Abstract

When actual intensity of transport traffic considerably exceeds the planned values, it leads to accelerated wear of road surface and formation of rutting. This problem is actual on high-speed main streets of Almaty city. Rutting in asphalt concrete pavement, especially in the areas of expansion joints, causes impacts of motor vehicles' wheels on the ends of joints (metal trims). Such loads lead to rapid failure of all expansion joints that are fixed in the roadway. It is obvious that the increase in traffic volume contributes to the increase in damage, but it is worth noting that uniform loading with a certain frequency leads to the same result, whereas impact loads occurring after the appearance and progression of damage have a much more damaging effect. To date, most efforts to reduce potholes and rutting at joints with expansion joints have focused on reducing rutting, especially in the areas adjacent to expansion joints.

Highlights

- The analysis of structural solutions of expansion joints and joints of the pavement in bridge structures, taking into account the operating conditions, is carried out.

- The main causes of damage and defects in the area of expansion joints, including fatigue failure and the influence of dynamic loads, have been determined.

- A study of modern materials and suture technology has been conducted to reduce vibrations and noise during transport.

- Methods have been developed to optimize the design and repair technology of expansion joints to increase the service life of bridge structures.

1. Introduction

There are problems with expansion joints on road bridges and overpasses in Kazakhstan [1-3]. These problems are related to several factors - increased traffic load, climatic conditions, quality of materials and human factor (violation of jointing technology) [4-8]. As it is known transport load includes two main factors: the first is dynamic load associated with the intensity of urban traffic, the second is static load associated with the congestion of urban roads in certain directions (traffic jams in peak hours) [9, 10]. The dynamics of motor vehicle traffic is not constant and the speed limit varies from 2-5 km/h to the permitted range of 60 km/h. The traffic flow also has significant differences in mass, passenger cars weighing from 900 kg to 3.5 tonnes, buses 12-19 tonnes, trucks 2 axles – 18 tonnes; 3 axles – 25 tonnes; 4 axles – 32 tonnes; 5 axles – 35 tonnes are moving on the roads. [11]. Since the axle spacing is different, the dynamic impact is also very different, so wheel impacts cause pavement failure on road bridges and overpasses [12-15]. Prolonged stopping on road bridges and overpasses also adversely affects and deforms the pavement. The increased dynamic impact is due to the difference in height between the top of the expansion joint and the pavement surface, forming a ‘step’ [16-18]. To avoid asphalt concrete rupture, expansion joints are used on road bridges and overpasses, which are made using different schemes and materials [19-20].

The scientific novelty of the work is to determine the indicators of deformation seams and areas of intersection of the pavement on bridges. These parameters remain one of the key sources of operational problems and costs for the maintenance of the bridge structure. In [5-8], several research areas are identified: classification of types of seams and their design features; behavioral studies and mechanisms of joint failure under cyclic loads and temperature changes; design of seamless systems and asphalt pavements; as well as management and maintenance programs.

2. Methodology

The area where the road surface and the expansion joint meet is the most vulnerable part of the bridge surface. It is assumed that the durability and operational reliability of this unit depend not only on the type of seam, but also on a combination of design solutions, material properties and coating technology [21, 22]. Optimization of these factors will significantly reduce the rate of defect formation and increase the service life between repairs.

