Abstract

This study presents the development of a technology for producing modified polymer-sulfur bitumen, intended for use as a binder in asphalt concrete for road and pavement construction. The main objective of the research is to improve the heat resistance, durability, and mechanical performance of asphalt pavements operating under high-temperature climatic conditions. The modification process involves incorporating sulfur and polymer additives into bitumen at controlled temperatures to enhance its structural stability. Experimental tests were conducted to investigate the influence of various modifiers, including polyethylene, polyethylene wax, and complex esters, on the physical and mechanical properties of the resulting polymer-sulfur bitumen. The study reveals that an optimal composition containing 3 % polyethylene wax (M2 modifier) significantly increases softening temperature and viscosity, indicating improved resistance to deformation and high thermal loads. The obtained results confirm that polymer-sulfur modification is an effective method to produce cost-efficient, durable, and environmentally sustainable binders for hot climate regions such as Uzbekistan.

1. Introduction

The rapid deterioration of asphalt concrete pavements, especially in hot climatic regions, remains one of the most pressing challenges in modern road engineering. High temperatures accelerate the degradation of bituminous materials, leading to rutting, cracking, and reduced service life of road pavements. With the increasing impact of climate change, the need to develop heat-resistant asphalt materials has become a critical research priority worldwide [1].

In Uzbekistan and other countries with similar climatic conditions, the deformation of asphalt pavements during hot seasons causes frequent surface irregularities and early failures. Traditional bitumen grades often lose their viscosity and adhesion properties when exposed to high temperatures, resulting in structural damage to the pavement. To mitigate these problems, sulfur and polymer modifiers have been introduced as promising additives to improve the thermal and mechanical behavior of bitumen [2-4].

Sulfur’s ability to modify and enhance the properties of construction materials has been extensively researched and exploited over the past four decades [5]. Similarly, sulfur modification enhances the stiffness, reduces production costs, and improves high-temperature stability [6]. However, most existing technologies rely on expensive or chemically unstable modifiers, limiting their practical application in developing countries.

The proposed technology contributes to the advancement of sustainable road construction by reducing bitumen consumption, utilizing industrial sulfur waste, and ensuring economic and environmental benefits. The results of this study are expected to support the production of high-performance asphalt mixtures for long-lasting and climate-adapted pavements in Uzbekistan and similar hot regions.

2. Methodology

The experimental work was aimed at developing a reliable technology for producing modified polymer-sulfur bitumen (PSB) with enhanced performance in hot climatic conditions. The process involved the preparation, modification, and characterization of bitumen samples containing different sulfur-polymer compositions.

2.1. Materials

The base material used in this study was BND 60/90 grade bitumen, commonly employed in Uzbekistan’s road construction industry. Technical sulfur was used as the main modifier, while various polymer additives were incorporated to improve the structural and rheological characteristics of the bitumen.

The sulfur-to-bitumen ratio was maintained at 20:80 % by weight, and the polymer content varied between 2-3 % relative to sulfur mass.

The special role of sulfur in nature, its remarkable properties that are not characteristic of most other chemical elements, gives rise to interest in sulfur chemistry and its use in road construction. Sulfur is а chemical element in group VI of the periodic table of elements of D.I. Mendeleyev, with an atomic mass of 32.060 and а density of 2.10 g/sm3. Sulfur has a melting point of 110-119 °C and а boiling point of 444.8 °C. Sulfur in the composition of sulfur-containing asphalt concrete performs several important functions:

– Partially reduces bitumen and reduces the total cost of the mixture. This is especially important for areas with limited bitumen resources.

– The addition of sulfur increases the high-temperature resistance of the asphalt concrete coating, which improves the elastic properties of the coating at high temperatures.

– Increases the compressive strength of the sulfur-containing asphalt concrete coating and ensures its ability to withstand high loads. It is very useful for heavy road traffic.

– Sulfur increases the strength of the asphalt concrete mixture, which increases the service life of the asphalt concrete cover.

sulfur is a product formed during oil and gas extraction, and its use benefits the environment. This also helps to reduce sulfur emissions.

