Abstract

The efficiency of quarry hydraulic excavators will depend on several factors, namely the climatic conditions of the area where hydraulic excavators are used, the degree of air pollution (pollination), the performance of the structural parts of the excavator, the reliability of the hydraulic system, the performance and cleanliness of the hydraulic working fluid. In this area, research was carried out on the performance of seals used in the hydraulic system of quarry excavators. The article presents the results of experimental tests of the existing type of oil seal a and b, as well as the proposed oil seal type c, shown in Fig. 1.

1. Introduction

In recent years, the need of the Republic of Uzbekistan to purchase quarry hydraulic excavators for operation at mining enterprises has increased, their advantages are based on many scientific works conducted in recent years.

Unlike hydraulic excavators, which have a lower wheel speed than mechanical excavators, their operating cycle is reduced by 15-18 %, which, in turn, leads to an increase in operating life by 30-35 %. In the work [1] chapter one presents quite impressive comparative results of analyzing the operation of hydraulic excavators, which are not inferior to mechanical excavators in the quarries of the Russian Federation and CIS countries. At the conclusion, it is mentioned that it provides greater specific digging forces and two times less at metal intensity achieves higher operational productivity in turn. Taking this into account, it is important to prevent negative factors affecting the reliable operation of hydraulic excavators.

For rational use of hydraulic system of mining excavators, it is necessary to ensure cleanliness of hydraulic working fluid and absence of its leakage.

To prevent ingress of dust, moisture and other contaminants adversely affecting the quality of hydraulic working fluid into the system, it is necessary to maintain tightness of hydraulic system. If the hydraulic system is not sealed, the working fluid is contaminated with organic and inorganic particles.

The most dangerous for parts and hydraulic power plant of the hydraulic system are dust particles, the hardness of these particles is high, which leads to absorption of parts of the hydraulic system, especially hydraulic pump, hydraulic control valve or hydraulic power plant.

The reliable operation of the seals that ensure the tightness of the hydraulic system depends on several factors. These factors should be considered during the design of each part of the system.

One of the factors negatively affecting the performance of hydraulic system seals is high pressure of the working fluid. Increased pressure in the system will cause the seals to fail before the specified time.

In addition, the performance and operating time of the seals are affected by the condition of the working fluid, ambient temperature and temperature rise during the system-wide flow of the working fluid.

To date, a number of research works have been carried out to improve the efficiency of operation of hydraulic equipment used in open pit mining, designs of seals of their hydraulic system and increase their performance [2-4], most of these works studied the temperature factors that negatively affect the performance of seals. hydraulic seals and the negative impact of the working fluid.

2. Referencing

In order to eliminate the leakage of working fluid in the hydraulic system of quarry hydraulic excavators, to prevent the entry of contaminating particles in the form of dust into the system, vacuum seals made of domestic raw materials, resistant to high pressure, sharply changing temperature and absorption have been developed. The dimensions of the developed packing gland seal have the same value as the dimensions of the applied basic packing gland seal. The developed sealant is prepared in the following composition: SKMS-30 (rubber), sulphur, DFG, stearic acid, ZnO and fillers. The composition and amount of filler is as follows: Calcite, zinc oxide ZnO, ankerite (Cf(Vg,Fe)[CO3]2), zinc sulphate ZnS, amorphous carbon, fluorite, graphite-3h (crystalline), quartz end potassium sulphate K2SO4. The gland seals were manufactured at Navoi Machine-Building Plant of Navoi Mining and Metallurgical Plant JSC.

The developed packing gland seal has the following technical characteristics: resistant to pressure up to 350 bar at 60 °C, fluid leakage rate is 0.5 m/s, operating temperature range from -35 °C to +100 °C, adapted to the environment of mineral oils and hydraulic fluids.

In order to determine the efficiency of the developed gland seal, experimental tests were carried out. In the experimental work, the proposed packing gland seal sample 3 (Fig. 2(c)), packing gland seal sample 2 (Fig. 2(b)), and packing gland seal sample 1 (Fig. 2(a)) were investigated. Sample 2 The seal is a material from a group of thermoplastic polyurethane elastomers of the TPU type. It is characterized by special wear resistance, excellent mechanical properties, extremely low residual deformation pressure and high tear resistance. 1-a sample of the seal is examined in the process of determining the specific composition 3-a sample of the seal specified above

Fig. 1Gland seals: a) gland packing sample 1; b) gland seal sample 2; c) proposed gland packing sample 3

а)

b)

c)

The experimental work was carried out in several stages, at the first of which the relative elongation of gland seals was studied. Relative elongation was determined on the RMI-250 elongation testing machine for rubber materials.

Tests of rubber materials were carried out on RMI-250 machines. The rupture testing machine for rubber of the RMI- 250 type is designed to determine the tensile strength and deformation of rubber and samples from rubber products according to the methodology set out in GOST 270-64. In addition, the machine can be used: 1) for testing textiles, rubberized fabrics, leather, plastics and other materials; 2) for testing the layering of duplicated fabrics, duplicated rubbers with fabrics; 3) with the use of special devices, it is possible to test: a) for rupture – samples in the form of rings and some ring-shaped finished products; b) compression – rubber and other materials; c) fracture – ebonite and plastic. The machine is manufactured according to the basic parameters and accuracy standards in accordance with the requirements of GOST 7762-55.

