Abstract

This paper has examined the cleaning of transformer oil by using electricity field on a theoretical and practical basis. Scientific analysis was done on the physicochemical characteristics of the oil and the effects of impurities on the electrical insulation characteristics of oil. A mathematical model explaining the movement of impurities under the action of an electric field was constructed on the basis of which, the extent of oil purification was established. According to the carried out theoretical and practical studies, the efficiency of transformer oil purification by constant electric field was tested. Based on the findings of theoretical modeling, the level of oil extraction against mechanical impurities is 40, and the electrical strength of the oil is enhanced by 16 and based on the findings of experiments that are carried out under laboratory conditions, the electrical strength is enhanced by 21. Due to the comparison between theoretical and practical outcomes, the deviation of the electrical strength indicator of the oil does not exceed 5 % and this fact supports the validity of the theoretical model developed. It was also determined that the purification process is affected by environmental factors like temperature, humidity, strength of electric field and composition of the oil. Enhancing oil purified in constant electric field is one of the effective solutions to the enhancement of the reliability of transformers and their service life.

1. Introduction

Transformers are one of the main elements of modern power systems, and their reliability and efficiency have a great influence on the stability of power supply. The oil used in the internal parts of transformers performs the function of electrical insulation and heat transfer. Therefore, the cleanliness and quality of the oil affect the long-term operation of the transformer [1]. It is necessary to theoretically study the physicochemical changes that occur during the process of transformer oil purification due to environmental factors (temperature, humidity, electric field strength, etc.) [2-3]. In this article, the theoretical solutions for cleaning transformer oil using an electric field are analyzed, taking into account the influence of the environment. Consequently, the process of purifying transformer oil using an electric field should be theoretically studied in depth, taking into account the influence of environmental factors [4-6]. Factors such as temperature, humidity, electric field strength, and the chemical composition of the oil have a great influence on the efficiency of the process. Taking these factors into account, it is possible to effectively purify transformer oil by selecting optimal parameters. In addition, it is possible to optimize the process based on theoretical models and mathematical equations, which leads to an increase in the reliability and service life of the transformer.

2. Purpose of the study

Development of better techniques to purify the transformer oil this serve as an insulating medium in power transformers utilized in the power supply of the transport system. It is projected that the process of separating mechanical contaminants, moisture and oxidation products in oil in the presence of a constant electric field will have their theoretical and experimental underpinnings developed:

– Theory the theory of the motion of charged particles in transformer oil under the influence of a constant electric field; development of the differential equations describing the motion of the charged particles.

– Evaluation of the effect of environmental conditions (temperature, humidity, strength of electric fields, and chemical compositions of the oil) on the cleaning process; research of the electrofiltration process under laboratory conditions and analysis of the obtained results of the theoretical model and the experimental data.

– Identification of the association between the cleaning efficiency and the parameters of the electric fields.

– Suggesting a viable electrofiltration process, which can be utilized in practice with regard to transport transformers.

The received scientific and practical findings allow enhancing the quality of the transformers in the power infrastructure of the transport system and increase their life span.

3. Materials and methods of research

In the research process, the theory of electrical engineering, the law of electromagnetic induction, electrocoagulation, and the theory of the electric field were used [7]. The electric field purification method is based on the separation of mechanical impurities in oil using the effects of electrostatic attraction and ionization [8-9]. In this process, the following steps are carried out: Generating an electric field: an electric field passing through an oil, used to attract charged particles (e.g., metal particles or ions) [10]. Ionization: Under the influence of an electric field, free particles in oil are ionized and move in the direction of the electric field [11]. Collection of mechanical impurities: ionized particles are collected using special electrodes or filters [12].

The effectiveness of this process depends on such factors as electric field strength, dielectric constant of the oil, temperature, and humidity. In the process of electric field purification of transformer oil, environmental factors act as follows: Temperature effect: increasing temperature reduces the viscosity of the oil, which contributes to the movement of mechanical impurities, and at very high temperatures, the chemical composition of the oil can change, which disrupts its dielectric properties [14]. The effect of moisture: moisture increases the electrical conductivity of the oil, the electrical resistance in the oil decreases under the influence of an electric field, and moisture intensifies the dissociation process in the oil, which complicates the ionization process. Effect of electric field strength: increasing the voltage accelerates the ionization process, but too high a voltage can lead to the formation of electrical waste in the oil, and the choice of the optimal voltage maximizes the efficiency of the process. The effect of the chemical composition of the oil: different types of oils (for example, mineral oil or synthetic oil) have different dielectric properties, and their movement under the influence of an electric field differs [14].