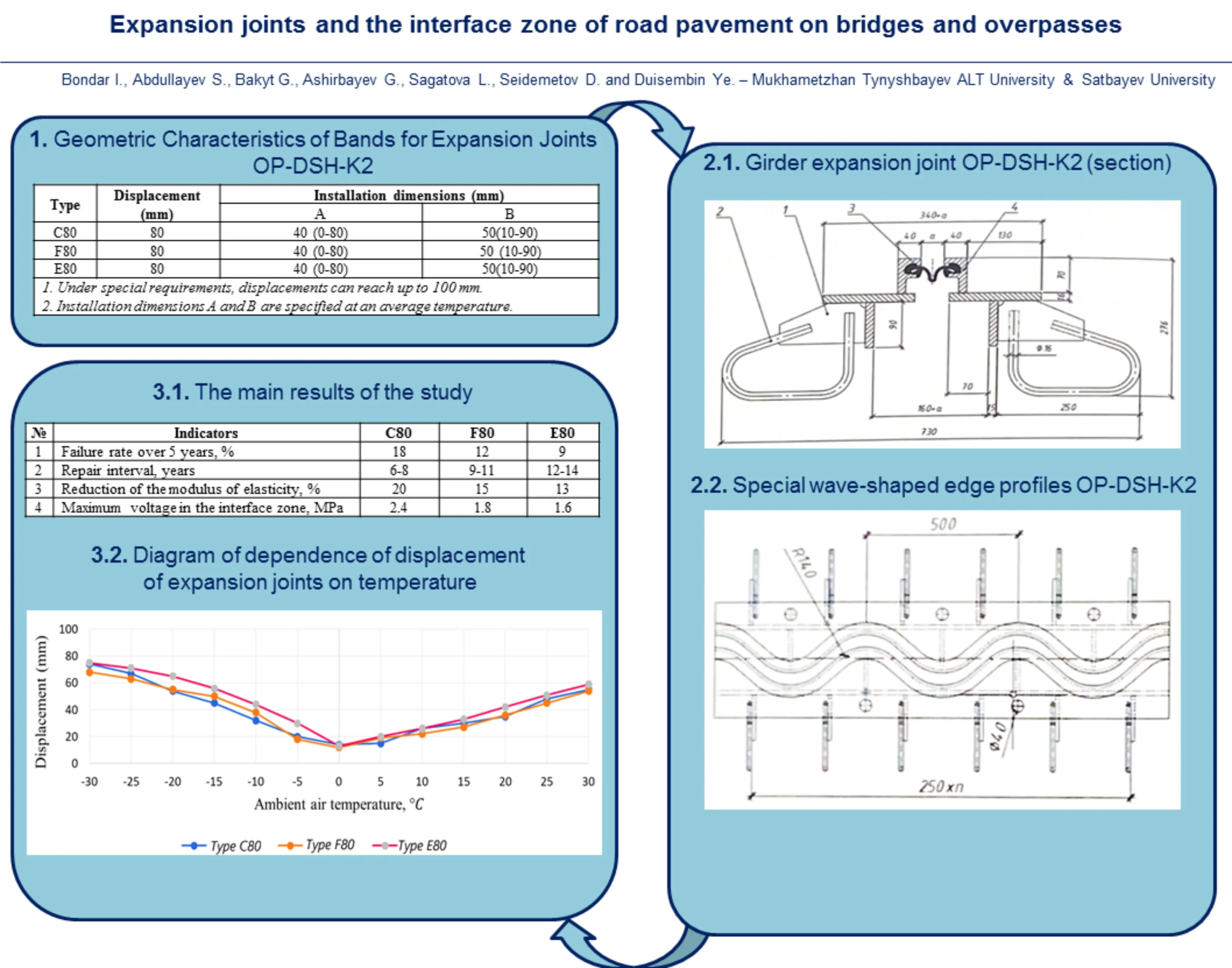

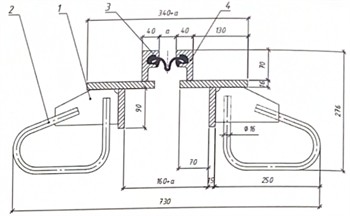

The expansion joint with rubber compensator consists of three parts: hot-rolled profiled steel beam (profile), rubber seals and anchors. Its advantages are simplicity of construction, ease of installation, durability and convenience. The main types of profile (edging) are: C-type (Fig. 1), F-type (Fig. 2), E-type (Fig. 3). Edge profile - elements OP-DSH-K2, edging in the deformation gap contours of adjacent structures (roadway on the structure, the end of the span structure, the edge of the head part of the support or the wardrobe wall of the stand) anchored in them and designed to absorb forces from overlapping gap elements and to protect the edged elements of the structure from destruction under the impact of vehicles. The list of applied edging in beam expansion joints of OP-DSH-K2 grade. The flanges of the edge profile serve for attaching the waterproofing membrane of the deck (Fig. 4).

