Abstract

The study investigates the structural and functional characteristics of zirconium-niobium oxide (Zr-Nb-O) coatings deposited using a modernized UVN-75-1 physical vapor deposition (PVD) system. The influence of deposition parameters on the microstructure, phase composition, hardness, and corrosion resistance of the coatings was systematically analyzed. X-ray diffraction, Auger electron spectroscopy, and microhardness testing were used to assess structural and mechanical behavior. It was found that oxygen incorporation and the Nb content in the Zr-Nb system significantly affect coating density and phase stability. The thermally optimized coatings demonstrated enhanced hardness up to 660 HV and improved corrosion resistance compared to single-component films. The novelty of this study lies in the comprehensive evaluation of Zr-Nb-O coatings produced by magnetron PVD and in the establishment of correlations between discharge parameters and mechanical-corrosive performance. These coatings exhibit strong potential for vibration-resistant and corrosion-protective applications in transport engineering, particularly for components operating under cyclic loads and dynamic stresses.

1. Introduction

The development of advanced protective coatings remains one of the most relevant directions in modern materials science. Traditional methods of extending the service life, wear resistance, and corrosion resistance of structural elements often do not provide sufficient performance in aggressive operating environments, particularly in aviation, energy, and mechanical engineering.

One of the promising approaches is the use of functional coatings based on transition metals, oxides, nitrides, and carbides. Among them, zirconium-based coatings attract particular attention due to their high corrosion resistance, low neutron absorption, and favorable mechanical properties at elevated temperatures and pressures. Alloying zirconium with niobium further enhances its strength, thermal stability, and corrosion resistance by neutralizing destructive impurities and forming stable two-phase microstructures [1-3].

Recent studies have shown that Zr-Nb-based coatings obtained by physical vapor deposition (PVD) techniques demonstrate significant improvements in surface performance and durability. However, a comprehensive investigation of their structural features, phase composition, microhardness, and corrosion resistance under varying technological parameters remains an important scientific and practical task.

The aim of this study is to analyze the structure and properties of Zr-Nb coatings, including nitrides and oxides, synthesized by magnetron sputtering in a modernized UVN-75-1 vacuum unit, and to evaluate their mechanical and corrosion performance for potential application in high-demand engineering industries.

Modern transport and mechanical systems operate under severe vibration, temperature, and corrosion conditions, which accelerate surface degradation and fatigue wear. Therefore, there is a growing need for multifunctional coatings that can maintain stability under cyclic mechanical loads. However, limited studies have focused on the influence of deposition parameters on the performance of Zr-Nb-O coatings under such conditions.

Previous studies have focused on modeling of mechanical and environmental factors influencing structural performance in transport systems [17], [19]. These works laid the methodological foundation for analyzing coatings designed to improve vibration resistance and surface stability in transport engineering applications.

This research aims to fill that gap by exploring the structural and functional properties of Zr-Nb-O coatings deposited by PVD for vibration-resistant transport applications.

2. Methods

2.1. Experimental setup

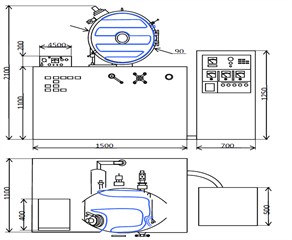

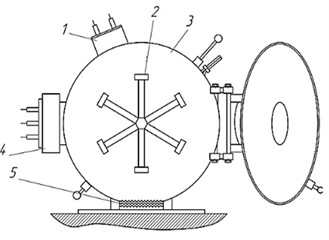

The coatings were synthesized by magnetron sputtering using a modernized UVN-75-1 vacuum deposition system. The cylindrical stainless-steel chamber (grade 12Х18Н10Т) has a diameter of 750 mm, a length of 550 mm, and a wall thickness of 6 mm. The system was equipped with a cold-cathode ion source and a direct-current magnetron sputtering device. A planetary holder allowed simultaneous deposition on up to six samples with a maximum diameter of 100 mm.

2.2. Substrate and target materials

The substrates were prepared from high-alloy chromium-nickel stainless steel 12Х18Н10Т. Zircaloy-2 alloy served as the cathode material. Its chemical composition is presented in Table 1.

Table 1Chemical composition of Zircaloy-2 cathode material (wt.%)

Alloy grade | Zr (base) | Sn | Fe | Cr | Ni | O2 |

Zircaloy-2 | Balance | 1.2-1.7 | 0.07-0.27 | 0.05-0.15 | 0.03-0.08 | ≤0.14 |

2.3. Coating deposition

Deposition was performed under varying discharge currents (1-3 A) and deposition times (20-100 min) to obtain coatings of different thicknesses. Zirconium-niobium coatings, as well as their nitrides and oxides, were deposited under reactive gas pressures ranging from 0.0039 Pa to 0.399 Pa.

