Abstract

A novel live animal screening machine was designed to solve the screening issue for yellow mealworm and frass in the artificial breeding production process. The control system based on semantic similarity computation, operation mode, overall structure, working principle and main structural parameters of the machine were designed and optimized in this study. Furthermore, the kinematics mathematical model of the crank-rocker of shaking and the screening mechanism was analysed. In addition, motion analysis of shaking and screening mechanism was conducted, and then the displacement, velocity and acceleration curves of pendulum rod and screening body were obtained. Finally, the structure design and motion simulation of all parts were finalized to confident with the design. The prototype performance tests of the yellow mealworm screening machine show that machine has a reasonable structure, convenient operation, good screening effect and high working efficiency. This study provides a new thought for screening yellow mealworms.

1. Introduction

Yellow mealworm, also known as gluten armor or tenebrio molitor L, belongs to coleoptera tenebrionidae. Because yellow mealworm has rich protein and amino acids, it can be used as new animal protein sources and scientific material, and has a high utilization value in terms of feed, food, pharmaceutical health care products and anti-bacterial protein. It is a very broad application prospects and ideal insect resource for artificial breeding [1-4]. With the rapid development of special breeding industry, the demand for yellow mealworm is rising, resulting in increasing the farming scale of yellow mealworm. Meanwhile, yellow mealworm frass also has rich nutrients and comprehensive biological activity substances, which can be used as an organic fertilizer and animal feed. Therefore, yellow mealworm frass can partly substitute for animal feed and can improve the growth rate and reproduction rates of livestock and poul [5-6].

A growth cycle of yellow mealworm can be divided into four stages, i.e. egg, larva, pupa and adult, and the larvae stage is about 120 days. In the larval breeding process, when it grows to 45 days, frass piled up too much. In order to provide a better breeding environment for yellow mealworm, yellow mealworm and frass need to be screened about every 15 days, in total screening 6 times throughout the larval stage. Currently, screening mainly relies on handwork, this method has low efficiency and high labour intensity, and screening effect is not ideal. In this study, one type of yellow mealworm screening machine is designed with many good features, e.g. good separating effect, simple structure, low cost, safe and easy to operate and high efficiency.

Screening machines are widely used in engineering fields and play an important role in the national economy. Based on the current research trends, on one hand motion analysis and structural adjustment of the existing screening machines needs to be carried on. On the other hand, the innovative designs aim at developing reasonable structure, power configuration and kinetic parameters, in order to further promote the application of screening machine.

Screening machine is widely used and has a lot of relevant researches. To reduce labor intensity for cleaning snail shelling, Gao, et al. [7] designed and developed a vibrating-type cleaning snail shelling machine, which is a simple structure and convenient to operate. Through a comprehensive scale analysis of the crank rocker mechanism of vibrating screen, the crank, connecting rods and rocker length were optimized by using maximum transmission angle as optimization goals, and corresponding motion analysis and experimental research were conducted. Han, et al. [8] designed 5XS-600 test bench of vibrating screen to determine the structural parameters and adjustment range of all mechanisms. Dynamic simulation for motion mechanism of vibrating screen was conducted. The major motion and vibration parameters of mechanism are adjustable, can adapt to the different material and meet the testing requirements of the different subjects. In the extraction process of wheat starch, Yuan, et al. [9] developed a separating screen to separate the starch and fiber, the machine consists of feeding, washing, screening mechanism, frame and other components. The kinematics analysis of the separating screen was conducted by using Matlab/Simulink and Pro/E. Because the multi-dimensional vibration can’t be achieved by traditional tea screening machine, Xie, et al. proposed a new tea screening machine with multi-dimensional vibration [10]. The mechanism can be panned in , , three directions and tea can be distributed uniformly on the surface of the screen. In addition, the sieve mesh was avoided to be blocked by the tea and the screening efficiency was improved. Zhu, et al. conducted technical improvement design of vibrating screen that used to vibrate tobacco before mixed with fragrant [11]. The sieve mesh was easily blocked in the traditional vibrating screen. This issue is resolved effectively by the technology and screening efficiency is improved. The method is simple and easy to implement, has low cost and good screening effect, and can automatically clean the screening mesh. Moreover, quick and easy maintenance, low maintenance cost, reduced labour intensity and the greatly improved efficiency of labour. Lu, et al. determined the shape and size of sieve mesh of grading screening machine by measuring the geometric parameters fritillaries and exploring its shape and size distribution law [12].