Fig. 1Expansion joint with rubber expansion joint type C80

Fig. 2Expansion joint with rubber compensator type F80

Fig. 3Expansion joint with rubber compensator type E80

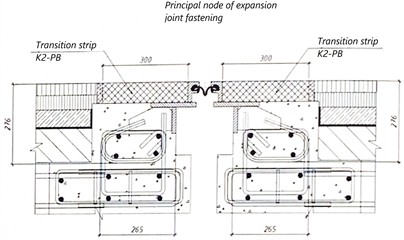

Fig. 4Edging for expansion joints OP-DSH-K2

Table 1Geometric characteristics of bands for expansion joints OP-DSH-K2

Type | Displacement (mm) | Installation dimensions (mm) | |

А | В | ||

С80 | 80 | 40 (0-80) | 50(10-90) |

F80 | 80 | 40 (0-80) | 50 (10-90) |

Е80 | 80 | 40 (0-80) | 50(10-90) |

1. Under special requirements, displacements can reach up to 100 mm 2. Installation dimensions A and B are specified at an average temperature | |||

Linearity of the shaped profile used in the DS along the length corresponds to the tolerance of 1.0 mm/1 m, within the whole length – 5 mm/10 m, Screw-shape is not more than 1 mm/1 m. The edge bearing profiles are made of shaped (long) rolled products. The manufacturing plant, which carries out shaping of the steel profile by solid hot rolling or solid hot processing, guarantees the absence of hidden defects along the entire length of the profile. At the request of the project the edge profile of the DS can be made by welding of shaped solid drawn profile and long angle rolled section by continuous welded seam according to GOST 14771, at that 30 % (up to 100 % at the request of the opening) of welded seams are subjected to ultrasonic examination. Welded seams of OS-DS-K2 grades meet the requirements of GOST 5264, GOST 8713 and GOST 14771.

Bearing profiles (edging) are treated with an increased degree of anticorrosion protection. Anticorrosive coating of DSH corresponds to the category of corrosive aggressiveness of the atmosphere not lower than C4 (high) according to GOST 346672. Durability of anticorrosive coating corresponds to category H (more than 15 years) according to GOST 346671.

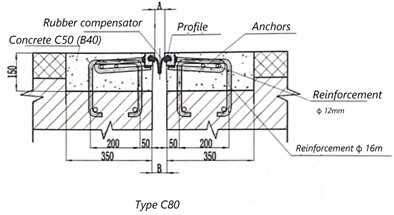

The main elements of the beam expansion joint of OP-DSH-K2 brand are edge bearing profiles (edging), anchoring elements and sealing compensator (Fig. 5).

Fig. 5Girder expansion joint OP-DSH-K2 (section): a – opening of DS; 1 – anchor plate; 2 – anchor ring; 3 – compensator; 4 – edging

Due to the presence of various configurations of the bearing profile execution, as well as a large variability of the anchor elements execution, the design of DS can be applied at any dimensions of the expansion joint lining areas and any thicknesses of asphalt pavement or other pavement.

In beam expansion joints, sealing expansion joints are used [21, 23], which allow for a displacement of the structure from 40 to 120 mm. For beam expansion joints with an opening of 100 mm and above, which are used on motorways near settlements with a permitted speed of motor vehicles over 90 km/h, as well as on roads in the settlements themselves, it is recommended to use additional noise-reducing structures. Here are two options of design solutions for noise reduction:

1) Application of special noise-reducing plates, such beam DSs are labelled ‘OP-DS-K2-shp’ (Fig. 6).

Fig. 6Expansion joint OP-DSH-K2-shp with noise-reducing plate

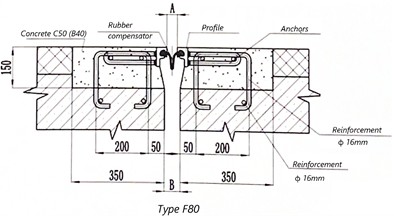

2) Application of expansion joint designs with special wave-shaped edge profiles, such beam joints are labelled ‘OP-DSh-K2-v’ (Fig. 7).

Fig. 7Special wave-shaped edge profiles OP-DSH-K2

3. Results

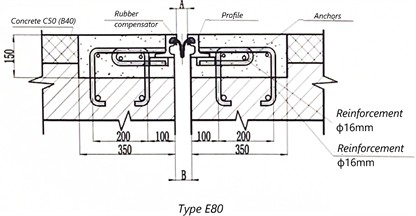

A survey of 28 bridge structures with various types of expansion joints showed that the junction area of the pavement is one of the most vulnerable parts of the bridge bed.