4. Results obtained and their discussion

4.1. Development of a mathematical model of the process of transformer oil purification in a constant electric field

The mathematical model of the process of cleaning transformer oil using an electric field is compiled based on the following equations: Charged particles move under the influence of an electric field according to the following differential equation: , where: – particle mass, – particle charge, – electric field strength, – coefficient of friction.

The oil's electrical conductivity () and dielectric constant () are related by the following relationship: , where: – frequency, – tangent of the dielectric loss angle.

The optimal electric field strength satisfies the following condition: .

The total field strength of the mechanical mixture layer, taking into account the electric field strength in the – layer and the conditional correction field strength , is determined as follows:

It should also be taken into account that due to the imbalance of volumetric charges between two layers, the time of electrical relaxation ( and , and – relaxation times of the first and second media, respectively; and – electric field permeability of the first and second media, respectively; – as a constant of the electric field: 8.85418781∙10-12 Ф/m-1 equal to) and surface charge is formed between the layers [12].

For the first medium, i.e., for solid mechanical impurities, the charge density in differential form is expressed as follows:

Here, the function of the dependence of the charge density on the layer thickness is -layer thickness [m].

For the second medium, i.e., for dense mechanical impurities, the charge density in differential form is expressed as follows:

The surface density function and electric field strength at the boundary between the layers of the solid and dense mechanical mixture are expressed as follows:

If we express the – variable in terms of , then we get the following expression:

In this expression is expressed taking into account the potential difference and relaxation as follows:

In the layers, the electric field strength equals the internal electric field strength, creating a dipole moment, resulting in polarization forces, namely:

If we assume that the resulting dipole moment is directly proportional to the external electric field, and the charge density is directly proportional to the potential difference, the above expression takes the following form:

If the concentration of mechanical impurities in transformer oil is very small and the generated external electric field is in the form of a flat capacitor, can be neglected.

If, , taking into account Eq. (5) and (8), we can take into account the following relationship:

We introduce the following notation, i.e., we introduce , which reflects the surface density, length, and dielectric properties of the first layer: .

If the concentration of mechanical impurities does not exceed 10 % (as is usually the case) then the time function of the mechanical impurity layer, according to Eq. (9), has the form:

We accept the following terms:

and we obtain Eq. (10):

To simplify the above expression, we introduce the following notations:

As a result, we get the following expression:

and Eq. (12) and introducing the notation – we obtain Eq. (13):

If a mandatory amount of transformer oil is purified from the electrostatic precipitator per unit of time, i.e., expressed through the mandatory flow of transformer oil, then the following expression is obtained:

where: – effective cross-sectional area of the electrostatic precipitator; – transformer oil consumption; – transformer oil flow rate to the electrostatic precipitator [m/s].

If the forced circulation of transformer oil is not carried out, then we reduce Eq. (13) for this condition to the following form:

where: is the coefficient of linear dimensions of the electrostatic precipitator, calculated depending on whether the coefficient of forced flow is greater or less than 1:

The relative consumption of transformer oil is calculated as follows:

where: – effective length of the electrostatic precipitator [m]; – effective height of the electrostatic precipitator [m]; – transverse component of the flow rate of mechanical impurities [m/s]; – effective velocity of transformer oil in the electrostatic precipitator [m/s].

The transverse component of the flow velocity of mechanical impurities in the general case is expressed as follows:

where: is the speed of transformer oil deviating from the main direction under the influence of the electric field; – velocity of transformer oil caused by the generated electric field and convection; – convection and velocity perpendicular to the forced transformer oil flow:

where: – coefficient depending on the type of fluid flow, taking a value from 0.5 to 1. In particular, 0.5 for turbulent flow, 1 for laminar flow; – characteristic value of current density under the influence of turbulent flow (here: – current flowing through the conductor, – conductor diameter); – coefficient of proportionality ; – mobility of charged particles generated by electroconvection; – characteristic size of transformer oil; – average field strength between the electrodes; Re – Reynolds number, ; (2320) boundary of turbulent and laminar flow; empirical proportionality coefficient.