It is rarely reported that screening yellow mealworm using screening machines, screening yellow mealworm is higher than the other screening requirements. To ensure no damage in animal screening process, the vibration of the sieve surface should be reduced as possible. Based on this requirement, a screening machine was designed for separating yellow mealworm and frass, this machine has good separating efficiency, reducing the labour intensity and improve the efficiency of screening operations.

2. Design of yellow mealworm screening machine

In the process of production of artificial breeding for yellow mealworm, yellow mealworm and frass have to be separated by the machine for different instar of the yellow mealworm in the breeding box. The instar larvae are about 45-120 days. In order to separate the different specifications of yellow mealworm and frass, the screening mesh has different specifications and can be replaced. Because yellow mealworms are living, the screening machine must meet some requirements, e.g. small vibration, little damage on yellow mealworm, good separation effect, simple structure, low cost, high efficiency, safe and easy to operate.

2.1. Overall structure and working principle

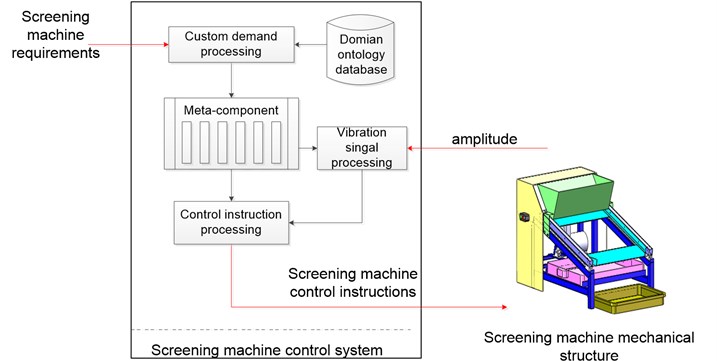

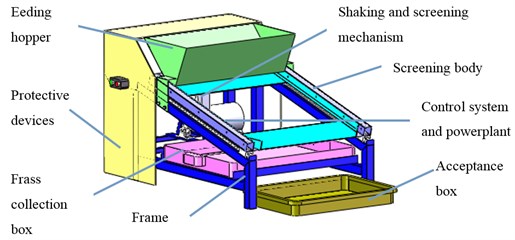

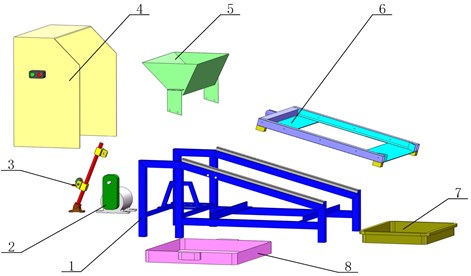

Yellow mealworm screening machine platform is composed of two parts: control system and mechanical structure (Fig. 1). According to the general structure of shaking screen and combined with the design requirements of the machine, the mechanical structure of yellow mealworm screening machine is determined, including frame, powerplant, shaking and screening mechanism, screening body, feeding hopper and protective devices etc. (Fig. 2). Power plant provides power for the machine under the control of control instructions, including the motor and gear reduction mechanism. In order to facilitate the use of the general production units, a common 220 V AC is used. Shaking and screening mechanism is the focus of this design, which uses the principle of crank rocker mechanism to allow the screen body to achieve a smooth reciprocating motion. The crankshaft is mounted on the crankshaft bearing base connected with gear reduction box via couplings to gain power. Pendulum rod base is fixed to the frame. The pendulum rod can swing and is coupled to the pendulum rod base through the bearing. Crank slider is located central pendulum rod and connected to the crankshaft via the slider connecting plates to converse the rotation of the crankshaft into the swing of the pendulum rod. The pendulum rod slider is at one end of pendulum rod and connected with the screen body via slider connecting plate, in order to converse swing of the pendulum rod to reciprocating of screen body. The screen body composed of slider, frame and mesh. The screen mesh has different specifications and can be changed in term of working requirements. The bottom of frame has four sliders and the screen body can smooth reciprocating in the frame rail. The frame used to connect the various parts. Power plant and shaking and screening mechanism are mounted on one side. On the other side is the inclined structure, the rails mounted on the upper part, the grass collection box is placed on the lower part, feed hopper is on the top of a frame, protective devices are at the side.