The experimental and testing work was carried out as follows, the investigated sample of the removable seal was placed in the RMI-250 brand rubber materials elongation testing machine. The tensile force of the specimen was increased from 5 kg/N at each step, starting from giving it a value of 5 kg/N to a tensile force of 30 kg/N.

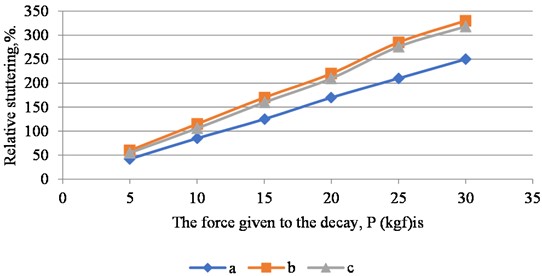

Based on the results of the experimental work presented in Fig. 2, the dependence of the relative elongation index on the force given to stretching of the samples of the investigated gland seal was established.

As can be seen from the graph shown in Fig. 2 of the dependence of the relative elongation of the seals on the force applied to the tension, the relative elongation of the seal proposed by us is close to the relative elongation of the seal of sample 2, which means that we can effectively apply the proposed seal according to this indicator.

Fig. 2Graph of dependence of relative elongation of the gland seal on tensile strength: a – gland packing sample 1; b – gland seal sample 2; c – proposed gland packing sample 3

The effective operation of the gland seals used in the hydraulic system is significantly affected by temperature conditions. In a hydraulic system, a sharp increase in the temperature of the working fluid or the parts on which the gland seals are applied leads to burning of the gland seals, as a result of which their elasticity is lost and their hardness increases [5-11]. This shortens the service life of these seals and also leads to leakage of operating fluid in the hydraulic system [12-17].

Sharp low temperatures also lead to loss of elasticity of gland seals.

In the Kyzylkum region the temperature of the atmosphere changes sharply, reaching +45 °C and higher in the summer heat and cooling to –20-25 °C in cold winter days.

At the next stage of experimental work the change of properties of gland seals under the influence of temperature was investigated.

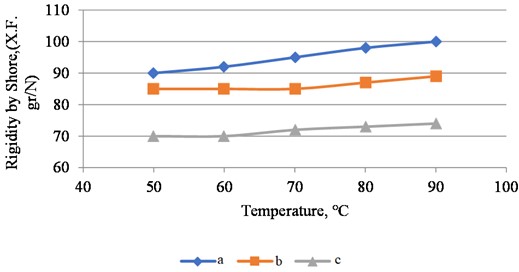

In the first stage of this experimental work the effect of high temperatures on the gland seals was studied. During the experimental work, several types of packing gland seals measured the stiffness of hydraulic fluid in the range from an initial temperature of 50 °C to a temperature of 90 °C, at which temperature was exceeded by 10 °C.

The following measuring instruments and materials were used during the experimental and testing works: Tellus 68 brand hydraulic fluid, UNI-T UT325 thermometer, magnetic mixing oven E1-6220, ASTM 2240 durometer, gfland packing gasket samples, stopwatch and auxiliary equipment.

The hardness of the compactors was measured several times at each temperature on the shore, the initial hardness of the sample, measured on the shore (X.F. gr∙N) sample 1 was found to be 90, sample 2 was found to be 85, and sample 3 was found to be 70, and the dependence of the rigidity of the studied compactors on higher temperatures is given in Fig. 3.

During test-experimental works the initial hardness of packing gland seals was measured at air temperature 30 °C, and it was found that the initial hardness of our proposed packing gland seal was 70 on the shore, while in this case the hardness of packing gland seal of sample 2 company was 85, and the compactor hardness in sample 1 was 90 on the shore.

Fig. 3Graph of dependence of salnic seal stiffness on high temperatures: a – gland packing sample 1; b – gland seal sample 2; c – proposed gland packing sample 3

As can be seen from the graph above, the hardness of the gland seals increases with an increase in temperature of more than 70 °C. As mentioned earlier, an increase in the hardness of the gland seals degrades their performance. No significant change was observed under the influence of temperature with respect to the initial hardness of the proposed packing gland seal.

Thus, the addition of 1.21 % ankerite (Cf(Vg, Fe)[CO3]2), 0.39 % zinc sulphate (ZnS) and 0.22 % potassium sulphate (K2SO4) 0.22 % elements in their composition during the development of gland seals eliminates the fragmentation of gland seals under the influence of high temperatures. temperature.