The patent by Vasiliev Yuriy Emmanuilovich, Motin Nikolay Vasilevich, Pekar Svetlana Sergeevna, Shubin Alexander Nikolaevich, and Yakobi Vasiliy Vilgelmovich describes the modification of sulfur. The modified sulfur constitutes 20-30 % of the bitumen content in the asphalt concrete mixture. This ensures the long-term durability of the sulfur asphalt concrete pavement. However, the drawback is that if sulfur is heated above 150 °C during the modification process, it begins to release hydrogen sulfide and sulfur dioxide gases, which are toxic to humans [9].

The patent of Tanayans Viktor Azatovich also mainly mentions information about the modification of sulfur and the removal of its harmful properties [10]. The drawback is that it is not mentioned that the modified sulfur is adapted to hot climatic conditions after its introduction into the bitumen composition and the preparation of a sulfur-containing asphalt concrete mixture.

The patent of Kairat Mirzasalimovich Beketov and Marat Flurovich Faskhutdinov specifically outlines which substances can be used to modify sulfur. Good results are achieved by modifying sulfur with unsaturated hydrocarbons, styrene, vinyl toluene, and especially dicyclopentadiene. Simple unsaturated mixtures are preferred as sulfur modifiers, as they are widely produced as monomers for polymer production and are inexpensive [11].

The patent by scientists such as Mаrinus Johаnnes Rеynhout, Rоb Alоysius Mаria Vаn Triеr, and Guy Lоde Mаgda Mаria Vеrbis primarily provides information on the modification of sulfur. The patent examines the modification process using 5-ethylidеne-2-nоrbornene, 5-vinyl-2-norbоrnene, and dicyclоpentadiene substances [12].

The disadvantages of the above-mentioned technology are the complexity of obtaining modified sulfur bitumen in this technology compared to other methods and the high yield of hydrogen sulfide gas at heating temperatures above 180 °C (hydrogen sulfide gas has a high negative impact on human health) [13].

2.2. Experimental procedure

Each modification process was carried out in a special reactor equipped with a temperature control and mechanical stirring system. Sulfur was first heated until it reached a reddish color, corresponding to the temperature range of 150-175 °C, depending on the modifier type. Then the selected polymer modifier was added in the required proportion, and the mixture was continuously stirred for 40-60 minutes to ensure homogeneity.

Simultaneously, the bitumen was dehydrated and liquefied at a temperature not exceeding 160 °C, as higher temperatures could degrade its viscosity and adhesion properties. Afterward, the prepared molten bitumen was gradually poured into the modified sulfur and stirred for an additional 60 minutes. The resulting polymer-sulfur bitumen was then cooled and prepared for physical-mechanical testing.

2.3. Testing methods

The aim is to determine whether sulfur meets standard requirements by analyzing its interaction with bitumen through various physical and mechanical properties. We determine the following properties of sulfur-modified bitumen according to GOST 22245-90 [14]:

– Viscosity grade of bitumen (at 0 °C and 25 °C).

– Softening point (using the ring and ball apparatus).

– Ductility (at 0 °C and 25 °C).

– Flash point (using the Brenken apparatus).

– Brittleness temperature (using the Fraass apparatus).

An example of the scientific novelty of the research is the increase in the physical and mechanical properties of polymer-sulfur bitumen in polymer-sulfur asphalt concrete at high temperatures. During this research, we carried out а series of tests to determine the sequence of polymer-sulfur bitumen modification, the technology of bitumen preparation, and the properties of the finished sulfur bitumen. We conducted these laboratory tests by adding various modifiers. The sequence of the performed work is presented below.