Fig. 1Yellow mealworm screening machine platform

When the machine working, the motor rotates and transfers power to the crankshaft through the gear reduction box. The crankshaft rotates and converse to swing of the pendulum rod via a slider. The pendulum rod swings was conversed into reciprocating of the screen body by the pendulum rod slider. The mixture of yellow mealworm and frass was input from the hopper, and then fell on the screen body. The mixture move down along the inclined body with reciprocating, yellow mealworm and frass were separated in this process, frass fell into the frass collection box under the frame below, yellow mealworm discharged from the bottom of the screen body and fell into the yellow mealworm acceptance box (Fig. 2).

2.2. Control system design of yellow mealworm screening machine

As shown in Fig. 1, a group of the yellow mealworm age, the screen size, the frequency and the run time is recorded in one meta-component. Each meta-component corresponds to a group of mealworm age and weight, which is demanded for yellow mealworm. According to the screening requirement of the yellow mealworm, the meta-components will provide these four control instructions to the control instruction processing and the vibration signal processing. Furthermore, the vibration signal processing records these instructions, and the control instruction processing handles screening machine abides by these control instructions. The sensor gets actual amplitude at set intervals, and sent them back to the vibration signal processing. If the actual amplitude is out of the range recorded in vibration signal processing, the vibration signal processing rectifies the actuator to reduce machine error. Also, the vibration signal processing records the run time to terminate the screening machine in order to get the weight of the yellow mealworm demanded.

Fig. 2Overall structure and working principle of yellow mealworm screening machine: 1 – motor, 2 – gearbox, 3 – crankshaft, 4 – pendulum rod, 5 – screening body, 6 – feeding hopper, 7 – acceptance box, 8 – frass collection box

a) Overall mechanical structure

b) Working principle

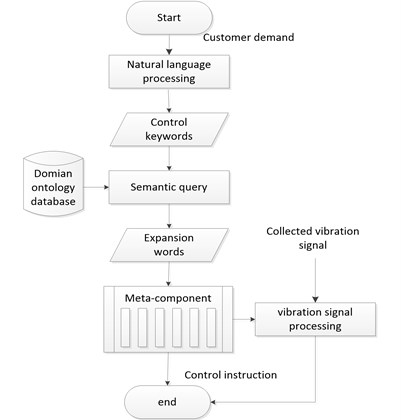

The screening machine control flow is shown in Fig. 3. Firstly, according the requirements for yellow mealworm, the control keywords are extracted from customers (screening machine) with natural language processing technology. Then, with the support of domain ontology database, the keywords are expanded by semantic query, control keywords set is gained. Furthermore, meta-components [15] are retrieved by expansion words; meta-component is an encapsulation of screening machine control instructions set, and each meta-component can emit a series of instructions; it can make a screening machine to achieve different functions. Ultimately, screening machine works under the control instructions of meta-component and vibration processing.