The average frequency of defects during the first 5 years of operation was 18 % for C80 type seams, 12 % for F80 and 9 % for E80.

The most common damages were: the formation of a “bump” (up to 35 % of cases), cracking in asphalt concrete (27 %) and local subsidence (21 %).

For structures older than 10 years, the failure rate increased by more than 2 times.

Tests of samples of asphalt concrete mixtures and sealing materials revealed that

the modulus of elasticity of asphalt concrete in the interface zone decreased by 15-20 % after 200 thousand loading cycles.

The materials used in the F80 and E80 seams demonstrated higher crack resistance (fatigue limit increase by 22-25 % compared to C80).

Elastomeric seals have shown durability higher by 30 % compared to traditional bitumen mastics. The main quantitative results are shown in Table 2.

Table 2The main results of the study

No | Indicators | C80 | F80 | E80 |

1 | Failure rate over 5 years, % | 18 | 12 | 9 |

2 | Repair interval, years | 6-8 | 9-11 | 12-14 |

3 | Reduction of the modulus of elasticity, % | 20 | 15 | 13 |

4 | Maximum voltage in the interface zone, MPa | 2.4 | 1.8 | 1.6 |

Let us calculate the total temperature displacement of the free end of the span structure by applying the formula [24]:

where: is the reliability coefficient for temperature effects; is the coefficient of linear thermal expansion, (1∙10-3); is the design length of the span structure from which the displacements are determined (2×24 m); – range of change of design temperatures from to taking into account the increase of this range due to the heating of the structure under the influence of sunlight, including non-uniform heating and non-uniform temperature distribution along the cross-section of the element [25].

Normative air temperatures in warm and cold seasons should be set equal: + 40 °C; –40 °C; can be accepted – 15 °C; + 15 °C.

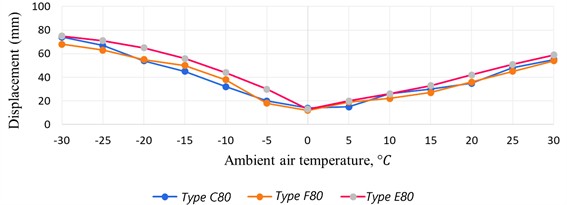

The distances between the edges of OP-DSH-K2 expansion joints of types C80, F80 and E80 measured at different temperatures in the range from –30 °С to +30 °С are shown in Fig. 8.

Fig. 8Diagram of dependence of displacement of expansion joints on temperature

4. Discussion

The calculated width determined by the Eq. (1) of one joint from the action of temperature –40 °C is equal to half of this value, that is, if by calculation turned out to be 16 cm, the half will be 8 cm. For a comfortable passage through the deformation joint the value of its opening should not be more than 8 cm [23, 26], otherwise due to the ‘failure’ of car wheels between the edging dynamic coefficient () increases, which is an additional unfavourable factor, increasing the impact of traffic load on the bridge spans. The presence of defects in the area of expansion joints significantly increases this coefficient () due to the disturbance of the smoothness of the carriageway micro-relief.

Judging from the results of Fig. 10, the presented types of expansion joints fulfil this task perfectly. The best performance at different temperatures in the range from –30 °C to +30 °C, i.e. the smallest displacement between the edge profiles of the OP-DSH-K2 expansion joints of the F80 type at –30 °C outside temperature was 6.8 cm, and at +30 °C the displacement was 5.4 cm.

5. Conclusions

It has been established that after commissioning of bridges and overpasses in a couple of years deformations, displacements, deep cracks and potholes in the zones of expansion joints will be inevitable in the zones of road asphalt concrete pavement with the depth from 3 cm to 10 cm. As a result of the research:

1) It is established that the interface zone of the deformation seam and the pavement is the most vulnerable element of the bridge bed, where dynamic loads from vehicles and thermal deformations of structures are concentrated.

2) Experimental studies have shown that the main causes of premature destruction of the coating near the seam are the accumulation of plastic deformations in asphalt concrete and impaired adhesion between the layers.