First, we need to modify the sulfur using the M1 modifier (polystyrene). For the modification process, a specific amount of sulfur is measured, which should constitute 20 % of the bitumen-sulfur ratio. Initially, the sulfur is heated in а special reactor until it turns а reddish tint аt а temperature of 170 °C, and then 2 % of M1 modified by weight of sulfur is added. The mixture is then stirred in the special reactor for 40 minutes. Simultaneously, BND 60/90 grade bitumen is dehydrated at a temperature not exceeding 160 °C. The liquefied and dehydrated viscous bitumen is then poured into the modified sulfur in the special reactor. After adding the bitumen, the mixture of bitumen and modified sulfur is stirred for 60 minutes to ensure a homogeneous blend. After the bitumen was poured, the bitumen and the modified sulfur were mixed for 60 minutes to form a homogeneous mixture [15].

3. Results and discussion

In these six test experiments, the ratio of sulfur to bitumen was taken as 20:80 %. The proportions of added modifiers were varied.

When determining the physical and mechanical properties of modified polymer sulfur bitumen obtained by the above-mentioned test methods, the following indicators are determined:

– Needle penetration depth into viscous bitumen (in the penetrometer).

– Softening temperature (in the ring and ball instrument).

– Extensibility (in a ductylometer).

After modifying the polymer-sulfur bitumens, we determined their properties. During the experiment, we assessed the viscosity of the bitumen according to GOST 11501-78 [16], the softening point according to GOST 11506-73 [17], and the ductility according to GOST 11505-75 [18] (Table 1).

Currently, scientific research is being conducted on the mathematical modeling of modified polymer-sulfur bitumen [19].

The use of sulfur as an additive to extend or replace asphalt has been demonstrated successfully in both laboratory tests and actual construction. The availability and cost of sulfur offer the potential to reduce paving material costs by as much as 21 percent. Binder cost reductions as high as 32 percent are feasible [20].

Table 1Properties of modified polymer-sulfur bitumen

No. | The proportion of bitumen and sulfur, % | Modifier name | Percentage of modifiers, % | Needle penetration depth, 0.1 mm 25 °C GОST 11501-78 | Bitumen softening temperature, °C GОST 11506-85 | Viscosity of bitumen, cm, 25 °C GОST 11505-78 |

100 | – | – | 68.2 | 50.1 | 55.9 | |

1 | 80:20 | М1 | 2 | 97 | 48 | 39 |

2 | 80:20 | Complex ether | 2 | 78 | 54 | 53 |

3 | 80:20 | M2 | 2 | 74 | 43 | 32 |

4 | 80:20 | M3 | 2 | 62 | 54 | 31 |

5 | 80:20 | М4 | 2 | 57 | 55 | 34 |

6 | 80:20 | M2 | 3 | 59 | 62 | 25 |

All the results obtained were carried out in accordance with the requirements of GОST testing.

The softening temperature of polymer-sulfur bitumen containing 20 % sulfur was determined by researcher Mamatmuminov during the processes of testing the softening temperature properties of high-temperature resistant polymer-sulfur bitumen on a ring and ball device.

The extensibility of polymer-sulfur bitumen containing 20 % sulfur was determined by researcher Mamatmuminov during the processes of testing the extensibility of high-temperature-resistant polymer-sulfur bitumen on a ductylometer device.

The softening temperature of polymer-sulfur bitumen containing 20 % sulfur was determined by researcher Mamatmuminov during testing processes on a penetrometer device for the viscosity properties of high-temperature resistant polymer-sulfur bitumen.

Fig. 1Softening temperature of polymer-sulfur bitumen containing 20 % sulfur

These images were obtained by researcher Mamatmuminov at the “Avtoyulsifat” Testing Laboratory of the Faculty of Road Engineering of Tashkent State Transport University on June 7, 2024, as part of ongoing testing processes to determine the physical and mechanical properties of polymer-sulfur bitumen.

