Abstract

In these studies, the effect of polypropylene fibers on the mechanical properties of concrete was studied, and special attention was paid to determining their optimal amount and acceptable length. The fibers were added to the concrete composition in amounts of 0.1-0.5 % and lengths of 10, 20, 30, 40, 50 mm and tested. According to the results of the study, the highest results were recorded at a fiber content of 0.2-0.3 % and lengths of 20-30 mm, and the compressive strength of concrete increased by up to 15.9 % compared to ordinary concrete. When adding fibers in excess (≥ 0.4 %) or with a length of 50 mm, a decrease in strength was observed. The results obtained showed that it is possible to increase the quality and improve the strength of concrete by selecting the optimal parameters of polypropylene fibers.

1. Introduction

Concrete is one of the most widely used isotropic materials among modern construction materials [1]. The reasons why concrete is a common structural material and is known as the primary structural material boil down to its high compressive strength, relative ease of processing, and cost-effectiveness [2]. Concrete has its major drawbacks even though it has been widely used [3]. Specifically, low tensile strength, brittleness, and crack formation are some of the negative factors of its long-term reliability in structures [4]. To minimize this, a lot of scientific works is being done on reinforcing concrete with different additives and reinforcement. There has been a particular concern with the technology of dispersed reinforcement with recent years [5, 6]. In such a system, one inserts different fiber types (steel, glass, basalt, polypropylene, etc.) into the concrete matrix and thus enhances deformation characteristics, fracture toughness, and the strength of the material [7]. Specifically, polypropylene fibers are becoming significant in various researches as a successful additive, because they are cheap, light, and non-reactive [8].

One of the scientific and practical tasks is to determine the optimum number of polypropylene fibers to be added to concrete. Due to the direct dependence of the effect of fibers on the strength indicators, wear resistance properties, and long-term durability of concrete, on the content of fibers [9-11]. When the amount of fibers is added in the required amounts, the fibers prolong the duration of cracking of the plasticity of the concrete, lead to a decrease in deformations in compression and elongation, and enhance the capacities of the concrete to work under pressure [12]. The investigations of the problem in the Uzbekistan conditions are a special need. The explanation is that the weather of our country is sharply continental, hot in summer and sharply cold in winter [13]. These conditions cause the microcracks to be frequent in the concrete structures, swift corrosion of concrete due to the cold-heat cycles. Wear resistance and long-life of concrete are of high significance especially in buildings and structures. Thus, the quality of concrete in Uzbekistan could be significantly enhanced by calculating the optimum quantity of polypropylene fibers [14].

2. Materials for experiment samples

Cement, water, fine and coarse aggregates and polypropylene fibers were structural materials in order to find the impact of polypropylene fibers in concrete, the appropriate quantity, and acceptability of these fibers. As we know, cement makes the greatest part of the concrete mixture and the binding material whose nature is the greatest determinant of its strength of the concrete. As a material in this research work, PS400D20 cement manufactured by Namangansement, one of the largest building materials manufactures in Uzbekistan, was used. This cement is characterized by very high quality indicators, consistent chemical composition and good binding property. Table 1 displays the chemical composition of cement.

Table 1Chemical composition of cement

Content | Silicon oxide, SiO2 | Calcium oxide, CaO | Aluminum oxide, Al2O3 | Magnesium oxide, MgO | Iron oxide Fe2O3 | Potassium oxide, K2O | Sodium oxide, Na2O |

Quantity | 19.30 | 65.60 | 5.40 | 2.30 | 3.90 | 0.50 | 0.40 |

Of special interest is also the aggregates employed in the concrete composition. The fine aggregates when utilized in the studies range 0-5 mm in size which are used to enhance the density of the concrete mix, to fill the voids and enhance strength. In addition to improving the workability of concrete, fine aggregates create a uniform structure as a matrix along with cement and water. Coarse aggregates have sizes 5-20 mm form the foundation of the concrete and they significantly contribute to compression and bending loads absorption. It is believed that coarse aggregates are the prime determinant of the density and of mechanical stability of the mass of concrete.

Additional material that was introduced to the concrete matrix was polypropylene fibers, which were the source of the research. Their length and quantity have a great influence on the mechanical properties of concrete. In the case where the fiber length is adequate, they are firmly in place in the concrete matrix and effectively restrain the spread of cracks. The addition of fibers in the perfect quantity improves the strength of the concrete but decreases brittle failures under the load. Table 2 shows the main parameters of polypropylene fibers in respect of density, tensile strength, elastic modulus, diameter and the length.