2.4. Characterization techniques

1) X-ray Diffraction (XRD): Structural analysis of coatings was carried out using CoKα radiation with an iron filter. The working current was 10 mA, the accelerating voltage was 30 kV, and the detector speed was 1°/min. The lattice parameters and phase composition were determined from diffraction maxima.

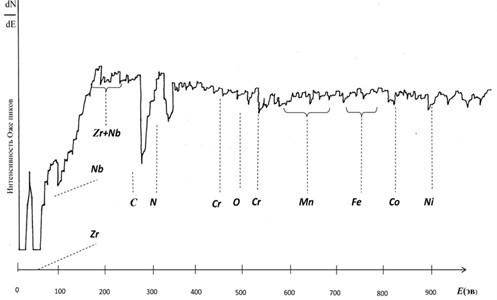

2) Auger Electron Spectroscopy (AES): Surface chemical composition was analyzed at 3 keV primary electron energy, with an anode voltage of 200 V and chamber pressure of ~1.3×10⁻5 Pa. Quantitative elemental sensitivity factors were applied to calculate the atomic concentrations.

3) Microhardness Testing: Measurements were performed on a PMT-3 tester using a diamond pyramid indenter under loads of 0.196 N (20 gf) and 0.490 N (50 gf). Coating thicknesses were correlated with microhardness values. The experimental procedure was developed based on earlier works dealing with the physicochemical characterization of composite and hydrated materials [18], [15]. Each measurement was repeated ten times under identical conditions. The microhardness values were expressed as mean ± standard deviation (SD), and the uncertainty of the results did not exceed 3 % (95 % confidence interval).

4) Corrosion Resistance: Samples were partially masked with chlorovinyl-84 varnish and immersed in an aggressive HCl:HNO3:H2O solution (1:1:2 by volume) for 1-60 min. The corroded surface fraction was determined using an MII-4 interferometer in accordance with GOST 9.041-74 standards. Each corrosion test was conducted in triplicate. The results are presented as average values with standard deviations to ensure the reproducibility and reliability of measurements.

3. Results

3.1. Structural and phase analysis

X-ray diffraction (XRD) revealed that Zr-Nb coatings possess a hexagonal close-packed (hcp) zirconium phase, with lattice parameters slightly larger than reference values. This indicates the formation of a solid solution with niobium. The diffractograms of nitrides were weak due to the thin coating thickness (~1 µm), where substrate peaks dominated. Computed lattice parameters varied with deposition conditions, confirming the influence of discharge current and deposition time on microstructure (Fig. 1-2) [4, 5, 6, 7].

Fig. 1General view of the UVN-75-1 vacuum unit

Fig. 2Scheme of technological device arrangement in the modernized chamber

3.2. Chemical composition

Auger electron spectroscopy (AES) confirmed the presence of zirconium, niobium, oxygen, and nitrogen in the coatings. A representative nitride film contained 91.6 at. % Zr, 1.1 at. % Nb, and 2.9 at. % N. Oxide coatings contained ~90 % Zr, ~1 % Nb, and up to 3 % O [7, 8].

Table 2Auger peak intensity and elemental sensitivity for Zr-Nb coatings

Element | Auger peak intensity, | Elemental sensitivity, | Ratio, / |

Zr | 19 | 0.033 | 575.76 |

Nb | 1.7 | 0.27 | 6.29 |

N | 2.8 | 0.15 | 18.67 |

Cr | 0.5 | 1.79 | 1.79 |

O | 2 | 0.35 | 5.71 |

Mn | 0.9 | 0.23 | 3.91 |

Fe | 0.8 | 0.16 | 5 |

Co | 1 | 0.18 | 5.56 |

Ni | 1.3 | 0.22 | 5.91 |

Fig. 3Auger spectrum of Zr-Nb nitride-based coating

3.3. Microhardness

The microhardness values strongly depended on coating composition and deposition parameters. The statistical analysis showed consistent results, with deviations not exceeding ±3 %. The data in Table 3 are presented as mean ± SD.

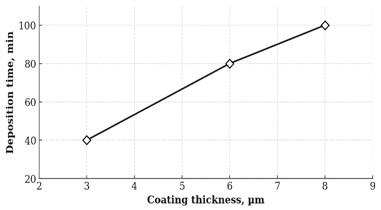

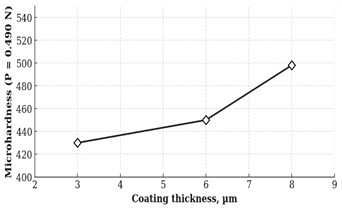

1) Zr-Nb metallic coatings: 428-490 HV under 20 gf load, with thicknesses of ~3-8 µm depending on deposition time (40-100 min).