Fig. 2Stretchability characteristic of polymer-sulfur bitumen with a sulfur content of 20 %

Fig. 3Viscosity of polymer-sulfur bitumen containing 20 % sulfur

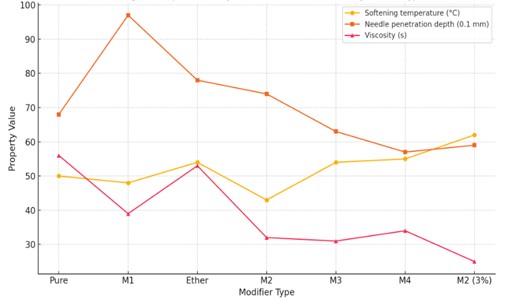

Fig. 4Physical and mechanical properties of polymer-sulfur bitumen, types and values оf mocculators

According to the results of the conduct research, the addition of various polymers, modifiers, and sulfur components to the composition of traditional viscous bitumen significantly changes its basic physical, mechanical, and operational properties. In particular, viscosity, softening temperature, and ductility differ significantly from the physical and mechanical properties of viscous bitumens among modified samples. This significantly affects the degree of normal resistance of bitumens to high temperatures and deformation.

In the extensibility property of polymer-sulfur bitumen, the extensibility of traditional bitumen at a temperature of 25 °C is 56 cm, while in modified bitumen, this indicator varies within the range of 25-39 cm. The decrease in ductility indicates the variability of the material’s properties when adding modifiers M1 and M2. This ensures equal distribution of bitumen in the mixture during construction, and also creates conditions for uniform mixture formation of materials. At the same time, excessively low ductility negatively affects the mechanical stability of bitumen properties. Therefore, it is required that these values be optimal.

Based on the results of the above analysis, it can be said that modifiers added to polymer-sulfur bitumen significantly improve its thermal, hardness, and brittleness properties. In particular, the M4 and 3 % M2 modifications increase the temperature stability, mechanical resistance, and suitability of the bitumen for processing technology. This makes it possible to recommend them as a promising binder material for high-climatic roads with high load intensity.

4. Analysis of experimental data

The results demonstrate that incorporating sulfur and polymer modifiers significantly alters the rheological and thermal behavior of traditional bitumen. The 3 % polyethylene wax (M2) sample exhibited the highest softening point (62 °C) and the lowest penetration value (59×0.1 mm), indicating improved viscosity and resistance to high-temperature deformation.

The addition of sulfur and polymer creates a more interconnected molecular network, which enhances thermal stability and mechanical strength. At the same time, excessive polymer content can reduce ductility, as seen in samples with low elongation values. Therefore, an optimal balance between flexibility and stiffness is crucial for high-performance bituminous binders.

These findings align with similar studies conducted by European and Russian researchers [7-9], confirming that sulfur modification combined with polymers can significantly extend pavement life while maintaining cost efficiency.

5. Conclusions

The results of research on sulfur modification demonstrate that when modified sulfur and bitumen are mixed together in a special reactor, the resulting polymer-sulfur bitumen exhibits significantly enhanced physical and mechanical properties. The modifiers used in the modification process increase both the binding of sulfur to bitumen and the high-temperature resistance of sulfur. Additionally, they improve the chemical stability of sulfur. During the research process, properties of polymer-sulfur bitumen such as viscosity, softening temperature, and ductility were studied.

These modification methods are widely used for construction materials, particularly asphalt concrete mixtures. This technology improves the operational performance indicators of road pavements. Furthermore, it reduces the cost of materials from an economic standpoint and also ensures environmental safety.

In future research, we recommend conducting scientific studies on adapting modified sulfur to various climatic conditions and investigating its long-term performance characteristics at high temperatures. Further research in this direction will enable the application of sulfur in construction and industry.

References

-

S. Yadgarov, R. Sayfutdinova, A. Axrarov, and Q. Muminov, “Climate factors change research for operating conditions of highways passing through mountainous areas,” in International Scientific Conference on Modern Problems of Applied Science and Engineering: MPASE2024, Vol. 3244, p. 040021, Jan. 2024, https://doi.org/10.1063/5.0242324

-

M. Mamatkulov, A. Narmanov, and A. Axrorov, “Some issues of assessing friction coefficient on highways,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: (PTLICISIWS-2022), Vol. 2789, p. 040095, Jan. 2023, https://doi.org/10.1063/5.0145464

