Abstract

This study employs molecular dynamics (MD) simulations to investigate the nano-scale current-carrying friction and wear behavior of copper/graphite conductive slip rings under varying electric field strengths, normal loads, and sliding velocities. A three-layer MD model comprising graphite, an air gap, and a copper substrate was constructed using Materials Studio and simulated via LAMMPS. Results show that increased electric field strength, load, and sliding speed exacerbate friction force and energy dissipation, while lower parameter values promote the formation of stable tribochemical films and enhance anti-wear performance. These findings provide theoretical guidance for optimizing conductive slip ring design in high-reliability industrial applications.

Highlights

- Developed a molecular dynamics model of the copper/graphite/air interface to reveal atomic-scale mechanisms of current-carrying friction and wear in conductive slip rings.

- Demonstrated that lower electric field, moderate load, and slow sliding speed promote stable tribochemical films, reducing friction and wear while enhancing service life.

- Identified optimal operating parameters that provide theoretical guidance for designing durable, high-reliability conductive slip rings in precision industrial applications.

1. Introduction

Conductive slip rings are critical electromechanical components widely employed in systems requiring rotary transmission of electrical power and signals, such as wind turbines, radar systems, aerospace platforms, and industrial robotics [1, 2]. Their functionality and operational lifespan are directly tied to the stability and efficiency of their tribological interfaces, which typically consist of metal-graphite contacts. Among them, copper/graphite pairs are extensively adopted due to their low electrical resistivity, self-lubricating properties, and relatively stable mechanical performance [3, 4]. Despite their advantages, the performance of these contacts deteriorates under varying environmental and operational conditions, particularly in high-speed or high-current applications where friction-induced degradation and wear are critical challenges.

Friction and wear behavior in conductive slip rings is influenced by multiple factors, including applied load, relative velocity, current density, and environmental atmosphere. Conventional research has mainly relied on macro-scale tribological testing; however, these methods lack the spatial and temporal resolution required to reveal atomic-level mechanisms. Notably, studies using atomic force microscopy (AFM) have provided important insights into friction at the nanoscale. Gulbiński et al. [5] and Simič et al. [6] employed AFM to investigate frictional behavior in thin-film systems, showing that nanoscale friction coefficients tend to remain within a stable range despite load variations. Nevertheless, such experimental methods are often time-consuming, costly, and limited in capturing real-time atomic interactions and interfacial chemistry.

To overcome these limitations, molecular dynamics (MD) simulation has emerged as a powerful tool for elucidating friction and wear processes at the atomic scale. It allows the observation of atomic trajectories, bond breakage and formation, energy dissipation, and tribochemical reactions in a controlled environment. For example, Wang et al. [7] studied the effect of van der Waals forces between copper and carbon atoms and found that reduced atomic separation led to lower friction coefficients. Yi et al. [8] and Zhang [9] explored the impact of sliding speed, temperature, and alloying elements on wear behavior, while Wang [10] examined transitions in wear mechanisms under prolonged frictional contact.

Despite these efforts, a systematic understanding of how electric field strength, load, and sliding velocity affect the nano-scale tribological behavior of current-carrying interfaces is still lacking. These parameters directly influence contact potential, surface reactivity, and interfacial stability, yet their coupled effects remain underexplored. Additionally, insights from MD simulations have rarely been translated into practical design recommendations for slip ring applications.

This study aims to bridge that gap by conducting a comprehensive MD simulation of copper/graphite slip rings under various electric field intensities, normal loads, and sliding velocities. By simulating a realistic interface and analyzing friction force evolution, energy dissipation trends, and atomic displacement behaviors, this work provides foundational insights into the optimization of conductive slip rings. Ultimately, the findings can inform the design of longer-lasting, high-performance rotary electrical transmission devices in intelligent and harsh-environment systems.

2. Theory and construction of the MD model

2.1. Basic theory of molecular dynamics

Molecular dynamics (MD) simulation is an advanced computational technique that utilizes Newton’s equations of motion to investigate the dynamic behavior of atoms and molecules under complex external conditions. The equation of motion for particles is shown in Eq. (1), which quantitatively describes the relationship between the net force acting on a particle and its resulting acceleration-forming the core of MD simulations:

where represents the position of particle as a function of time; is the mass of particle ; and is the force exerted on particle at any given moment. The force is derived from the potential energy function , as expressed in Eq. (2):

where is the position of the particle. is calculated by Eq. (3):

The particle’s velocity and acceleration are updated using Eqs. (4) and (5):

The force field plays a critical role in MD simulations by accurately describing the interactions between atoms and molecules [11, 12]. The accuracy of the force field directly impacts the agreement between simulation results and real physical phenomena. The ReaxFF force field addresses the limitations of conventional force fields in describing chemical reactions, while avoiding the computational cost of first-principles calculations.