2) (Zr-Nb)N coatings: hardness of 412-490 HV, but very thin (~1 µm).

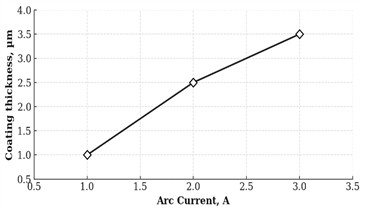

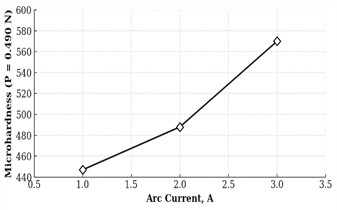

3) (Zr-Nb)O coatings: highest hardness, up to 660 HV, with thicknesses of 1–4 µm depending on current (1-3 A).

Figs. 4-7. Influence of sputtering parameters on coating thickness and hardness.

Table 3Microhardness of Zr-Nb, (Zr-Nb)N and (Zr-Nb)O coatings at different deposition parameters

No | Coatings | Sample number | , min | , A | Microhardness | ,μm | |

0.196 Н (20 N) | 0. 490 Н (50 N) | ||||||

1 | Zr-Nb | 1111 | 40 | 2.5 | 428-458 | 412-447 | ⁓3 |

1122 | 80 | 2.5 | 428-458 | 412-447 | ⁓6 | ||

1133 | 100 | 2.5 | 458-490 | 487-510 | ⁓8 | ||

2 | (Zr-Nb)N | 3333 | 20 | 2 | 412 | 412-429 | ⁓1 |

3311 | 30 | 2 | 412-428 | 412-429 | ⁓1 | ||

3322 | 50 | 2 | 490 | 429-510 | ⁓1 | ||

3 | (Zr-Nb)O | 2233 | 40 | 1 | 458 | 447 | ⁓1 |

2211 | 40 | 2 | 510 | 466-510 | ⁓2-3 | ||

2222 | 40 | 3 | 526-660 | 495-645 | ⁓3-4 | ||

Fig. 4Influence of sputtering time on Zr-Nb coating thickness

Fig. 5Dependence of microhardness on coating thickness

Fig. 6Effect of discharge current on Zr-Nb oxide coating thickness

Fig. 7Effect of discharge current on Zr-Nb oxide microhardness

3.4. Corrosion resistance

Corrosion tests in aggressive HCl:HNO3:H2O solution demonstrated a strong dependence on coating type and thickness. All measurements were repeated three times, and the mean values with standard deviations are reported in Table 4.

1) Zr-Nb metallic coatings: resistant up to 15 min, partial delamination after 30 min.

2) (Zr-Nb)N coatings: unstable, complete corrosion within 1 min.

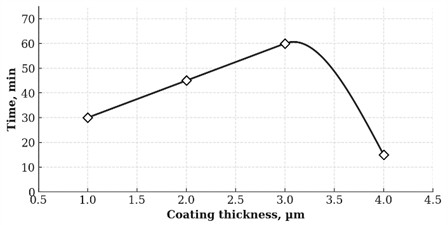

3) (Zr-Nb)O coatings: highest resistance; 3-4 µm thick coatings retained integrity after 30-60 min, with only ~20 % of the surface affected [9-11].

Table 4Corrosion resistance of Zr-Nb coatings in aggressive medium

No | Coatings | Sample number | , min | , А | Microhardness | Coating thickness , µm | |

0,196 N (20 kgf) | 0,490 N (50 kgf) | ||||||

1 | Zr-Nb | 1111 | 40 | 2.5 | 428-458 | 412-447 | ~3 |

1122 | 80 | 2.5 | 428-458 | 412-447 | ~6 | ||

1133 | 100 | 2.5 | 458-490 | 487-510 | ~8 | ||

2 | (Zr-Nb)N | 3333 | 20 | 2 | 412 | 412-429 | ~1 |

3311 | 30 | 2 | 412-428 | 412-429 | ~1 | ||

3322 | 50 | 2 | 490 | 429-510 | ~1 | ||

3 | (Zr-Nb)O | 2233 | 40 | 1 | 458 | 447 | ~1 |

2211 | 40 | 2 | 510 | 466-510 | ~2-3 | ||

2222 | 40 | 3 | 526-660 | 495-645 | ~3-4 | ||

Fig. 8Effect of coating thickness on corrosion resistance of Zr-Nb films

4. Discussion

The experimental results demonstrate that the structure and performance of Zr-Nb-based coatings are strongly affected by deposition parameters and coating composition. The XRD and AES analyses confirmed that solid solutions of zirconium and niobium, along with their oxide and nitride phases, can be effectively synthesized by magnetron sputtering in the UVN-75-1 system. The observed consistency of microhardness and corrosion results was statistically confirmed; the standard deviation did not exceed 3 %, indicating reliable measurement repeatability.