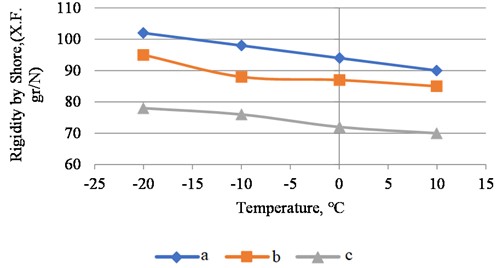

At the next stage of experimental work the influence of low (cold) temperatures on gland seals was studied. In this case, the change in hardness of the studied gland seals was determined at temperatures of 10 °C, 0 °C, –10 °C and –20 °C. In the experimental work, coolant was used to cool the packing gland compilers, while the temperature that the coolant will create was studied using a thermostat.

From the experimental results, it was found that the hardness of the packing gland seal shown in Fig. 4 is dependent on the low temperature.

Fig. 4Graph of dependence of gland seal hardness on low temperatures: a – gland packing sample 1; b – gland seal sample 2; c – proposed gland packing sample 3

From the graph shown in Fig. 4, it can be seen that when exposed to low temperatures, the hardness of the gland seals increases, causing them to become brittle.

3. Conclusions

To eliminate the leakage of working fluid in the hydraulic system of quarry hydraulic excavators, to prevent the ingress of contaminating particles in the form of dust into the system, gland seals made of domestic raw materials, resistant to high pressure, sharply changing temperature and absorption were developed.

The technical performance of the developed packing gland seals was improved by adding special fillers to them. In this case calcite, ZnO, ankerite, ZnS, amorphous carbon, fluorite, graphite – 3 h, K2SO4 and quartz were used as filler.

The developed packing gland seal is resistant to pressure up to 350 bar at 60 °C and is able to work at temperatures from –35 °C to +100 °C.

The dependence of the relative elongation of the packing gland seal on the force imparted to the stretching has been established. In this case, the maximum relative elongation of the developed gland seal was 318 %.

The hardness of the gland seals at high hot and cold temperatures was measured, and the effect of temperatures on their hardness and character was determined. The hardness of the developed packing gland seal was 74 onshore at 90 °C, and the hardness onshore was 78 at –25 °C.

References

-

B. V. Slesarev, “Justification of parameters and development of means for increasing the efficiency of operation of quarry hydraulic excavators,” Institute of Mining Engineering, 2005.

-

Kozyrev, V. V., Petrov, G. S., Petrov, and M. Yu., “Development of nanostructured composite materials to ensure the tightness of seals of hydraulic distributors P80,” in International Scientific and Practical Conference, 2016.

-

E. V. Alifanov, A. M. Chaikun, M. A. Venediktova, and I. S. Naumov, “Features of rubber formulations based on ethylene propylene rubbers and their application in special purpose products,” Aviation Materials and Technologies, Vol. 2, pp. 51–55, 2015.

-

Y. A. Mikhailin, Structural Polymer Composite Materials. Scientific bases and technologies, 2016.

-

N. A. Abduazizov, G. E. Raikhanova, A. V. Vinogradov, and A. S. Zhuraev, “Influence of working fluid on operating efficiency of hydraulic systems of open pit mining machines,” Gornyi Zhurnal, No. 12, pp. 88–93, Dec. 2023, https://doi.org/10.17580/gzh.2023.12.14

-

Abduazizov Nabijon Azamatovich, Muzaffarov Amrillo, Toshow Jawahir Burievich, Juraev Rustam Umarxanoxich, and Zhuraev Akbar Shavkatovich, “A complex of methods for analyzing the working fluid of a hydrostatic power plant for hydraulic mining machines,” International Journal of Advanced Science and Technology, Vol. 29, No. 5s, pp. 852–855, 2020.

-

Maxim G. Rakhutin, Giang Quoc Khanh, Aleksandr E. Krivenko, and Tran van Hiep, “Evaluation of the influence of the hydraulic fluid temperature on power loss of the mining hydraulic excavator,” Journal of Mining Institute, Vol. 261, pp. 374–383, 2023.

-

T. Buri and K. Akbar, “Development of technical solutions for the improvement of the smooth starting method of high voltage and powerful asynchronous motors,” Rudenko International Conference “Methodological Problems in Reliability Study of Large Energy Systems” (RSES 2021), Vol. 2552, Jan. 2023, https://doi.org/10.1063/5.0116131

-

L. Atakulov, S. K. Kakharov, and S. B. & Khaidarov, “Selection of optimal jointing method for rubber conveyor belts,” Gornyi Zhurnal, Vol. 9, pp. 97–100, 2018.

-

I. P. Egamberdiev, L. Atakulov, R. O. Muminov, and K. K. Ashurov, “Research of vibration processes of bearing units of mining equipment,” International Journal of Advanced Trends in Computer Science and Engineering, Vol. 9, No. 5, 2020.

-

O. B. Mustafayev and S. B. Sobirov, “Increasing the efficiency of rocks distribution tools in air-assisted well drilling,” E3S Web of Conferences, Vol. 463, p. 03002, Dec. 2023, https://doi.org/10.1051/e3sconf/202346303002

-

O. U. Zokhidov, O. O. Khoshimov, and S. S. Khalilov, “Experimental analysis of microges installation for existing water flows in industrial plants,” E3S Web of Conferences, Vol. 463, p. 02023, Dec. 2023, https://doi.org/10.1051/e3sconf/202346302023

Cited by

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.