If , then if we express Eq. (14) through Eq. (15), (16), (17) and (19), it will take the following form:

where: – coefficient indicating the degree of purification of transformer oil from mechanical deposits, which, as experiments show, can increase to the value (equals ) and is expressed as follows:

Taking into account the interpretation of Eq. (20) and Eq. (21), we obtain the following expression:

If the voltage supplied to the electrostatic precipitator remains constant, then the values inside the parentheses of Eq. (22) remain constant, and the parameters , , outside the parentheses are also considered constant parameters. Accordingly, the following notations are introduced:

from Eqs. (22) and (23), we obtain the following expression:

If there is a sufficient cleaning time, i.e., , it becomes possible to compare the degree of cleaning of mechanical sediments with experimental results. For this, we will use the least squares method.

/ is not a linearly variable function, therefore we introduce the following notation for this ratio, let's say . Thus, we express through the relationship:

If we logarithm this expression by exponent, we get the following expression:

where we introduce the following notations: ; ; .

If we add such markings as, then, according to the condition of the least squares method, we obtain the following expression:

As a result, the equation of the dependence of the concentration of residual mechanical impurities on the transformer oil flowing through the electrostatic precipitator and the constant voltage applied to the electrostatic precipitator for purification was obtained. A mathematical model of efficient purification of transformer oil from various mechanical impurities using a constant electric field was developed based on the magnetic induction, length and surface density of the electrode, height and efficiency of the electrostatic precipitator, activity of charged impurities, oil consumption, mass and characteristic size, proportionality coefficient for turbulent and laminar flows, and the value of the applied constant voltage [13-16].

4.2. Analysis of theoretical results based on the obtained mathematical expressions

There is no feasibility of complete purification when it comes to purifying transformer oil of mechanical impurities with a constant electric field as indicated above. Consequently, through the theoretical research, we get the values of the function of the degree of oil purification of mechanical impurities with the consideration of the constant voltage and the transformer oil consumption in the MS Excel program [15-18]. To do this, we present the following preliminary parameters. Table 1 presents the initial values for determining the function of transformer oil purification from mechanical impurities under constant oil flow conditions.

Table 1Initial values for determining the function of the degree of purification of transformer oil from mechanical impurities in a constant mode of oil consumption

0.831033 | 0.2 | 0.115 | 1. | 1. | 5. |

0.848642 | 0.24 | 0.115 | 1. | 1.2 | 5. |

0.86382 | 0.28 | 0.115 | 1. | 1.4 | 5. |

0.877187 | 0.32 | 0.115 | 1. | 1.6 | 5. |

0.889149 | 0.36 | 0.115 | 1. | 1.8 | 5. |

0.894695 | 0.38 | 0.115 | 1. | 1.9 | 5. |

0.905052 | 0.42 | 0.115 | 1. | 2.1 | 5. |

0.919058 | 0.48 | 0.115 | 1. | 2.4 | 5. |

0.923382 | 0.5 | 0.115 | 1. | 2.5 | 5. |

0.931591 | 0.54 | 0.115 | 1. | 2.7 | 5. |

0.935495 | 0.56 | 0.115 | 1. | 2.8 | 5. |

0.939278 | 0.58 | 0.115 | 1. | 2.9 | 5. |

0.942947 | 0.6 | 0.115 | 1. | 3. | 5. |

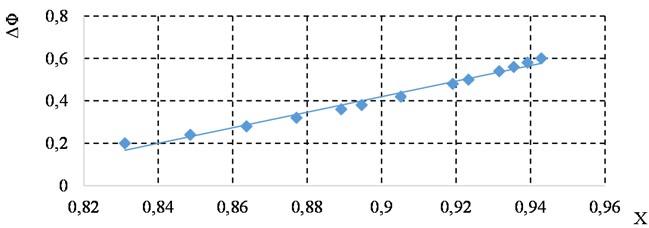

To construct the graph of the dependence of mechanical impurities in transformer oil on the voltage supplied to the electrofilter, the transformer oil flow rate , the coefficient , and the parameter m (the power of ) were conditionally assumed to be constant. Based on the values presented in Table 1, the functional relationship graph shown in Fig. 1 was obtained. In this graph, a total of 14 voltage values arranged in ascending order are presented. As the applied voltage increases, the degree of purification of transformer oil from mechanical impurities at a given oil flow rate decreases; that is, supplying voltage above the optimal level has a negative effect on the purification efficiency [18].

According to the findings of the calculations, the theoretical studies demonstrated that the level of oil purification in transformers was (0.17 – 0.57) = 40 percent on average. This represents a gain of 16 percent in electrical power of the oil.