3) Quantitative dependences between the parameters of the seam design and the rate of formation of coating defects have been revealed, which makes it possible to predict the timing of the inter-repair period.

References

-

K.-N. Kim, Y.-M. Kim, and T. H. M. Le, “Development of plug joint with polymer-modified rubber asphalt as filling material,” Polymers, Vol. 15, No. 21, p. 4256, Oct. 2023, https://doi.org/10.3390/polym15214256

-

J. Marques Lima and J. de Brito, “Inspection survey of 150 expansion joints in road bridges,” Engineering Structures, Vol. 31, No. 5, pp. 1077–1084, May 2009, https://doi.org/10.1016/j.engstruct.2009.01.011

-

G. Bakyt, Y. Jailaubekov, S. Abdullayev, G. Ashirbayev, and I. Ashirbayeva, “Assessment of carbon dioxide emissions in road transport, using exhaust gas cleaning technology, in the Republic of Kazakhstan,” Vibroengineering Procedia, Vol. 48, pp. 87–92, Feb. 2023, https://doi.org/10.21595/vp.2023.23163

-

L. Chang and Y.-J. Lee, “Evaluation and policy for bridge deck expansion joints,” Purdue University, West Lafayette, IN, JTRP Technical Reports, Jan. 2001.

-

A. Abdykadyrovk, S. Marxulyk, A. Baikenzheyeva, G. Bakyt, S. Abdullayev, and A. E. Kuttybayeva, “Research of the process of ozonation and sorption filtration of natural and anthropogenicly pollated waters,” Journal of Environmental Management and Tourism, Vol. 14, No. 3, p. 811, Jun. 2023, https://doi.org/10.14505/jemt.v14.3(67).20

-

I. Bondar, M. Kvashnin, D. Aldekeyeva, S. Bekzhanova, A. Izbairova, and A. Akbayeva, “Influence of the deformed state of a road bridge on operational safety,” Eastern-European Journal of Enterprise Technologies, Vol. 2, No. 7 (116), pp. 29–34, Apr. 2022, https://doi.org/10.15587/1729-4061.2022.255275

-

S. Kosenko, I. Bondar, M. Kvashnin, A. Vorobyev, and O. Pokrovskaya, “Experimental assessment of the railway bridges’ metal spans bearing elements stress state,” in Lecture Notes in Networks and Systems, Cham: Springer International Publishing, 2022, pp. 347–355, https://doi.org/10.1007/978-3-031-11058-0_33

-

S. Shu et al., “Combined use of polyurethane prepolymer and aromatic oil in physicochemical rejuvenation of aged SBS modified bitumen for performance recovery,” Polymers, Vol. 15, No. 5, p. 1120, Feb. 2023, https://doi.org/10.3390/polym15051120

-

S. S. Abdullayev, G. B. Bakyt, M. N. Aikumbekov, I. S. Bondar, and Y. T. Auyesbayev, “Determination of natural modes of railway overpasses,” Journal of Applied Research and Technology, Vol. 19, No. 1, pp. 1–10, Mar. 2021, https://doi.org/10.22201/icat.24486736e.2021.19.1.1487

-

S. S. Abdullayev, I. S. Bondar, G. B. Bakyt, G. K. Ashirbayev, A. M. Budiukin, and Y. Y. Baubekov, “Interaction of frame structures with rolling stock,” in Series of Geology and Technical Sciences, Vol. 445, 2021, pp. 22–28, https://doi.org/10.32014/2021.2518-170x.3

-

P. Di Mascio, G. Loprencipe, L. Moretti, L. Puzzo, and P. Zoccali, “Bridge expansion joint in road transition curve: effects assessment on heavy vehicles,” Applied Sciences, Vol. 7, No. 6, p. 599, Jun. 2017, https://doi.org/10.3390/app7060599

-

P. Múčka, “Road roughness limit values based on measured vehicle vibration,” Journal of Infrastructure Systems, Vol. 23, No. 2, Jun. 2017, https://doi.org/10.1061/(asce)is.1943-555x.0000325

-

I. Kim, J. Cho, G. Zi, B. Cho, S. Lee, and H. Kim, “Detection and identification of expansion joint gap of road bridges by machine learning using line-scan camera images,” Applied System Innovation, Vol. 4, No. 4, p. 94, Nov. 2021, https://doi.org/10.3390/asi4040094