Precise temperature control is another key factor in ensuring simulation accuracy, typically achieved using correction factors to finely adjust the system temperature. Common thermostat algorithms include Velocity Rescaling, Berendsen Thermostat, and Nosé-Hoover Thermostat. In this study, the Nosé-Hoover Thermostat is used due to its ability to accurately reproduce natural temperature fluctuations in an isothermal ensemble, which is crucial for understanding complex thermodynamic behavior in realistic physical environments.

2.2. Model construction

An accurate MD model was constructed using Materials Studio to simulate the graphite/copper interface in air. The model includes a top graphite layer (30 Å × 30 Å × 15 Å) composed of stacked hexagonal carbon layers, a middle air layer with randomly distributed O2(20) and N2(80) molecules, and a bottom copper substrate of the same size.

The graphite/air/copper interface was simulated in LAMMPS to study frictional behavior. Both graphite and copper were divided into fixed, thermostatted, and free-moving layers. Fixed layers simulated clamping, thermostatted layers controlled temperature, and free-moving layers captured material deformation during friction.

The time step for all simulations was set to 0.25 femtoseconds (fs), and the total simulation time was 500 picoseconds (ps) for each simulation scenario. The graphite layer contained approximately 3,600 carbon atoms, while the copper substrate consisted of about 4,800 copper atoms. The gas layer included 100 molecules (20O2 and 80N2), totaling 300 atoms. A cutoff distance of 10.0 Å was applied in the ReaxFF potential to account for short-range atomic interactions and bond formation.