Fig. 1Graph of the dependence of the degree of purification on the voltage and oil consumption

4.3. Analysis of the practical results of the conducted experimental studies

The experimental research was done in lab conditions and had the purpose of a practical evaluation of the transformer oil purification process with the help of constant electric field. Transformer oil was experimented on in an electrostatic precipitation equipment, which was designed specially, at different electric field voltages [17]. The extent of the reduction in mechanical impurity and moisture content of the oil was determined during the course, as well as the parameters of electrical conductivity and dielectric strength of the oil were re-evaluated. Fig. 2 presents the processes of conducting experimental research and the analysis of the obtained results.

Fig. 2Transformer oil inspection process

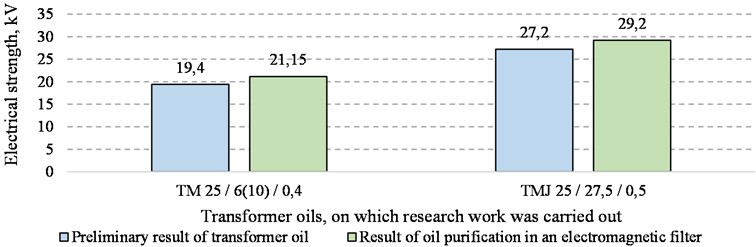

The results obtained are also compared to the theoretical model and conclude on the effect of constant electric field on the cleaning efficiency. With the help of this method, the effectiveness of the cleaning process and the state of transformer oil are traced and evaluated scientifically. Table 2 presents the oil filtration results of a mobile oil purification device.

Table 2Results of oil filtration of a mobile oil purification device

S/n | Transformers | Trial name | Preliminary result of transformer oil | Result of oil purification in an electromagnetic filter |

1. | TMJ 25 / 27.5 / 0.4 | Electrical strength, kV | 27.2 | 29.2 |

2. | TM 25 / 6 (10) / 0.4 | 19.4 | 21.15 |

Fig. 3 presents a general analysis of the results from practical and theoretical research on the electrical strength of transformer oil.

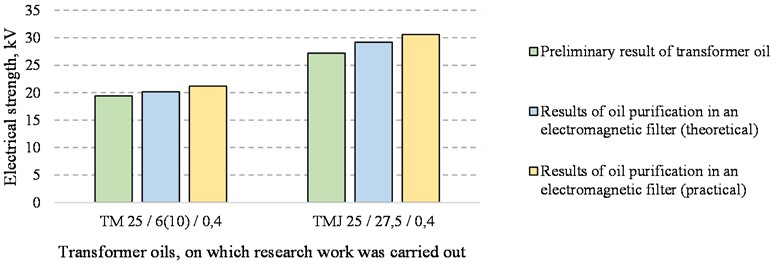

Based on the obtained results, a practical study revealed that the breakdown voltage in transformers increased by an average of 21 %. A comparison of practical and theoretical studies, based on these results, showed a 5 % difference in the electrical strength indicator of the oil. Table 3 presents a comprehensive analysis of the oil’s electrical strength indicator, comparing the results of practical and theoretical studies based on the findings mentioned above.

Fig. 4 presents a general analysis of the oil’s electrical strength indicator based on the results obtained from comparing practical and theoretical studies.

Fig. 3General analysis of the results of practical and theoretical research of transformer oil

Table 3Based on the results obtained, a comparison of practical and theoretical studies was carried out on the basis of a general analysis of the oil's electrical strength indicator

S/n | Transformer motors | Trial name | Preliminary result of transformer oil | Results of oil purification in an electromagnetic filter (theoretical) | Results of oil purification in an electromagnetic filter (practical) |

1. | TMJ 25 / 27.5 / 0.4 | Electrical strength, kV | 27.2. | 29.2 | 30.6 |

2. | TM 25 / 6 (10) / 0.4 | 19.4 | 20.15 | 21.2 | |

6. | General | 46.8 | 49.35 | 51.8 | |

Fig. 4Analysis of the results of practical and theoretical correction of transformer oil

The above data reveal that the finding of theoretical studies indicated that the level of purification of transformer oil was 40, the electrical strength of the oil was raised by 16 % and in practicals the findings on an experimental set up indicated that the electrical strength of the oil was raised by 21 %. The rationalization of this difference is due to the terms taken in the theoretical model (oil temperature, mechanical impurities distribution, electrodes shape and size, laminar or turbulent flow rate) [20-22]. The gap between the theoretical model and the practical outcomes is by 5 % percent that proves the adequate reliability of the model. Moreover, the effectiveness of the application of a constant electric field to enhance the dielectric properties of oil is practically proven by experiments carried out under the conditions of the laboratory.