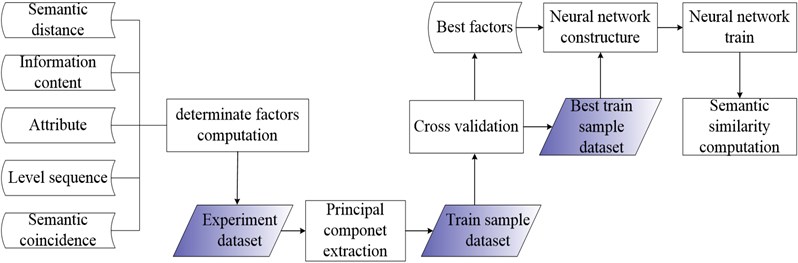

Semantic query expansion is the core module of yellow mealworm screening machine control system, and semantic similarity is the key of semantic query expansion. Semantic similarity is a degree who measures the similarity between concepts from a quantitative point of view. It is the knowledge foundation of Information extraction, Information retrieval, Data mining, and Artificial intelligence [16, 17]. Since there is no semantic similarity computation method suited to this domain now, the semantic similarity computation method based on neural network is proposed here (Fig. 4).

Firstly, getting the neural network experimental data set. Semantic distance, information, content, attributes, level sequence and semantic coincidence are considered as the determinate factors; and they will determine the similarity between concepts. Neural network experimental data set is got by the analysis, description and computation of these determinate factors.

Secondly, principal component analysis is conducted to the experimental set. The number of extracted principal components is determined by the cumulative contribution ration and future value. Neural network training sample data set is constituted by the selected principal components.

Thirdly, the opportune valuate function is adopted as the measure criterion. Cross validation is conducted to the neural network train sample dataset, then the best factors and train sample dataset will be getting.

Fourthly, neural network contracts. The generalized regression neural network is adopted here. According to the dimension of the train sample data set, the node number of neural network input layer is determined. The spread factor of Generalized Regression neural network can also be got from the last step.

Fifthly, training the neural network with the best train sample data set.

Finally, conducting semantic similarity computation with the trained neural network. As computing semantic similarity between concepts, the determine factors of the two concepts should be computed, following the first step. The principal component of these determines factors can be got by the second step. Then, setting the principal component as input data, the semantic similarity of the two concepts can be computed by the trained neural network.

Fig. 3Screening machine control flow chart

Fig. 4Semantic similarity computation method based on a neural network

If the customer needs the 45-days-old yellow mealworm about 10 kilogram, we can input the requirement of the screening machine control system, such as “screen 45 day-old yellow mealworm ten kilograms”, “45 days old tenebrio molitor 10 kg” or “ select 45 days tenebrio molitor L. 10 Kg” etc. After taking the yellow mealworm to the machine, the screening machine control system will order the screening machine gets the yellow mealworm demanded (Fig. 5).

Fig. 5Yellow mealworm screening: a) yellow mealworm screening machine, b) yellow mealworm and frass before screening, c) yellow mealworm after screening, d) frass after screening

2.3. Mechanical design of yellow mealworm screening machine

Screening machine can classify various kinds of raw materials and primary products into different grades according to the particle size of materials or remove the water and impurities by using some actions like rotation, vibration, reciprocation and shaking. It is the necessary equipment for the next step processing and improving product quality. There are many different types of screening machine, which can be divided into four types according to the movement characteristics of screen surface: fixed screen, rotary screen, vibrating screen and shaking screen. The working part of the fixed screen is fixed and materials can be screened by sliding along the working surface. It is simple structure, easy manufacture and does not consume power. The main disadvantage is low productivity and low screening efficiency, generally only 50-60 %. Rotary screen has many features, e.g. slow uniform rotation, small impact and vibration, smooth operation, easy maintenance and longer life, however, there are some limitations, e.g. the low utilization rate of screen surface, working surface only take up 1/6-1/8 of the entire screen surface area, huge equipment, low screening efficiency, large power consumption. Vibrating screen rely on a vibration exciter to generate high frequency mechanical vibration on the screen surface. The screening efficiency is 60 %-98 %, power consumption is small, and it is simple structure and easy to operate, adjust and maintenance. Compared with rotary screen, screen surface of shaking screen can be fully utilized and the motion characteristic is good, so the screening capacity and screening efficiency is higher, but its efficiency is not high as vibrating screen. Based on analysis of the characteristics of various screening machinery and the design requirements, i.e. small vibration in the screening process and little damage to yellow mealworm, shaking screen is selected in this study.