3. Nano-scale current-carrying friction and wear performance study

3.1. Effect of electric field strength on friction and wear performance

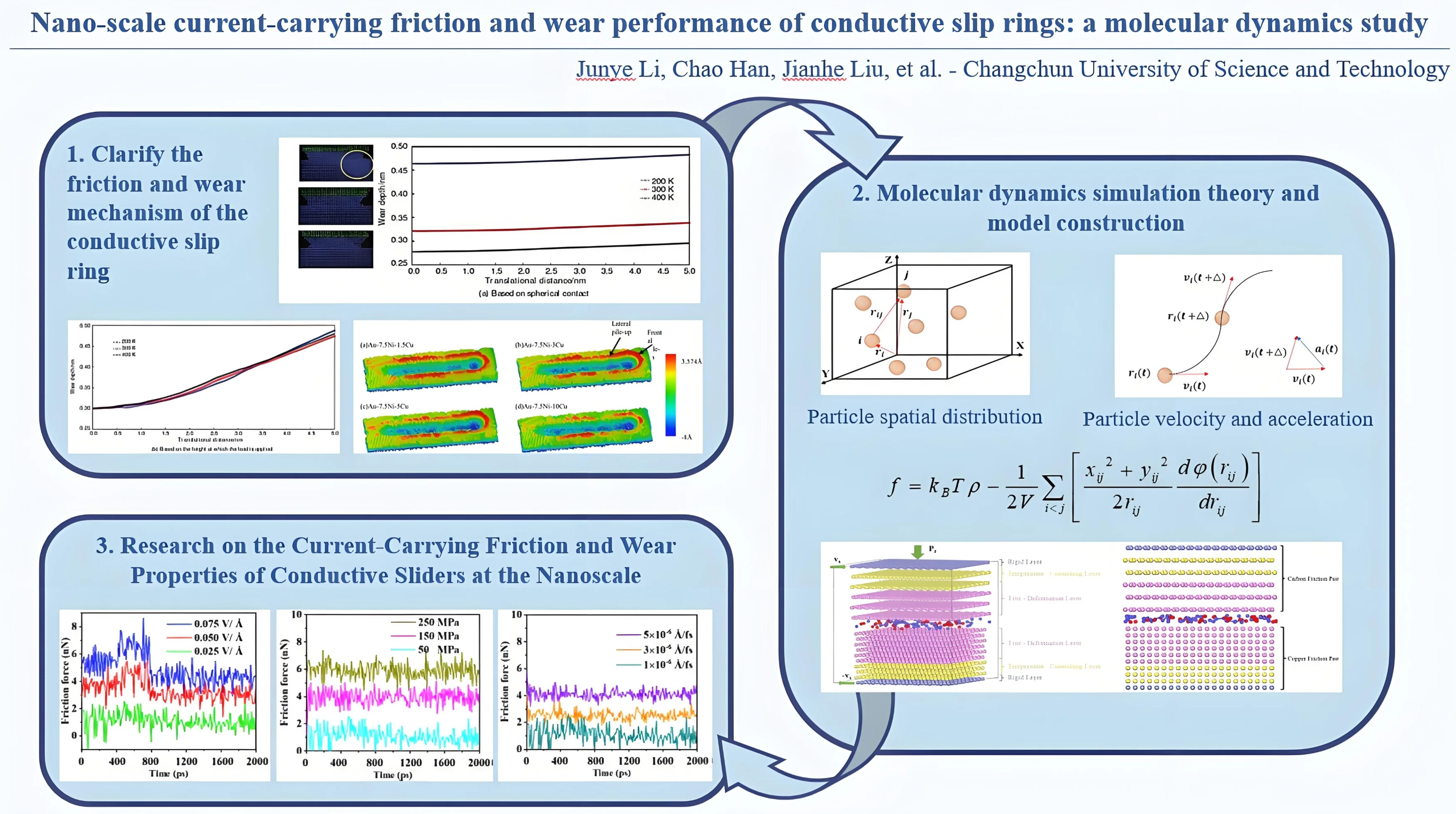

MD simulations were used to examine how electric field strength affects the friction and wear of conductive slip rings. Variations in friction force and system energy were analyzed to assess anti-friction performance. Fig. 1 shows the tribological behavior of the copper substrate under different field conditions.

Fig. 1Effect of electric field strength on the anti-friction performance of conductive slip rings friction force and system energy under electric field strengths of 0.025 V/Å, 0.050 V/Å, and 0.075 V/Å. Simulations were conducted with a fixed load of 150 MPa and a sliding speed of 3×10⁻6 Å/fs

a) Friction force

b) System energy

As shown in Fig. 1(a), the evolution of friction force under electric field strengths of 0.025 V/Å, 0.05 V/Å, and 0.075 V/Å exhibited three distinct stages. In the initial stage, friction force increased sharply due to the activation of friction and tribochemical reactions, accompanied by atomic migration and chemical bond formation at the contact interface. In the second stage, as chemical bonds stabilized and surface morphology became smoother, friction force decreased, reflecting the redistribution and stabilization of system energy. In the final stage, friction force reached a relatively steady fluctuation range, indicating dynamic equilibrium [13]. Notably, friction force increased with higher electric field strength, while lower electric fields (0.025 V/Å) resulted in smaller friction force variations, suggesting improved wear resistance and extended service life.

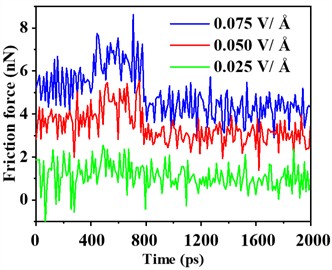

Fig. 1(b) shows that system energy exhibited a significant initial decrease followed by stabilization under all electric field strengths. This behavior corresponds to the formation of stable adsorption films during the running-in period, which reduced energy dissipation and friction force. Moreover, lower electric field strength led to higher total system energy and better anti-friction performance.

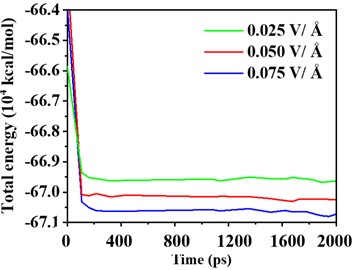

3.2. Effect of load on friction and wear performance

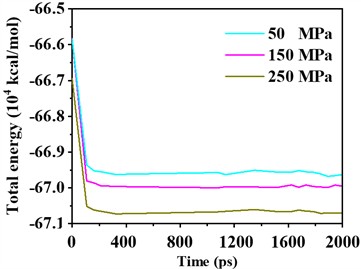

MD simulations were also used to analyze the effects of different contact loads on the tribological behavior of conductive slip rings. Fig. 2 presents the evolution of friction force and system energy under loads of 50 MPa, 150 MPa, and 250 MPa.