A key observation is that oxide coatings (Zr-Nb-O) showed superior performance compared to both metallic and nitride coatings. Their enhanced hardness (up to 660 HV) and improved corrosion resistance suggest that oxygen incorporation stabilizes the microstructure and prevents rapid degradation in aggressive environments. Conversely, nitride coatings exhibited poor corrosion resistance despite acceptable microhardness, indicating limited suitability for practical use without additional modifications.

The correlation between deposition current, coating thickness, and mechanical properties highlights the importance of optimizing process parameters. Increasing deposition time resulted in thicker coatings and higher microhardness for metallic Zr-Nb films, whereas oxide coatings showed a stronger dependence on discharge current. These results are consistent with earlier studies on multi-component ion-plasma coatings [1-3, 9-13].

The observed microstructural stability and hardness evolution of Zr-Nb-O coatings correspond well with previously reported findings on transport-related composite and protective systems [16], [18].

From an application perspective, Zr-Nb oxide coatings demonstrate strong potential as protective layers for components in aerospace, energy, and transport engineering. Their resistance to both mechanical wear and chemical attack makes them suitable for environments with high thermal and corrosive loads. Considering the operational vibration and corrosion challenges typical for railway and industrial environments [14], [19], the developed coatings can effectively minimize fatigue-related microdamage on metallic components operating under cyclic stresses.

Despite the promising results, this study has certain limitations. The coating performance was evaluated under laboratory conditions, which may differ from actual operational environments. The long-term fatigue resistance and adhesion under cyclic thermal-mechanical loads were not fully investigated and will be addressed in future work. Furthermore, the influence of substrate roughness and intermediate diffusion layers on coating integrity requires additional study.

5. Conclusions

This study investigated the structural, chemical, and mechanical characteristics of Zr-Nb-based coatings synthesized by magnetron sputtering. The following conclusions were drawn:

1) Coating composition and process parameters significantly influence the structural and functional properties of the coatings.

2) Oxide coatings (Zr-Nb-O) demonstrated the highest hardness (up to 660 HV) and the best corrosion resistance among all tested samples, especially at thicknesses of 3-4 µm.

3) Nitride coatings (Zr-Nb-N), although mechanically stable, exhibited low corrosion resistance and are less suitable for long-term protection in aggressive media.

4) The optimization of discharge current and deposition time is essential to balance coating thickness, hardness, and adhesion.

5) Zr-Nb oxide coatings show promise for industrial applications, particularly in aerospace and energy sectors, where high durability and corrosion resistance are required.

Further research will focus on the development of multilayer and nanolaminate Zr-Nb systems to enhance toughness and thermal stability, as well as the implementation of hybrid surface modification techniques, such as ion implantation and laser treatment, to improve adhesion and reduce residual stresses. In addition, long-term performance testing under real service conditions will be conducted to evaluate the coatings’ durability. Considering the excellent corrosion resistance and biocompatibility of Zr-Nb alloys, future studies will also explore potential biomedical applications.

The findings confirm that the developed Zr-Nb-O coatings possess superior mechanical and protective properties, making them suitable for practical use in vibration-exposed transport structures. The established relationship between deposition conditions and coating performance provides a foundation for the design of next-generation protective films for railway, automotive, and aerospace components. The findings are consistent with earlier research on the operational reliability and environmental resilience of transport systems [14], [16], [19], confirming the continuity of this research direction.

References

-

O. V. Krysina, N. N. Koval, A. N. Shmakov, and Z. S. Vinokurov, “In situX-ray diffraction investigation of nitride coatings at high-temperature oxidation,” in Journal of Physics: Conference Series, Vol. 669, p. 012034, Jan. 2016, https://doi.org/10.1088/1742-6596/669/1/012034

-

O. V. Krysina, N. N. Koval, and V. V. Shugurov, “Modern methods and technologies for creating and processing materials,” Collection of Scientific Papers, Vol. 1, pp. 117–123, 2015.