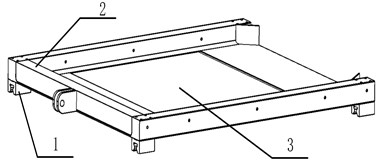

2.3.1. Mechanical design of screening body

The screen body composed of slider, frame and mesh (Fig. 6). Screen frame was made of square steel tube and welded structure with steel plate, three sides are square steel tube and central is a steel plate. According to size of breeding box for yellow mealworm, screen frame dimensions were determined: length×width×higher equal to 700 mm×1000 mm×50 mm. The screen surface is an important working part to complete the screening process. Woven mesh structure is simple, light weight and high porosity. Since some materials have certain flexibility, it can reduce the clogging phenomenon in the screening process and improve screening efficiency [16]. Woven mesh was used in this study, which is fixed to the square hole in the screen frame by bolts, and its dimensions are: length × width equal to 700 mm × 600 mm. In order to meet the screening needs for different instar of the yellow mealworm, 3 sizes (60, 45 and 30 items) are available (Table 1). According to the size of yellow mealworm and frass, mesh specifications can be determined and be replaced based on different instar of yellow mealworm. The bottom of the screen frame is fixedly with 4 sliders that make screen body to do the smooth reciprocating motion on rails.

Fig. 6Screening body: 1 – slider, 2 – frame, 3 – screening mesh

Table 1Size of yellow mealworm and frass

Order | Instar (days) | Insect length (mm) | Insects diameter (mm) | Frass size (mm) | Size of screen hole (mm) | Standard mesh (item) |

1 | 45 | 15 | 1 | < 0.2 | 0.250 | 60 |

2 | 60 | 20 | 1.5 | < 0.2 | 0.250 | 60 |

3 | 75 | 25 | 2.2 | < 0.2 | 0.355 | 45 |

4 | 90 | 30 | 3 | < 0.2 | 0.355 | 45 |

5 | 105 | 35 | 4 | < 0.2 | 0.600 | 30 |

6 | 120 | 40 | 5 | < 0.2 | 0.600 | 30 |

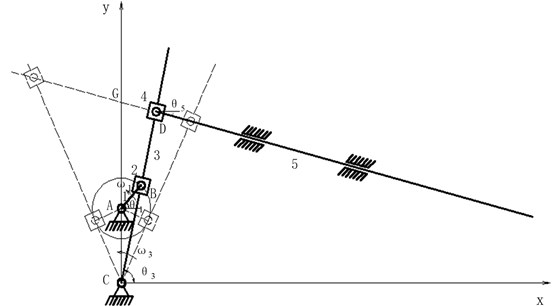

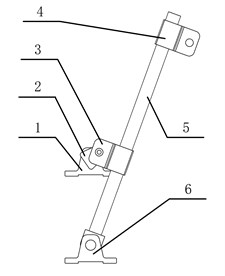

2.3.2. Mechanical design of shaking and screening mechanism

In order to reduce damage to yellow mealworm in the screening process, the straight-line translational work mode of screen box is used, namely a screen box does reciprocating motion in the tilted slide, yellow mealworm and frass move from the upper to the lower of screen box at a certain speed, and are separated in the screening process. To simplify the machine structure and reduce the machinery manufacturing costs, crank-rocker is adopted in shaking and screening mechanism (Fig. 7). Kinematic analysis mathematical model is created using analytical method. Based on the closed vector equation of mechanism position, displacement equation is obtained. The velocity equation is obtained using the first derivative to time. The acceleration equation is obtained using the second derivative to time. And then Motion analysis is performed, displacement curve, velocity curves and acceleration curves of slider are plotted.