5. Theoretical solution

The second section of the theoretical component of the study explained the motion of the charged particles in transformer oil under the action of a constant electric field in terms of the differential equations. According to this model, functional relationships between the strength of the electric field, dielectric properties of the oil, and the particle density were established and the mathematical foundations of the purification process were worked out. The practical section involved experimental work done under laboratory conditions with the use of electrostatic precipitation apparatus. The theoretical model was practically proved by the comparison of the initial and after-purification parameters of the oil (electrical strength, moisture content, volume of mechanical impurities, dielectric losses). The findings enabled the enhancement of the dependability of transformers through the effective purification of transformer oil.

6. Scientific novelty of the research

– A mathematical model of a transformer oil purification process under the impact of a constant electric field has been created.

– A new operational equation of the correlation between the electric field strength – oil consumption - concentration of mechanical impurities has been obtained.

– It is proposed that an electrostatic precipitator operate in multi-parameter conditions, which are forced and free flow conditions, and consider laminar-turbulent flows, the Reynolds number, the components of the electroconvective velocity, distribution of bulk charges, and transverse mobility of mechanical impurities in the model.

– A detailed strategy of the quantitative evaluation of the impact of temperature, humidity, the composition of the oil and the strength of the field to the cleaning process has been developed.

– The dissimilarity in the theoretical model and the laboratory tests was discovered to be 5 percent and the dependability of the formed model in practice was confirmed.

– The degree of transformer oil purification with the use of the electrofiltration technology was set to have a maximum efficiency limit of 40 %.

7. Conclusions

1) Judging by the theoretical and practical studies carried out, the efficiency of the transformer oil purification under the constant electric field was tested. Based on the results of the theoretical modeling it was seen that the level of oil purification against the mechanical impurities is 40, and electrical strength of the oil rises by 16 % and based on the outcomes of experiments performed under the laboratory conditions, it was seen that the electrical strength rises by 21 %.

2) The comparison between theoretical and practical outcomes has led to a conclusion that the difference in the electrical strength indicator of the oil is not more than 5 % and this fact proves the correctness of the formulated theoretical model. It was also determined that the environmental factors, including the temperature, humidity, electric field strength and the composition of the oil, have a serious impact on the purification process.

3) The results received were suggested as a potential solution to the introduction of transformer oil electrofiltration technologies and the enhancement of efficiency of the transport energy infrastructure and a decrease in the risks of the work.

References

-

B. I. Kovalsky, Y. N. Bezborodov, L. A. Feldman, A. V. Yudin, and O. N. Petrov, “Modern methods of cleaning and regenerating used lubricating oils,” Siberian Federal University, Krasnoyarsk, 2011.

-

D. V. Shuvarin, “New technologies for purification and regeneration of energy oils,” in Environmental Safety of Energy: Experience, Problems, Innovative Solutions, pp. 49–57, 2015.

-

D. T. Yusupov and B. K. Avazov, “Cleaning of used transformer oil,” Journal NX – A Multidisciplinary Peer Reviewed Journal, No. 3, pp. 719–724, 2021.

-

A. S. Kurochkin, V. L. Osadchiy, and E. V. Lvov, “Method of ultra-deep purification of transformer oil and oil-filled equipment as a way to increase the reliability of transformer operation,” in Transformers: Operation, Diagnostics, Repair, and Service Life Extension, pp. 233–243, Sep. 2010.

-

T. P. Salikhov, V. V. Kan, and D. T. Yusupov, “Method of circulation washing of transformers using adsorbents and ceramic membranes,” FerPI Scientific and Technical Journal, pp. 62–66, 2014.

-

Q. Liu and Z. Wang, “Streamer characteristic and breakdown in synthetic and natural ester transformer liquids with pressboard interface under lightning impulse voltage,” IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 18, No. 6, pp. 1908–1917, Dec. 2011, https://doi.org/10.1109/tdei.2011.6118629

-

I. M. Bogachkov and Yu. A., “Method for cleaning transformer oil,” Oil and Gas Magazine, pp. 87–91, 2011.

-

G. M. Mikheev, G. M. Mikheev, V. A. Tarasov, and T. G. Mikheeva, “Electroconvective purification of dielectric liquids,” Technical Physics Letters, Vol. 34, No. 5, pp. 391–393, Jun. 2008, https://doi.org/10.1134/s106378500805009x

-

P. Ivanov and M. Dimitrov, “Application of electrostatic techniques for purification of aged transformer oil,” in IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 27, No. 2, pp. 567–574, 2020.

