 2024, https://doi.org/10.1016/j.measurement.2024.115061

-

W. Xiao et al., “Deep learning-aided guided wavefield imaging of delaminations in composite laminates,” Mechanical Systems and Signal Processing, Vol. 238, p. 113232, Sep. 2025, https://doi.org/10.1016/j.ymssp.2025.113232

-

T. E. Michaels, J. E. Michaels, and M. Ruzzene, “Frequency-wavenumber domain analysis of guided wavefields,” Ultrasonics, Vol. 51, No. 4, pp. 452–466, 2011, https://doi.org/10.1016/ j.ultras.2010.11.011

-

J. F. Kaiser, “On a simple algorithm to calculate the ’energy’ of a signal,” in International Conference on Acoustics, Speech, and Signal Processing, pp. 381–384, 1990, https://doi.org/10.1109/ icassp.1990.115702

-

A.-O. Boudraa and E.-H. S. Diop, “Image contrast enhancement based on 2D Teager-Kaiser operator,” in 15th IEEE International Conference on Image Processing, pp. 3180–3183, Jan. 2008, https://doi.org/10.1109/icip.2008.4712471

-

P. Kudela, M. Radzieński, and W. Ostachowicz, “Identification of cracks in thin-walled structures by means of wavenumber filtering,” Mechanical Systems and Signal Processing, Vol. 50-51, pp. 456–466, Jan. 2015, https://doi.org/10.1016/j.ymssp.2014.05.041

About this article

This work was supported in part by the National Natural Science Foundation of China (Grant No. 12102184). The authors also wish to express their profound gratitude to Dr. Maciej Radzieński at the Institute of Fluid-Flow Machinery, Polish Academy of Sciences, for his expert contribution to the wavefield measurement experiments.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.