2.3.3. Motion analysis mathematical model of shaking and screening mechanism

Motion analysis of shaking and screening mechanism is conducted. At first, a Cartesian coordinate system is established (Fig. 7), namely the swing center of pendulum rod is the origin, the horizontal direction is -axis and the vertical direction is the -axis. Relevant parameters of mechanism motion are determined and the description is shown in Table 2.

2.3.3.1. Position analysis

Crankshaft AB uniformly rotate with constant angular velocity , each member bar is represented as a vector and expressed by a complex number with exponential form.

Fig. 7Crank-rocker mechanism diagram: 1 – crankshaft, 2 – crankshaft slider, 3 – pendulum rod, 4 – pendulum rod slider, 5 – screen body

Table 2Description of relevant parameters of mechanism motion

Symbol | Implication |

Distance between the centre of rotation of the crankshaft and the slider B (mm) | |

Distance between the swing centre of pendulum rod and the centre of crankshaft rotation (mm) | |

Distance in y-axis between the swing centre of pendulum rod and rail (mm) | |

Angle between rails and the -axis (°) | |

Rotation angle of crank AB (°) | |

Angular displacement of pendulum rod CD (°) | |

Angular velocity of crank AB (rad·s-1), | |

Angular velocity of pendulum rod CD (rad·s-1) | |

Displacement of screen body in direction (mm) | |

Displacement of slider B (mm) | |

Displacement of slider D (mm) | |

Velocity of slider B (mm·s-1) | |

Velocity of slider D (mm·s-1) | |

Velocity of screen body (mm·s-1) | |

Acceleration of slider B (mm·s-2) | |

Angular acceleration of pendulum rod CD (rad·s-2) | |

Angular acceleration of slider D (rad·s-2) | |

Acceleration of screen body (mm·s-2) |

Based on the closed graphics CABC and CGDC:

Based on Eqs. (1) and (2), the displacement of slider B (), the angular displacement of pendulum rod CD (), the displacement of slider D () and the displacement of screen body in () can be obtained.

2.3.3.2. Velocity analysis

The velocity equation is obtained using the first derivative to time on Eqs. (1) and (2):

Based on Eq. (3), the velocity of slider B (), the angular velocity of pendulum rod CD (), the velocity of slider D () and the velocity of the screen body (VD) can be obtained.

2.3.3.3. Acceleration analysis

The acceleration equation is obtained using the second derivative to time on Eqs. (1) and (2):

Based on Eq. (4), the acceleration of slider B (), the angular acceleration of pendulum rod CD (), the acceleration of slider D () and the acceleration of the screen body (AD) can be obtained.

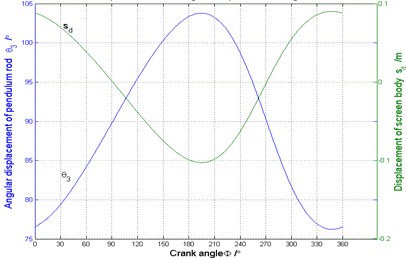

2.3.4. Motion analysis of shaking and screening mechanism

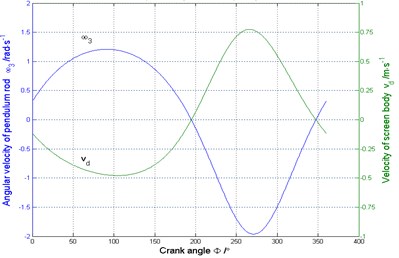

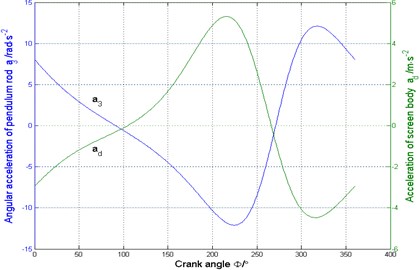

Kinematic analysis of shaking and screening mechanism is conducted, e.g. the variation law of displacement, velocity and acceleration variation of pendulum rod and screen body. The angular displacement, angular velocity and angular acceleration of pendulum rod and displacement, velocity and acceleration of screen body can be obtained, respectively. And then the corresponding curves also can be obtained (Fig. 8). The minimum and maximum value of the corresponding cranks rotational angle was calculated (Table 3). Also, the variation law of kinematic parameters of the screening box can meet the screening requirement, e.g. displacement, velocity and acceleration.