-

A. Beketov and S. Khalimova, “Impact of roughness and friction properties of road surface of urban streets on the traffic safety,” Communications – Scientific letters of the University of Zilina, Vol. 25, No. 3, pp. F51–F63, Jul. 2023, https://doi.org/10.26552/com.c.2023.051

-

J. Sodikov, Q. Musulmonov, and D. Imamaliev, “Developing novel registration of road traffic accidents,” Communications – Scientific letters of the University of Zilina, Vol. 24, No. 4, pp. F62–F71, Oct. 2022, https://doi.org/10.26552/com.c.2022.4.f62-f71

-

M. Al-Mehthel, H. I. Al-Abdul Wahhab, S. H. Al-Idi, and M. G. Baig, “Sulfur extended asphalt as a major outlet for sulfur that outperformed other asphalt mixes in the gulf,” in Sulphur World Symposium, Apr. 2010.

-

I. S. Sadikov, Z. S. Pulatova, S. S. Salikhanov, R. A. Sayfutdinova, and I. B. Khoshimov, “Development of the street and road network in Tashkent,” in Problems in the Textile and Light Industry in the Context of Integration of Science and Industry and Ways to Solve Them: PTLICISIWS-2, Vol. 3045, p. 050026, Jan. 2024, https://doi.org/10.1063/5.0197553

-

I. Sadikov, F. Tursunboev, A. Djumaev, and T. Pulatova, “Around roads and recreation areas-reducing environmental damage to vehicles through greening in accordance with environmental landscape,” in Asia-Pacific Conference on Applied Mathematics and Statistics, Vol. 2471, p. 030080, Jan. 2022, https://doi.org/10.1063/5.0089600

-

T. Yi-Qiu and A. Ai, “World Cup 2010 traffic simulation long-term aging of polypropylene asphalt paving mixtures,” in Proceedings of the 2007 26th Southern African Transport Conference (SATC), pp. 761–767, Jul. 2007.

-

Y. E. Vasiliev, N. V. Motin, S. S. Baker, A. N. Shubin, and V. V. Yakobi, “Method of obtaining modified sulfur,” (in Russian), MADI, Moscow, Leningradsky Avenue, 64, Aug. 2013.

-

V. A. Tanayants, “A method for obtaining modified sulfur used in the production of sulfuric asphalt,” (in Russian), Moscow, 2005.

-

K. M. Beketov and M. F. Faskhutdinov, “Method for producing modified polymerc sulfur,” Kazakstan, 2014.

-

M. J. Reynhout, R. A. M. van Trier, and G. L. M. M. Verbis, “Modified sulphur and product comprising modified sulphuras bndert,” Netherlands, 2006.

-

R. G. Telyashev et al., “Method for obtaining sulfur-bitumen binder,” (in Russian), Patent RU2585618C1, 2016.

-

“Oil bitumen road viscous technical conditions,” (in Russian), Moscow, GOST 22245-90, 1990.

-

I. S. Sodiqov, S. M. Tilakov, E. S. Sottiqulov, and A. T. Mamatmuminov, “Improving serobitum production technology,” (in Uzbek), Architecture and Construction Problems, Vol. 3, 2022.

-

“Oil Bitumen. Method for determining the depth of needle penetration,” (in Russian), Moscow, GOST 11501-78, 1978.

-

“Bitum oil method for determining the softening temperature by ring and ball,” (in Russian), Moscow, GOST 11506-73, 2008.

-

“Bitumen oil. The method of determining stretch,” (in Russian), Moscow, GOST 11505-75, 2008.

-

M. Mirsaburov and D. T. Mamatmuminov, “A problem with an analogue of the Bitsadze-Samarskii condition on the segment of degeneracy and an internal segment parallel to it in the domain for a certain class of degenerate hyperbolic equations,” Russian Mathematics, Vol. 69, No. 3, pp. 19–23, Jun. 2025, https://doi.org/10.3103/s1066369x25700215

-

H. H. Weber and W. C. Mcbee, “New market opportunities for sulfur asphalt,” in The Sulphur Institute’s 7th International Symposium ‘Sulfur Markets – Today and Tomorrow’, Mar. 2000.

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.