Abstract

In order to understand the ignition and growth process of CL-20-based explosives, a comparative study of ignition and growth characteristics of CL-20 and HMX-based explosives was carried out. The ignition and ignition growth of CL-20, HMX, CL-20 and HMX-based explosives were studied respectively by means of ignition test and time-pressure test. The results showed that the reaction growth rate of CL-20 explosives was the fastest, indicating that the CL-20 explosives were easy to ignite, and it was easy to grow into more intense reaction form after ignition.

1. Introduction

CL-20 is recognized as energy-containing material with the highest energy density in the world. Since 1987, CL-20 explosives have been synthesized from NWSWC. Many kinds of plastic bonded explosives, pouring solidification and mixed explosives containing CL-20 have been developed in America, Europe, Japan and India. Some of these explosives have been applied to various warheads. The results of foreign research show that CL-20-based mixed explosive has high explosive velocity and high explosive pressure, and its explosive power is higher than that of TNT, RDX and HMX-based explosives.

In 2001, Blame Asay [1] carried out explosive burning experiments on the degree of intense reaction of explosives. Micro-experiment Wave interferometer measures the shell expansion velocity and displacement, thus quantitatively evaluating the intensity of explosive reaction. However, it is found that there is no obvious difference in the expansion speed of explosive shell under different burning conditions. It is believed that the shell expansion velocity under the action of explosive reaction is a cumulative effect. In 2007, Yoh et al. [2-3] carried out explosive burning experiment and numerical calculation for LX-10 explosive. Based on the linear viscoelastic material model and considering the explosive expansion effect and shell fracture, the distribution of shell fragments after ignition of explosive is calculated. However, compared with the size of the fragments collected in the experiment, the deviation of the calculated results is larger. In 2012, Sorber et al. [4-5] performed violent measurement devices for insensitive explosive reaction Improvement. Two kinds of plate heaters were used to heat explosives and seal steel shells strictly. After the metal slider is flying out under high temperature and high pressure, the probe is triggered, and the velocity of the slider is measured by using the laser external velocity meter, and the reaction intensity of the explosive is evaluated quantitatively by the velocity. In 2015, Chen [6] calculated the degree of reaction intensity after ignition of solid propellants. Device Solid motor propellant charging structure is adopted. The deformation of shell at different time and the deformation of shell at different ignition positions are calculated. The intensity of explosive reaction is analyzed according to the velocity of shell rupture.

CL-20-based explosive is a new type of explosive which has been mainly developed at present [7-9]. The recognition of its non-impact ignition characteristics in the industry is not sufficient. However, most of the current safety operating specifications are based on the experience summary of traditional materials. It is necessary to carry out further research work of CL-20-based new materials in thermal and other non-impact ignition, which not only reveals the mechanism of ignition and growth, but also provides guidance and support for subsequent research and popularization. In order to evaluate the safety of CL-20-based explosives under thermal stimulation, a comparative study of ignition and growth characteristics between CL-20 and HMX-based explosives has been carried out. The results of this study can provide basic data for evaluating the safety of HMX-based and CL-20-based explosives.

2. Test design

In this paper, CL-20 and HMX explosives and CL-20-based mixed explosives CL-20-1 and HMX-based mixed explosives HMX-1 are selected. The states of the four samples are powdery. See Table 1 for sample parameters.

Table 1Explosive sample parameters

No. | Explosive | Composition |

1 | CL-20 | CL-20 |

2 | CL-20-1 | CL-20, Al, etc. |

3 | HMX | HMX |

4 | HMX-1 | HMX, Al, etc. |

The general idea is: from the three aspects of non-impact ignition, reaction growth and severity of reaction of explosives, the quantitative characterization study of several explosives is carried out using the existing model tests, and the difference of non-impact ignition characteristics of four explosives is obtained through comparison of test results.

The ignition energy of four samples was recorded by the camera in the experiment, and the ignition energy of the sample was calculated.

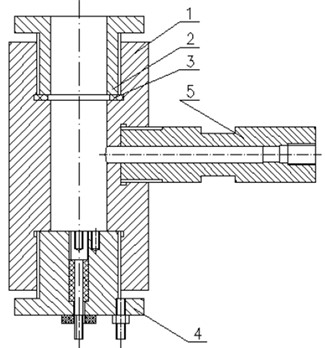

The time-pressure test is used to judge the reaction growth characteristics of four explosives [10-11]. The time-pressure test device diagram is shown in Fig. 1. It consists of five parts: pressure vessel body, ignition plug, blowout plate, clamping plug and side arm. In the time-pressure test, weigh 8±0.1 g of explosive sample, place it in the test device, ignite the explosive sample with 5±0.2 Ω resistance wire and 12 V power-on voltage, and record the p-t curve by pressure sensor.