Table 3Range of displacement, velocity and acceleration for pendulum rod and screen body

Kinematic parameters | Variation range | The minimum of corresponding crank angle [°] | The maximum of corresponding crank angle [°] |

Angular displacement of pendulum rod, | 1.33-1.81 rad | 347 | 195 |

Angular velocity of pendulum rod, | –1.96-1.21 rad·s-1 | 271 | 91 |

Angular acceleration of pendulum rod, | –12.10-12.10 rad·s-2 | 224 | 318 |

Displacement of screen body, | –0.10-0.09 m | 195 | 347 |

Velocity of screen body, | –0.48-0.77 m·s-1 | 105 | 266 |

Acceleration of screen body, | –4.48-5.31 m·s-2 | 316 | 216 |

2.3.5. Design of shaking and screening mechanism

The shaking and screening mechanism consists of crankshaft, crankshaft bearing base, crankshaft slider, pendulum rod, pendulum rod base, pendulum rod slider, slider connecting plate and other bearings (Fig. 9). SBR20 linear guide with a diameter of 20 mm is selected to the pendulum rod, linear slide unit SBR20UU is used in crankshaft slider and a pendulum rod slider, 6204 deep groove ball bearings are used for various bearings and the corresponding bearing bases are selected.

2.3.6. Design of other parts

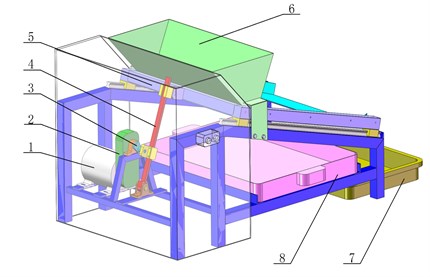

The frame is used to connect to various parts (Fig. 10), the power plant and shaking and screening mechanism are mounted on one side, the other side is an inclined structure. The rails and hopper are attached to the upper of frame, frass collection box can be placed at the bottom and protective device is fixed on the side. The square steel tube is used for the main body of the frame, the material of the hopper and protective device is the steel plate.

The prototype of the yellow mealworm screening machine is shown in Fig. 5. The interference was checked and motion simulation was conducted. The results showed that the machine can run stably and can meet the job requirements.

Fig. 8Kinematics analysis of shaking and screening mechanism

a) Displacement and angular displacement diagram

b) Velocity and angular velocity diagram

c) Acceleration and angular acceleration diagram

Fig. 9Shaking and screening mechanism: 1 – crankshaft bearing base, 2 – crankshaft, 3 – crankshaft slider, 4 – pendulum rod slider, 5 –pendulum rod, 6 – pendulum rod base

Fig. 10Parts of yellow mealworm screening machine: 1 – frame, 2 – powerplant, 3 – shaking and screening mechanism, 4 – protective devices, 5 – feeding hopper, 6 – screening body, 7 – acceptance box, 8 – frass collection box

3. Conclusion

A type of novel yellow mealworm vibration automatic control screening machine was designed in this study. The control system based on semantic similarity computation and main mechanical, structural parameters of the machine was carefully designed and optimized. The prototype performance tests of the machine so that machine can screen the yellow mealworm and frass, and has a good screening effect and high working efficiency. Furthermore, the machine has mall vibration and little damage on yellow mealworm in the screening process. In addition, the machine has other advantages like a simple structure, safe and easy to operate and low cost.

References

-

Xu Shicai, Liu Xiaowei, Wang Qiang, Shen Xuejian Tenebrio molitotr L. feed production from fermentation of corn stalks. Acta Agriculturae Boreali-occidentalis Sinica, Vol. 22, Issue 1, 2013, p. 194-199.