-

M. D. Vecchio, R. B. Poulin, P. T. Feghali, D. M. Shah, and R. Ahuja, “Voltage breakdown and high-voltage design,” in Transformer Design Principles, pp. 399–445, 2010.

-

X. Wang and Z. D. Wang, “Study of dielectric behavior of ester transformer liquids under ac voltage,” IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 19, No. 6, pp. 1916–1925, Dec. 2012, https://doi.org/10.1109/tdei.2012.6396948

-

D. Yusupov and B. Avazov, “Theoretical solutions for cleaning transformer oils using an electric field taking into account the effects of environments,” 4th International Scientific and Technical Conference “Actual Issues of Power Supply Systems”: ICAIPSS2024, Vol. 3331, No. 4, p. 050018, Jan. 2025, https://doi.org/10.1063/5.0306610

-

A. Kumar and S. Patel, “Impact of Environmental factors on the efficiency of electrostatic oil purification,” Journal of Applied Physics, Vol. 127, No. 8, p. 083102, 2020.

-

X. Zhang and Y. Liu, “Numerical simulation of electrohydrodynamic flow in transformer oil,” International Journal of Heat and Fluid Flow, Vol. 87, p. 108765, 2021.

-

J. Chen, Z. Wang, and J. Li, “electrostatic precipitation for removal of particulate contaminants in transformer oil,” IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 26, No. 5, pp. 1534–1541, 2019, https://doi.org/10.1109/tdei.2019.008123

-

J. Peltonen, M. Murtomaa, and J. Salonen, “Measuring electrostatic charging of powders on-line during surface adhesion,” Journal of Electrostatics, Vol. 93, pp. 53–57, Jun. 2018, https://doi.org/10.1016/j.elstat.2018.03.007

-

D. T. Yusupov, B. K. Avazov, O. M. Kutbidinov, and M. Bazarov, “Cleaning of transformer oils using the electric field,” IOP Conference Series: Earth and Environmental Science, Vol. 1231, No. 1, p. 012024, Aug. 2023, https://doi.org/10.1088/1755-1315/1231/1/012024

-

U. T. Berdiyev, A. K. Vetcher, F. F. Hasanov, and B. B. Avazov, “Soft magnetic materials for electric machine construction,” in 3rd International Scientific Conference Construction Mechanics, Hydraulics and Water Resources Engineering (CONMECHYDRO 2021 AS), Vol. 2612, p. 050014, Jan. 2023, https://doi.org/10.1063/5.0117785

-

O. T. Boltayev and I. N. Ismoilov, “Comparative analysis of methods of reducing electromagnetic effects of power transformers,” Railway Transport: Topical Issues and Innovations, No. 2, pp. 212–216, 2025.

-

D. T. Yusupov, M. Sh. Muxammadjonov, U. T. Berdiev, O. M. Kutbidinov, and D. R. Abdurakhimov, “Development of the algorithm of additional cooling process for oil power transformers with ONAN cooling system,” in 15th International Conference on Thermal Engineering: Theory and Applications, 2024.

-

D. T. Yusupov, I. K. Ismoilov, A. E. Norboev, A. B. Sa’Dullaev, and O. E. Babaev, “Development of a simulation model for assessing the technical condition of the magnetic circuit of oil power transformers by measuring the temperature of the tank and the external environment,” in E3S Web of Conferences, Vol. 510, p. 04013, Apr. 2024, https://doi.org/10.1051/e3sconf/202451004013

-

H. K. Sauchuk et al., “Physical and thermal properties of binary (Bi-Ti-O)-TiO₂ UHF-ceramics,” in International Conference on Thermal Engineering, 2024.

-

J. Smith and R. Johnson, “Electrostatic cleaning of transformer oil using high electric fields,” IEEE Transactions on Dielectrics and Electrical Insulation, Vol. 25, No. 4, pp. 1234–1245, 2018.

-

U. Berdiyev et al., “The study of electric motors based on composite materials,” in 4th International Scientific and Technical Conference “Actual Issues of Power Supply Systems”: ICAIPSS2024, Vol. 3331, p. 030046, Jan. 2025, https://doi.org/10.1063/5.0305937

About this article

The authors have not disclosed any funding.

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

The authors declare that they have no conflict of interest.