-

V. P. Tabakov, A. V. Chikhranov, and Y. A. Dolzhenko, “Multilayer coatings based on niobium nitride,” Strengthening Technologies and Coatings, Vol. 17, No. 6, pp. 256–262, Jan. 2021, https://doi.org/10.36652/1813-1336-2021-17-6-256-262

-

R. H. Saidakhmedov, K. K. Kadirbekova, and O. O. Elensky, “Study of non-stoichiometric composition and properties of ion-plasma coatings based on titanium nitrides,” News of Universities of the Republic of Uzbekistan, No. 1, pp. 29–33, 2005.

-

N. Abdujabarov, R. Shokirov, J. Takhirov, and S. Bobomurodov, “Mechanical properties of V95P alloy wire after high-temperature annealing,” in 2021 Asia-Pacific Conference on Applied Mathematics and Statistics, Vol. 2471, p. 030004, Jan. 2022, https://doi.org/10.1063/5.0090031

-

R. H. Saidakhmedov, K. K. Kadirbekova, and O. O. Elensky, “Influence of modes of formation of ion-plasma process on composition and properties of coatings,” News of Universities of the Republic of Uzbekistan, No. 1–2, pp. 96–98, 2005.

-

T. R. Allen, R. J. M. Konings, and A. T. Motta, Corrosion of Zirconium Alloys. Amsterdam: Elsevier, 2012.

-

R. H. Saidakhmedov, K. K. Kadyrbekova, and R. B. Agzamov, “Study of properties of zirconium-based coatings doped with niobium,” in 17th International Conference Interaction of Ions with Surface (VIP-2005), pp. 402–404, 2005.

-

V. A. Belous, E. V. Karaseva, G. I. Nosov, V. I. Sokolenko, V. M. Khorosikh, and G. N. Tolmacheva, “Influence of Al+, Mo+, Zr+ ion implantation on the mechanical properties of the zirconium alloy Zr1 Nb,” in 51th International Scientific Conference “Actual Problems of Strength”, pp. 73–73, 2011.

-

R. Saydakhmedov and K. Kadirbekova, “Composition and properties of wear-resistant coatings based on titanium carbide synthesized by the PVD method,” in The Third International Scientific Conference Construction Mechanics, Hydraulics and Water Resources Engineering (CONMECHYDRO 2021 AS), Vol. 2612, p. 060035, Jan. 2023, https://doi.org/10.1063/5.0126356

-

R. Saydaxmedov and K. Kadirbekova, “Study of the composition and properties of vacuum coatings based on titanium carbide,” in E3S Web of Conferences, Vol. 264, p. 05023, Jun. 2021, https://doi.org/10.1051/e3sconf/202126405023

-

R. Krause-Reichberg et al., “Analysis of local areas near interfaces in nanostructured multicomponent (Ti-Zr-Hf-V-Nb)N coatings obtained by cathodic arc deposition,” Physics of Metals and Metallography, Vol. 114, No. 8, pp. 731–740, 2013.

-

K. Kadirbekova and Z. Abdikulova, “Research of the structure and properties of nanostructured coatings based on chrome,” Vibroengineering Procedia, Vol. 58, pp. 300–306, May 2025, https://doi.org/10.21595/vp.2025.24967

-

O. T. Aliev, M. M. Talipov, K. M. Kamilov, and O. R. Ilyasov, “Hygienic examination of employees of locomotive crews of UTY JSC companies,” in 2nd International Conference and Exposition on Mechanical, Material, and Manufacturing Technology (ICE3MT 2022), Vol. 2943, No. 1, p. 040057, Jan. 2023, https://doi.org/10.1063/5.0134056

-

M. M. Talipov, O. T. Aliev, O. R. Ilyasov, and O. V. Kovaleva, “Modern method for purifying wastewater from railway embarking using diatomite in a filter band,” in International Conference on Thermal Engineering, 2024.

-

S. Sulaymanov, M. M. Talipov, R. S. Razikov, O. R. Ilyasov, and O. V. Kovaleva, “Protection of the environment from pollution by wastewater from railway transport using natural sorbents,” in International Conference on Thermal Engineering, 2024.

-

E. Shipacheva, S. Shaumarov, A. Gulamov, and M. M. Talipov, “Modeling of interaction of external enclosing structures of buildings with the internal and external environments,” in International Conference on Thermal Engineering, 2024.

-

E. Shipacheva, S. Shaumarov, A. Gulamov, M. M. Talipov, and S. Kandakharov, “Water structure and its influence on cement stone and concrete properties,” in International Conference on Thermal Engineering, 2024.

-

M. Talipov, “Computational modeling and analysis of mechanical power consumption in train assemblers’ work,” in International Conference on Applied Innovations in IT, Vol. 13, No. 2, pp. 419–426, Jun. 2025, https://doi.org/10.25673/120513

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.