Table 2Main characteristics of polypropylene fiber

Fiber | Appearance | Density, kg/m3 | Tensile strength, MPa | Modulus of elasticity, MPa | Fiber diameter, μm | Fiber length, mm |

Polypropylene |  | 910 | 470 | 4200 | 32 | 10, 20, 30, 40, 50 |

3. Method

In order to investigate the impact that polypropylene fibers have on concrete, dispersed reinforcement was conducted by incorporating both 10, 20, 30, 40, 50 mm fibers into concrete at the rates of 0.1, 0.2, 0.3, 0.4, 0.5 % of total weight.

Laboratory experiments were conducted to produce concrete of class B25 as per the design index by incorporating polypropylene fibers to the concrete mixture. The test was conducted using the indicators of regulatory documents formed due to the requirements of the current interstate standard DAST 27006-2019, which is presented in the table below (Table 3). Fiber concrete preparation process is shown in Fig. 1.

Fig. 1Fiber concrete preparation. Photo taken by Asalxon Juraeva at the Namangan State Technical University Laboratory, May 2025

Table 3General indicators of concrete of class B25 (kg/m3)

Concrete density | Water | Cement | Crushed stone 5 20 | Sand 0 5 | Water/cement ratio |

2350 | 190 | 440 | 1080 | 640 | 0.43 |

Special laboratory tests were carried out to identify cubic strength of the concrete and fiber concrete under compression. Experimental testing was conducted at the laboratory of the Faculty of Civil Engineering of Namangan State technical University. The samples of polypropylene fiber concrete were made in the standard sizes with the cross-sectional sides of 100×100×100 mm. There were six groups to which the samples were classified in the experiment. All the groups were separated by the fiber lengths and the number of fibers. Concrete Preparation of the samples was done as per the interstate standard DAST 10180-2012 on using control samples to determine the strength.

In order to estimate the cube samples mass, each sample was first weighed independently on scale. The obtained data served as an input in further analysis of the test outcomes and finding out the degree to which fibers within the concrete composition impact the weight and density. Weight determination work was done in this manner to provide a reference to future mechanical tests. An automatically controlled universal press UTEST UTC-4722.FPR that has a capacity of 2500 kN and a compressive strength of concrete and fiber-reinforced concrete was used to determine the compressive strength of concrete and fiber-reinforced concrete. It is manufactured and fully compliant with ASTM and AASHTO standards and is employed in the international practice to test the samples of concrete cylinders and cubes. The mechanisms incorporated in this press equipment enable a fine and continuous increment of force. This guarantees reliability of test results. The press can test samples of different sizes and the load value is accurately measured with special measuring sensors according to its technical features.

In the case of the test, the samples were put in the middle of the bottom plate of the press. A primary reason as to why this is so is to ensure that the load fully and uniformly distributes during the test. Otherwise, an early failure can occur because there is imbalance in the application of forces. The samples were subjected to the load which was constantly and gradually increased. The loading rate was 0.6 MPa/s. The loading was maintained till full failure of the sample was witnessed.

The highest value of force observed in each experiment was used as the breaking force. This figure is the primary parameter in determining the cubic strength of concrete and fiber concrete. The values of breaking forces obtained were then used to determine the strength indicators, using special formulas. Testing of fiber concrete according to polypropylene fibers is depicted in Fig. 2.

4. Results and discussion

The disparities between regular concrete and the fiber-reinforced fiber-reinforced concrete were identified not only in terms of numerical metrics, but also through the eye of the observer on the failure mechanisms, which is a scientifically sound method of conducting the experiment. The concrete cubes broke brittlely and following the experiment they had taken the shape of two truncated pyramids. The fibers failed the fiber-reinforced concrete samples, not by fragmentation of one another. The look of the fiber-reinforced concrete cube samples sprinkled with polypropylene fibers post-test is illustrated in Fig. 3.

Fig. 2Testing process of fiber concrete based on polypropylene fibers. Photo taken by Asalxon Juraeva at the Namangan State Technical University Laboratory, June 2025

Fig. 3Appearance of polypropylene fiber-based fiber concrete after testing. Photo taken by Asalxon Juraeva at the Namangan State Technical University Laboratory June 2025

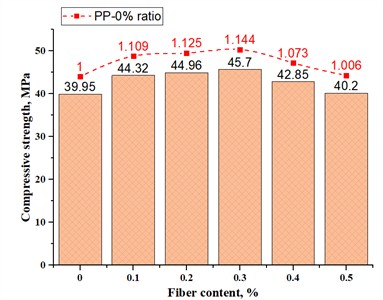

Introduction of polypropylene fibers produced a profound impact in compressive strength characteristics of fiber concrete. Although the compressive strength of normal concrete amounts to 39.95 MPa it was determined that in fiber concrete that has been dispersely reinforced with fibers of 10 mm long, the indicators are between 40.2 MPa up to 45.7 MPa. Fig. 4 indicates the graph of compressive strength of fiber concrete depending on polypropylene fibers, length 10 mm.