Fig. 2Effect of load on the anti-friction performance of conductive slip rings friction force and system energy under normal loads of 50 MPa, 150 MPa, and 250 MPa. Simulations were conducted with an electric field strength of 0.050 V/Å and a sliding speed of 3×10⁻6 Å/fs

a) Friction force

b) System energy

As shown in Fig. 2(a), friction force exhibited three characteristic stages across all load conditions. The initial stage involved a sharp increase due to the activation of tribochemical reactions and atomic migration. In the second stage, friction force gradually decreased as the surface morphology stabilized and chemical bonds saturated. In the third stage, friction force entered a relatively stable fluctuation range, indicating that the system reached dynamic equilibrium [13]. Increased load resulted in higher friction force, while a lower load (50 MPa) yielded the smallest variations in friction force, implying enhanced wear resistance.

As illustrated in Fig. 2(b), system energy decreased sharply at the beginning of the friction process and then stabilized. Lower loads resulted in higher total system energy and lower friction force, indicating superior anti-friction performance under light load conditions.

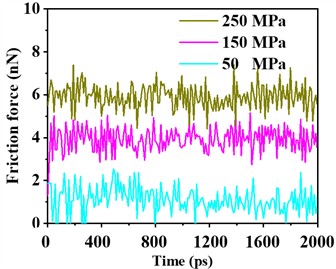

3.3. Effect of sliding speed on friction and wear performance

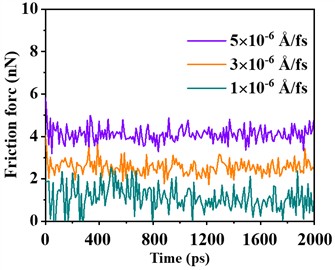

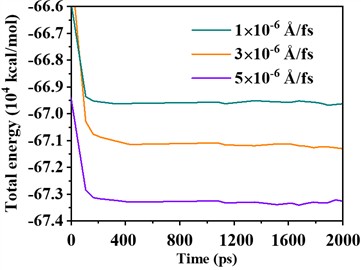

Finally, the influence of sliding speed on the tribological performance of conductive slip rings was investigated using MD simulations. Fig. 3 depicts the evolution of friction force and system energy at sliding speeds of 1×10⁻6 Å/fs, 3×10⁻6 Å/fs, and 5×10⁻6 Å/fs.

As shown in Fig. 3(a), friction force followed a three-stage trend similar to that observed under varying electric field and load conditions. In the initial stage, friction force rose sharply due to tribochemical activation. In the second stage, it gradually decreased as stable chemical bonds formed. In the final stage, friction force stabilized, marking dynamic equilibrium [13]. Higher sliding speeds resulted in greater friction force, while the lowest speed (1×10⁻6 Å/fs) produced minimal friction force variations, suggesting improved wear resistance and longer service life.

Fig. 3(b) demonstrates that system energy initially decreased sharply before stabilizing. Lower sliding speeds led to higher total system energy and lower friction force, further confirming superior anti-friction performance under slower operating conditions.

Fig. 3Effect of sliding speed on the anti-friction performance of conductive slip rings friction force and system energy at sliding speeds of 1×10⁻6 Å/fs, 3×10⁻6 Å/fs, and 5×10⁻6 Å/fs. Simulations were conducted under a fixed electric field strength of 0.050 V/Å and a load of 150 MPa

a) Friction force

b) System energy

4. Conclusions

This work presents a comprehensive molecular dynamics simulation study on the nano-scale friction and wear behavior of copper/graphite conductive slip rings under different electric field strengths, contact loads, and sliding speeds. The findings demonstrate that electric field strength significantly affects the interfacial interactions; higher fields lead to increased friction and energy loss due to intensified atomic collisions and tribochemical activity. Contact load alters the mechanical deformation and adhesion at the interface; moderate loads (e.g., 50 MPa) facilitate smoother sliding and reduced wear, while higher loads intensify surface damage. Sliding velocity impacts energy dissipation and interface stability; lower speeds provide better lubrication conditions and reduce structural disruptions.

Across all simulations, the formation of tribochemical adsorption films played a dominant role in stabilizing friction and minimizing wear. The optimal operating conditions were identified as low electric field (0.025 V/Å), moderate load (50 MPa), and slow sliding speed (1×10⁻6 Å/fs).