-

Y. Wei, R. Ji, Q. Li, and Z. Song, “A condition assessment tool for steel bridge deck pavement systems based on data balancing methods and machine learning algorithms,” Buildings, Vol. 14, No. 9, p. 2959, Sep. 2024, https://doi.org/10.3390/buildings14092959

-

J. Qureshi, “A review of fibre reinforced polymer bridges,” Fibers, Vol. 11, No. 5, p. 40, May 2023, https://doi.org/10.3390/fib11050040

-

Z. Vlaović, T. Gržan, I. Župčić, D. Domljan, and G. Mihulja, “Strength, durability, and aesthetics of corner joints and edge banding in furniture design: a review,” Applied Sciences, Vol. 14, No. 22, p. 10285, Nov. 2024, https://doi.org/10.3390/app142210285

-

S. Abdullayev, G. Bakyt, A. Kamzina, N. Suleyeva, and N. Tokmurzina-Kobernyak, “Dynamic interaction of the TE-33A diesel locomotive and the track in a curve with a radius of 600 meters,” International Journal of Mechanical Engineering and Robotics Research, Vol. 13, No. 2, pp. 205–212, Jan. 2024, https://doi.org/10.18178/ijmerr.13.2.205-212

-

J. Jang, M. Shin, S. Lim, J. Park, J. Kim, and J. Paik, “Intelligent image-based railway inspection system using deep learning-based object detection and weber contrast-based image comparison,” Sensors, Vol. 19, No. 21, p. 4738, Oct. 2019, https://doi.org/10.3390/s19214738

-

S. Abdullayev, G. Bakyt, A. Kamzina, K. Sarsanbekov, and A. Abdullayeva, “Interaction of the TE33a diesel locomotive and the railway track on curved section with radius 290 m,” Communications – Scientific letters of the University of Zilina, Vol. 25, No. 4, pp. B315–B326, Oct. 2023, https://doi.org/10.26552/com.c.2023.069

-

J. Wang and S. Lee, “Data augmentation methods applying grayscale images for convolutional neural networks in machine vision,” Applied Sciences, Vol. 11, No. 15, p. 6721, Jul. 2021, https://doi.org/10.3390/app11156721

-

J. Hartung, A. Jahn, O. Bocksrocker, and M. Heizmann, “Camera-based in-process quality measurement of hairpin welding,” Applied Sciences, Vol. 11, No. 21, p. 10375, Nov. 2021, https://doi.org/10.3390/app112110375

-

S. Abdullayev, N. Tokmurzina, and G. Bakyt, “The determination of admissible speed of locomotives on the railway tracks of the republic of Kazakhstan,” Transport Problems, Vol. 11, No. 1, pp. 61–68, Jan. 2016, https://doi.org/10.20858/tp.2016.11.1.6

-

Y. Shi, L. Cui, Z. Qi, F. Meng, and Z. Chen, “Automatic road crack detection using random structured forests,” IEEE Transactions on Intelligent Transportation Systems, Vol. 17, No. 12, pp. 3434–3445, Dec. 2016, https://doi.org/10.1109/tits.2016.2552248

-

G. Bakyt, S. Abdullayev, N. Suleyeva, A. Yelshibekov, Z. Seidemetova, and Z. Sadvakassova, “Simulation of dynamic processes of interaction of car and railway track during train passage of curved sections of the track,” Transport Problems, Vol. 15, No. 2, pp. 59–70, Jun. 2020, https://doi.org/10.21307/tp-2020-020

-

I. S. Bondar, D. T. Aldekeyeva, and Z. K. Ospanova, “Stress-strain states of reinforced concrete spans of a railroad overpass using a spatial finite element model,” Vibroengineering Procedia, Vol. 54, pp. 320–326, Apr. 2024, https://doi.org/10.21595/vp.2024.24086

-

B. Manzoor, I. Othman, S. Durdyev, S. Ismail, and M. Wahab, “Influence of artificial intelligence in civil engineering toward sustainable development-a systematic literature review,” Applied System Innovation, Vol. 4, No. 3, p. 52, Aug. 2021, https://doi.org/10.3390/asi4030052

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.