Fig. 4Compressive strength of fiber concrete based on 10 mm long polypropylene fibers

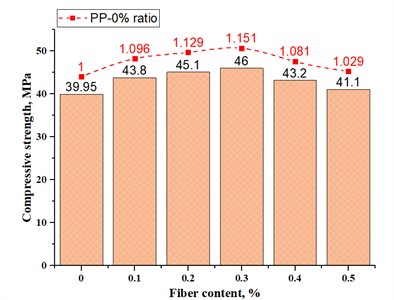

Fig. 5Compressive strength of fiber concrete based on 20 mm long polypropylene fibers

The maximum was obtained by increasing to 0.3 percent fibers, and compressive strength was 45.7 MPa. It was 14.39 percent greater than the standard concrete. A significant reduction in compressive strength was noted with the increase in the quantity of fibers to 0.4 0.5 percent. In other words, at 0.4 percent it was 42.85 MPa and only 40.2 MPa at 0.5 percent, which is close to the standard concrete indicators. This effect is attributable to the fact that too many fibers render densification of the concrete matrix cumbersome, augment porosity and lessen viscosity.

Also, concrete samples that were added with polypropylene fibers of a length of 20 mm recorded values near those acquired with fibers of length of 10 mm. At the addition of fibers to concrete of 0.1 percent, the strength rose to 43.8 MPa. A result exceeding 11.38 percent as compared to the compressive strength of ordinary concrete was obtained. The highest value was noted by the increase of the amount to 0.3 and the compressive strength was 46.0 MPa. Fig. 5 demonstrates the plot of compressive strength of fiber concrete in relation to polypropylene fibers with the length of 20 mm.

When 30 mm long polypropylene fibers were incorporated into concrete in 0.1 percent, a sample had a strength of 44.23 MPa; this is a 10.71 percent improvement over regular concrete.

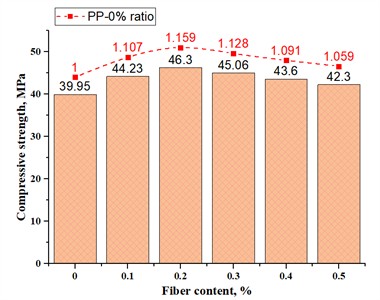

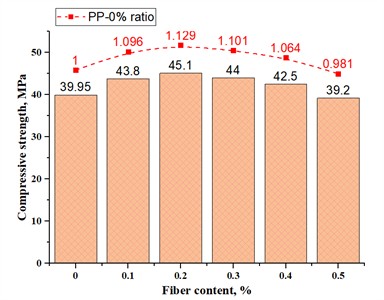

At the point where the fiber content was raised to 0.2, the maximum was 46.3 MPa (15.89 % improved). But as the fiber content in it increased, the compressive strength declined. The indicator reduced to 45.06 MPa at the level of 0.3 % fiber, which is 12.89 higher. The values of 0.4/0.5 percent fiber additions in the sample were 43.6 MPa and 42.3 MPa, respectively. Fig. 6 indicates the graph of compressive strength of fiber-reinforced concrete depending on polypropylene fibers having a length of 30 mm. The outcomes received regarding the compressive strength of concrete during the addition of polypropylene fibers (with a length of 40 mm) reveal that the more the content of the fibers, the higher is the strength, and after that the strength declines. Specifically, the compressive strength of the sample containing 0.1 % fibers was 43.8 MPa that was 9.64 percent greater than the ordinary concrete level. Fig. 7 indicates the compressive strength graph of fiber concrete depending on the polypropylene fibers with the fibre length of 40 mm.

Fig. 6Compressive strength of fiber concrete based on 30 mm long polypropylene fibers

Fig. 7Compressive strength of fiber concrete based on 40 mm long polypropylene fibers

The maximum measurement was 45.1 MPa when the fiber content was raised to 0.2 (12.9 % growth). Subsequently, the strength kept on dwindling in the subsequent stages. The obtained compressive strengths were 44 MPa at 0.3 % fiber, 42.5 MPa at 0.4 % fiber and 39.2 MPa at 0.5 % fiber.