These insights offer valuable guidelines for the design and operation of conductive slip rings in high-reliability applications, particularly in environments requiring precision signal transmission and mechanical durability. Future research may focus on extending the model to include more complex surface roughness, multi-component materials, and time-varying current fields to better mimic real-world conditions.

References

-

P. Wang, F. Wei, Z. Zhao, Y. Guo, S. Du, and Z. Hao, “Effect of heat treatment temperature on mechanical and tribological properties of copper impregnated carbon/carbon composite,” Tribology International, Vol. 164, p. 107209, Dec. 2021, https://doi.org/10.1016/j.triboint.2021.107209

-

G. Mei, “Tribological performance of rigid overhead lines against pantograph sliders under DC passage,” Tribology International, Vol. 151, p. 106538, Nov. 2020, https://doi.org/10.1016/j.triboint.2020.106538

-

D. Koh, S. K. Banerjee, J. Brockman, M. Kuhn, and S. W. King, “X-ray photoelectron spectroscopy investigation of the valence band offset at beryllium oxide-diamond interfaces,” Diamond and Related Materials, Vol. 101, p. 107647, Jan. 2020, https://doi.org/10.1016/j.diamond.2019.107647

-

S. Yuan et al., “Insights into the surface oxidation modification mechanism of nano-diamond: An atomistic understanding from ReaxFF simulations,” Applied Surface Science, Vol. 540, p. 148321, Feb. 2021, https://doi.org/10.1016/j.apsusc.2020.148321

-

W. Gulbiński, T. Suszko, and D. Pailharey, “High load AFM friction and wear experiments on V2O5 thin films,” Wear, Vol. 254, No. 10, pp. 988–993, Jul. 2003, https://doi.org/10.1016/s0043-1648(03)00304-1

-

R. Simič and M. Kalin, “Adsorption mechanisms for fatty acids on DLC and steel studied by AFM and tribological experiments,” Applied Surface Science, Vol. 283, pp. 460–470, Oct. 2013, https://doi.org/10.1016/j.apsusc.2013.06.131

-

G. Wang, G. Zhao, J. Song, and Q. Ding, “Study on the tribological properties of copper coated by graphene and h-BN from the atomic scale,” Applied Surface Science, Vol. 573, p. 151548, Jan. 2022, https://doi.org/10.1016/j.apsusc.2021.151548

-

N. Yi, Z. N. Zhang, and J. Y. Zhang, “Molecular dynamics simulation of friction and wear behaviors of au coating for conductive slip ring,” (in Chinese), Tribology, Vol. 38, No. 1, pp. 108–114, 2018, https://doi.org/10.16078/j.tribology.2018.01.014

-

Y. Zhang et al., “Molecular dynamics simulation of friction and wear of AuNiCu alloy,” (in Chinese), Precious Metals, Vol. 44, No. 3, pp. 57–66, 2023, https://doi.org/10.3969/j.issn.1004-0676.2023.03.013

-

Y. Z. Wang, “Study on tribological behavior of pure carbon slide plate of pantograph of railway vehicles in high speed,” (in Chinese), Central South University, 2023.

-

J. G. Greener, “Differentiable simulation to develop molecular dynamics force fields for disordered proteins,” Chemical Science, Vol. 15, No. 13, pp. 4897–4909, Mar. 2024, https://doi.org/10.1039/d3sc05230c

-

E. I. Assaf, X. Liu, P. Lin, and S. Erkens, “Introducing a force-matched united atom force field to explore larger spatiotemporal domains in molecular dynamics simulations of bitumen,” Materials and Design, Vol. 240, p. 112831, Apr. 2024, https://doi.org/10.1016/j.matdes.2024.112831

-

Q. Xu et al., “How polytetrafluoroethylene lubricates iron: an atomistic view by reactive molecular dynamics,” ACS Applied Materials and Interfaces, Vol. 14, No. 4, pp. 6239–6250, Feb. 2022, https://doi.org/10.1021/acsami.1c23950

About this article

The authors are grateful to the referees for their constructive comments and suggestions, which have improved the manuscript. This research was funded by Shanghai Science and Technology Project, grant number 23DZ2229032; Science and Technology Development Plan Project of Jilin Province, grant number 20220201036GX.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.