Fig. 1Time-pressure test device diagram

The intensity of the reaction study is used to obtain the severity of the two explosive reactions. The project team intends to quantify the intensity of the reaction of the explosive by two parameters, the maximum pressure after ignition of the sample in the closed space and the time required to reach the maximum pressure.

3. Test results and analysis

3.1. Ignition characteristic test result and analysis

In determining the ignition characteristics of two kinds of explosive samples, the ignition energy is changed by changing the test voltage and power-on time by using electric wire ignition test sample. Ignition characteristics are studied by using Eq. (1) to quantify the ignition energy, and the ignition time of the explosive is taken by a camera located 30 cm from the sample of explosive [12-14]:

where is the power-on voltage, is the electric wire resistance, and is the power-on time.

During the test, the resistance wire resistance is 8 Ω, the power-on voltage is 24 V, and the explosive sample quantity is 8 g±0.1 g. The ignition energy of the four samples is shown in Table 2 by recording the ignition time of different explosive samples.

Table 2Ignition energy of explosive samples

No. | Sample | Ignition time / s | Energy / J |

1 | CL-20 | 1.72 | 123.84 |

2 | CL-20-1 | 2.85 | 205.20 |

3 | HMX | 3.03 | 218.16 |

4 | HMX-1 | 2.91 | 209.52 |

It can be seen from the above table that the ignition energy of CL-20 explosives in the four samples is significantly lower than that of other explosives, that is, CL-20 explosives are more likely to ignite, and the ignition energy of the other three explosives is basically the same.

3.2. Study on reaction growth characteristics test results and analysis

The research on reaction growth characteristics is carried out using the time-pressure test shown in Fig. 1. The test principle is as follows: In the test, the explosive sample is sealed in a sealed container with a certain volume and ignited with the specified ignition object. In the test, the pressure sensor is installed in the pressure measuring hole. After the test sample is ignited, the pressure sensor measures the change process of pressure with time and obtains the value. The reaction growth rate is judged by the value. The larger value proves that the reaction growth rate is faster. The values of four explosives obtained by this method are shown in Table 3.

Table 3Reaction growth characteristics of four explosives

No. | Sample | / MPa / ms |

1 | CL-20 | 193.6 |

2 | CL-20-1 | 18.28 |

3 | HMX | 83.39 |

4 | HMX-1 | 13.67 |

It can be seen from Table 3 that the value of single CL-20 explosive is about 2 times of HMX of single substance, 10 times of CL-20-1 and 15 times of HMX-1, that is, the value of single CL-20 explosive is much higher than that of other explosives. It is proved that single CL-20 explosive has the fastest reaction growth rate, i.e. after ignition, it is easier to grow into a form of intense reaction. Secondly, the values of the two kinds of mixed explosives are smaller than those of single explosives, which proves that the mixed explosives reduce the reaction growth rate.

3.3. Experimental results and analysis of severity of reaction

According to the maximum pressure and the time required to reach the maximum pressure in the United Nations Recommendations for the Transport of Dangerous Goods, the severity of the reaction of explosives can also be used as the basis for judging the test results:

Test Series 1 Time Pressure Test Criteria: If the maximum pressure reached is greater than or equal to 2070 kPa, the result is "+", i.e. the substance shows the ability to detonate. If the maximum pressure reached in any one test is less than 2070 kPa, the result is "-", i.e. the substance does not show the possibility of detonation. Failure to ignite does not necessarily indicate that the substance has no explosive nature.

The 8 g ± 0.1 g explosive sample was placed in a closed container during the test. The maximum pressure and maximum pressure arrival time of the four explosive samples recorded by the pressure sensor are shown in Table 4.

Table 4Maximum pressure and maximum pressure arrival time for four explosive samples

No. | Sample | Maximum pressure / MPa | Arrival time / ms |

1 | CL-20 | 264 MPa | 0.167 |

2 | CL-20-1 | 42.13 | 15.7 |

3 | HMX | 86.24 | 2.7 |

4 | HMX-1 | 33.11 | 22 |

It can be seen from the data in Table 4 that CL-20 explosives, regardless of maximum pressure and maximum pressure arrival time, are much smaller than the other three explosives, demonstrating that CL-20 reaction is more intense.