-

Sun Long, Feng Ying, He Zhao, Chen Zhiyong, Zhao Min Isolation and purification of small antimicrobial peptide from larvae of mealworm, Tenebrio molitor. Chinese Journal of Applied Entomology, Vol. 49, Issue 3, 2012, p. 686-692.

-

Wang Chunqing, Ma Minglong, Ding Xiuwen, Lu Shuchen Effect of different proportion of wheat bran and corn straw on the growth performance in yellow powder larva. China Animal Husbandry and Veterinary Medicine, Vol. 40, Issue 1, 2013, p. 210-212.

-

Jiang Surong, Cai Yan, Zhou Yujue Effects of Different Feedstuffs on the Content of Water, Crude Protein and Fat in Tenebrio Mmolitor L. Journal of Sichuan Agricultural University, Vol. 30, Issue 2, 2012, p. 243-246.

-

Yang Wen Le, Xue Jingming Effects of different feeding formulas on the larval growth and development of yellow mealworm. Heilongjiang Animal Scienceand Veterinary Medicine, Vol. 11, 2013, p. 92-94.

-

Wang Jinhua, Wang Xuemei, Yang Yuhui, Wu Xiaoli, Shang Yanfei, Wu Jinyu Analysis on the conventional nutrients in tenebrio molitor manure and silkworm excrement. Journal of Anhui Agricultural Sciences, Vol. 40, Issue 21, 2012, p. 10924-10925.

-

Gao Yingwu, Chen Zhenyu, Gao Xingyu, et al. Design and experiment of vibrating screen of shelling washer for field-snail. Transactions of the CSAE, Vol. 23, Issue 5, 2007, p. 121-125.

-

Han Xiao-Ping, Hu Hua-Cheng, Zheng De-Cong Design and simulation research of 5XS-600 shaker test-bed. Chinese Agricultural Mechanization, Vol. 3, 2011, p. 107-110.

-

Yuan Fucai, Hu Shijian, Sun Hailiang, Wang Lizhu The three-dimensional modeling and kinematic analysis of sieve separation of wheat starch. Journal of Mechanical Transmission, Vol. 36, Issue 4, 2012, p. 29-31.

-

Xie Jun, Zhang Xiaoqing, Wang Chengjun, Yang Qizhi Mechanism design and kinematics simulation of three translation tea Sieving machine. Chinese Journal of Engineering Design, Vol. 19, Issue 3, 2012, p. 208-212.

-

Zhu Zhong, Li Chunguang, Wang Haibin, Zhu Dongfeng, Sun Mi Design and test of technology improvement on vibrating grizzly before cut leaf tobacco flavoured. Journal of Anhui Agricultural Sciences, Vol. 40, Issue 2, 2012, p. 1166-1168.

-

Lu Songzhuo, Zhang Wei, Song Jiang Analysis of mechanophysical properties of fritillaria ussuriensis maxim and designing of grade sieve machine. Journal of Chinese Agricultural Mechanization, Vol. 34, Issue 5, 2013, p. 141-145.

-

Cao Rui, Hao Liyun, Wu Lingda A theme-oriented data automatic organization method. Advanced Materials Research, Vol. 998, 2014, p. 772-775.

-

José M. Chaves-González, Jorge Martínez-Gil Evolutionary algorithm based on different semantic similarity functions for synonym recognition in the biomedical domain. Knowledge-Based Systems, Vol. 37, 2013, p. 62-69.

-

Sánchez D., Batet M. A semantic similarity method based on information content exploiting multiple ontologies. Expert Systems with Applications, Vol. 40, Issue 4, 2013, p. 1393-1399.

-

Wu Shumin, Wu Shuhui Design method for screening plate of feeding side of screening machine. Mining and Processing Equipment, Vol. 8, 2013, p. 136-137.

About this article

This research is founded by the National Natural Science Foundation of China (No. 61162010 and No. 61261024).