Fig. 8Compressive strength of fiber concrete based on 50 mm long polypropylene fibers

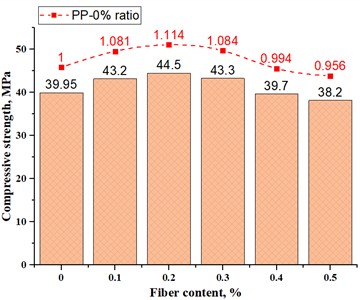

Examination of compressive strength of concrete containing 50 mm long polypropylene fibers (Fig. 8) indicates that the longer the fibers, the less effective they were compared to shorter fibres. Based on the findings, first, a strength of 43.2 MPa was obtained at the addition of 0.1 percent of the fibers (an increase of 8.13). The maximum indicator was 44.5 MPa (11.38 %), when the content of fiber was 0.2 %. Then there was a loss in compressive strength. Although the highest value was 43.3 MPa (8.39 %), at 0.3 percent of the fibre content, the highest value was 39.7 MPa (–0.63 %), which followed by a value of 38.2 MPa (–4.38 %). This implies that the long fibers are not evenly spread within the concrete framework, but rather they get into knot and clusters together creating gap and weak areas in the internal make-up of the concrete.

5. Future scope

The current study not only presents the possibility of polypropylene fibers in improving the mechanical characteristics of concrete but also presents a number of avenues that can be explored in future in the quest to add both scientific value and practice. The optimization of fiber dosage and length at a broader set of conditions is one of the most significant spheres of the future work. Although this study has revealed the effect of fibers with the percentage range of 0.1-0.5 percent and lengths of 10-50 mm, the response of fiber geometry and cementitious matrix could be different when using high-strength concrete, lightweight concrete, or self-compacting concrete. Hence, more research needs to be done with regards to the customization of fiber characteristics to certain types of concrete to ensure optimum performance and efficiency. The other potential area of research is the study of the polypropylene fiber reinforced concrete under varying environmental and service conditions. An example is that freeze thaw cycles, exposure to aggressive reagents including sulfates and chlorides, or high temperature environments can have a profound impact on fiber-matrix interaction. Polypropylene fibers are made of thermoplastic materials and their workability at higher temperatures such as fire situation must be taken seriously to determine. Also, one of the questions that must be answered by accelerated aging tests and field studies in real-time is the durability of fiber-reinforced concrete in environments with sea waters or under long-term immersion in water.

In order to further strengthen the scientific basis, advanced characterisation techniques, including scanning electron microscopy (SEM), X-ray diffraction (XRD), and micro-computed tomography (µCT) could be utilised in future studies to examine interfacial transition zone between fibers and cement paste. This will assist in establishing the processes by which crack bridging, load transfer and energy absorption occur and eventually achieve a better understanding of the role played by polypropylene fibers in terms of toughness and durability. These may also help to develop analytical and numerical models that would predict how fiber-reinforced concrete will behave under different stress conditions.

The other important step in future research is scaling-up the laboratory specimens to actual structural elements. Although cubes, prisms, and small beams are useful in terms of obtaining data on strength and fracture resistance, large-scale members (slabs, bridge decks, industrial floors) might have other failure modes and patterns of fiber distribution. Structural level experimental studies will thus enable testing of laboratory results under real world conditions, a prerequisite in building design codes and building standards. Finite element modeling and computational simulations should be developed to explain the random distribution, orientation and clustering of fibers in the matrix as well as the work of experiment. These models are potentially crucial in forecasting the load-bearing capacity, crack propagation and service life of polypropylene fiber reinforced concrete. Moreover, polypropylene fibers can be combined with other cementitious substances like fly ash, silica fume, or slag, and this can provide synergistic advantage. A mix of polypropylene and steel, glass or basalt fibers could also offer balance in strength, ductile and crack control in hybrid reinforcement. These hybrid systems should be systematically investigated in future studies to find out whether they can be used to address the limitations exhibited by polypropylene when used by itself in higher dosages.

6. Conclusions

1) In order to establish the optimum quantity and length of polypropylene fibers in concrete, dispersed reinforcement was conducted through addition of 10, 20, 30, 40 and 50 mm length fibers in different proportions of 0.1, 0.2, 0.3, 0.4 and 0.5 percentages of polypropylene fiber volume to the concrete. This methodological study made a complete insight on the influence of geometric parameters and dose of fiber on the mechanical performance of fiber-reinforced concrete.

2) The results of the experiment indicated that the length and content of fibers have a great impact on the compressive, tensile, and flexural strengths of concrete. The overall mechanical response of the composite material depends on the geometrical arrangement of the fibers in that the bond interaction with the cement matrix is controlled by them.