4. Conclusions

At present, the explosive CL-20 is the most widely studied three generation explosives. But its safety research is not sufficient, especially how to increase after ignition is not very much. From the point of view of ignition to reaction growth, this paper systematically studied the ignition growth characteristics of CL-20 explosives through three experiments, and compared with the ignition growth characteristics of commonly used second generation explosives. From the point of view of safety, CL-20 explosive growth rate is faster and pressure is higher. The results show that:

1) The ignition energy of single CL-20 explosive is significantly lower than that of the other three explosives, which proves that CL-20 explosive is easier to ignite.

2) The reaction growth rate of single CL-20 explosive is the fastest, indicating that it is easy to ignite, and it is easy to grow into more intense reaction form after ignition.

The novelty of this paper lies in the following three points: Firstly, an extensively studied explosive containing CL-20 was adopted. Secondly, the safety of CL-20 explosive studied from the previous research focus on the ignition condition, but this paper focus on the ignition growth characteristic. In this paper, the study not only included the ignition growth time, the ignition growth rate and ignition growth pressure are also obtained. Finally, the conclusion proves that the ignition growth rate is faster and ignition growth pressure is higher than the typically second generation explosives. Thus, through this research, it is necessary to pay attention during use and study of CL-20 explosives. This paper provided data support for the safety study and use of CL-20 explosives.

References

-

X. Zhang, “Rapid combustion experiment and numerical simulation of TATB-based PBX,” Energetic materials, Vol. 18, No. 50, pp. 551–557, 2010.

-

J. J.-I. Yoh, “High-end modeling and simulation of cookoff of HMX-based energetic materials,” in Computational Science and Its Applications – ICCSA 2006, pp. 484–490, Jan. 2006, https://doi.org/10.1007/11751649_53

-

J. J. Yoh, M. A. Mccclelland, and J. L. Maienschein, “Test-based thermal explosion model forHMX,” in 31st International Symposium on Combusion, 2007.

-

S. Sorber, C. Stennett, and M. Goldsmith, “Developments in a small scale test of violence,” in Shock Compression of Condensed Matter – 2011: Proceedings of the Conference of the American Physical Society Topical Group on Shock Compression of Condensed Matter, Vol. 1426, pp. 563–566, Jan. 2012, https://doi.org/10.1063/1.3686341

-

P. J. Rae, C. L. Bauer, C. Stennett, and H. M. Flower, “Small scale thermal violence experiments for combined insensitive high explosive and booster material,” in Proceedings of the14th International Detonation Symposium, 2010.

-

L. Chen, “Thermal safety theory and analysis method of explosives,” National Defense Industry Press, 2015.

-

P. J. Baker, “Impact-initiated detonative and nondetonative reactions in confined tritonal, composition H-6, and PBXN-109,” in 1lth Symposium (International) on Detonation, Snowmass, 1996.

-

P. C. Souers and P. Vitello, “Initiation pressure thresholds from three sources,” Propellants, Explosives, Pyrotechnics, Vol. 32, No. 4, pp. 288–295, Aug. 2007, https://doi.org/10.1002/prep.200700030

-

S. K. Chidester, R. Garza, and C. M. Tarver, “Low amplitude impact testing and analysis of pristine and aged solid high explosives,” in 1lth Symposium (International) on Detonation. Snowmass, pp. 93–100, Oct. 2015.

-

S. P. Sivapirakasam, M. Surianarayanan, and G. Swaminathan, “Hazard assessment for the safe storage, manufacturing and handling of flash compositions,” Journal of Loss Prevention in the Process Industries, Vol. 22, No. 2, pp. 254–256, Mar. 2009, https://doi.org/10.1016/j.jlp.2008.09.001

-

J. H. Li et al., “The reaction threshold of JOB-9003 explosive under low amplitude loading,” Explosion and shock waves, Vol. 35, No. 6, pp. 876–880, 2015.

-

J. H. Li, S. G. Wen, and D. W. Tan, “The experimental study on the reaction threshold of explosive under low amplitude shock,” Explosion and Shock Waves, Vol. 31, No. 2, pp. 148–152, Feb. 2021.

-

Y. C. Liu, J. H. Wang, C. W. An, and Y. W. Yu, “Effect of particle size of RDX on mechanical sensitivity,” Chinese Journal of Explosives and Propellants, Vol. 27, No. 2, pp. 7–9, 2004.

-

W. H. Yang et al., “ICT nondestructive testing for high explosive density,” Chinese Journal of Explosives and Propellants, Vol. 24, No. 3, pp. 33–35, 2001.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.