3) It was established that additions of polypropylene fibers of 0.1-0.3 percent enhanced the compressive strength of the concrete. Nonetheless, as the proportion of the fiber rose to 0.4-0.5 percent, compressive strength declined because of entagling fibers and unequal distribution in the mix. This implies that the presence of a high amount of fiber generates inefficiency and causes strength reduction.

4) Optimal doses of fiber have enhanced the density, homogeneity and microstructure of the concrete in addition to its stress resistance to crack formation. This proves that the fibers also contribute significantly to the stabilization of the deformation behavior of the concrete and to its durability.

5) The paper offers new knowledge on quantitative correlation between fiber geometry and mechanical improvement in concrete. On the engineering side, the results highlight the potential practicality of the polypropylene fiber-reinforced concrete in the current construction, especially with the buildings that demand more control over the cracks, toughness, and durability. The suggested fiber content level (0.1 to 0.3 %) can be used in the design of a performance and material-saving structure.

References

-

A. Martazaev and S. Khakimov, “Dispersed reinforcement with basalt fibers and strength of fiber-reinforced concrete beams,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030011, Jan. 2025, https://doi.org/10.1063/5.0266797

-

R. Mavlonov and S. Razzakov, “Numerical modeling of combined reinforcement concrete beam,” in E3S Web of Conferences, Vol. 401, p. 03007, Jul. 2023, https://doi.org/10.1051/e3sconf/202340103007

-

F. Almohammed and M. S. Thakur, “Forecasting compressive strength of concrete with basalt and polypropylene fiber by using ANN, RF and RT models,” Asian Journal of Civil Engineering, Vol. 25, No. 2, pp. 1671–1690, Aug. 2023, https://doi.org/10.1007/s42107-023-00870-4

-

Y. Wang et al., “Strength characteristics of polypropylene fiber-modified rubber foamed concrete,” Buildings, Vol. 15, No. 10, p. 1663, May 2025, https://doi.org/10.3390/buildings15101663

-

B. Rakhmanov, S. Razzakov, and L. Kosimov, “The research on the influence of temperature on the properties of synthetic fibres for load-handling devices,” in E3S Web of Conferences, Vol. 460, p. 10003, Dec. 2023, https://doi.org/10.1051/e3sconf/202346010003

-

Y. Chen, M. S. Waheed, S. Iqbal, M. Rizwan, and S. Room, “Durability properties of macro-polypropylene fiber reinforced self-compacting concrete,” Materials, Vol. 17, No. 2, p. 284, Jan. 2024, https://doi.org/10.3390/ma17020284

-

E. Najaf and H. Abbasi, “Impact resistance and mechanical properties of fiber‐reinforced concrete using string and fibrillated polypropylene fibers in a hybrid form,” Structural Concrete, Vol. 24, No. 1, pp. 1282–1295, Aug. 2022, https://doi.org/10.1002/suco.202200019

-

S. Gong et al., “Effect of polypropylene fiber and nano-silica on the compressive strength and frost resistance of recycled brick aggregate concrete,” Nanotechnology Reviews, Vol. 12, No. 1, p. 20230, Dec. 2023, https://doi.org/10.1515/ntrev-2023-0174

-

K. Saravanan, R. Viswanathan, V. Sivakumar, and B. Thangavel, “Investigating the influence of polypropylene and steel fibers on the mechanical properties of UHPFRC,” Matéria (Rio de Janeiro), Vol. 29, No. 4, Jan. 2024, https://doi.org/10.1590/1517-7076-rmat-2024-0708

-

S. Razzakov and A. Martazaev, “Mechanical properties of concrete reinforced with basalt fibers,” in E3S Web of Conferences, Vol. 401, p. 05003, Jul. 2023, https://doi.org/10.1051/e3sconf/202340105003

-

R. Mavlonov, S. Razzakov, and S. Numanova, “Stress-strain state of combined steel-FRP reinforced concrete beams,” in E3S Web of Conferences, Vol. 452, p. 06022, Nov. 2023, https://doi.org/10.1051/e3sconf/202345206022

-

E. S. George, R. Hari, and M. K. Madhavan, “Performance assessment of blended self-compacting concrete with ferrochrome slag as fine aggregate using functional ANOVA,” Journal of Building Engineering, Vol. 89, p. 109390, Jul. 2024, https://doi.org/10.1016/j.jobe.2024.109390

-

A. Martazaev, M. Orzimatova, and M. Xamdamova, “Determination of optimum quantity of silica fume for high-performance concrete,” in The 3rd International Symposium on Civil, Environmental, and Infrastructure Engineering (ISCEIE) 2024, Vol. 3317, p. 030012, Jan. 2025, https://doi.org/10.1063/5.0266799

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.